Top 7 shoe design video tutorials

Written by nTop

Published on February 3, 2021

3D printed midsoles have been a hot topic in shoe design for a few years now, however, with nTop’s capabilities designers can add further functionality and aesthetics to their footwear. Here are our top shoe design tutorial videos.

Below are some helpful videos on sneaker design, as well as some bonus topics that Industrial Designers may find interesting. If you are new to nTop’s 3D design and engineering software, here is a quick summary:

Speed - Iterate faster in nTop. Whether it’s complex lattice designs that may take hours in other software or quick changes to traction patterns, you’ll notice that you can play around and see real-time updates to your creations in seconds.

Customization - Using data can inform shoe design in a variety of ways. Custom-fit shoes can alleviate pain for individuals with disabilities or other medical issues, much the same way as custom-made shoes provide benefits to top athletes. Customization can also take the form of unique aesthetics for each customer, such as embossing.

Interoperability - nTop can import a variety of files like the midsole files your company already has. Take existing prototypes and designs and add to the aesthetics or performance within nTop. When you’ve created something awesome, export it as a familiar file type that can be incorporated back into your manufacturing process. Plus, we also have capabilities for print prep and mold making.

Textured 3D printed midsoles

This is a great video to watch if you are just getting started in shoe design using nTop- Sam Kratky, Application Engineer here at nTop, goes into the basics of creating midsole textures and how to use data to drive your designs.

nTop Live: Custom lattices and textured midsoles for multi-functional shoe design

video: nTop Live: Custom lattices and textured midsoles for multi-functional shoe design

Watch and learn how to:

- Use a pressure map to customize the density or thickness of a lattice or 3D printed foam

- Design and apply custom textures and traction patterns to the sole of the shoe

- Create a library of custom and reusable workflows and quickly explore design variations

Custom sneaker cushioning

While cushioning and comfort is a very important aspect of sneaker soles, performance and durability can also be affected by midsole design. In this video, one of our Customer Success Engineers, Annika Norden, teaches how to configure the shape and density of a custom shock absorption pattern based on pressure data.

nTop Live: Configurable cushioning design for sneaker midsoles

video: nTop Live: Configurable cushioning design for sneaker midsoles

Watch and learn how to:

- Configure and control custom geometric patterns in nTo

- Use field-driven design and data to optimize their size and orientation

- Refine and optimize your designs using simulations and experimental results

A fully 3D printed shoe

As part of our Design for Additive Manufacturing series, Industrial Design edition, Izzy de la Guardia from Fast Radius joined us to show how she created a sneaker designed to be printed as one part on an HP Multi-Jet Fusion printer.

Industrial design DfAM Series: Designing a 3D printed shoe

video: Industrial design DfAM Series: Designing a 3D printed shoe

In this video Izzy shoes how:

- Non-uniform, field-driven lattice structures can be used to create more visually appealing and functional designs

- Model-based data can be used to inform design decisions

Procedural 3D Textures

Andrew Reitz, Product Engineer at nTop , goes into detail in this three-part video on creating parametric traction textures. This can improve not only aesthetics but also design performance. And he will also show how to incorporate simulation results.

nTop Live: Data-driven computational design of footwear Traction textures part 1

video: nTop Live: Data-driven computational design of footwear Traction textures part 1

Another great aspect of this video is how Andrew demonstrates how to make a file easily readable and shareable with a team. This video shows how to:

- Design parametric traction elements in nTop with Field-Driven Design

- Control your textures with user-defined parameters or simulation data as inputs

- Convert your workflow into an easy-to-use and shareable custom block

This video also has a Part 2 and Part 3.

Additional Resources for Industrial Designers

If you found these videos helpful, here are a few more bonus videos that may inform your design workflows as well.

nTop Live: Design 3D printed animal prosthetics from 3D scan data

video: nTop Live: Design 3D printed animal prosthetics from 3D scan data

nTop Live: Parametric modeling of hyper-realistic 3D textures for industrial design

video: nTop Live: Parametric modeling of hyper-realistic 3D textures for industrial design

nTop Live: Reverse engineering 3D scanned industrial parts in nTop

video: nTop Live: Reverse engineering 3D scanned industrial parts in nTop

See what you can build with nTop! Request a demo. Are you a student, educator, or researcher? You may be eligible for an academic license.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- GUIDE

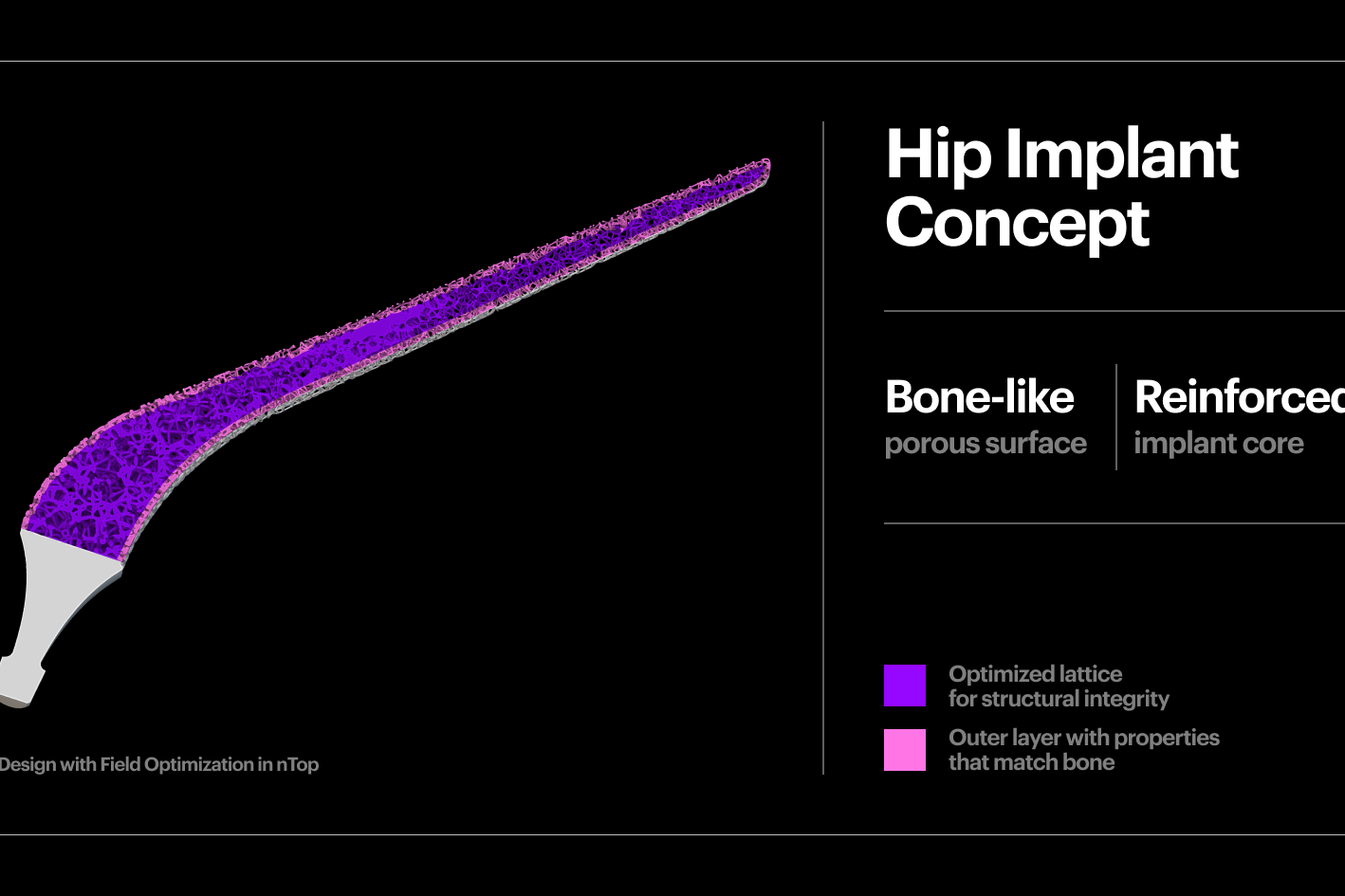

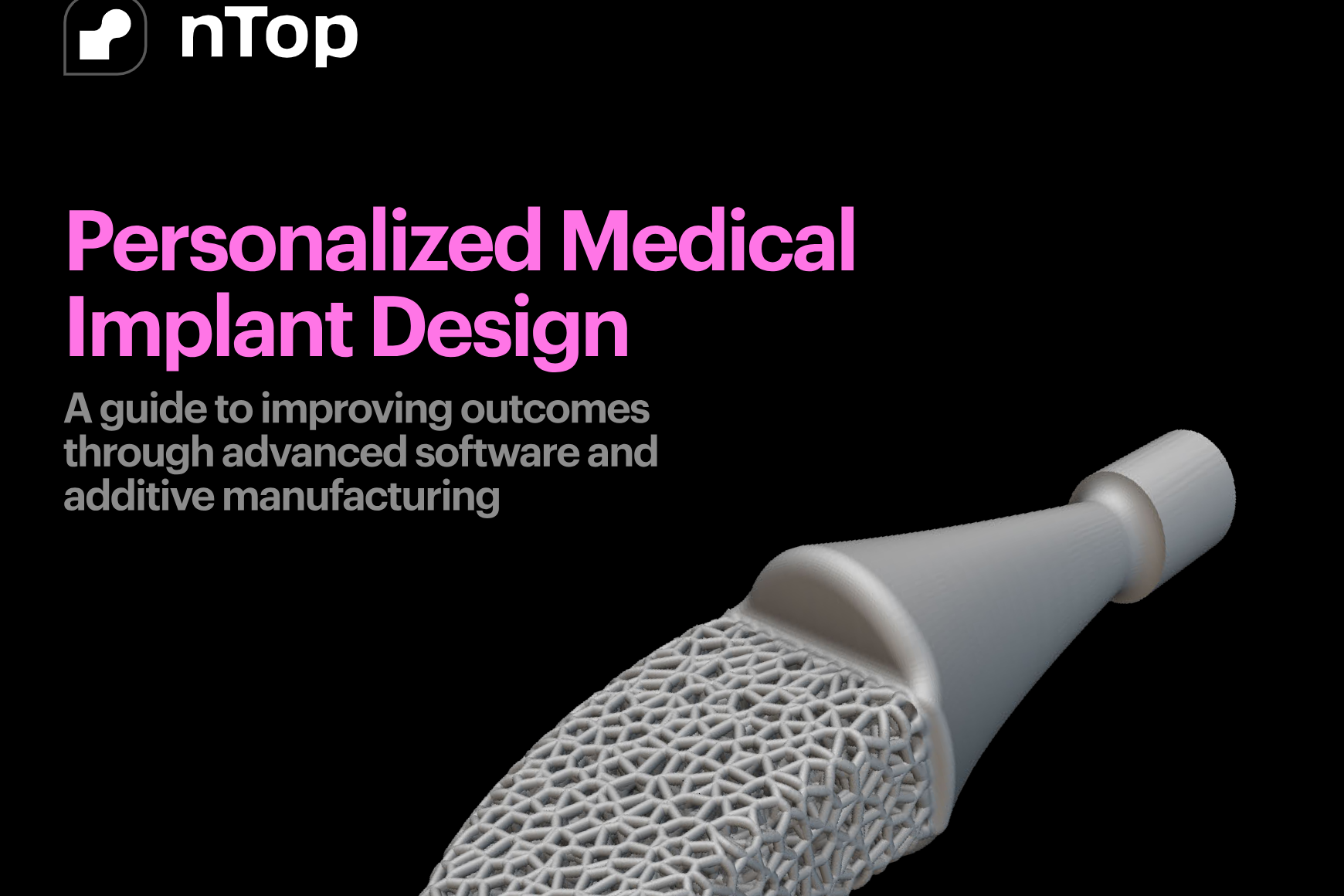

Download: Advanced design software and additive manufacturing for personalized implants

