nTop and ORNL collaborating to develop innovative toolkits

Written by nTop

Published on March 5, 2020

Along with ORNL we are going to develop a number of new toolkits with the intent of connecting design and additive manufacturing processes. We will ultimately make these toolkits available to all nTop users.

This week we announced a collaboration with Oak Ridge National Laboratory (ORNL) through a two year Cooperative Research and Development Agreement (CRADA) which covers two phases of development funded by the Department of Energy.

The goal of the collaboration is to capture ORNL’s experience and expertise in advanced manufacturing processes to create toolkits in nTop that will allow them to design and manufacture parts with unprecedented control and material properties. These toolkits will then be made available not only to ORNL and its partners but also to users of nTop.

The first phase will include the development of an nTop toolkit to optimize design and print parameters for the Big Area Additive Manufacturing (BAAM™) machine via direct connectivity to ORNL slicer to fabricate parts on the BAAM systems.

BAAM system. Image courtesy of Oak Ridge National Laboratory/US Department of Energy

Phase two will include the creation of a toolkit to use nTop’s capability to volumetrically engineer direct metal grain growth with an Arcam electron beam manufacturing (EBM) system.

Additionally we will develop an nTop toolkit to design simulation driven honeycomb infill for fused deposition modeling (FDM) type systems. And finally, we will collaborate on the optimization of support structures for direct metal laser sintering (DMLS) and EBM based on ORNL’s years of experience with multiple systems.

From my perspective, ORNL have been doing groundbreaking research and development in the advanced manufacturing space that has led the way for the broader industry. We are humbled to be able to assist them by providing software tools to help them advance their research even further, and make those very same tools available to nTop users.

Michael Borish, ORNL’s lead researcher, commented, “As a leader in advanced manufacturing, ORNL works with industry to help them bring new technologies, such as the nTop software toolkit, to the marketplace.”

We are both excited and eager to be working on this project together. To read more about this and see our press release check out this write up by 3dprint.com

Duann Scott (left), Philip Schiffrin (center) and Jonathan Harris (right) visiting ORNL to kick off the project.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

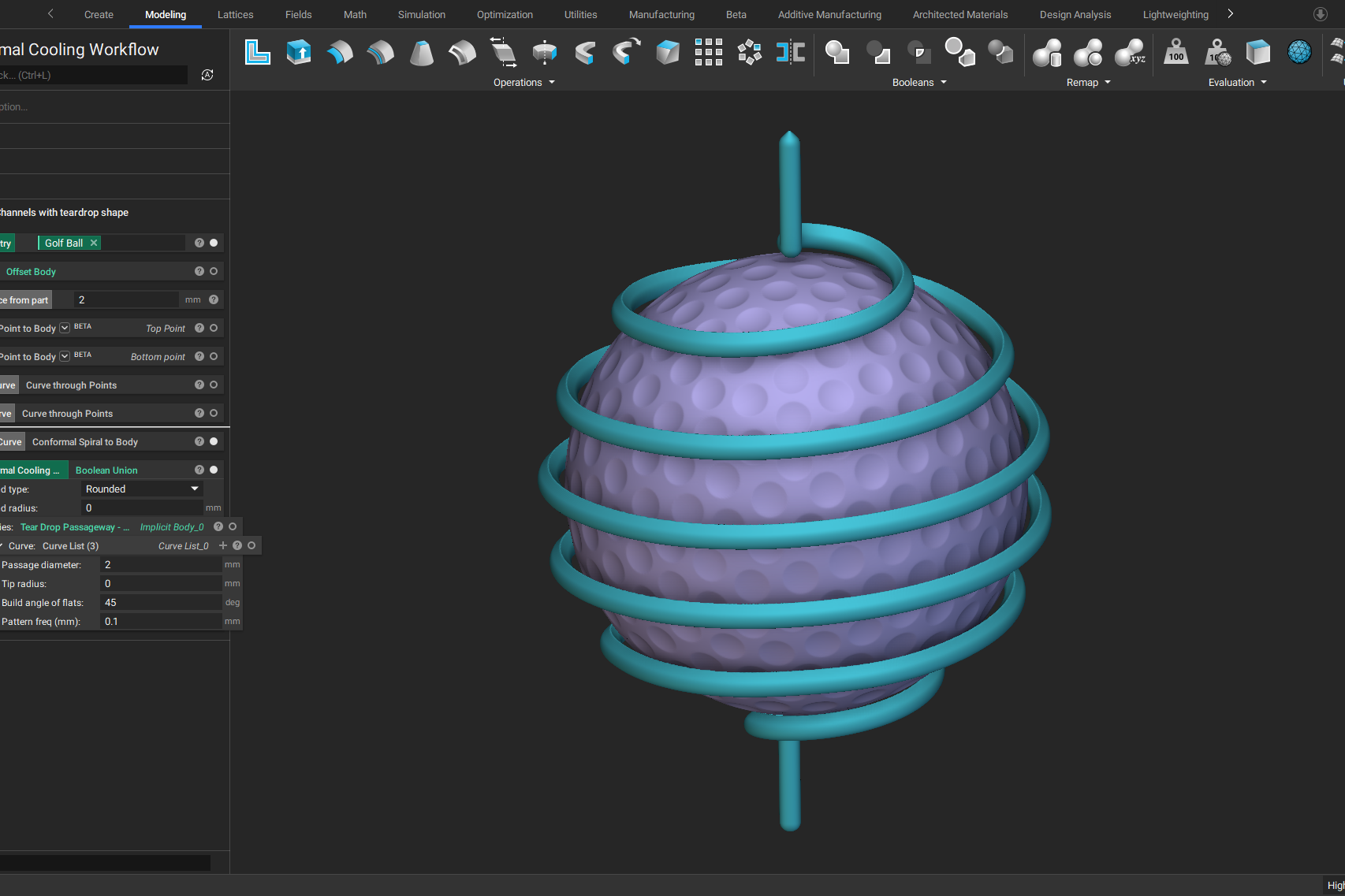

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

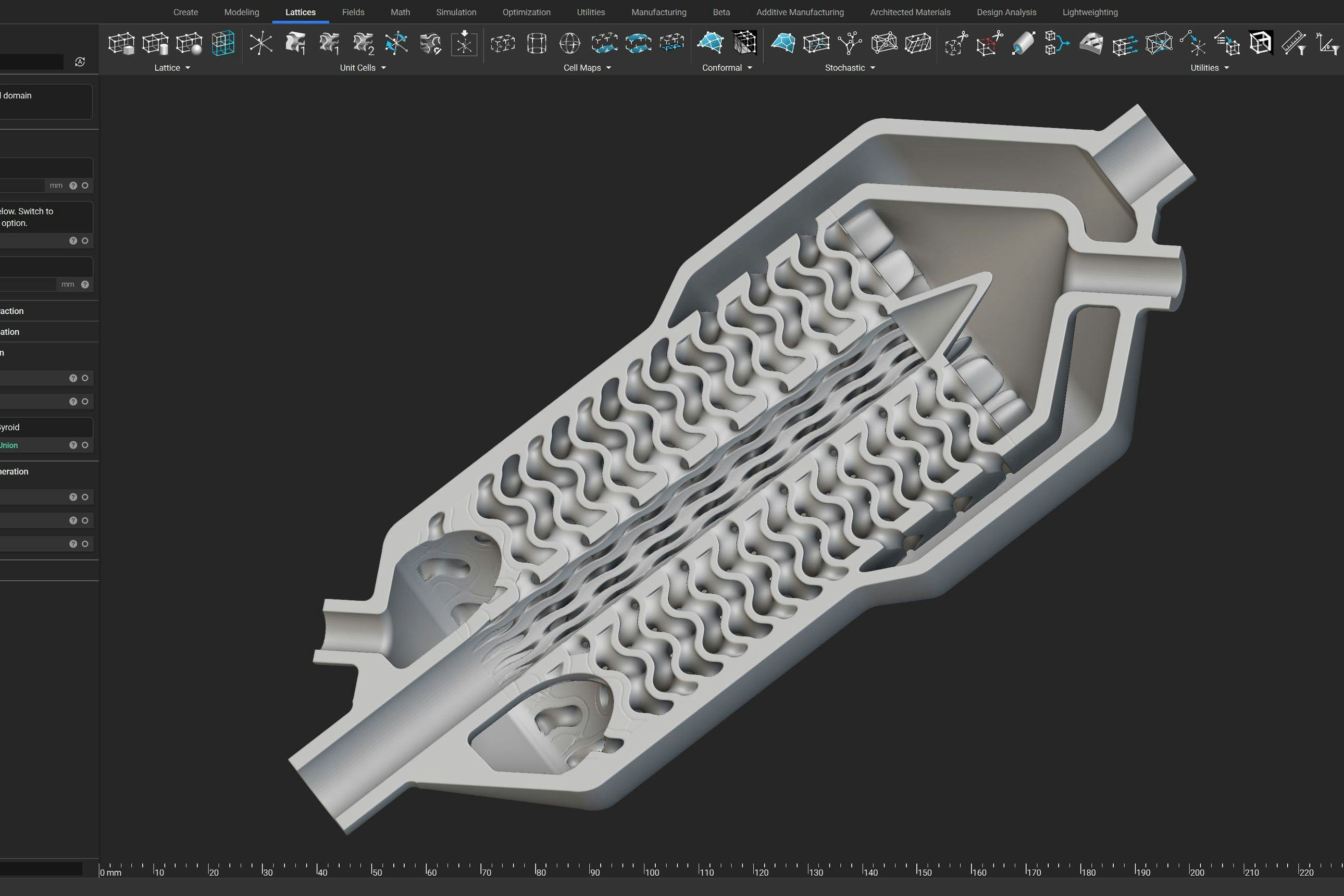

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop