Improve climbing harness designs with 3D printing

Video: Improve climbing harness designs with 3D printing

Published on July 14, 2022

Applications

Key Software Capabilities

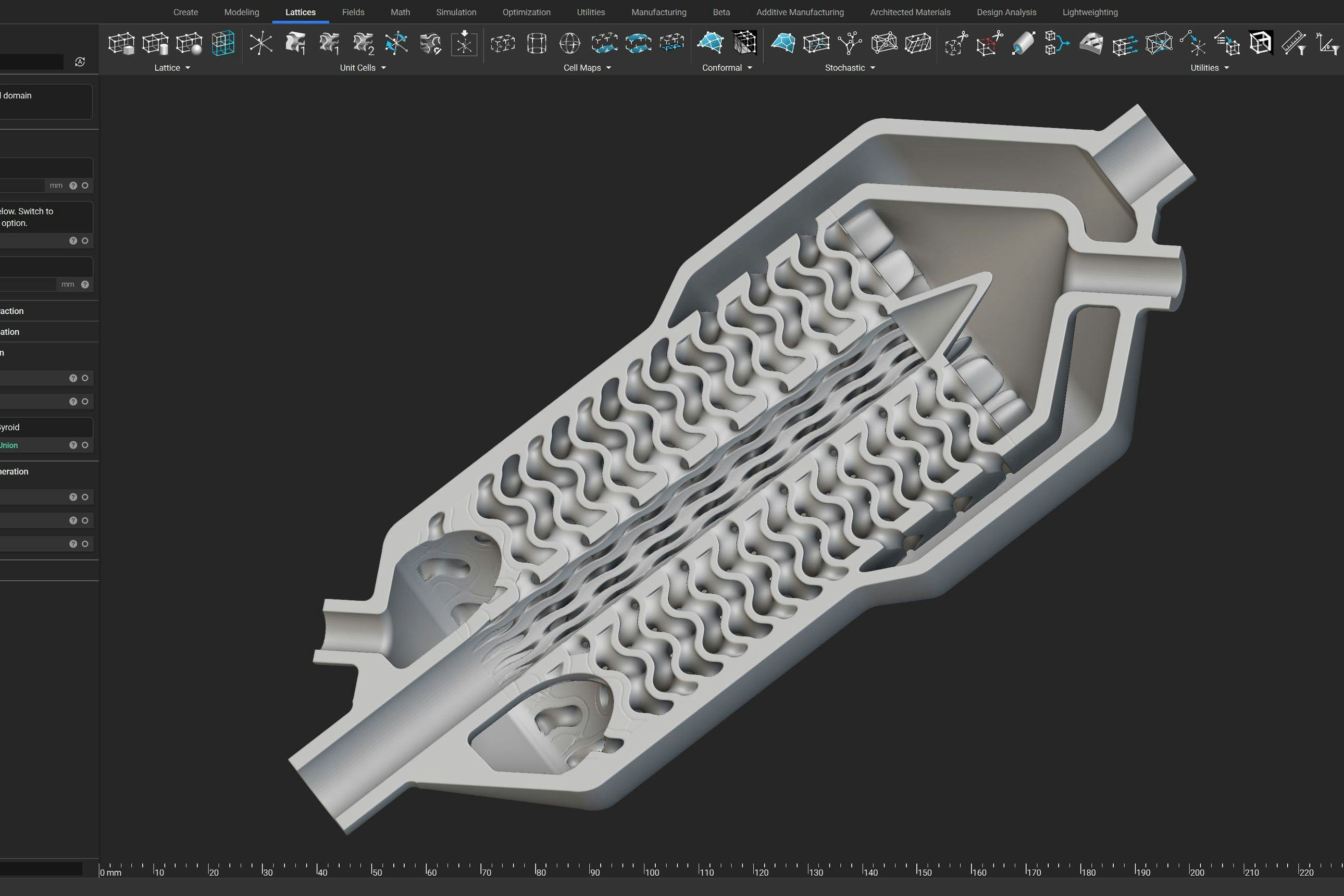

- Lattice structures

3D printed foam replacements are far more controllable and predictable than traditional foams. You can control their stiffness and design them in any shape without the need for tooling. They can be used to manufacture more comfortable, safer, and lighter products that can be individually customized.

In this nTop Live, Guenael Morvan, Application Engineer at nTop, shows you how to create lattices on a climbing harness and prepare them for manufacturing on a resin-based 3D printer.

He shows you how to create a lattice foam and select the right unit cell size to increase user comfort. Finally, he walks you through the steps you need to follow to generate support structures for 3D printing automatically.

Watch and learn how to:

- Create lattices on a climbing harness and choose unit cells following DfAM rules

- Create conformal Voronoi lattices with controlled stiffness

- Mesh and create support material for export to a 3D printer slicer

Download the files

Recreate the steps that Guenael followed in this nTop Live. To download all the necessary files for this training, click here.