The FDM Fixture Generator is expanding: Introducing the masking module

Written by nTop

Published on March 26, 2021

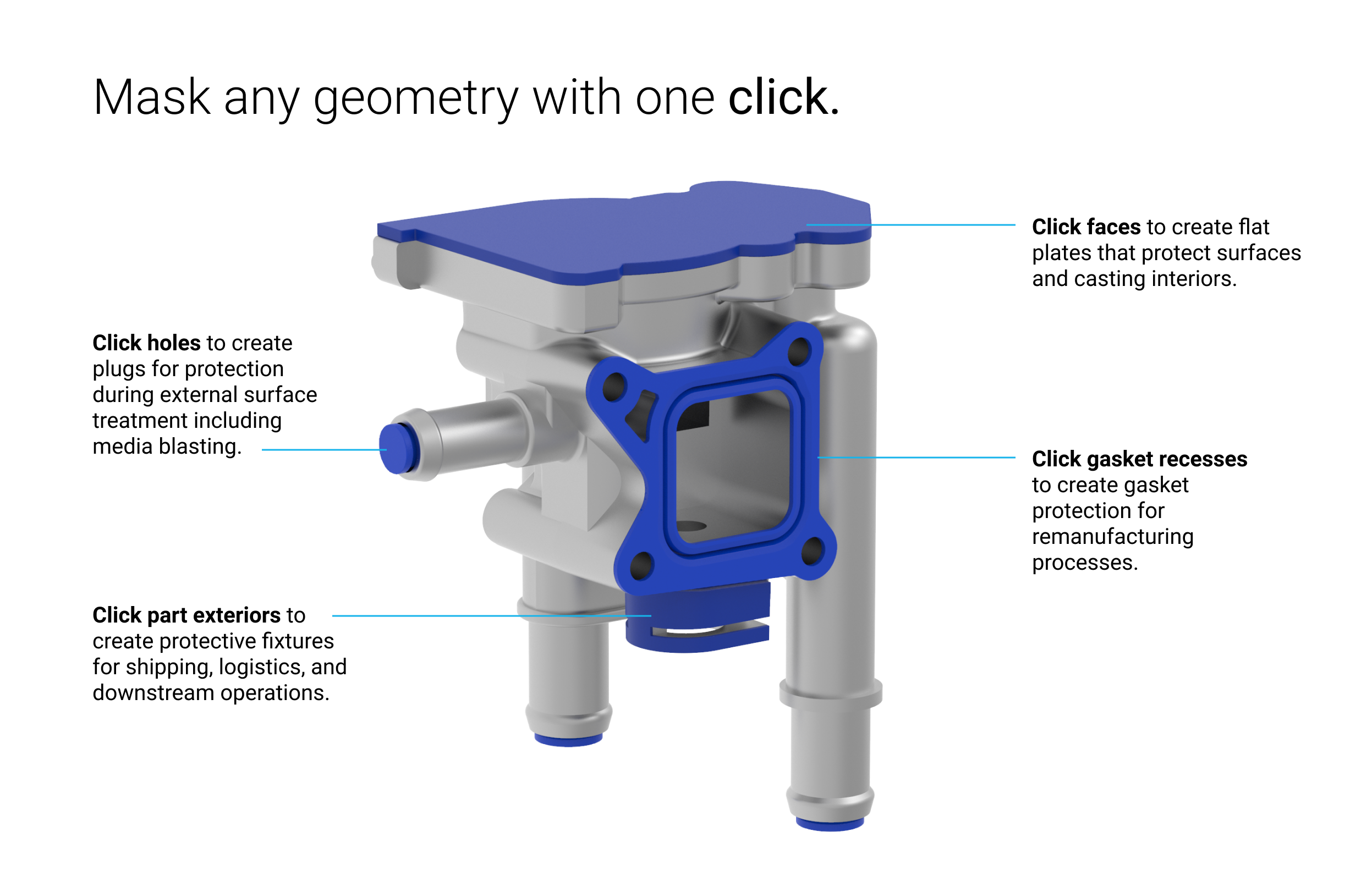

The second module of the FDM™ Fixture Generator is now available to all. This time the focus is on 3D printed fixtures for masking applications. The tools created from the collaboration between Stratasys and nTop enable manufacturers to generate and 3D print custom fixtures with just a couple of clicks.

The new Masking Fixture Module of the FDM™ Fixture Generator turns complex part surfaces into protective plugs, masks, and enclosures. We created this design tool to enable manufacturers to make the most out of 3D printed jigs and fixtures on the factory floor. The FDM Fixture Generator automates 90% of the design work required for simple jigs and fixtures.

Manufacturing engineers using this tool can keep parts safe and clean throughout the manufacturing process without the hassle of designing one-off jigs and fixtures. Our early customer feedback has been extremely positive, and users have identified several applications in which this functionality can help. Protecting critical faces, gaskets, holes, or mating surfaces with tight tolerances during a painting, coating, or bead blasting post-processing step are a few use cases.

3D printed masking fixtures eliminate the need for manual masking techniques, regardless of model complexity. The Masking Fixture Module automates the design of these fixtures and saves you hours of work in CAD for every job.

Watch this video to learn more about the Masking Fixture Module of the FDM™ Fixture Generator:

Video about the Masking Fixture Module of the FDM™ Fixture Generator

The Masking Fixture Module is the result of an ongoing collaboration between Stratasys and nTop. We worked with several customers to define this project’s scope and to provide practical feedback on its usefulness.

Many users in the aerospace and defense industry see the potential of this tool in reducing scrap rate and increase throughput. A machine shop creating medical devices and aerospace parts is excited to use this tool to protect faces during deburring and abrasive processes.

The FDM™ Fixture Generator, a design automation tool that saves time and labor costs, and is now available for all to download and put to use.

Last year, nTop and Stratasys teamed up with a common goal: to remove design bottlenecks and maximize manufacturing efficiency through time and material savings.

Jigs and fixtures account for approximately 10% of all end-use parts 3D printed today. Yet, less than 1% of all fixtures used in factories around the world are 3D printed. That’s not because manufacturers couldn’t benefit from them. The industry needs automated Design for Additive Manufacturing tools that will simplify the design of fixtures and will make them more accessible to the factory floor.

The Masking Fixture Module is the second output of this ongoing collaboration. A few months back, we released the Assembly Fixture Module, a workflow that automates the design of kitting trays, storage cases, and other simple fixtures to support manufacturing operations.

Sounds interesting? Get full access to the FDM™ Fixture Generator and start saving design time and reducing scrap rate today.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

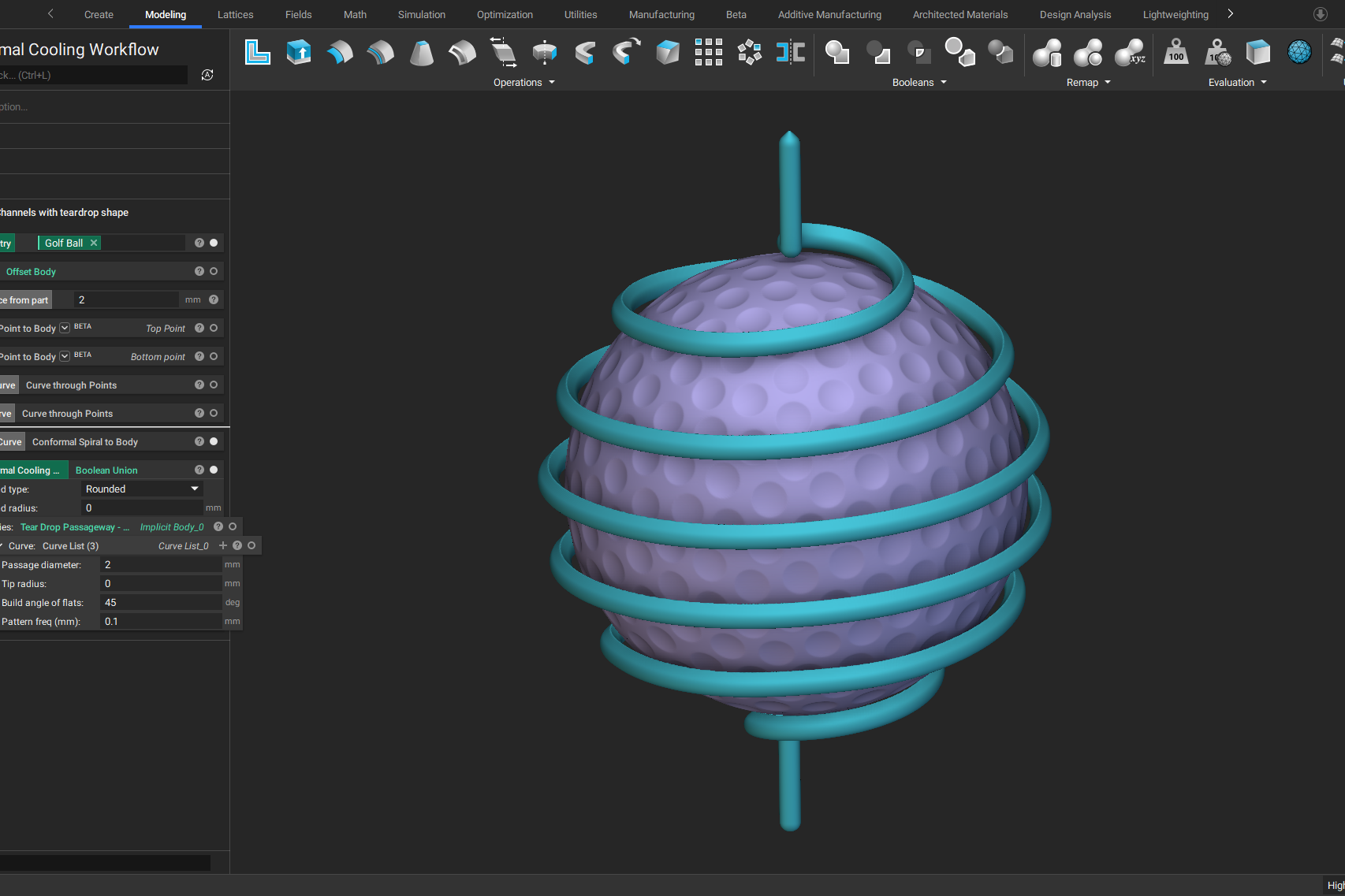

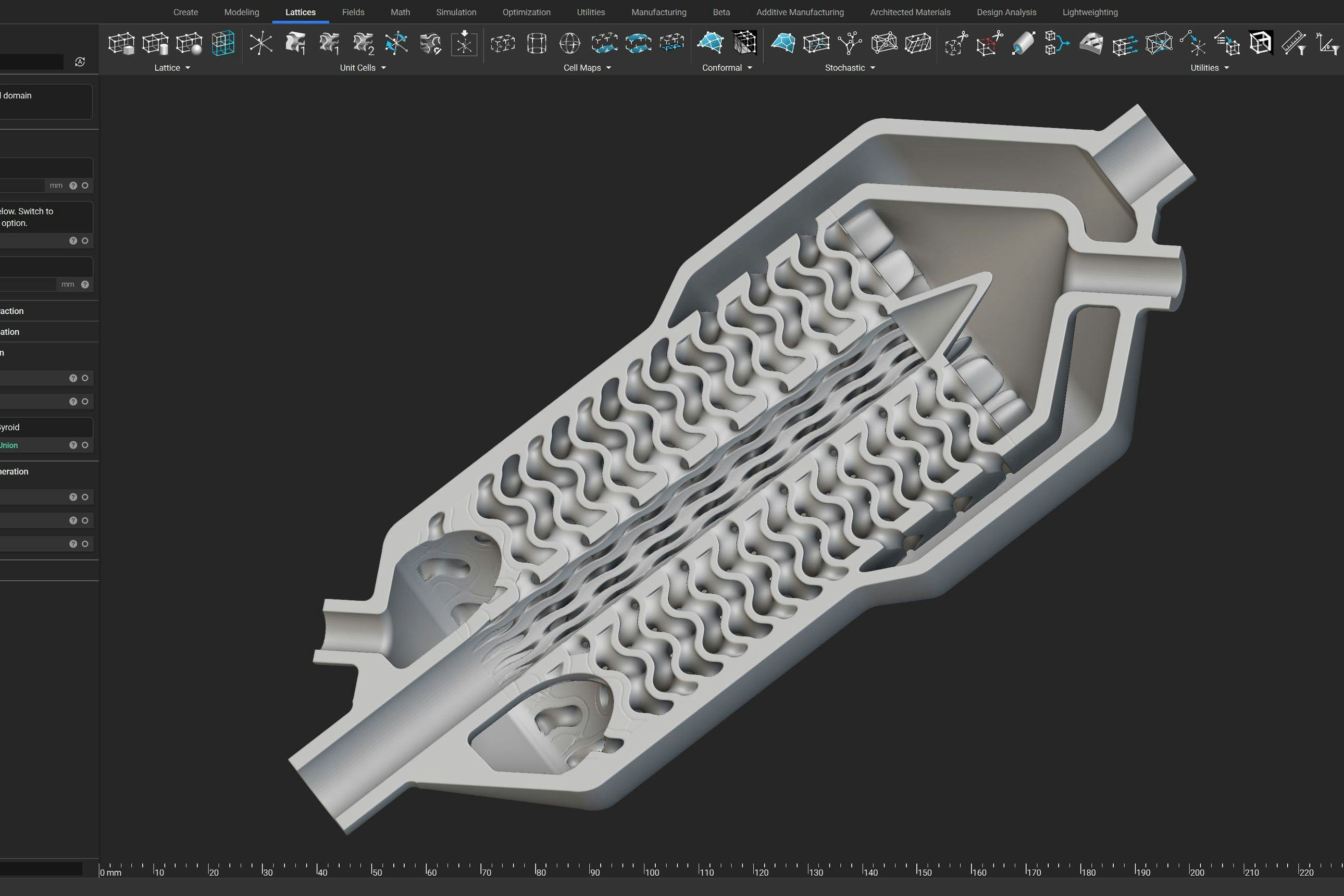

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop