Lightweighting 3D printed injection mold tools

video: Lightweighting 3D printed injection mold tools

Published on January 12, 2022

Applications

Key Software Capabilities

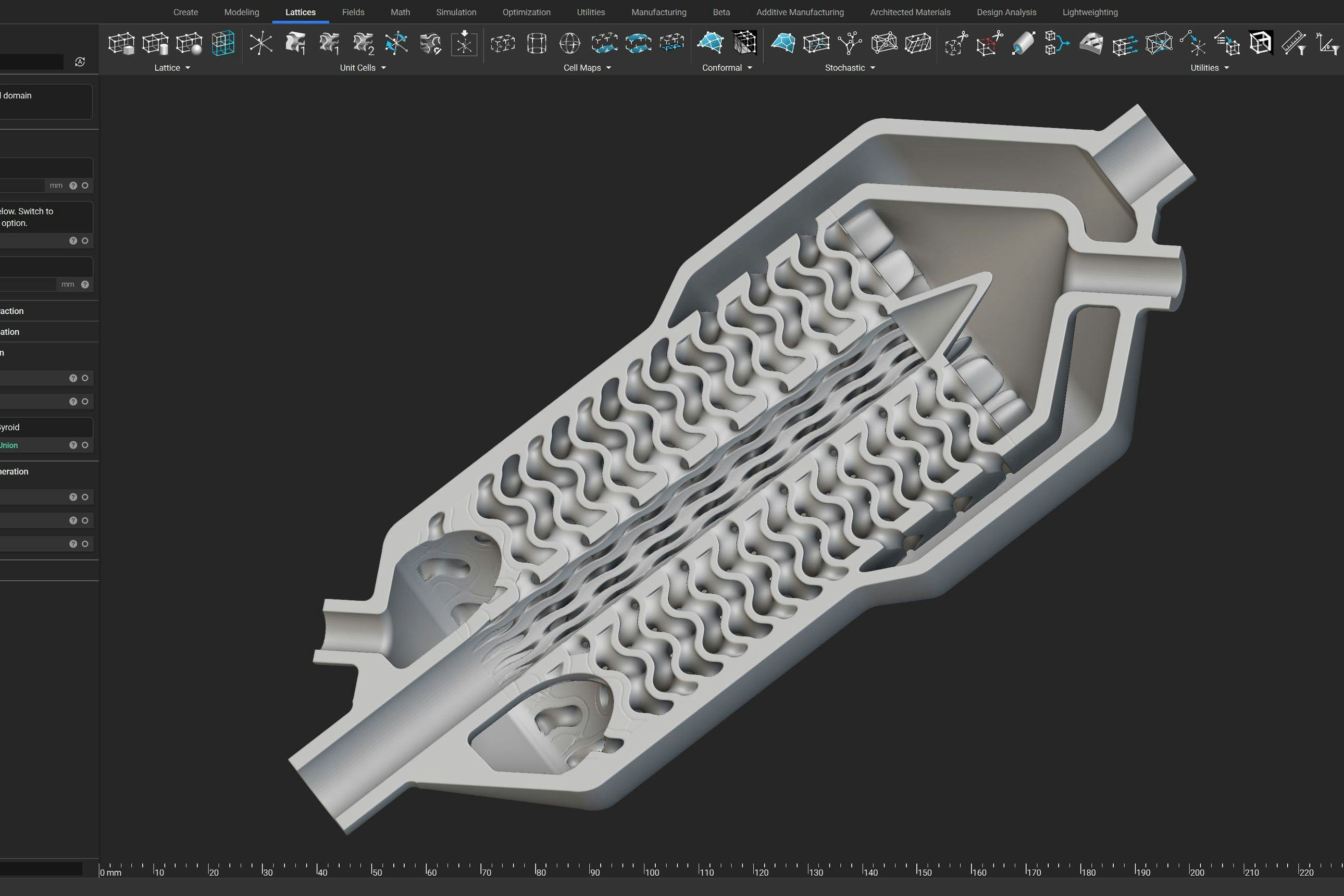

- Lattice structures

Reduce cost and manufacturing time

3D printed molds and tooling are becoming more and more common on the factory floor. However, material strength and best practices on mold design can be elusive concepts for many manufacturers.

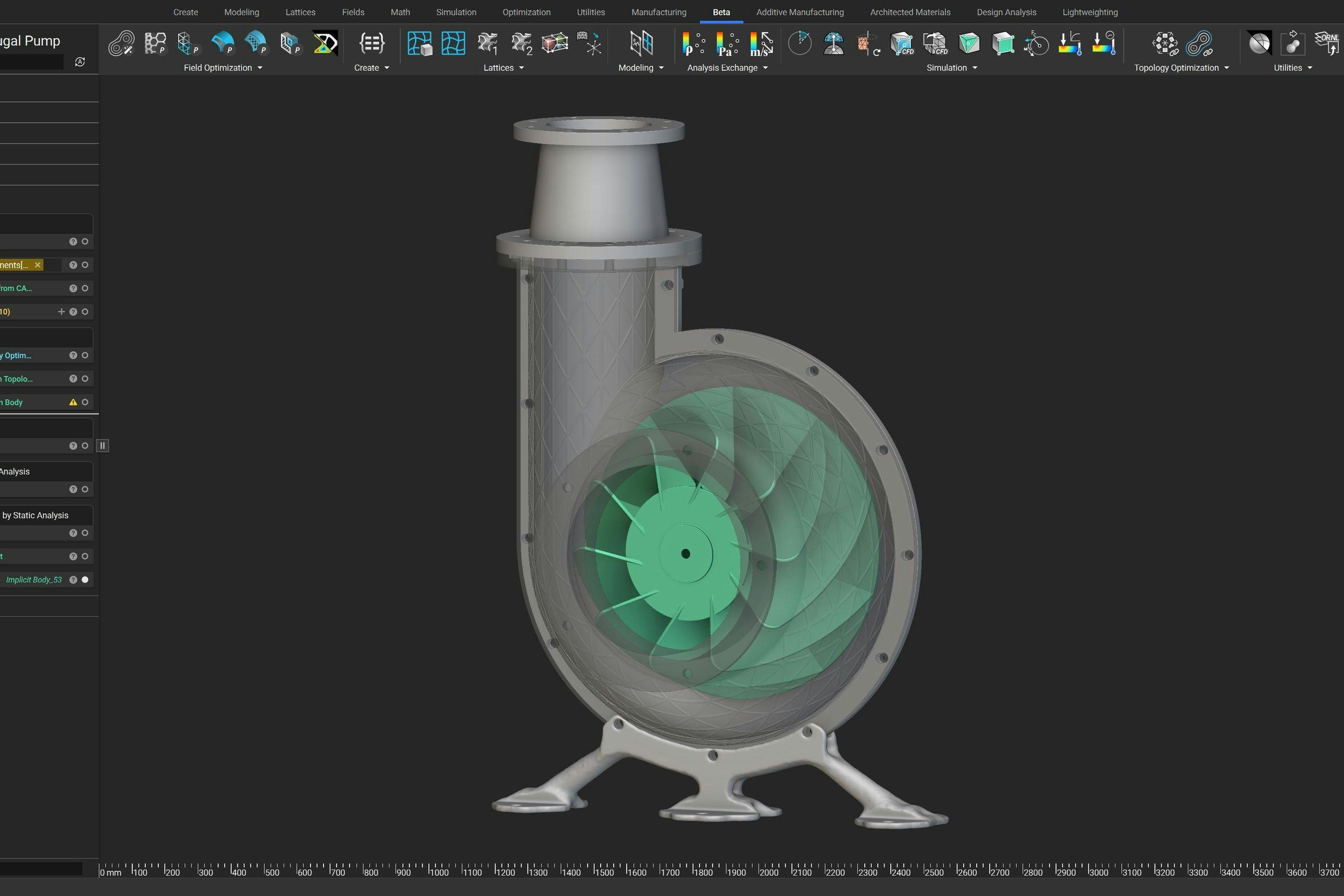

In this webinar, the engineers of nTop and Fortify 3D present a workflow to generate lightweight 3D printed molds. As a proof-of-concept, the design was manufactured using Fortify's composite resin system and tested under real-life conditions.

After the optimization in nTop, the result was a 22% faster 3D print time, 30% reduction in material cost, a 33% increase in throughput.

Watch this webinar recording and learn how to:

- Design strong and accurate 3D printing molds & tooling

- Optimize to reduce its weight, print time, and manufacturing cost

- Speed up new product development & achieve a competitive advantage with 3D printed tooling