Eliminate STL files from your additive manufacturing process with nTop + EOS

Written by nTop

Published on August 23, 2019

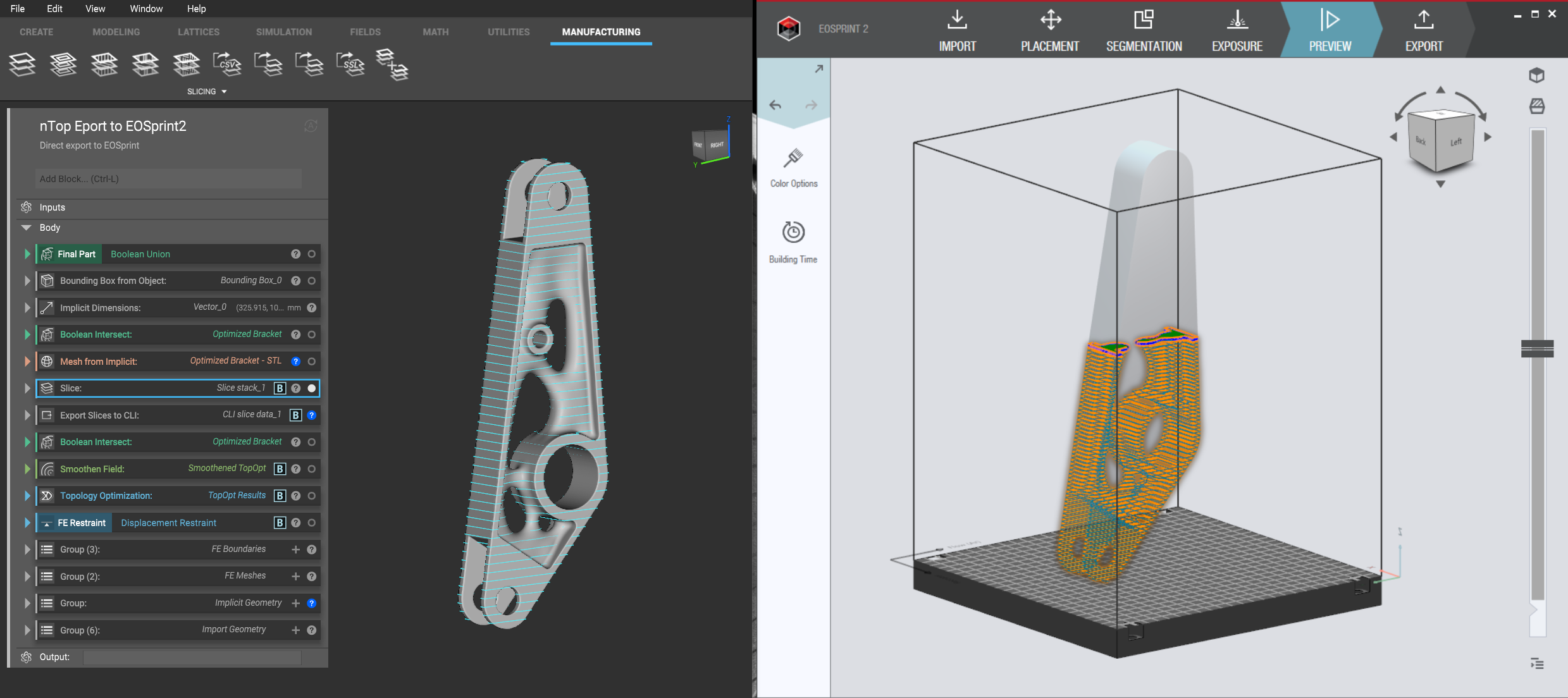

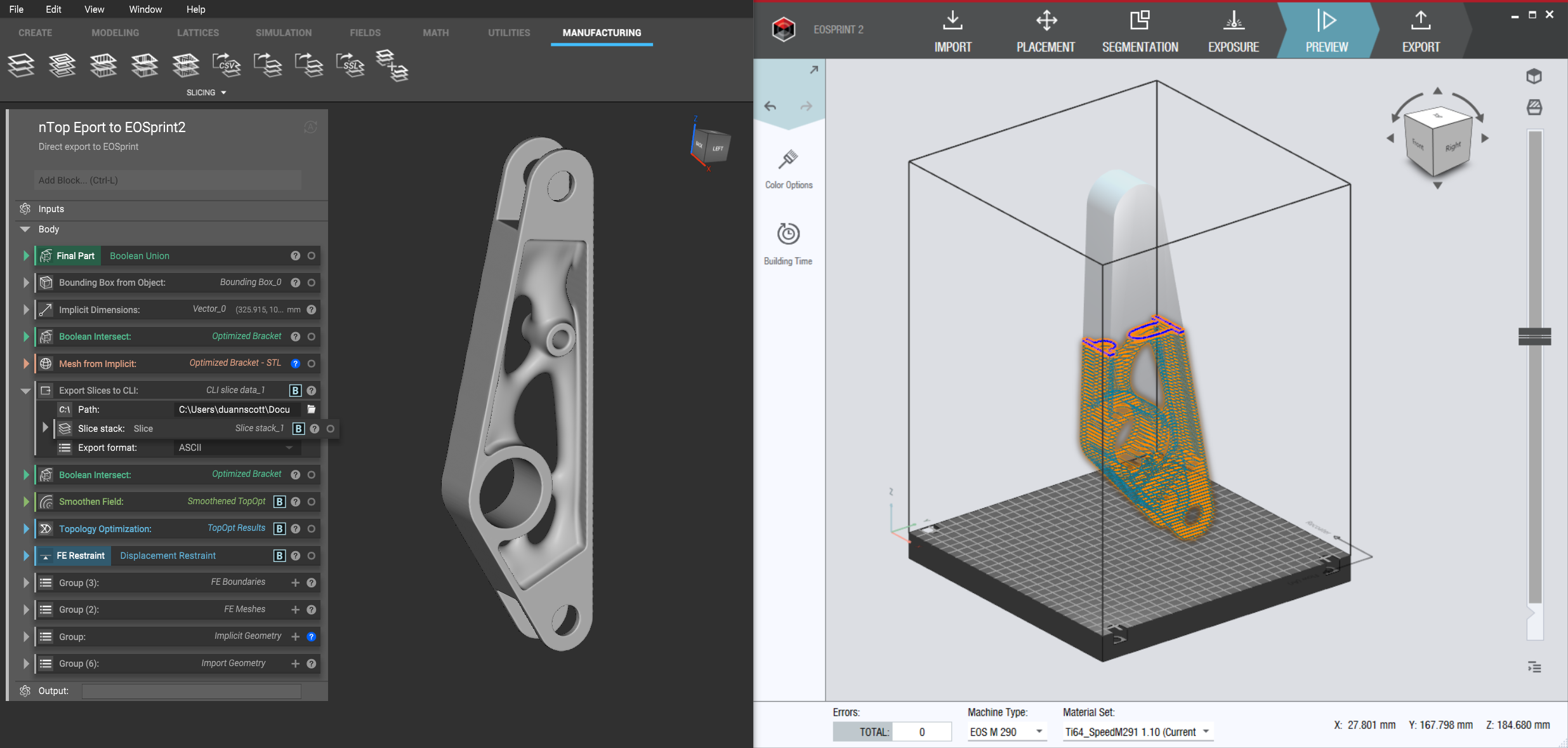

Learn about how you can eliminate the need for STL files and go direct from design to manufacturing with nTop software and EOSPRINT.

nTop is thrilled to announce new advancements in interoperability with EOS. Our new capability allows engineers to go from design direct to manufacturing with EOS without the need to convert to STL or use 3rd party software for build preparation. This end-to-end integration at the slice file level builds on nTop’s mission to enable engineers to design and manufacture the highest performing products in the least amount of time: better parts, faster.

nTop and EOS are two companies that share a common interest in changing and disrupting the world of design and manufacturing. To create change and disruption our teams needed to work well together. Collaboration was key and, in fact, it came naturally to both of us. Over the past few months there were many site visits, workshops, and virtual meetings to ensure that this hard work would greatly benefit our current and future customers.

EOS’s Additive Minds Team was an integral part of this project as they are the expert consultants for their customers: leaders in the aerospace, automotive, medical and other industries. When those industry leaders want to incorporate additive manufacturing they ask the Additive Minds team for advice and guidance in both hardware and software deployment.

Eliminating STL!

