nTop partnerships: Connecting workflows and integrating solutions

Written by nTop

Published on May 2, 2019

nTop will continue to connect and collaborate with new partners as we build up the power of our internal tools. We will also continue to invest resources to connect with others in the advanced manufacturing industry. If you would like to explore a partnership with nTop, or if there is a particular connection you would like to see included in our platform, please do not hesitate to reach out to partnerships@ntop.com

Since modern day manufacturing processes and technologies have generally outpaced the development of design tools, there has been a recent gap in innovative software solutions that can fully utilize today's advanced manufacturing techniques. In particular, many software solutions were not built with additive or advanced manufacturing in mind, and they certainly were not built with a goal to easily integrate with other software solutions. In light of that, nTop has developed unique capabilities that focus on enabling designers and engineers to extract the most value out of advanced manufacturing processes by connecting directly to other software and hardware solutions.

One such solution nTop enables is the design of complex, high-performance geometry based on functional requirements. As there are other needed parameters and processes along the design path, strategic partnerships with other solution providers are critical. To truly enable a workflow that properly connects disciplines, a robust integration is required between traditional CAD software, simulation platforms and the manufacturing process itself.

At nTop we are partnering with engineering simulation, manufacturing software and hardware companies to enable our shared customers to have the most frictionless experience, which in turn saves them time in the engineering process, maintains data in translation across platforms, and reduces costly mistakes.

The partnership program at nTop is ensuring that designers and engineers can efficiently integrate knowledge from design, engineering, simulation and manufacturing with no loss of information or data. This ensures changes in the design process can move both upstream and downstream without breaking the underlying data model, or the geometry it controls.

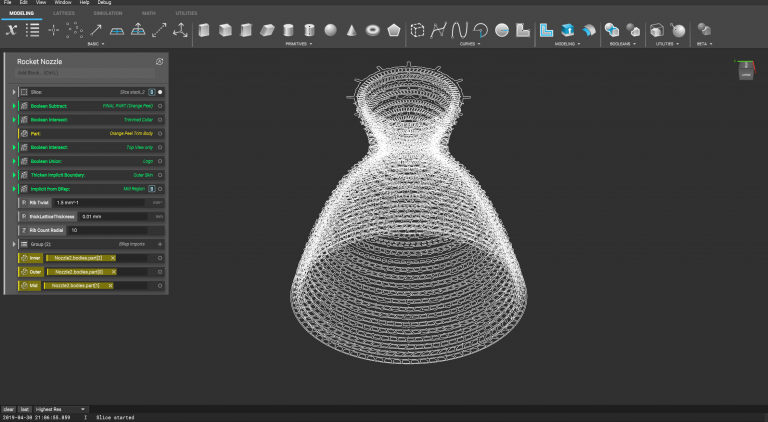

As part of this, we are helping to move the industry away from mesh (such as the dreaded STL format) and b-rep models, typically used in legacy CAD and CAE systems, towards a more direct-to-manufacture approach. This is accomplished through the implicit modeling technology which can accurately produce slicing and toolpath data without additional discretization. While for some interactions we will resort to simple file transfer, we are also exploring connectivity via API, command line interface, our own block system and more.

Our launch partners include software companies such as ANSYS, Dassault and Siemens, hardware companies such as Renishaw, EOS, and Velo3D, along with consulting companies and institutions such as Oakridge National Labs, Betatype and Additive Minds.

There are several ways in which these partnerships can be beneficial to end users, and below is one example workflow these partnerships enable:

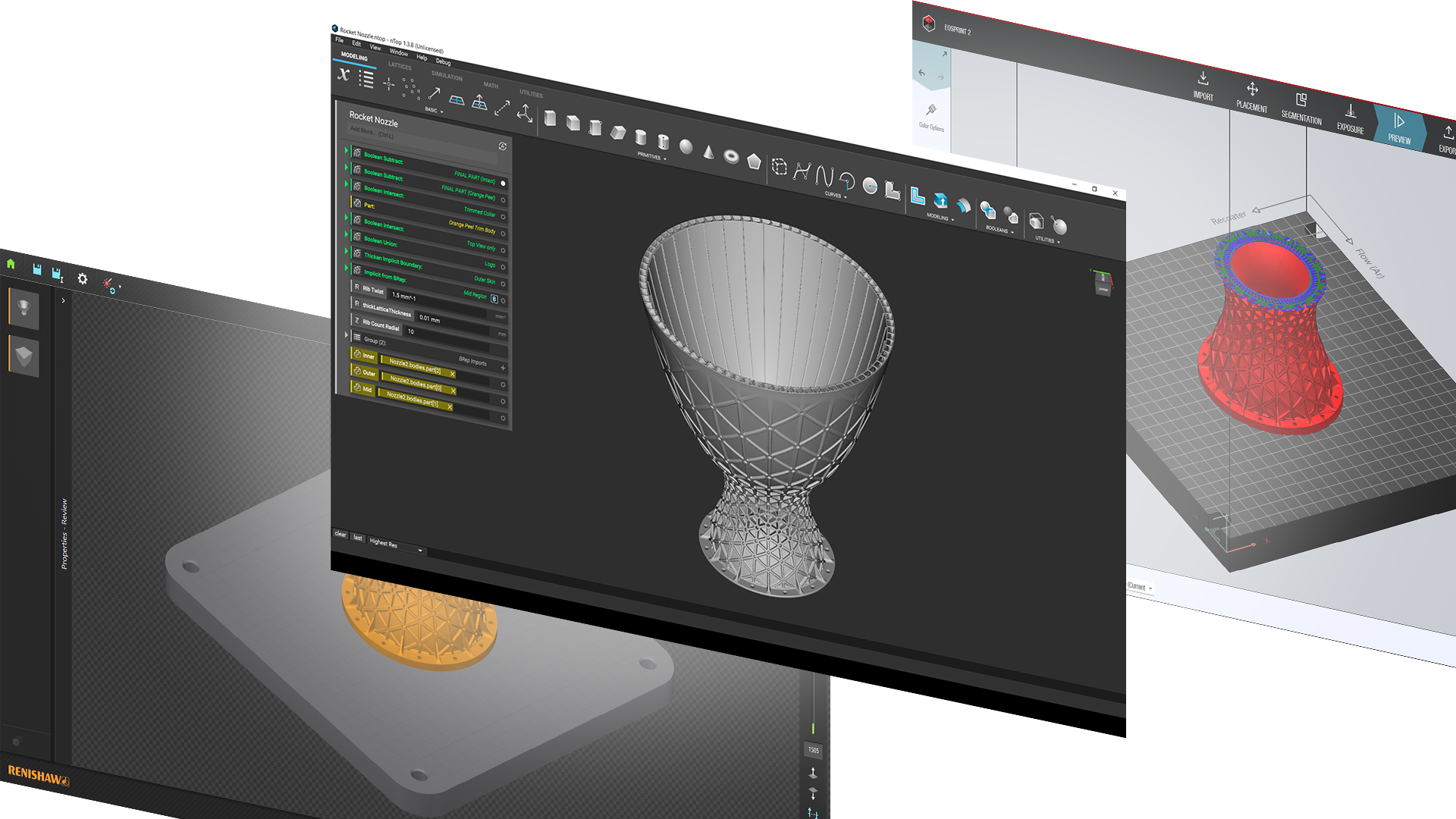

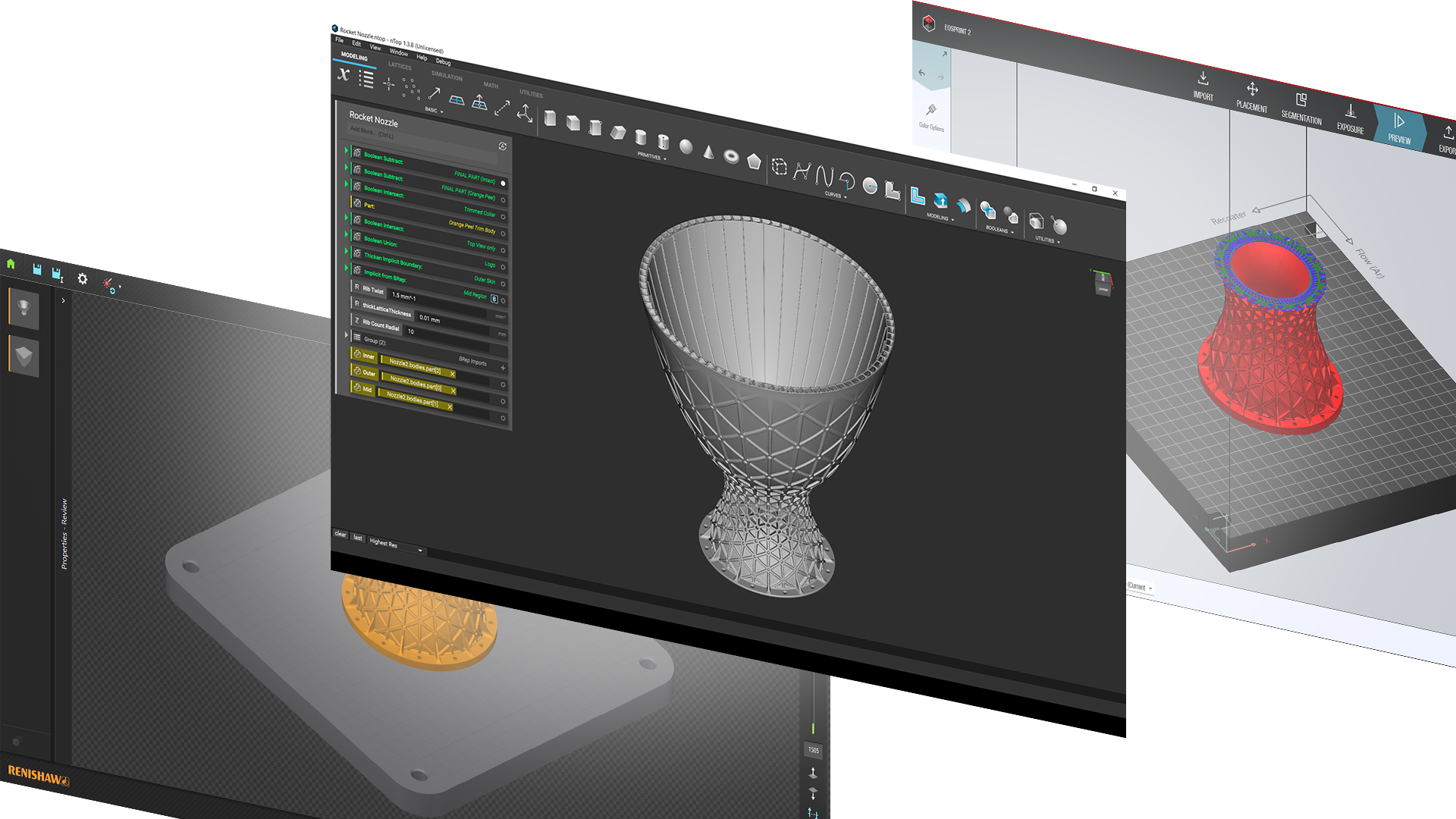

1. Design a base mechanical structure, such as a rocket nozzle, in a tool like Solidworks or CATIA.

2. Import the Parasolid file into nTop to convert to an implicit model,

3. Optimize the design using our advanced design tools such as topology optimization based on our internal simulation tools.

