How nTop integrates into enterprise PLM systems

Written by Daeho Hong | Product Manager (Integrations) at nTop

Published on October 13, 2021

At nTop, we always strive to support our customer’s product development process and ecosystem. This post explains how you can integrate nTop into your Product Lifecycle Management system for tracing design activity and managing information.

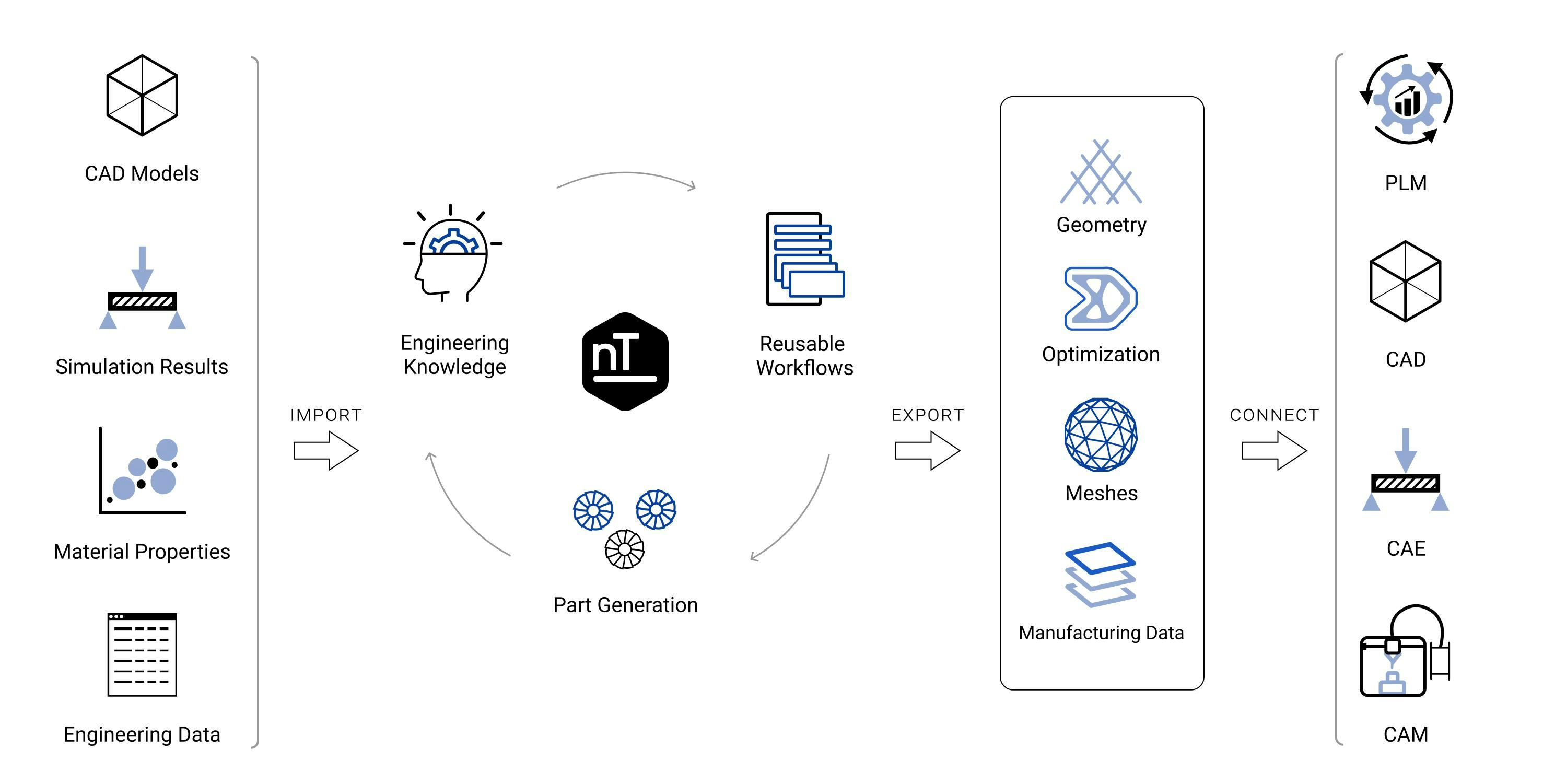

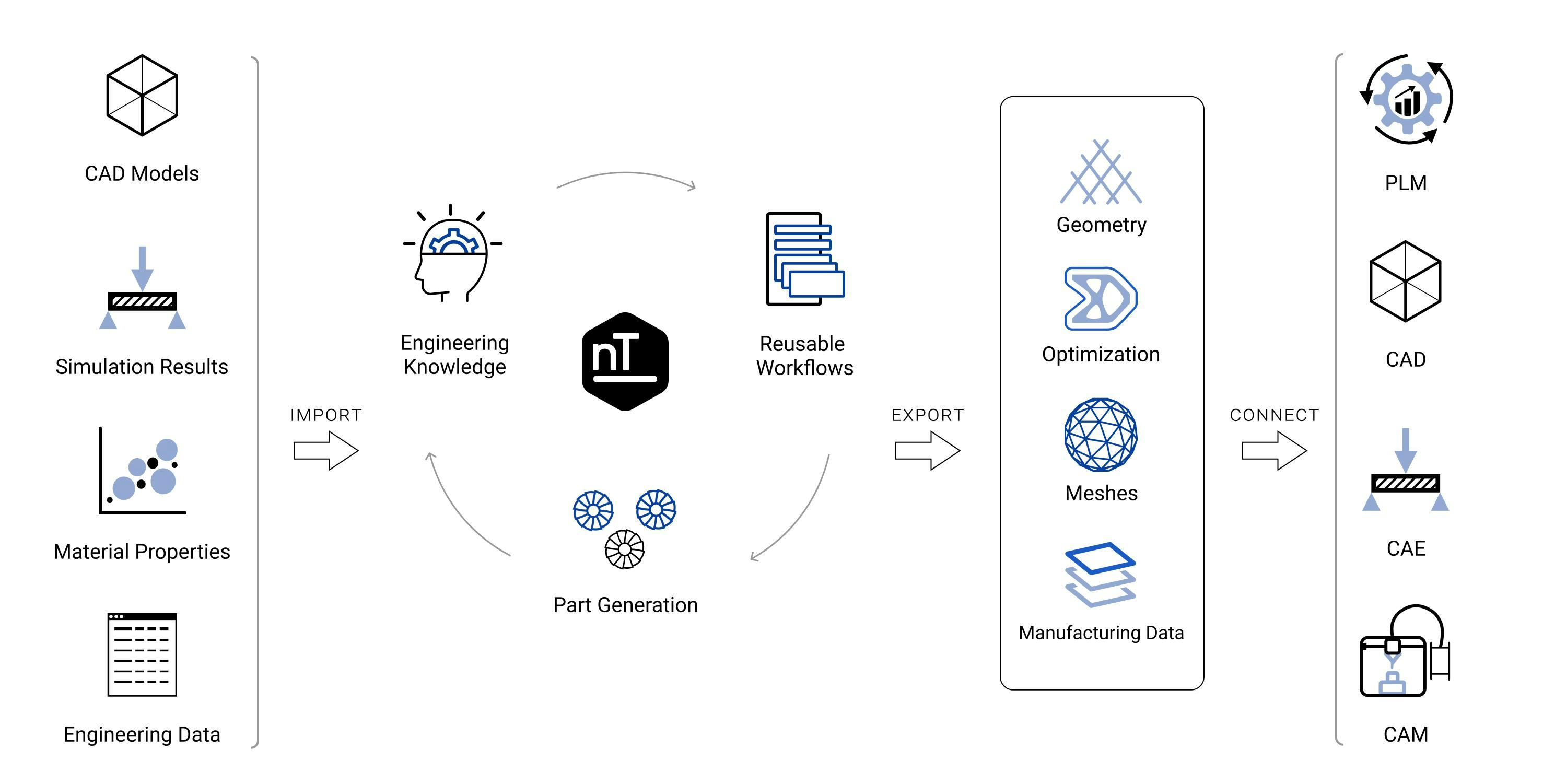

A typical design workflow in nTop usually involves importing and exporting many different types of data: CAD and CAE files, meshes, manufacturing data, engineering tables, and other information relevant to design.

Overview of a data flow in a typical nTop workflow.

