Leveraging Formlabs elastomeric materials to create a library of lattice responses

Written by Jessica Bergau

Published on April 9, 2020

The fifth NFL Helmet Challenge Design for Additive Manufacturing eSeries Guest Blog

It seems like every day there are new products hitting the market that incorporate amazing lattice designs. From football helmets to running shoes, companies are eager to be on the cutting edge of additive manufacturing and consumers flock to products with promises of improved performance and eye-catching aesthetics.

New Balance’s 990 Sport shoe with 3D printed midsole.

It’s true that intelligent lattice design and additive manufacturing have created a new frontier in product development. But how can product designers and companies ensure their marketing promises aren’t just hot air? Designing with lattices opens up a world where properties of an object that used to be set by material selection can now be varied by changing aspects of the lattice. Material properties like durometer and modulus of elasticity can be varied spatially across a single part manufactured from a single material.

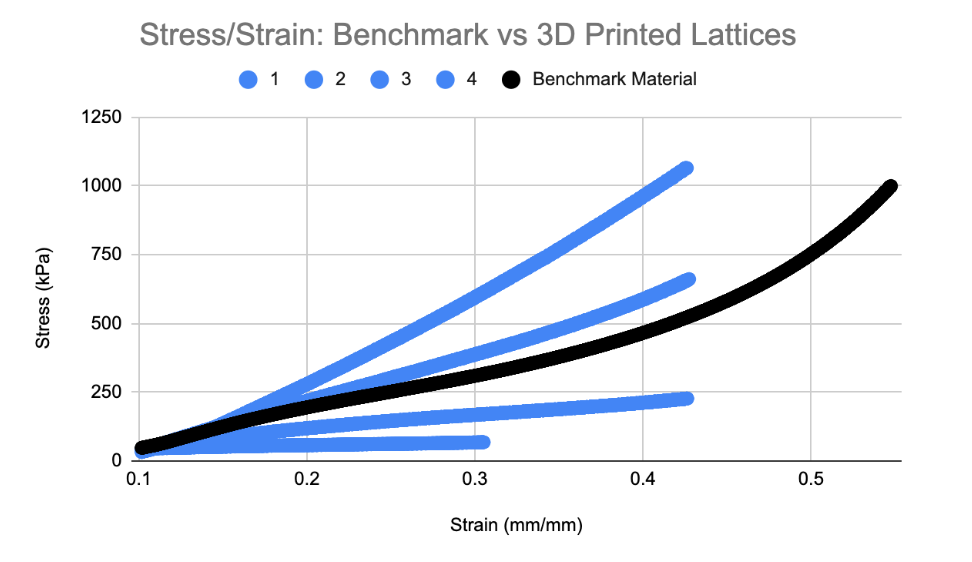

Stress/strain graph of a benchmark material compared to four 3D printed lattices.

Product designers may utilize this capability to step outside the bounds of traditional stacked foams, using lattices to alleviate tension or provide dynamic support. Even responses that may seem undesirable on the surface can provide benefit in certain applications. Can the inclusion of a lattice that buckles at a certain force prevent injuries?

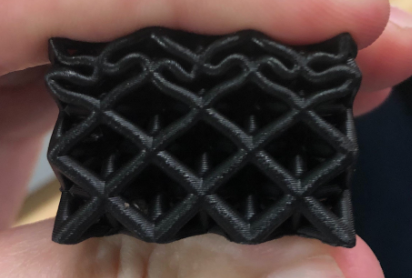

A buckling lattice printed in Rebound Resin.

In our webinar, learn how to take your next project from concept to product by creating lattices with Formlabs printers and integrating them into products using nTop workflows. We’ll give you an overview of how to determine elastomeric latticed material properties using simple tests and show you a process to leverage Formlabs 3D printers and nTop design software to create latticed products that deliver on their hype.

Jessica Bergau

Jessica Bergau is an Applications Engineer at Formlabs, focusing on prototyping and validating 3D printing applications intended for mass production. Jessica works closely with New Balance to move their 3D printed midsole project forward, as well as other large customers interested in next generation manufacturing. Jessica joined Formlabs from the University of Florida where she founded a student run organization to develop FDM printed assistive devices for children with upper limb differences.

Related content

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

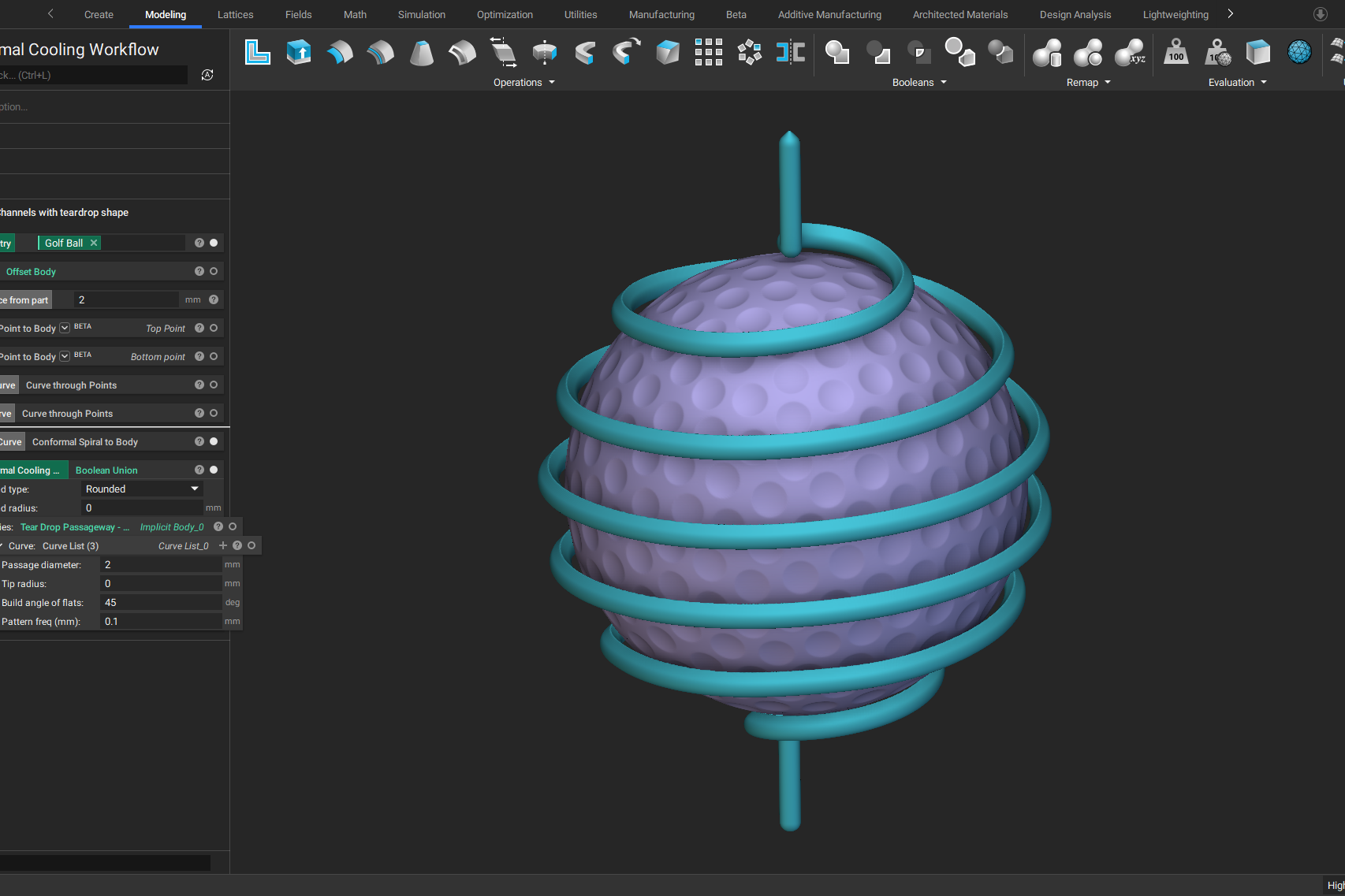

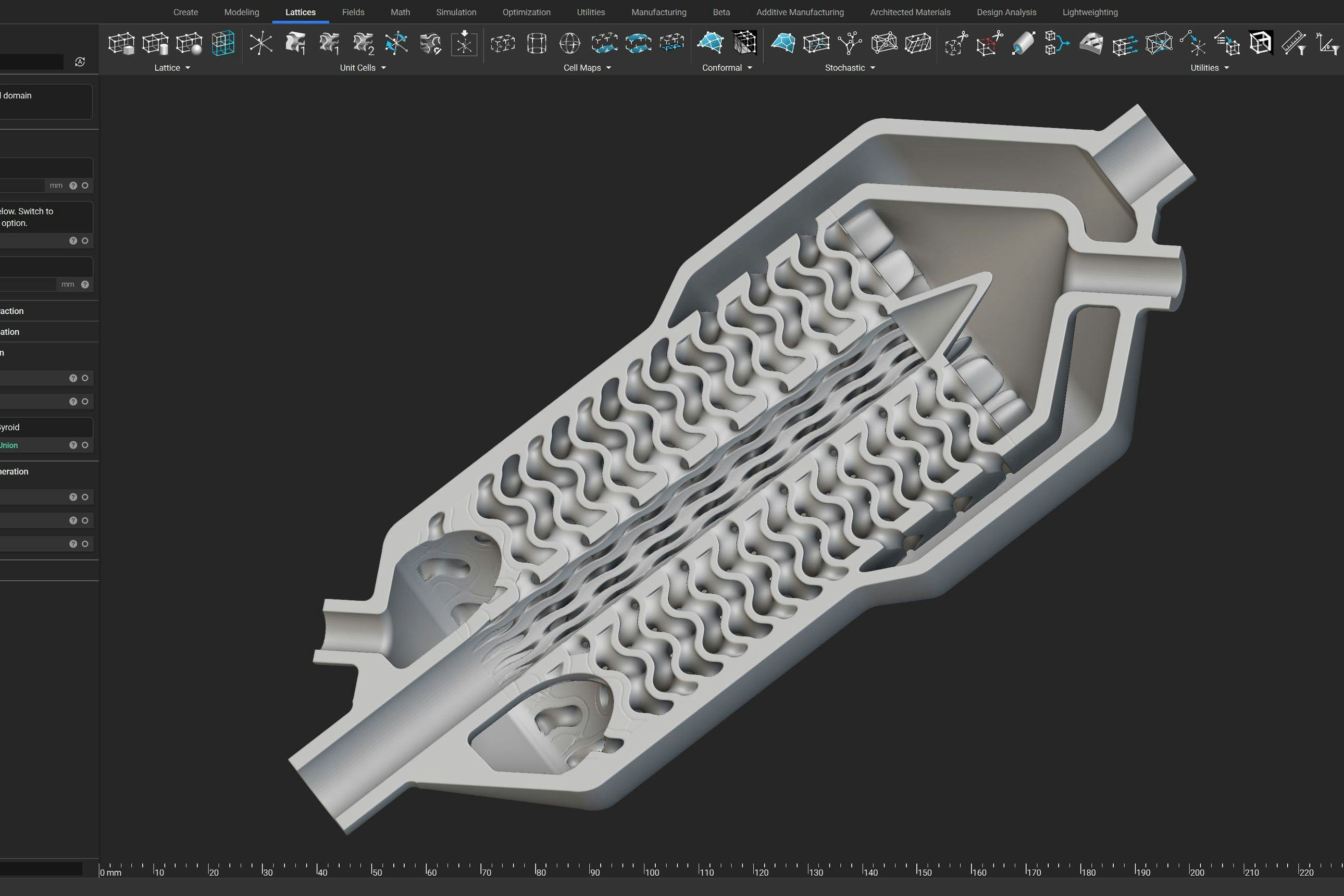

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop

- VIDEO

5 reasons why you should use nTop to create heat exchangers