nTop Toolkit

Additive manufacturing

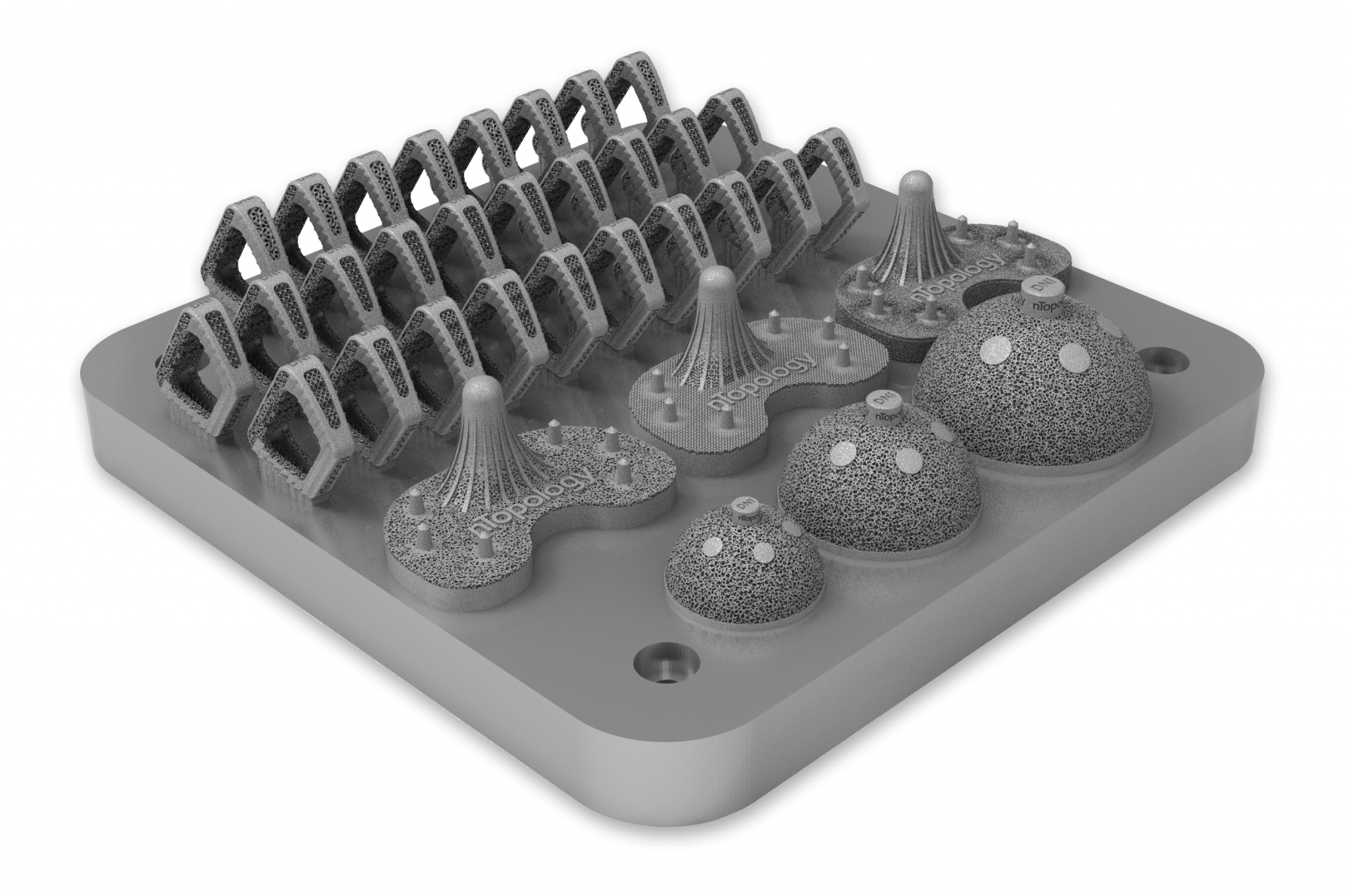

Use our Additive Manufacturing Toolkit to generate geometric data that can connect to your tools and additive manufacturing processes.

From design to machine

Direct connectivity to the most popular industrial additive manufacturing systems on the market ensures accurate communication of design intent to production quickly and efficiently saving time and costly errors in data translation. nTop is working with all major manufacturing partners to provide an even deeper connection to enable more than just geometry to be communicated in the manufacturing process.

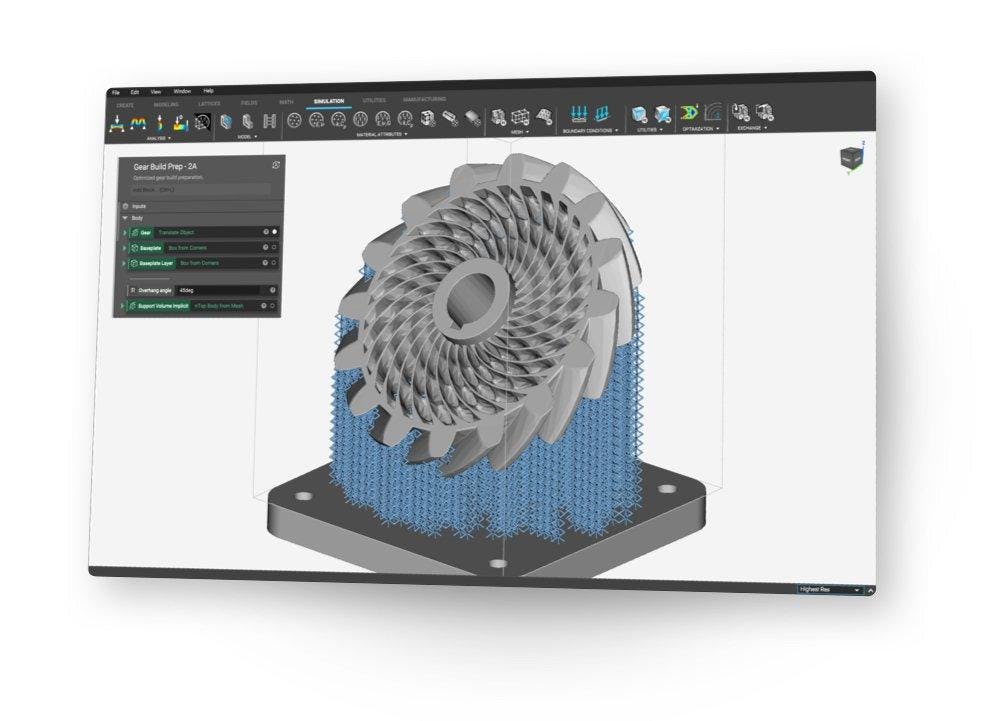

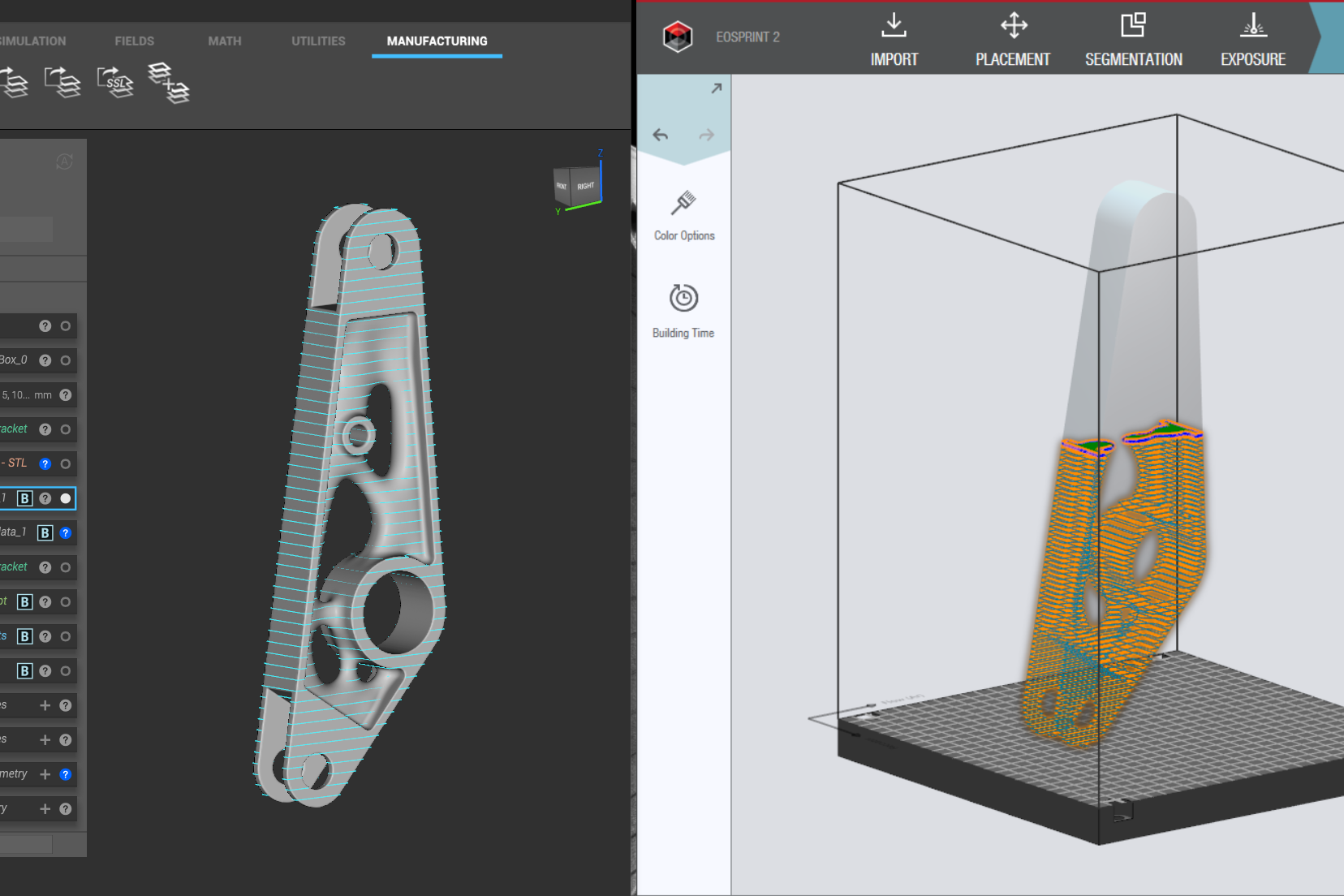

Build prep

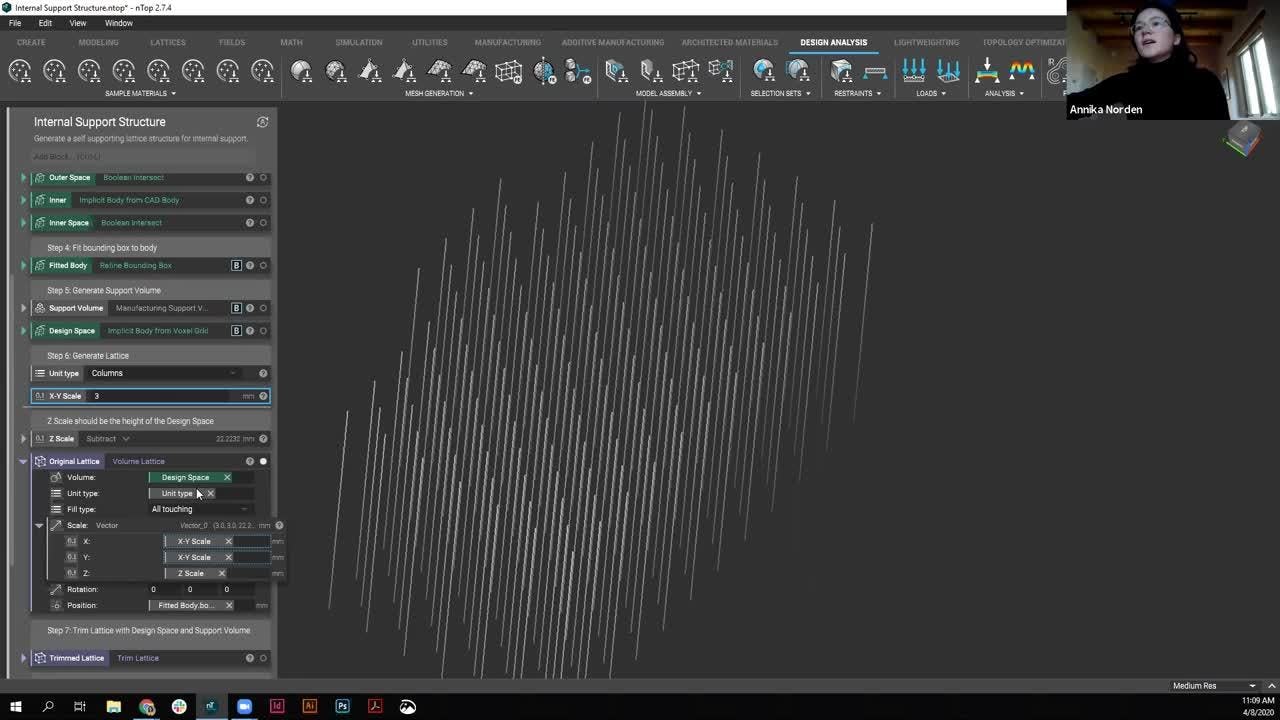

Position, orient, and support parts with a large library of lattice structures for every additive manufacturing process.

Use automated supports, or design your own reusable support structure strategies which can be automated or manually controlled.

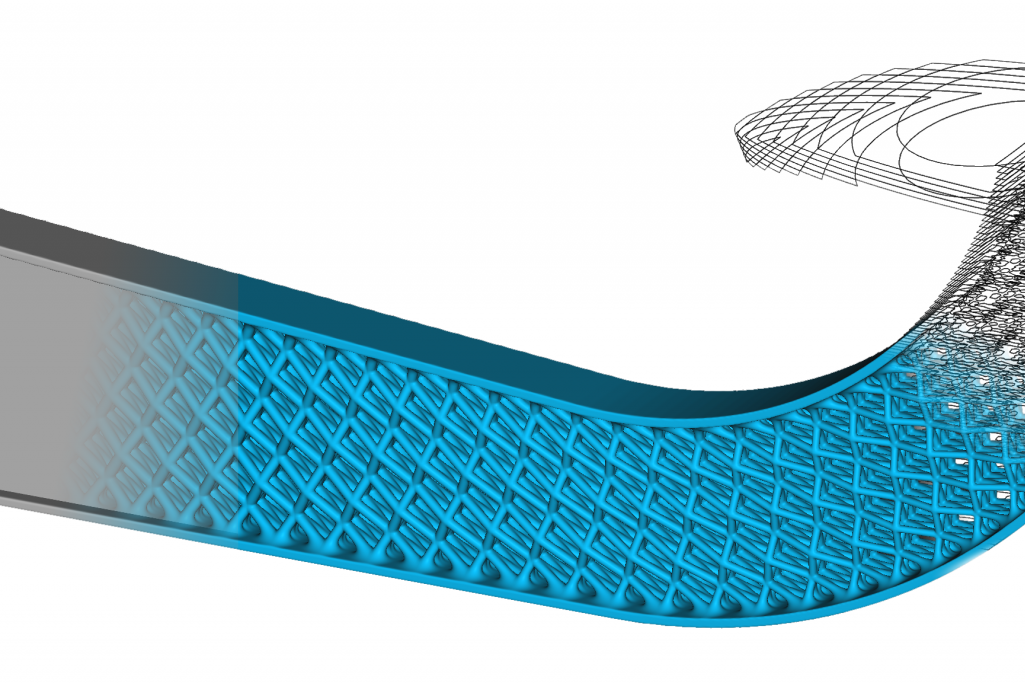

Slicing

Full control over slicing, offsets, hatching, and points allow for the programming of multiple build strategies for a single part or build.

Ready to accelerate your engineering process?

Get in touch with nTop Engineering and get started today.

Related resources

- ARTICLE

Advanced design tools for additively manufactured medical devices

- ARTICLE

Eliminate STL files from your additive manufacturing process with nTop + EOS

- ARTICLE

NFL Helmet Challenge: Making the players safer with advanced technologies

- VIDEO

Custom support structures for additive manufacturing

- PRODUCT UPDATE

nTop for additive manufacturing