The Field-Driven Design capabilities of the software enable engineers and designers to utilize the imported data to generate optimized geometry that meets design goals. After the workflow is complete, the design outputs are exported in relevant formats to feed downstream operations; design analysis, documentation, manufacturing, etc.

Managing nTop workflows and the associated data flow in a streamlined, traceable, and controlled fashion may initially seem challenging. However, the process can be automated and greatly simplified by integrating nTop into your enterprise PLM system.

nTop PLM Connector

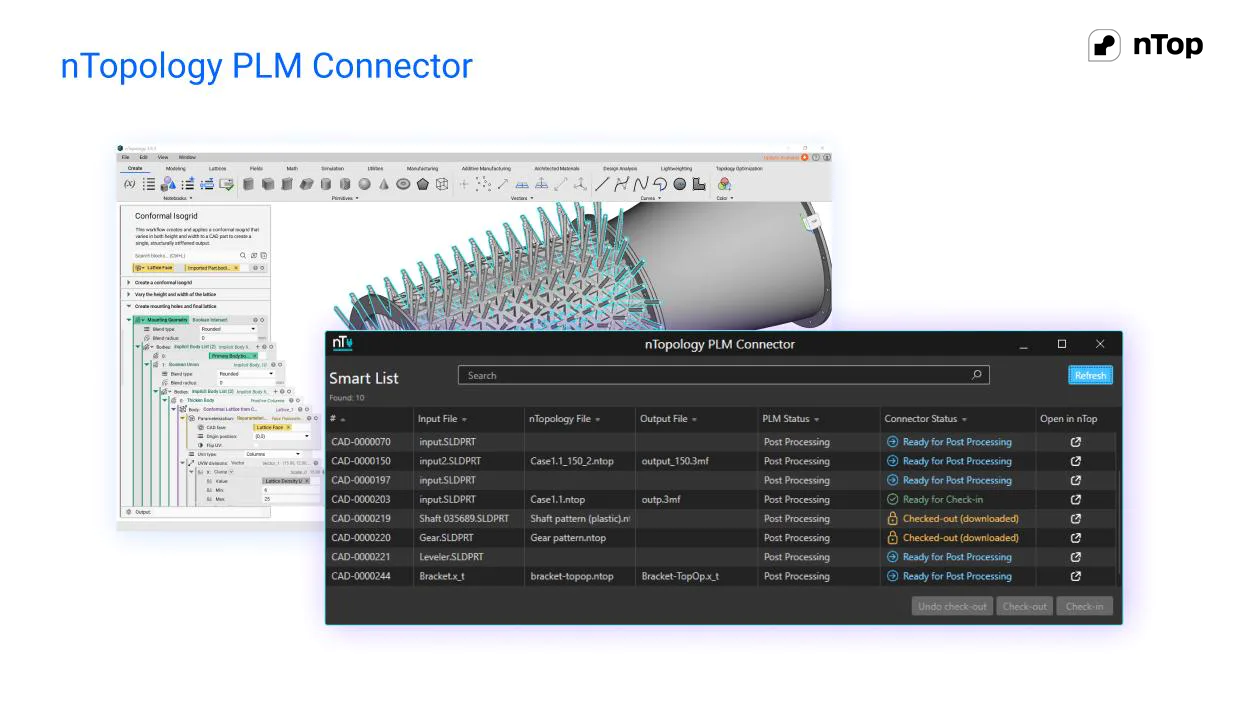

nTop now integrates to PLM systems through the nTop PLM Connector.

The nTop PLM Connector is a prototype standalone executable that interacts with your PLM system. It enables automated and version-controllable data exchange between nTop and your PLM system for compliance and cross-team collaboration.

Some of the core capabilities of the nTop PLM connector include:

- Login access with your native PLM credentials

- List view of relevant PLM documents

- Check-in and check-out of PLM documents

- Secure file exchange during nTop design sessions

- File path replacement in nTop Notebooks

- Secure local cache data management

Reference PLM integrations

We can provide reference integrations with complete documentation to Siemens TeamCenter and Aras Innovator. Leveraging these proven integrations, additional connections with other popular PLM software, such as PTC Windchill and DS Enovia, can be developed upon request.

Every PLM system is unique. For this reason, we designed nTop’s PLM integration strategy to accommodate your custom requirements.

The following example shows how we implemented a PLM workflow and document data structure in Siemens TeamCenter. Note that, regardless of any differences in the PLM software, the users interact with the design documents using the graphic interface of the nTop PLM connector.

Example: PLM design workflow

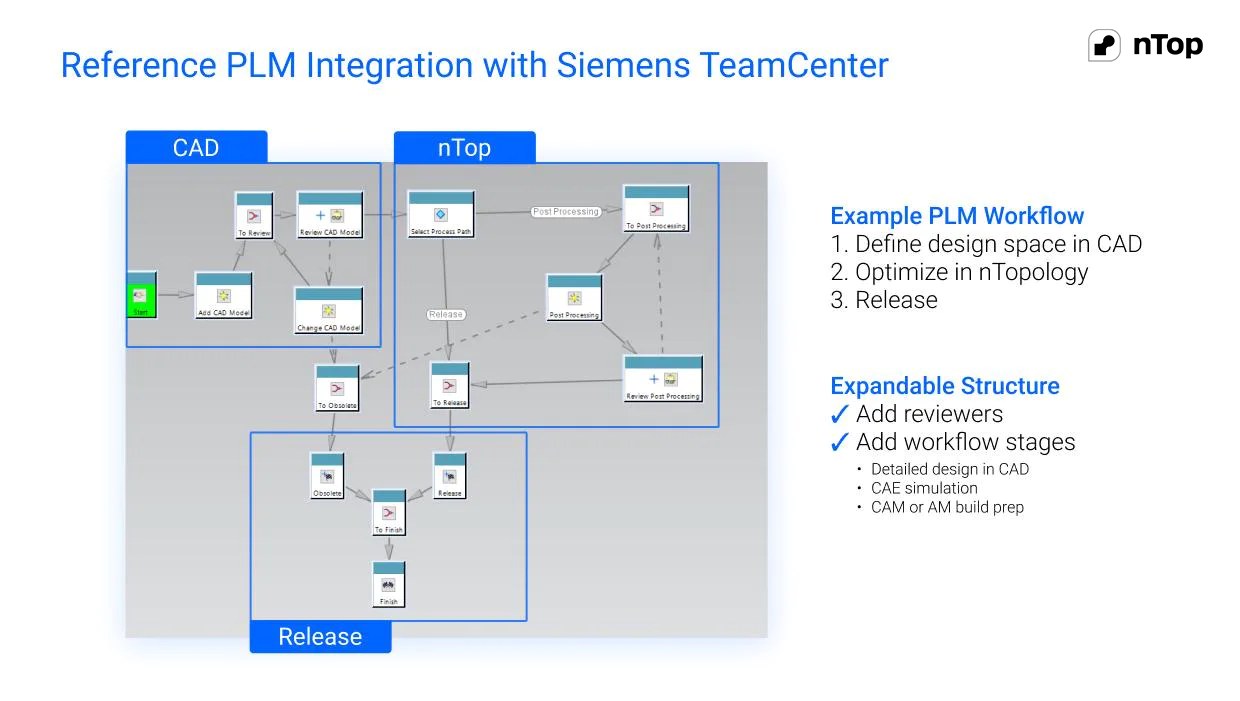

The example PLM workflow of the reference integration has two main stages: an initial definition of the design space in CAD and optimization in nTop. We also included a review step in both stages for approval before release.

Example PLM workflow in Siemens TeamCenter that includes initial design in CAD and optimization in nTop.

This reference workflow can be easily modified or extended to better fit your product development process. For example, additional design stages upstream and downstream of nTop or review steps can be added through your PLM system.

Example: Document data structure

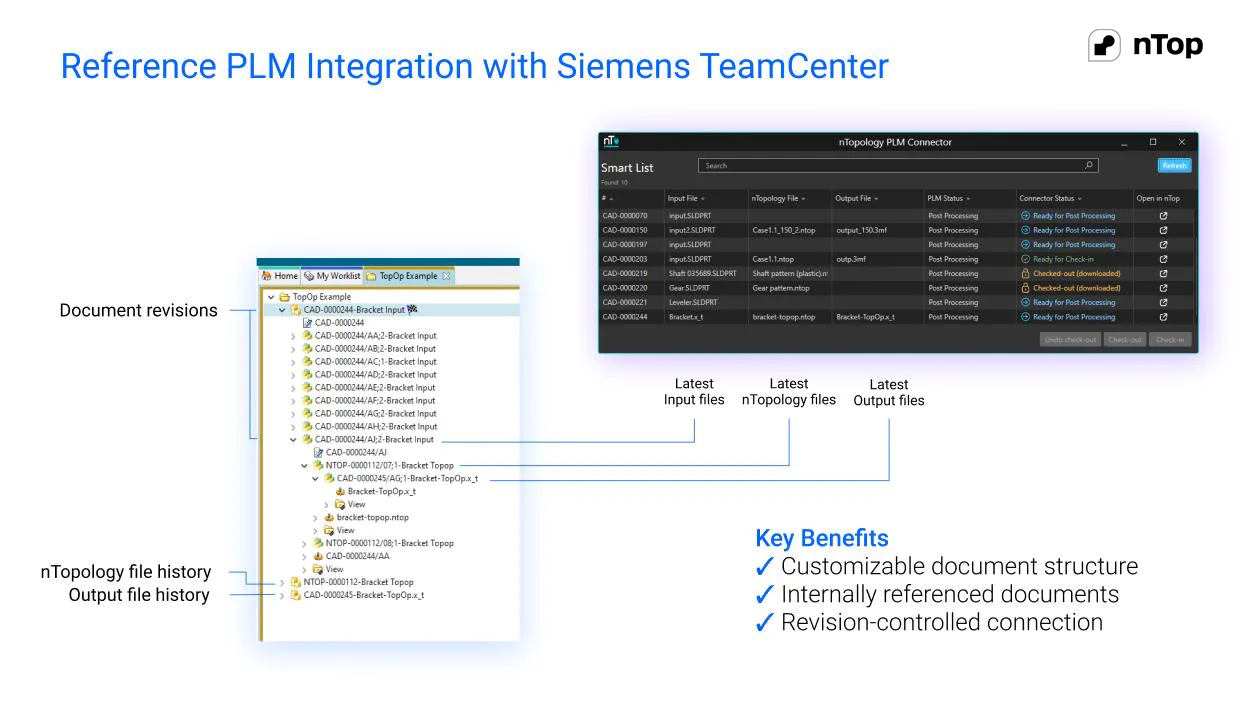

There are no strict rules on how to organize nTop design documents in your PLM system. In the reference integration example, we decided to manage CAD inputs, nTop workflows, and nTop outputs as a group. Each version-controlled item exists as an individual document that is referenced in the PLM workflow.

Example nTop design document data structure in Siemens TeamCenter.

Benefits of integrating nTop into PLM

Adding new software to your enterprise PLM ecosystem does not come without costs. Yet, the benefits of augmenting your software stack with the advanced engineering design capabilities of nTop can quickly outweigh the initial investment.

Expedited product development

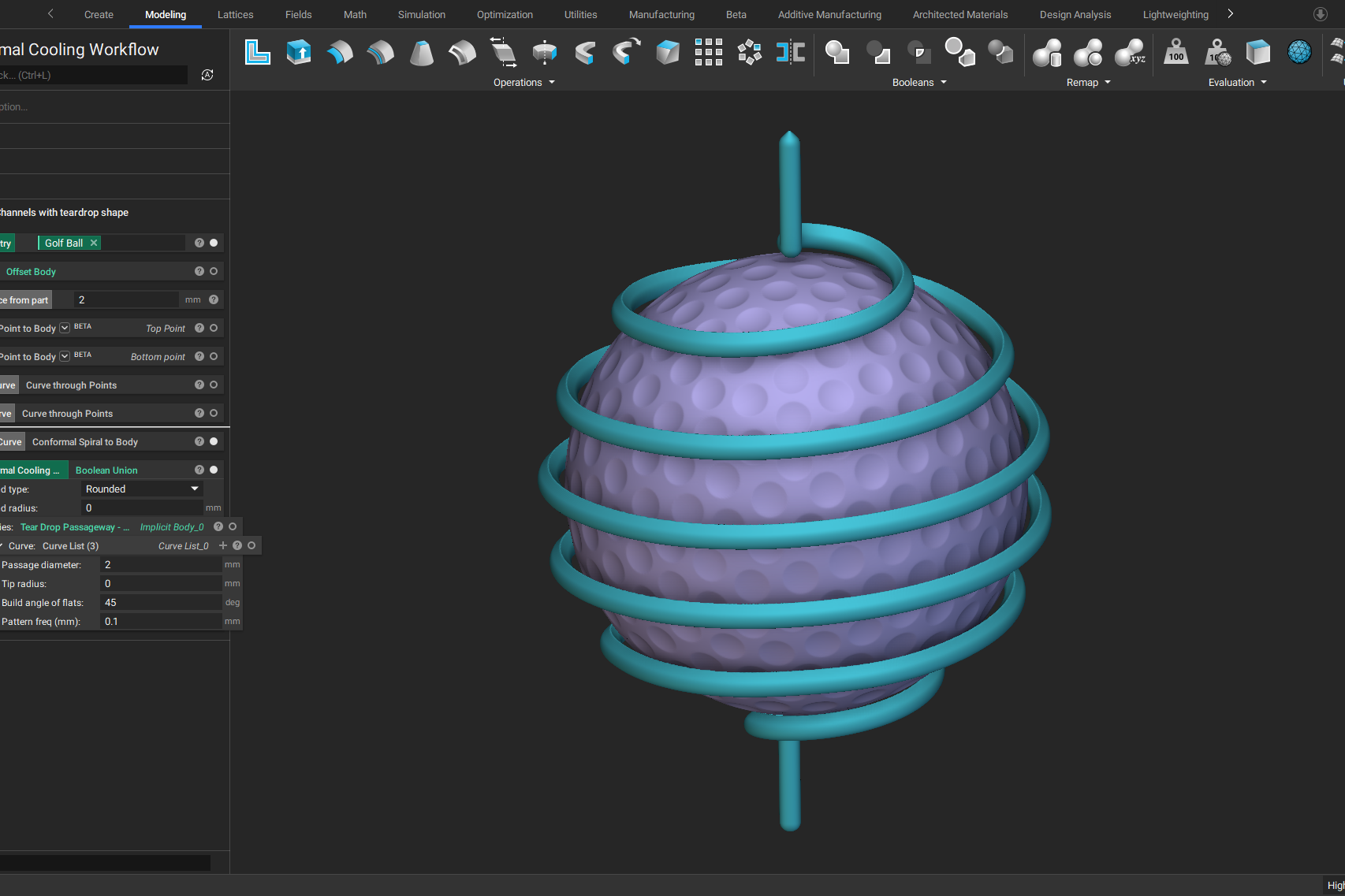

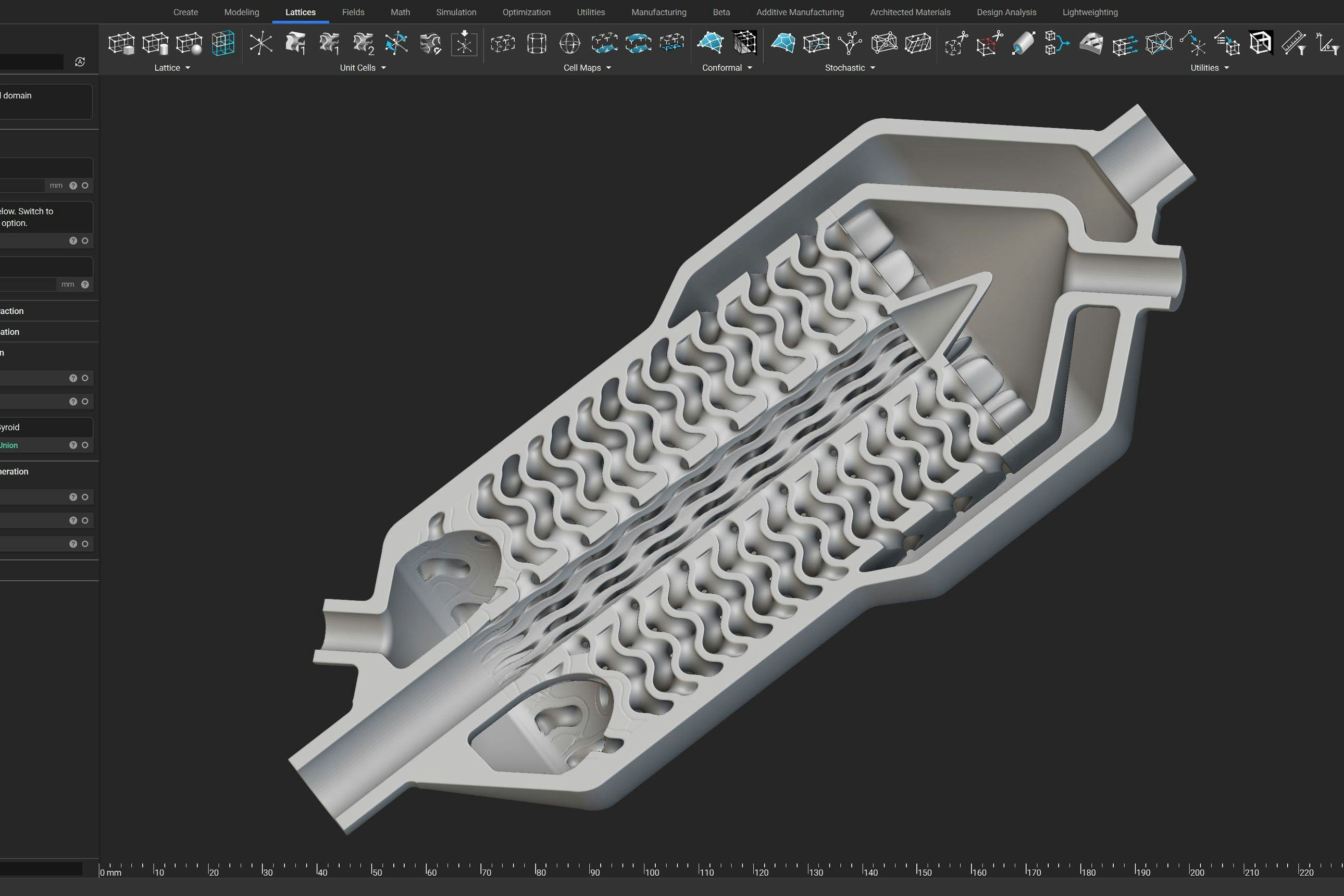

In a pilot study with an enterprise customer, the engineering team added conformal ribs to the external surfaces of an aerospace component.

The workflow that included work in traditional CAD software and nTop produced optimized and verified results in 90% less time than the workflow that included work in CAD alone. In both cases, the whole process was orchestrated by the PLM system.

In a pilot study with an aerospace customer, optimizing the conformal ribbing of a similar component took the engineering team approximately 80 hours to complete when using CAD alone — and less than 8 hours when using CAD and nTop together.

Similar time savings have been recorded across industries and applications. The compound effect of these streamlined design workflows has been proven time and time again to significantly accelerate the whole product development lifecycle — from R&D and concept development to detailed design and manufacturing.

When translated to engineering hours, integrating nTop into their enterprise PLM ecosystem is saving our pilot customers tens of thousands of dollars every month.

Data management and traceability

From a more practical perspective, integrating nTop into your PLM system offers additional technical advantages.

For example, nTop can access through the PLM connection data generated in other engineering software or gathered experimentally. With the software’s Field-Driven Design capabilities, your engineering team can use this data to drive advanced geometry and develop high-performing products.

Moreover, the PLM connection enables nTop users to trace all design documents and engineering data involved in the design process to comply with design and engineering procedures.

Key takeaways

In this post, we explored how nTop integrates with your enterprise PLM system. Our goal is to help you streamline the integration of nTop into your engineering software ecosystem.

Here are the key takeaways:

- The time savings you will enjoy by integrating nTop into your PLM system will quickly outweigh the initial implementation cost.

- nTop provides the nTop PLM Connector and reference PLM integrations with Aras Innovator & Siemens TeamCenter. Other PLM systems are also supported.

- Implementation of PLM workflows and document structure is fully customizable and extendable to fit your process and support your digital thread.

If you would like to learn more about nTop’s integration with PLM systems or request additional documentation or information on the nTop PLM Connector, please contact us.

Daeho Hong

Product Manager (Integrations) at nTop

Related content

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop

- VIDEO

5 reasons why you should use nTop to create heat exchangers