- GUIDE

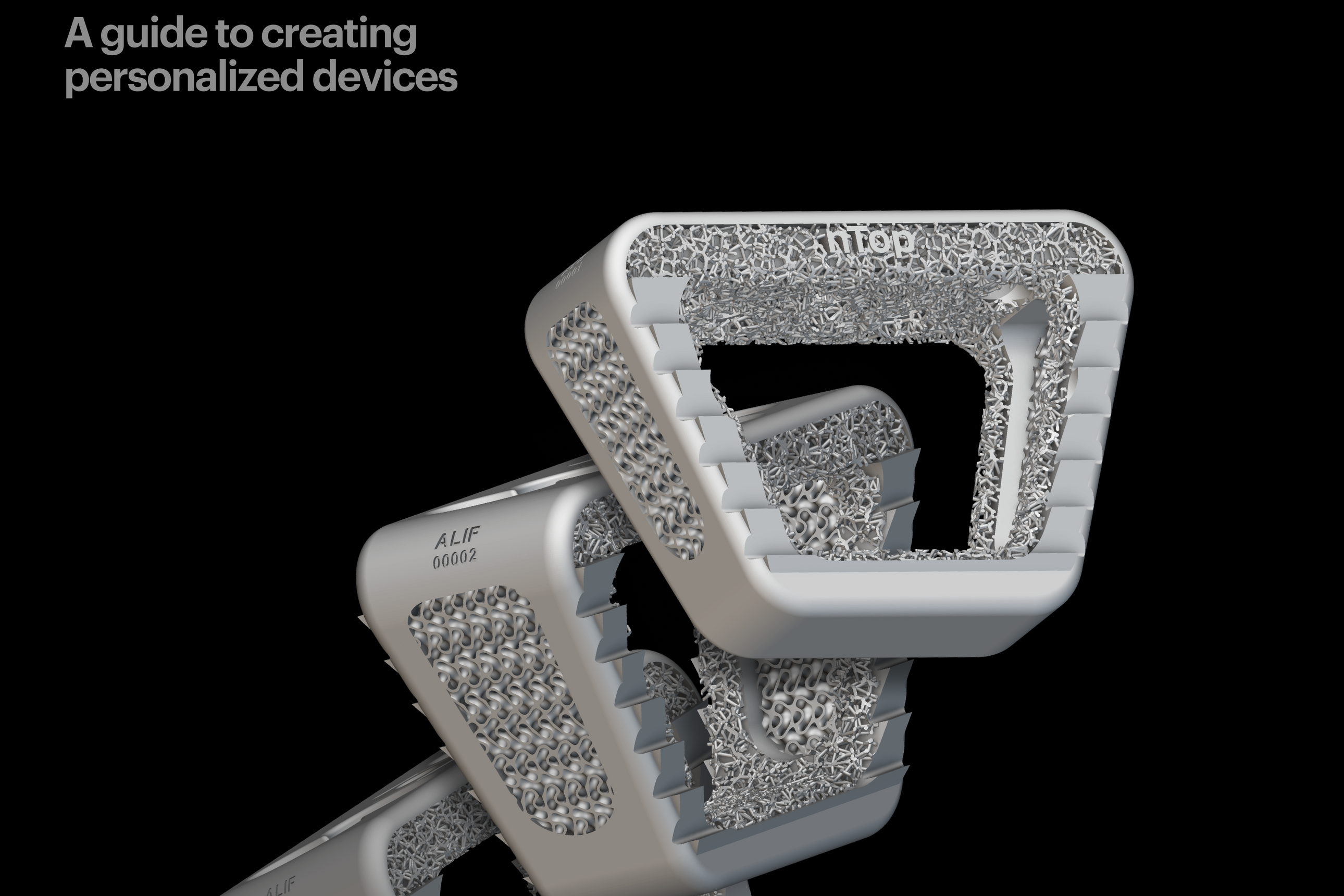

Download: Design Automation for Medical Devices

- CASE STUDY

Designing a cooler camera housing

- VIDEO

Design a spooky Halloween candy bowl in nTop

- ARTICLE

Improving the biomechanical profile of additive hip implants with Field Optimization