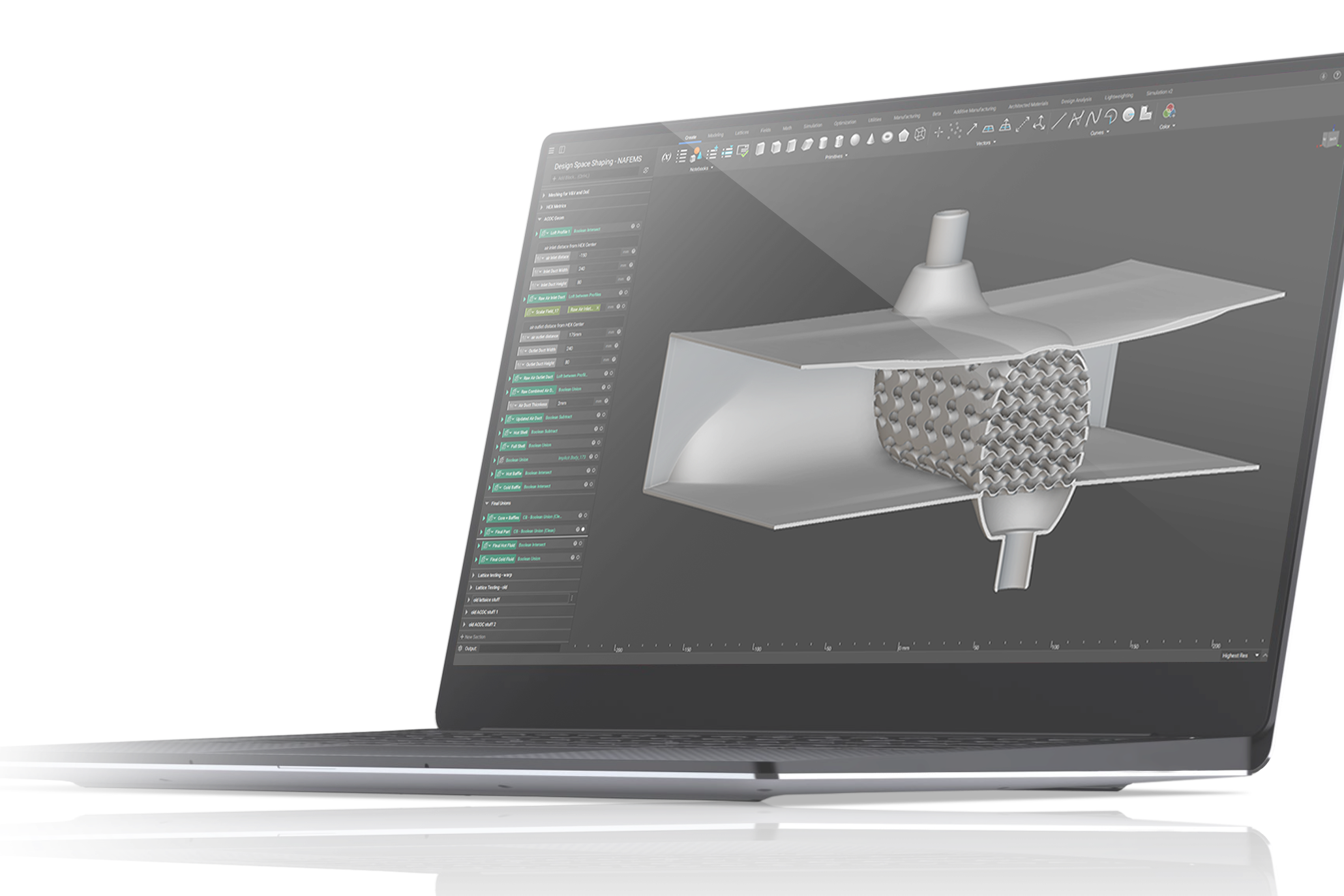

Metal DfAM eSeries: Leveraging design freedom to disrupt power generation

video: Metal DfAM eSeries: Leveraging design freedom to disrupt power generation

Published on August 18, 2020

Roger Smith, Sierra Turbines; Will Hasting, VELO3D; Ryan O'Hara, nTop

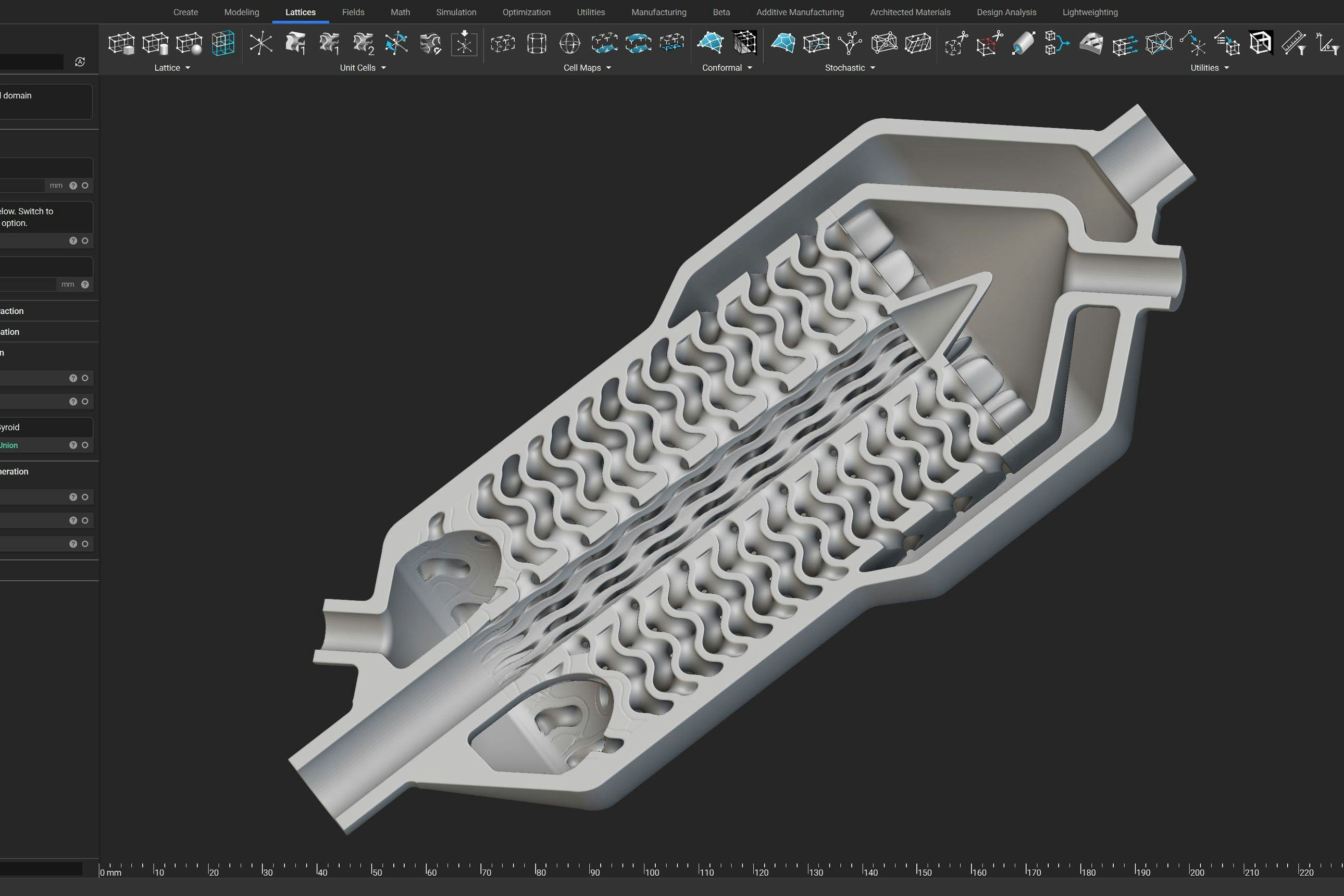

Sierra Turbines recently partnered with VELO3D to print a prototype for their 20-kilowatt microturbine engine with a unicore in Hastelloy X. They aim to print 95 percent of their engine through metal additive manufacturing, taking advantage of the design freedom possible through VELO3D’s support-less printing process.

Key takeaways:

- Why Sierra Turbines has selected metal AM as a manufacturing process for their aerial system application

- How nTop and VELO3D enable customers to push the possibilities to produce a higher-performing gas microturbine

- Discuss why DfAM should be an enabler for metal AM and not a requirement

Related content

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

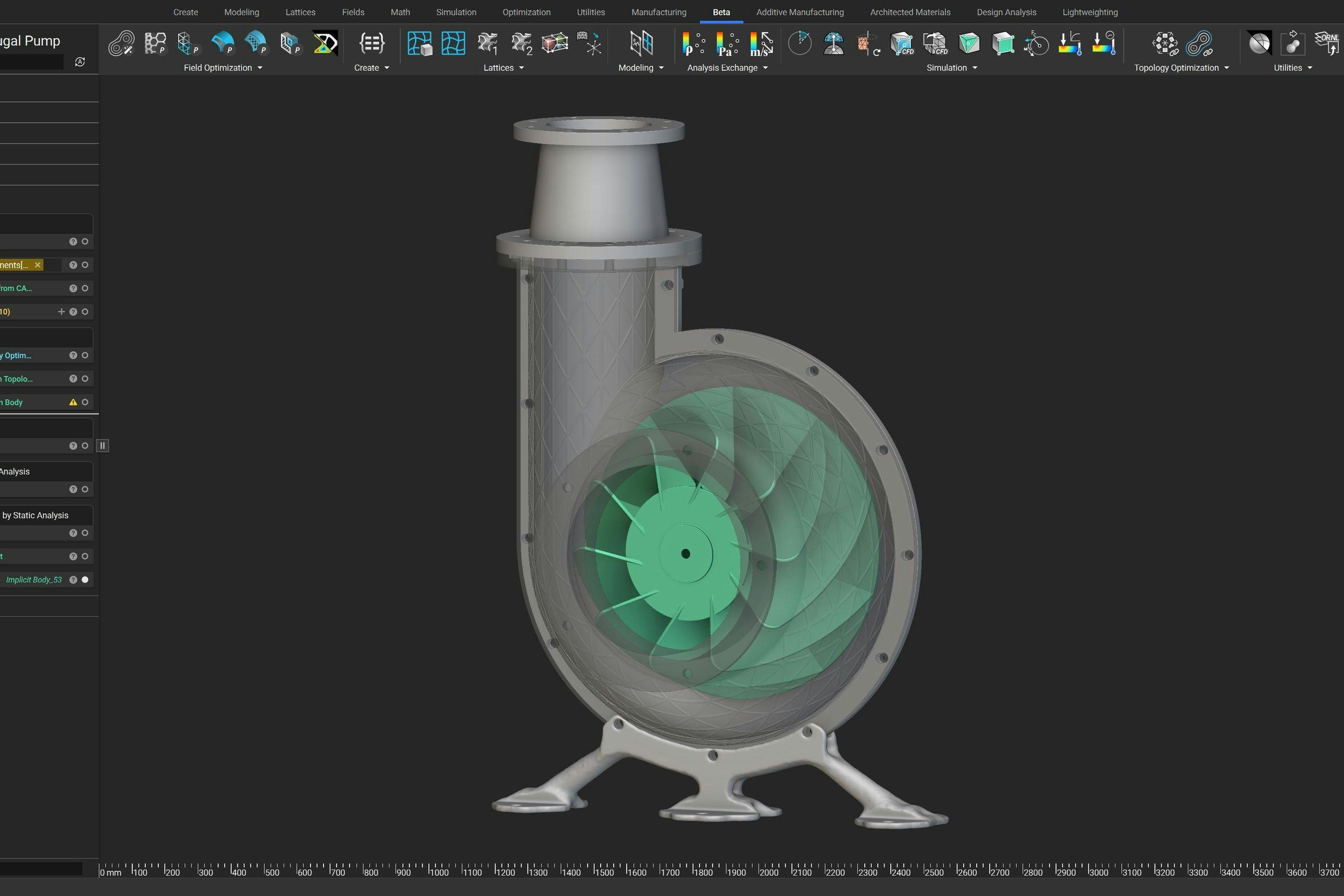

Lightweighting an impeller for additive manufacturing

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- ARTICLE

Flow management innovations: reducing pressure drop and energy

- ARTICLE

Efficient thermal and fluid management strategies for aerospace heat exchangers