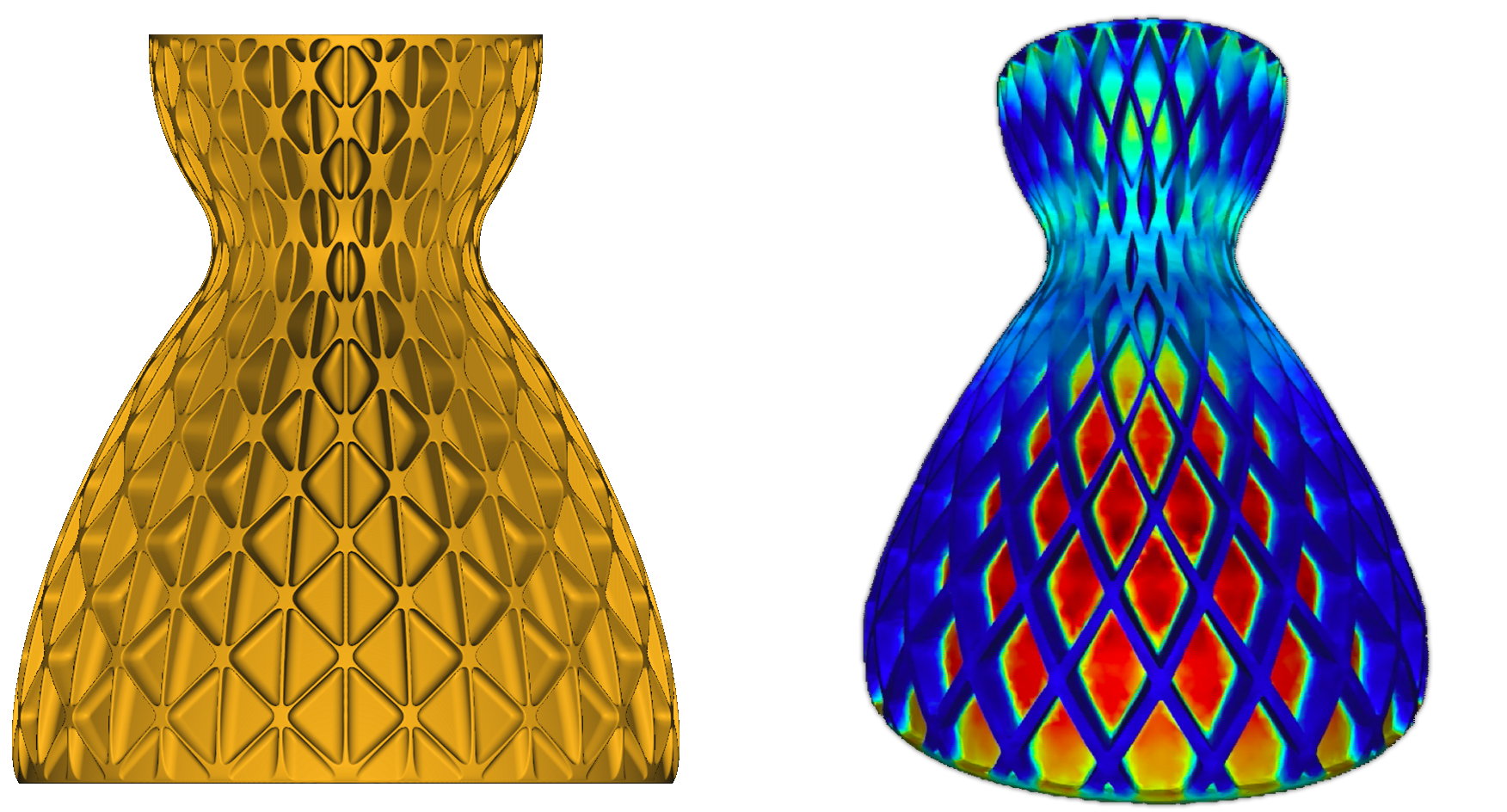

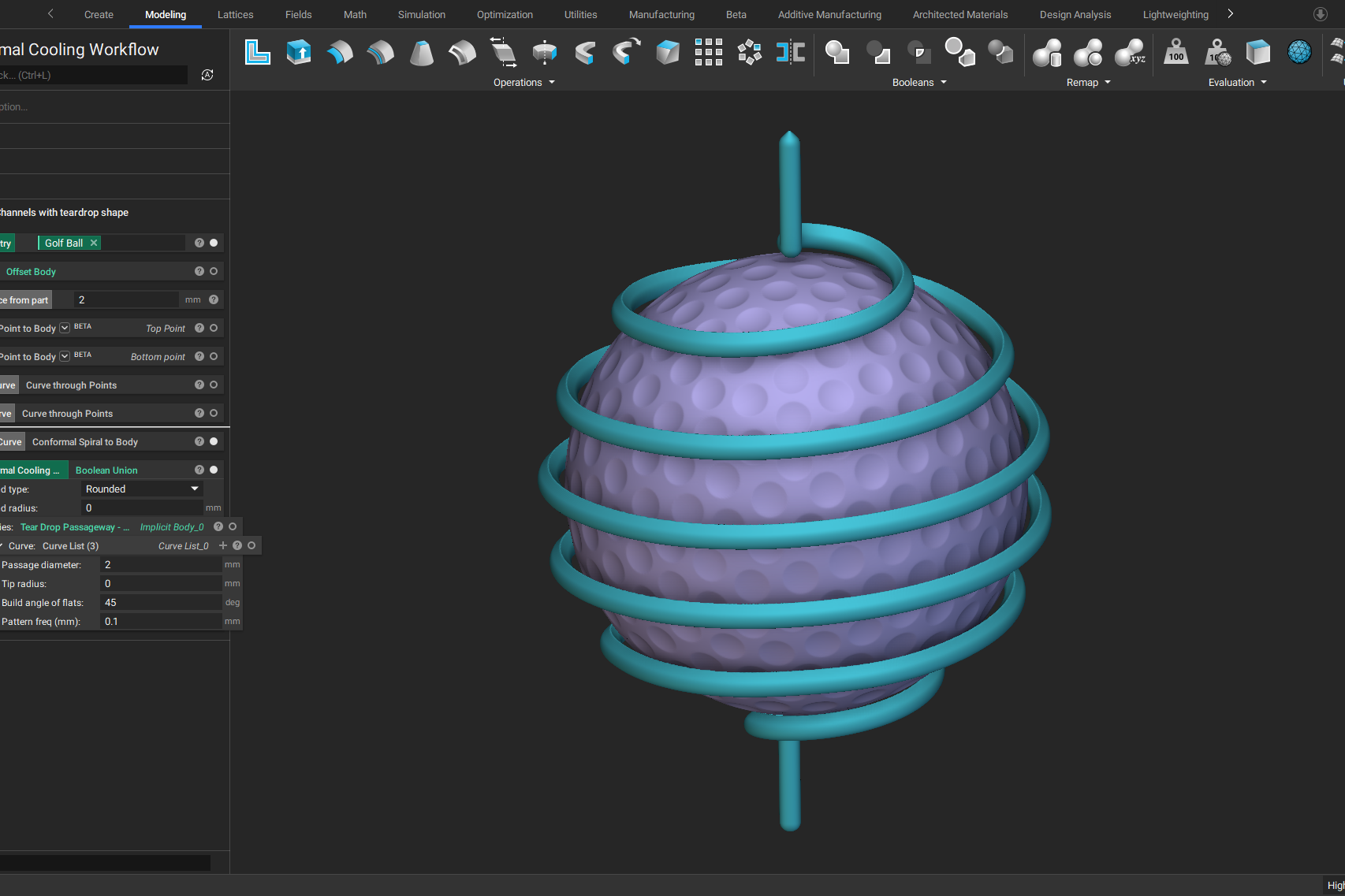

Left: Using implicit modeling technology, ribbing structures can easily be created. Right: Use a field-driven design approach, design parameters like rib thickness can be varied based on stress results from simulation data.

4. Export .inp file directly to Abaqus for validation

5. Slice implicit geometry and export CLI file directly to build software such as EOSPRINT2 or QuantAM

Contour and hatching slice data from nTop sent directly to printers eliminates intermediary, mesh file types, reduces geometry errors, and makes the design-to-manufacture process more efficient.

Partnerships with hardware vendors such as Renishaw and EOS deliver a streamlined workflow for end users, where slice data and toolpath information can be set up in nTop, and delivered directly to machines.

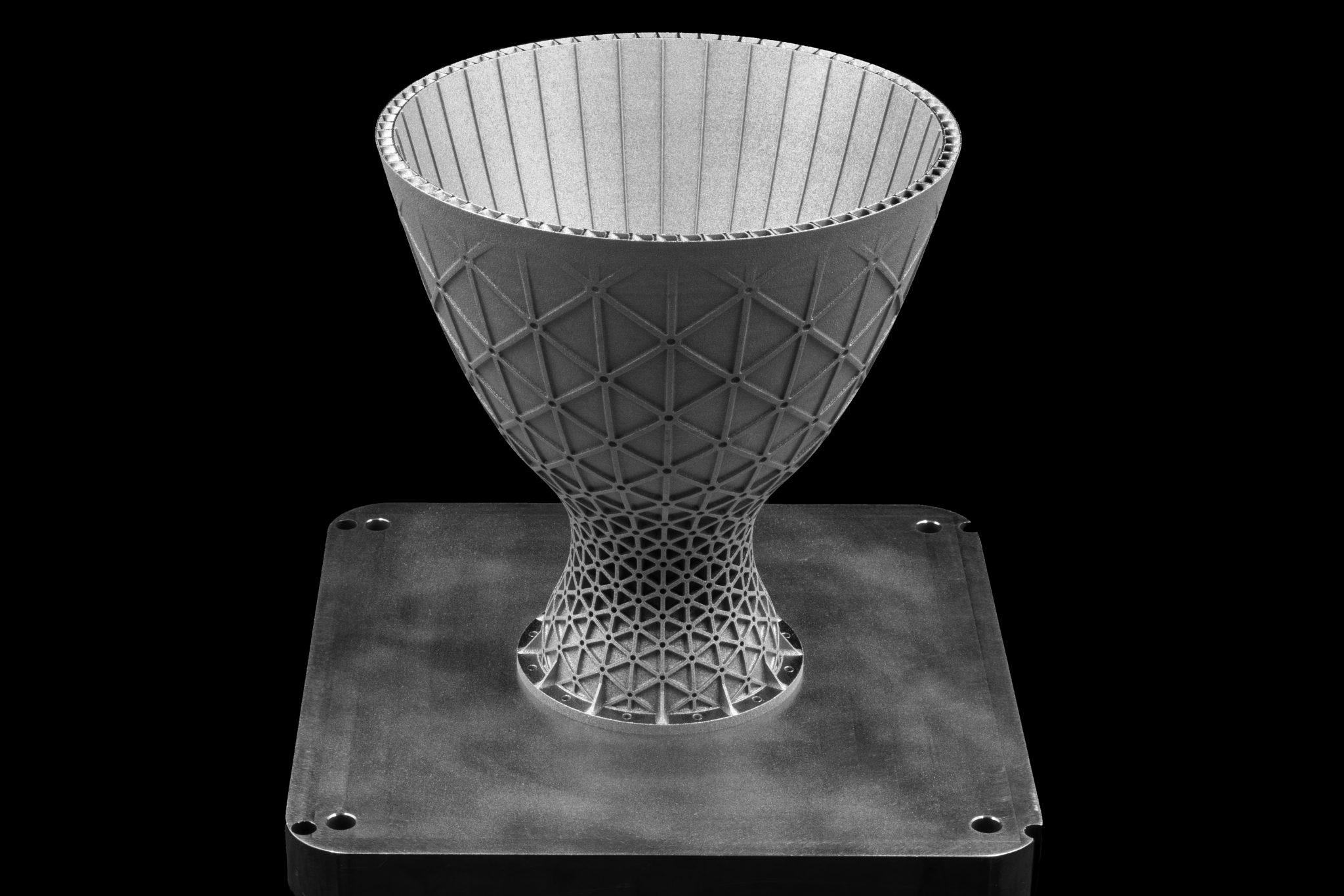

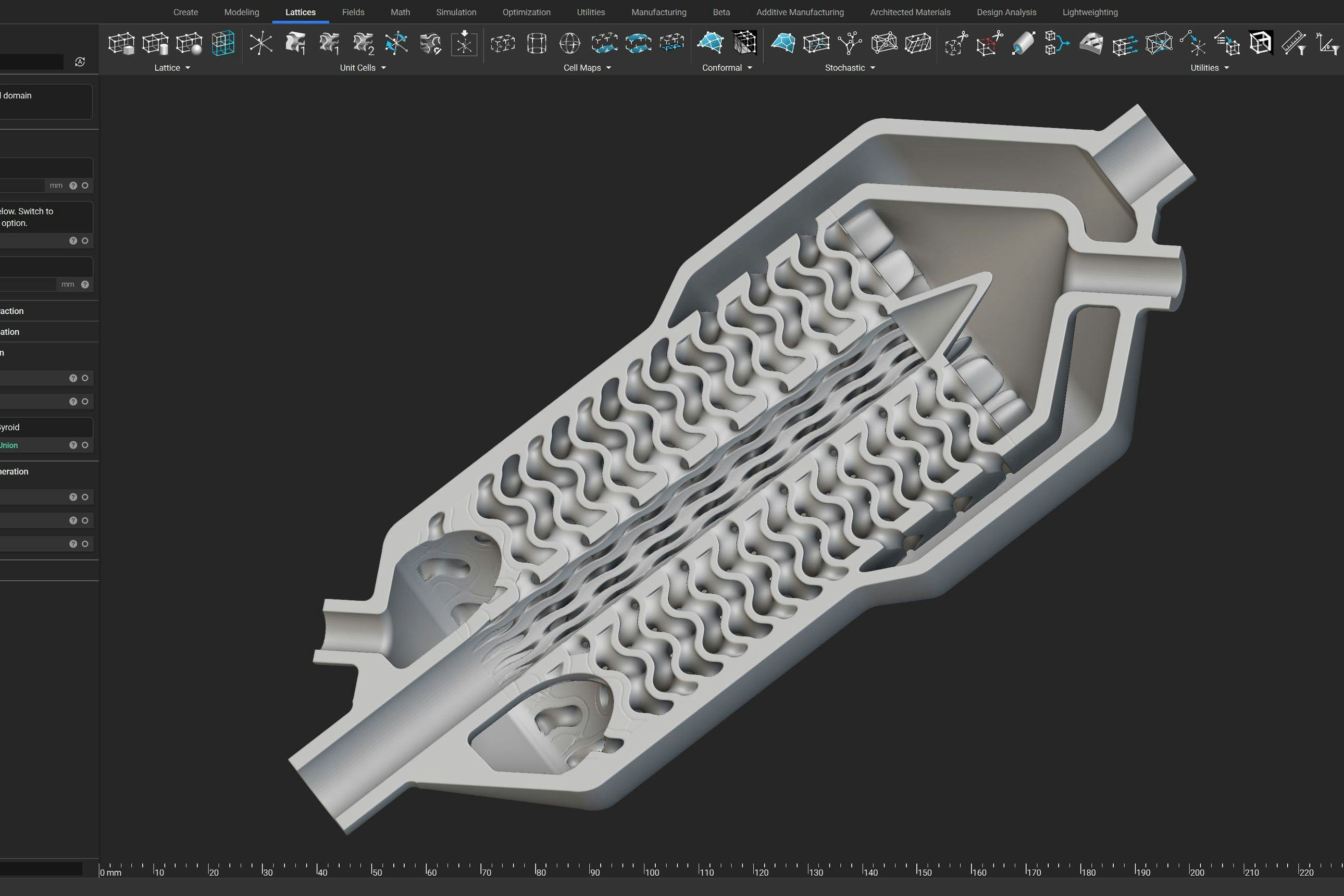

Rocket nozzle, additively manufactured part, designed in nTop. Photo courtesy of Betatype.

nTop will continue to connect and collaborate with new partners as we build up the power of our internal tools. We will also continue to invest resources to connect with others in the advanced manufacturing industry. If you would like to explore a partnership with nTop, or if there is a particular connection you would like to see included in our Platform, please do not hesitate to contact us.

And finally, we would love to connect with you at one of a few industry trade shows in which we'll be participating later this month. We would love to talk with you about future nTop integrations!

- RAPID + TCT, Detroit MI, May 20-23, booth 953

- Space Tech Expo USA, Pasadena, CA, May 20-22, Booth 6014

nTop hopes to see you there!

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop