Air Force designs a 50% lighter CubeSat bus assembly with nTop

Applications

Key Software Capabilities

- Lattice structures

- Integrations

Summary

The U.S. Air Force Institute of Technology (AFIT) used nTop to develop an additively manufactured CubeSat bus assembly. The resulting assembly is lighter, stiffer, and contains significantly fewer parts.

About: The Air Force Institute of Technology is the Department of the Air Force’s leader for advanced, multi-disciplinary academic education, as well as its institution for initial technical and professional continuing education.

- Industry: Aerospace and defense

- Size: 200+ employees

- Location: Wright Patterson AFB, Ohio, USA

- Product: 3D-printed CubeSat bus assembly

The project

Design a lighter bus with fewer points of failure

nTop enabled the engineering team to create lightweight and optimized parts with functional requirements built directly into the model.

CubeSats are small, relatively inexpensive satellites used for research and communications.

The structural bus forms the backbone of the satellite and provides the basic infrastructure necessary for the satellite to function. The physical modularity of the bus and payload system allows for a small satellite to be easily configured.

The challenge

Design a bus structure that meets goals and has a repeatable manufacturing process.

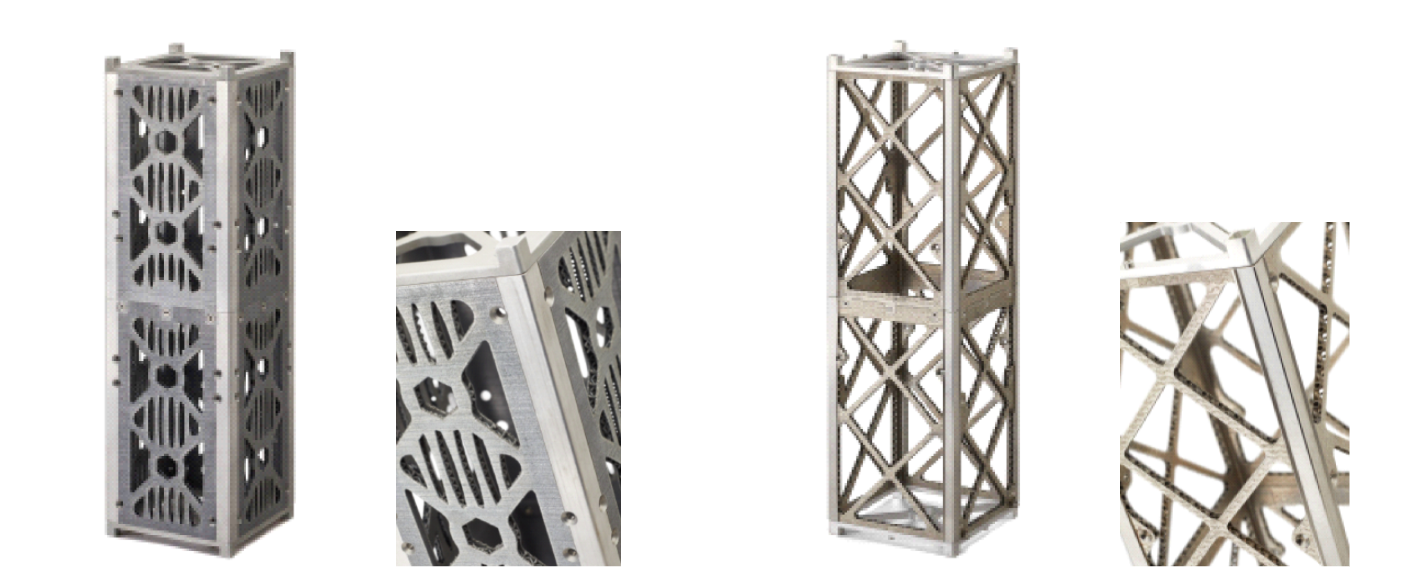

Close-up views of the legacy CubeSat bus design (left) and the redesigned chassis (right).

In the precision-driven field of space operations, the ability to rapidly respond to constant, progressive advancements is essential to meet the demands of evolving technologies. Space satellites require materials with superior stiffness to weight ratios to provide structural integrity while minimizing mass.

Manufacturing the bus with traditional machining processes is time-consuming. The assembly includes nearly 150 parts, creating 150 potential failure points and upping the cost of quality control.

The solution

Design a lighter, stiffer structure with nTop

The team developed a new design based on sandwich structures with 50% reduced weight, and 20% increased stiffness. The new bus assembly weighs 555 grams less than the legacy design, which corresponds to approximately $8,000 to $10,000 in launch cost savings. The engineers of AFIT successfully achieved all program goals, reducing the parts count to only 25, slashing production time.

The results

50%

Assembly weight reduction

20%

Greater stiffness

33%

Faster production

6x

Fewer parts

Why nTop?

nTop’s lightweighting and vibration capabilities enabled AFIT to achieve previously unattainable material properties and design structures with a lighter weight and a targeted physical response. Implicit modeling provided the necessary control to develop these advanced structures. Finally, direct-to-manufacture capabilities helped the team save valuable time.

Lightweighting

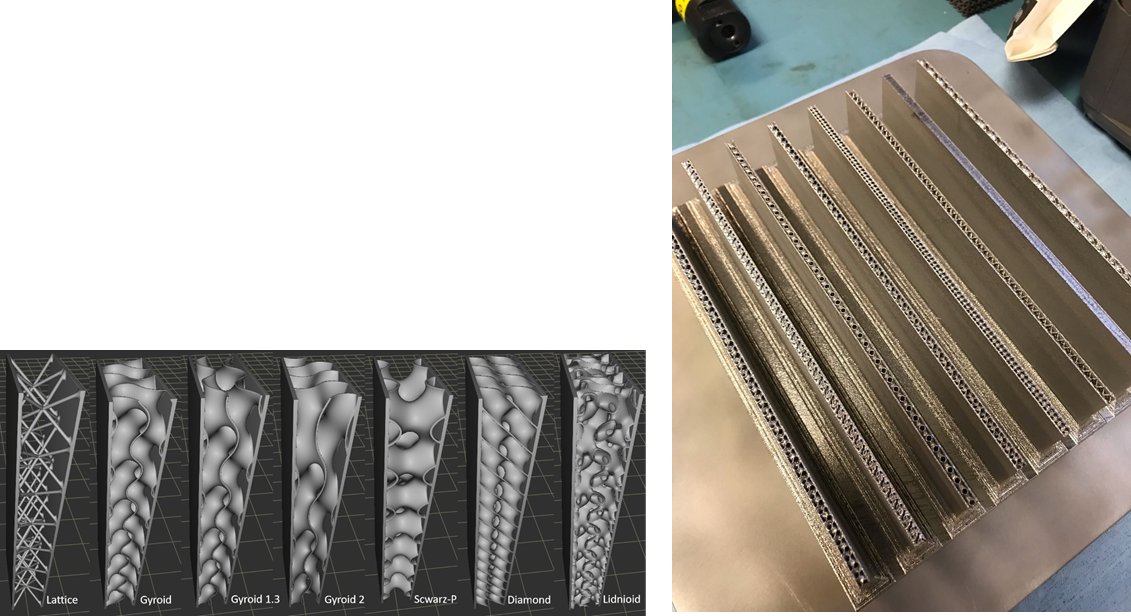

The AFIT R&D team explored multiple thin-walled TMPS and strut-based lattice structures and assessed their performance using engineering simulation software, ultimately identifying a design based on Inconel 718.

The final structure uses a shell and gyroid infill with a wall thickness of 250 microns. The result was a chassis with half the weight of a similar aluminum alloy design with a 20% increase in stiffness.

Internal lattice and gyroid design options generated in nTop software and 3D-printed samples of options printed on Concept Laser M2.

Direct from design to manufacturing

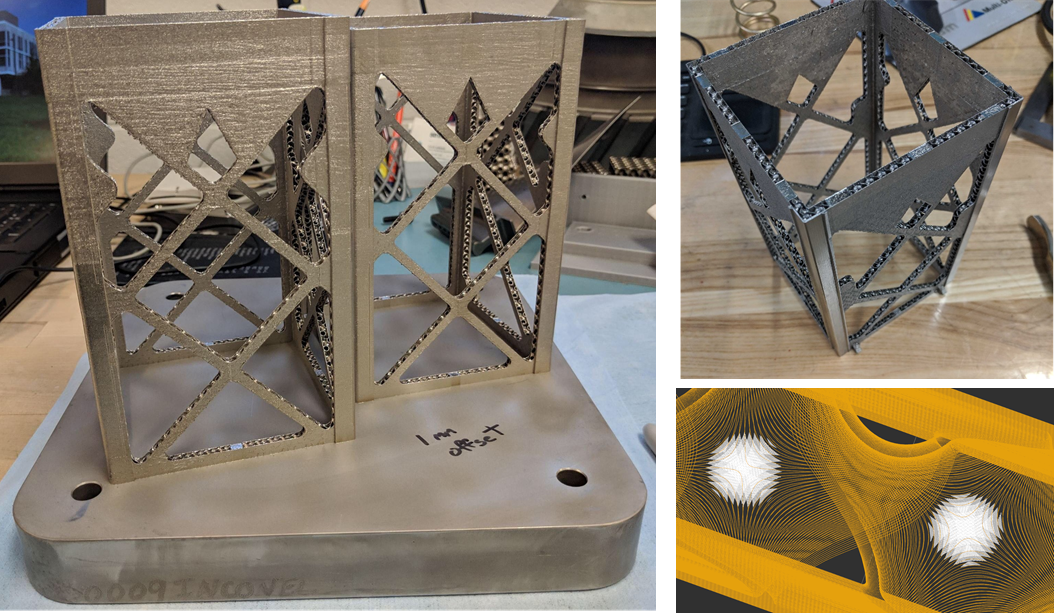

Using nTop’s direct-to-manufacture capabilities, the team bypassed the need to generate STL files. Instead, they created slices and tool paths directly in the design software, achieving a high level of control.

A 3D-printed and finished CubeSat was ready for testing in 3.5 business days. The bus was then evaluated and certified, meeting the requirements for launch.

Additively manufactured CubeSat bus sections. The gyroid design inside the extremely thin walls provided stiffness and durability.

Conclusion

With a short delivery time, it’s now possible to produce a CubeSat structural bus that aerospace engineers can easily reconfigure based on changing satellite mission requirements. Coupling modularity with increased stiffness and lower weight, this rapid manufacturing capability represents a revolutionary step forward for the satellite design community.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

Lightweighting an impeller for additive manufacturing

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

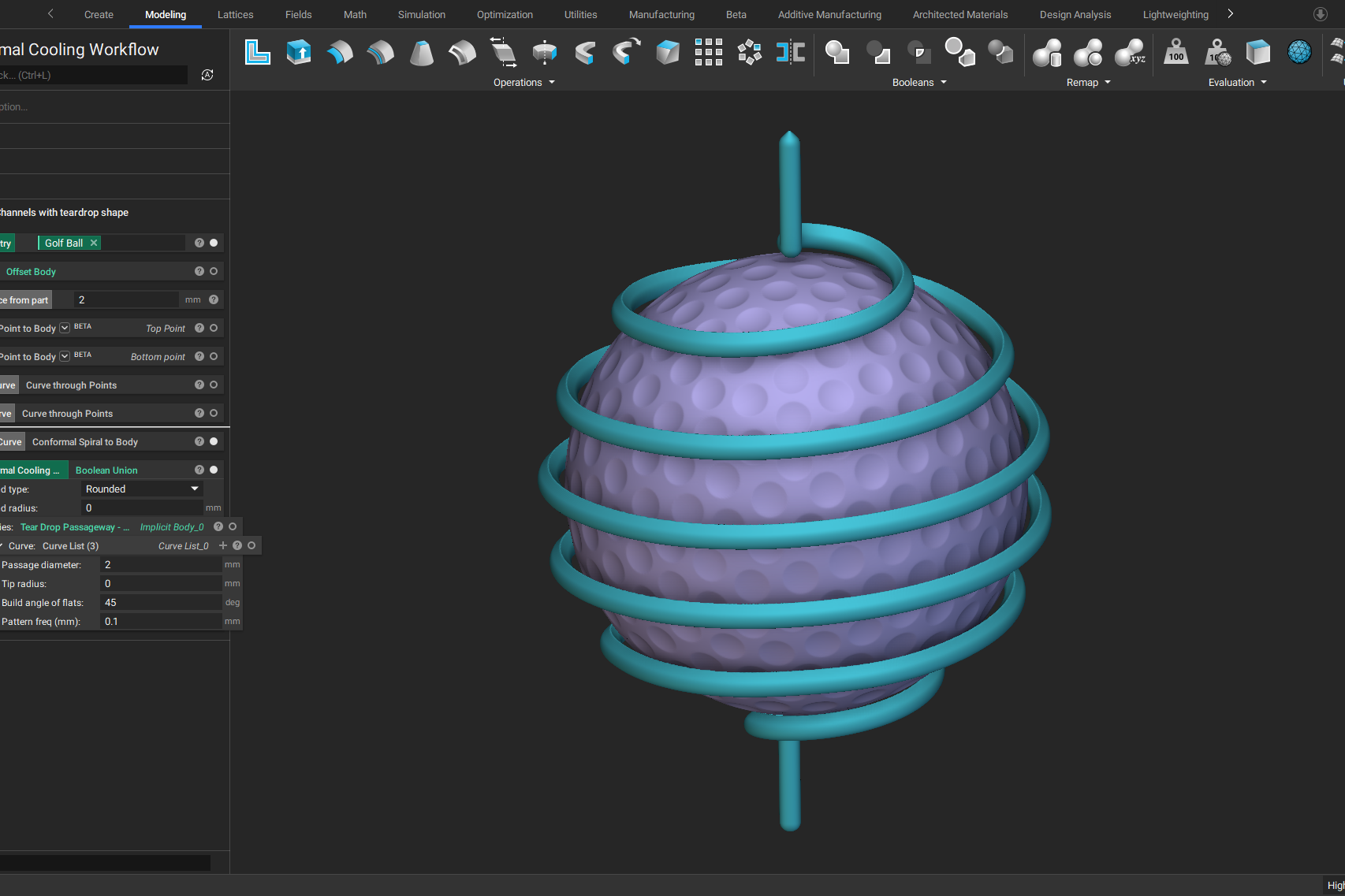

Optimizing thermal management with conformal cooling to extend operational life