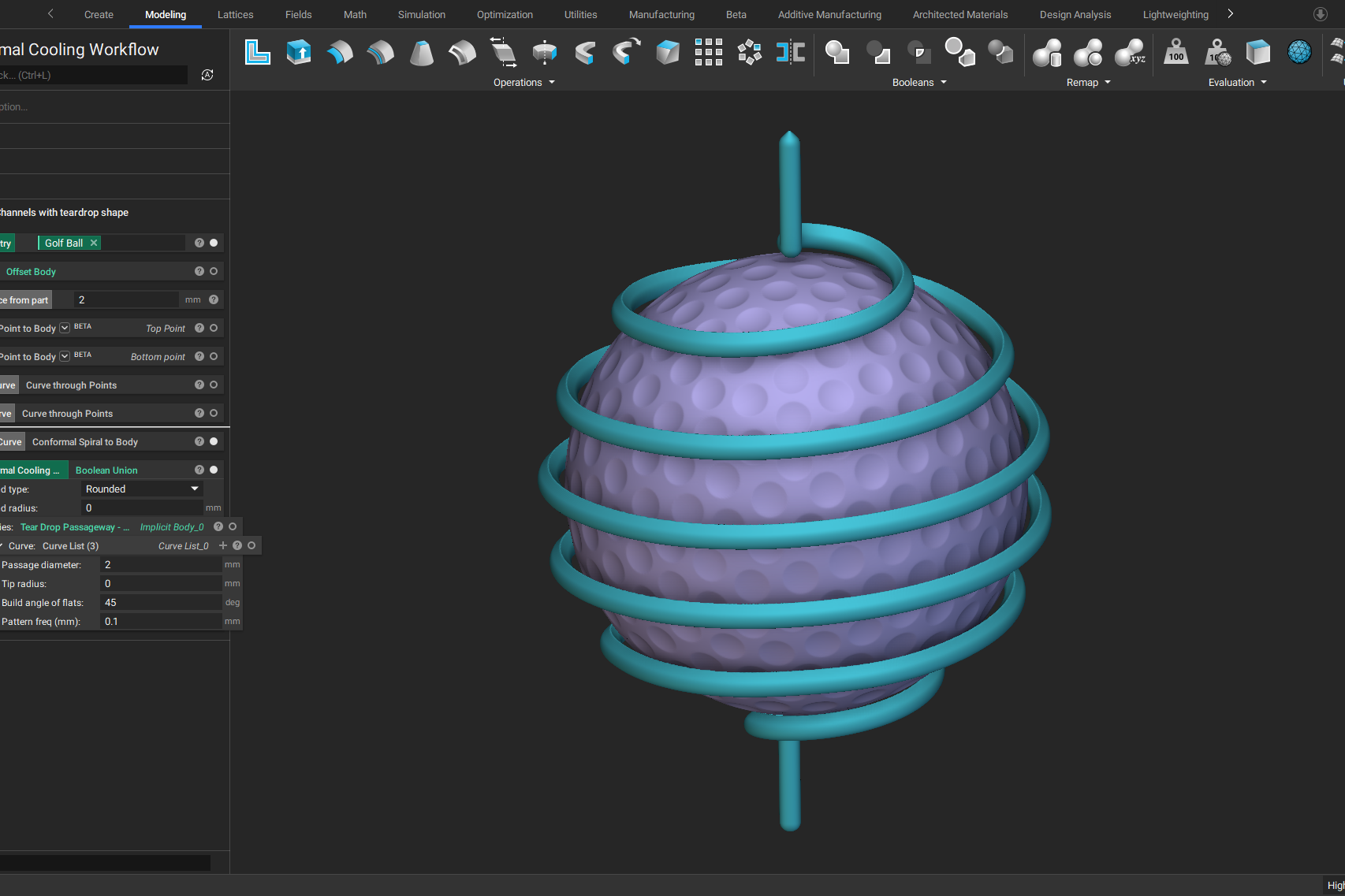

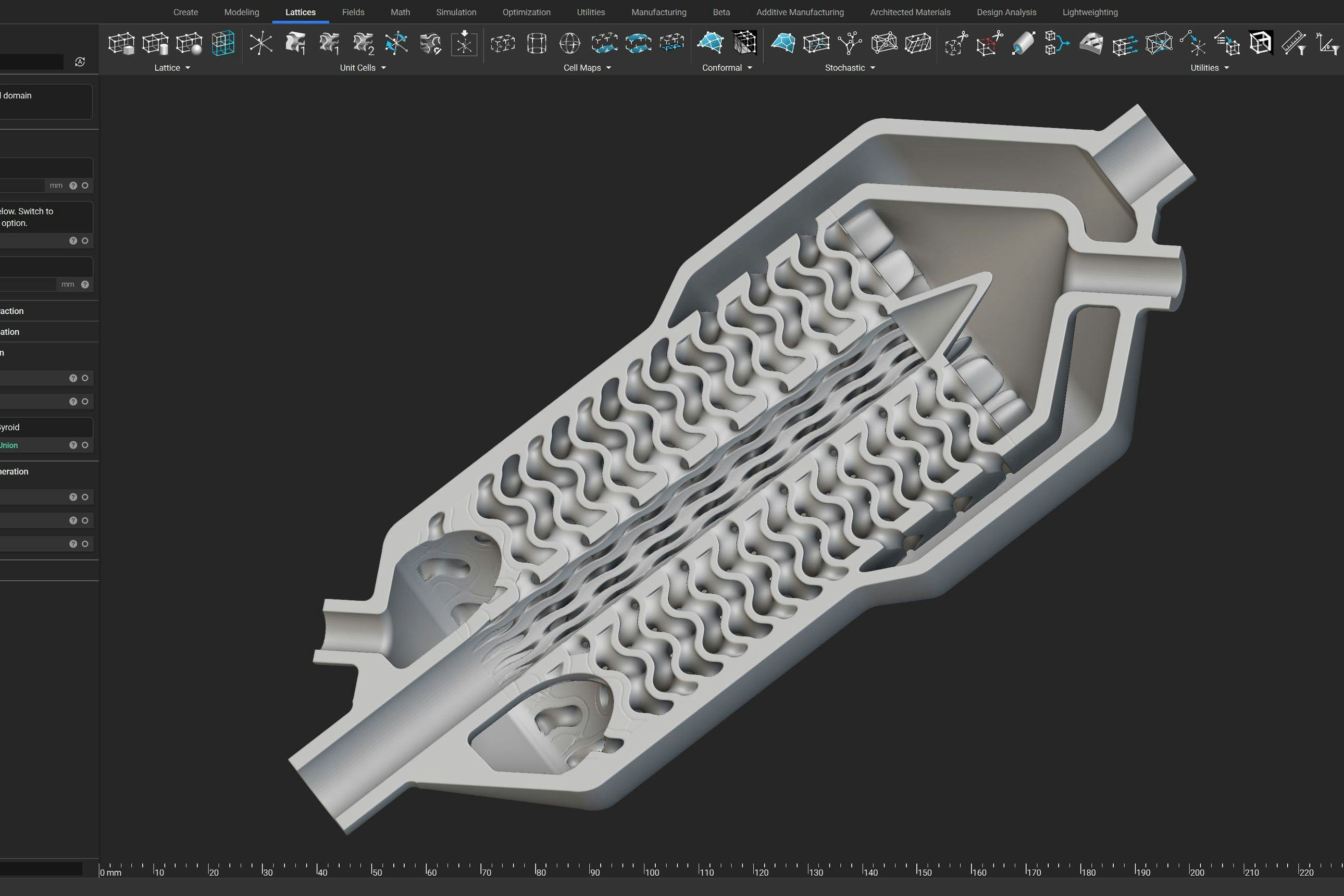

Here’s why this matters to you: this interoperability allows nTop users to go directly from our platform to the EOS machine software without any additional 3rd party software and, more importantly, no STL files. This means significantly less discretization. Additionally, this allows for design parameters of lattice structures, feature details, localized and simulation driven material properties resulting in the ability to design at the macro, meso and micro scale. Ultimately, the as-designed part is what you get saving you design time and non-value-added engineering time dealing with 3rd party software and loss of data with unwieldy, often very large STL files.

Direct connectivity from nTop to EOSPRINT via slice data.

“Working with EOS software team has enabled us to create a direct workflow between nTop software and EOSPRINT that allows our shared customers to realize their designs faster and more reliably. Eliminating the need to use the dreaded STL and 3rd party software in turn eliminates loss of data in translation and costly human errors. The Additive Minds team are crucial to our partnership, in giving us valuable feedback as well as working together on projects to ensure our customer’s success.” Duann Scott, Director of Business Development and Partnerships at nTop.

Cary Baur, Manager, R&D / Applications Development - Polymers at EOS says of our partnership, “EOS North America is excited to be collaborating with nTop to enable a more intuitive, streamlined front-end workflow for additive manufacturing. As organizations work to scale their AM production, intuitive part design and data management platforms become more and more critical to their success. Thanks to our collaborative relationships with partners such as nTop, we can ensure our customers have industry-leading solutions that grow with their needs.” While this might feel like just the beginning this partnership announcement is a first major step for us and we are currently working on deeper connectivity via the EOSPRINT SDK and some ground breaking projects we can’t wait to share… so stay tuned.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop