The Danish Technological Institute and nTop collaborate to bring further innovation to the European market

Written by nTop

Published on February 5, 2021

At the end of 2020, the Danish Technological Institute (DTI) and nTop joined forces in a new collaboration about topology optimization. DTI is already a Danish market leader in Additive Manufacturing, but unlike many of the other players in the market, they also have extensive experience in design, construction, and consultancy.

With the possibilities offered by nTop, DTI will be able to combine their Additive Manufacturing experience and expertise with the capabilities of software-based design optimization to an even greater extent - and realize some truly unique designs that can only be made with Additive Manufacturing.

This is DTI's biggest metal printer – the SLM 500. It has four lasers, and everything (printing, vacuuming, and powder recycle) is handled in a closed environment. Image courtesy of DTI.

For instance, DTI specializes in significantly improving designs in terms of weight optimization and thermal properties, and the collaboration will boost these efforts, both for commercial assignments and state-of-the-art R&D projects. One example is the newly started Easy-E initiative, where thermal topology optimization is used for energy optimization of a variety of industrial products, thus aiding the green transition.

“The Danish Technological Institute is already a front runner in Additive Manufacturing, but with topology optimization, we’re able to take the technology to the next level and design products that are truly optimized for their purpose – and that can only be manufactured with AM. In this process, the nTop software is a valuable tool that helps us achieve the desired optimization in terms of e.g. weight, strength, and efficiency,” says Thomas Westersø, consultant at the Danish Technological Institute.

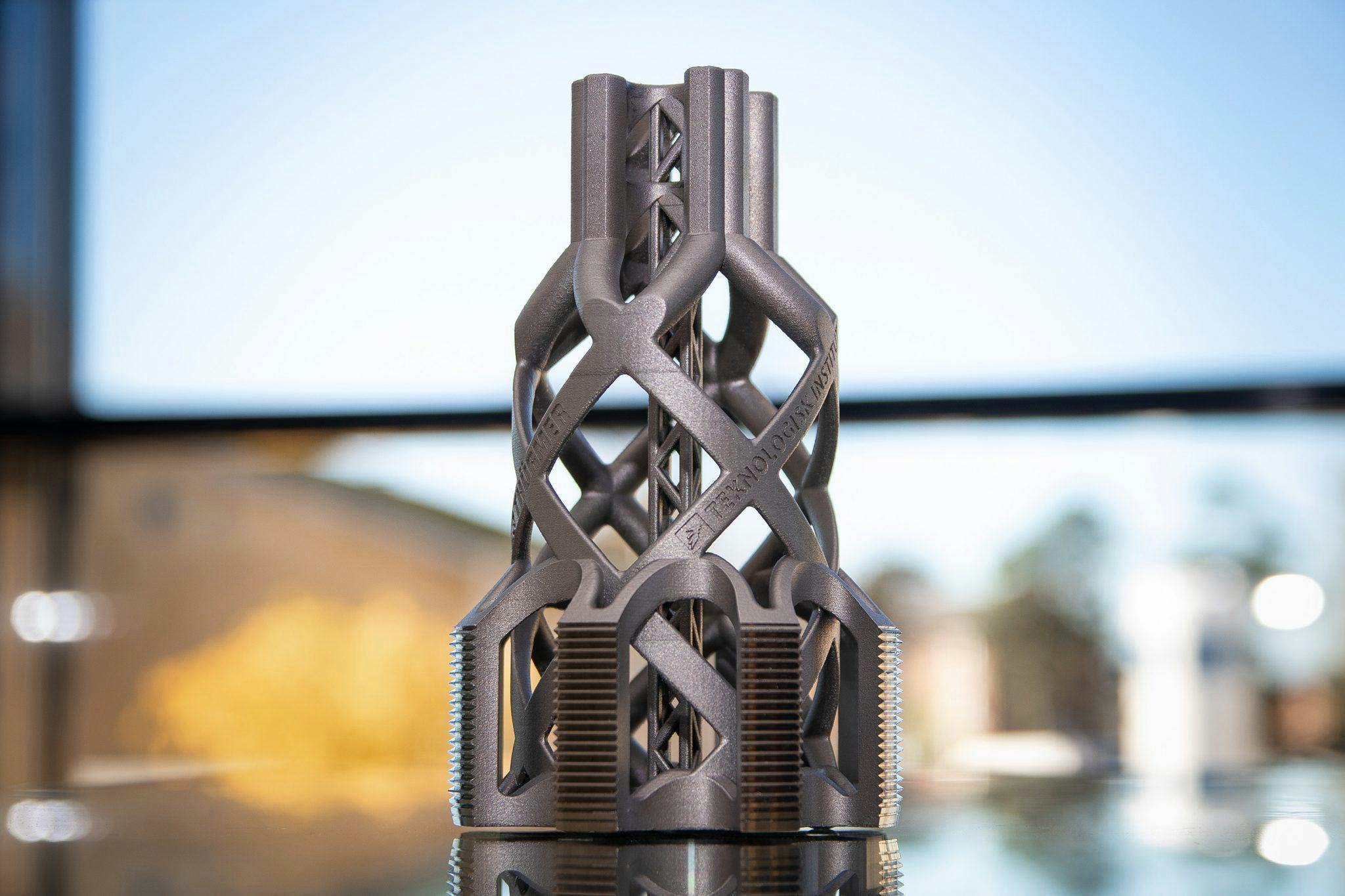

DTI demonstrated that a cutting tap for cutting threads could be topology optimized. This one is supposed to be used for offshore windmills, so weight is a critical factor when being helicoptered to the platform and carried to the top. Image courtesy of DTI.

Working with DTI will showcase the capabilities of nTop in an industrial Additive Manufacturing context, just as it will assist DTI’s clients in unleashing their full potential through computer-driven design optimization – thereby helping them to stay ahead of the curve.

Industrial 3D printing of titanium nozzles used for cookie dough extrusion – these are used for vanilla wreaths. Image courtesy of DTI.

Request a demo and see how nTop can help you stay ahead of the competition.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

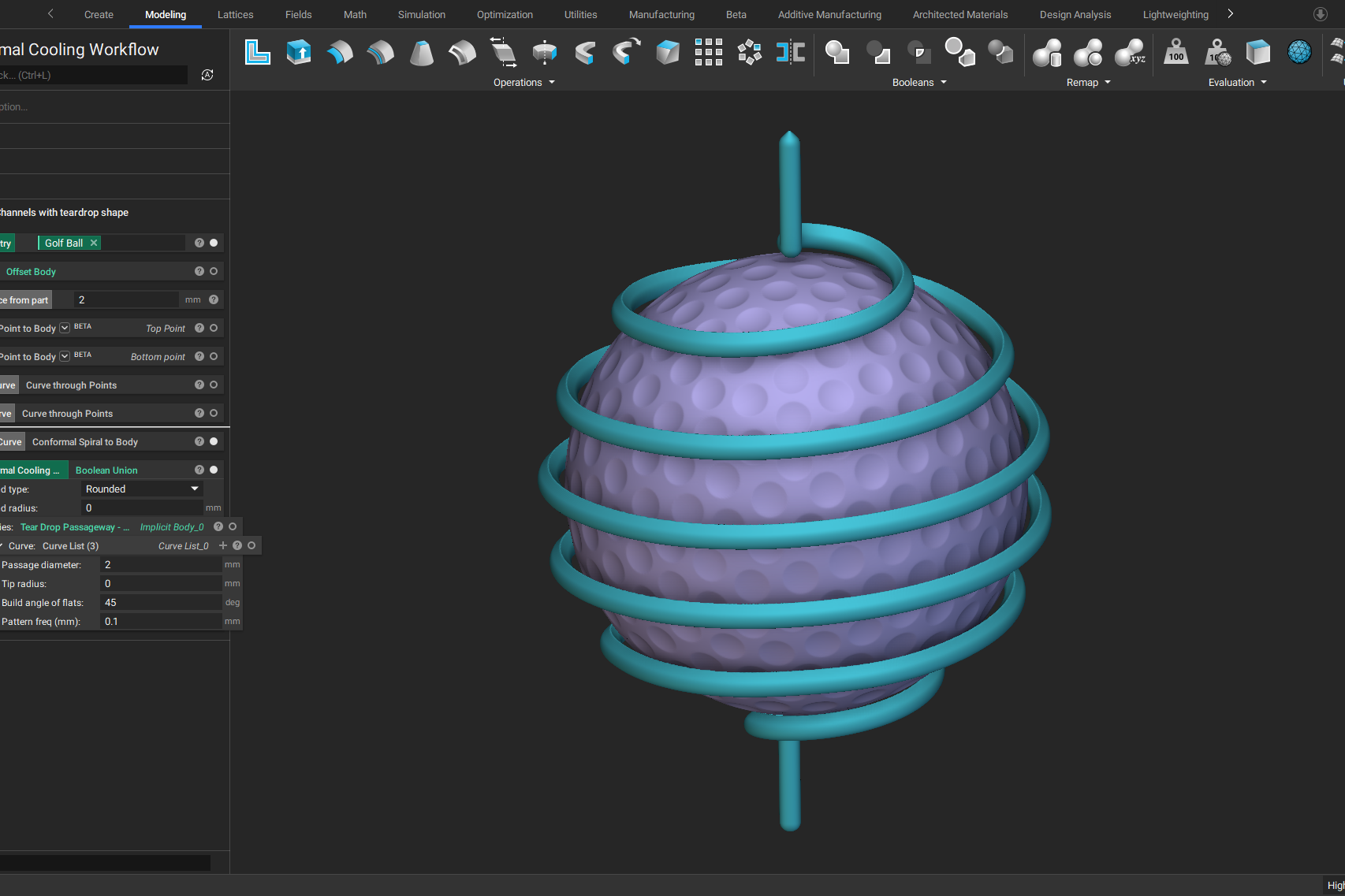

Optimizing thermal management with conformal cooling to extend operational life

- ARTICLE

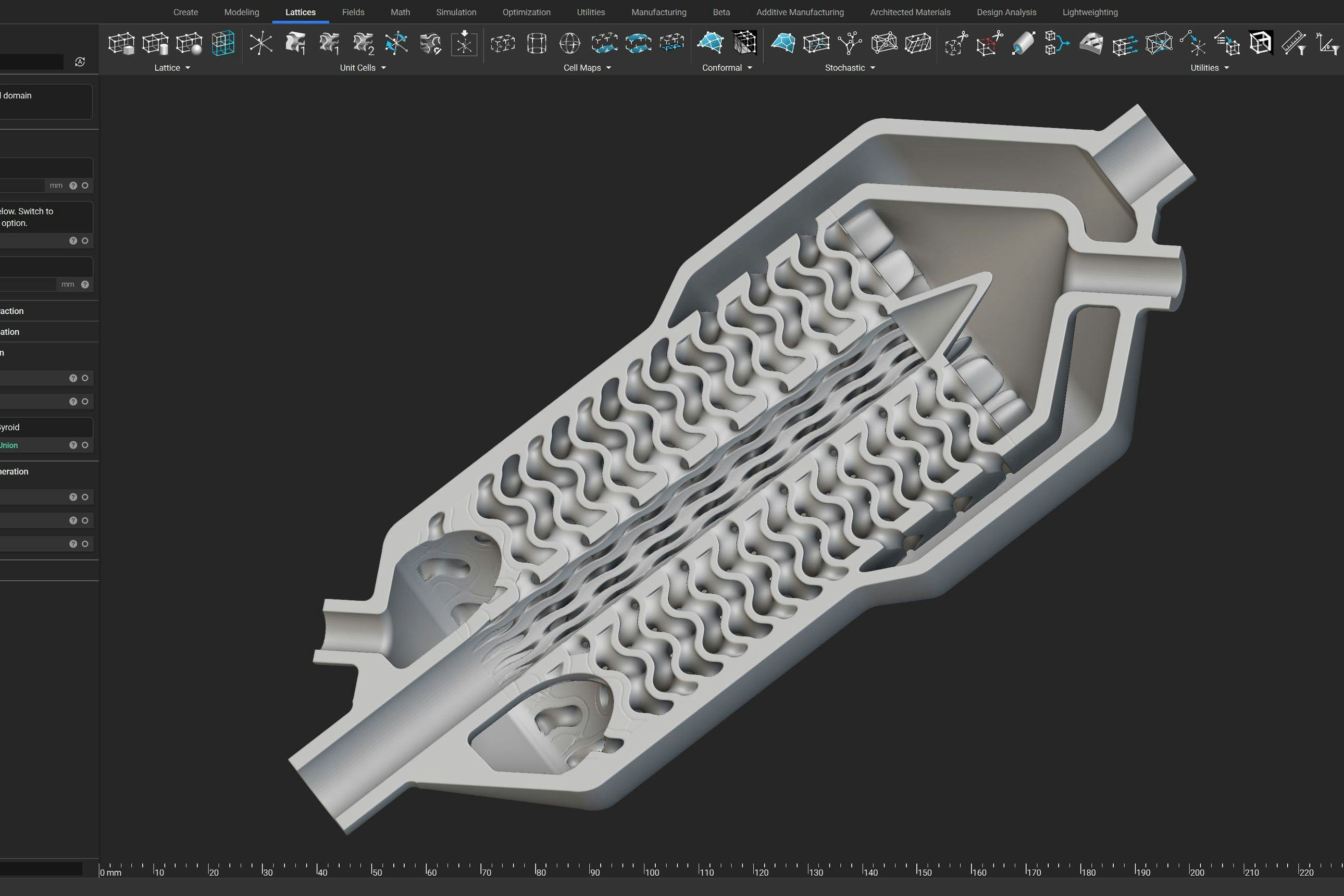

Advancing structural performance of aerospace heat exchangers

- VIDEO

Design a spooky Halloween candy bowl in nTop

- VIDEO

5 reasons why you should use nTop to create heat exchangers