Innovate. Iterate. Create.

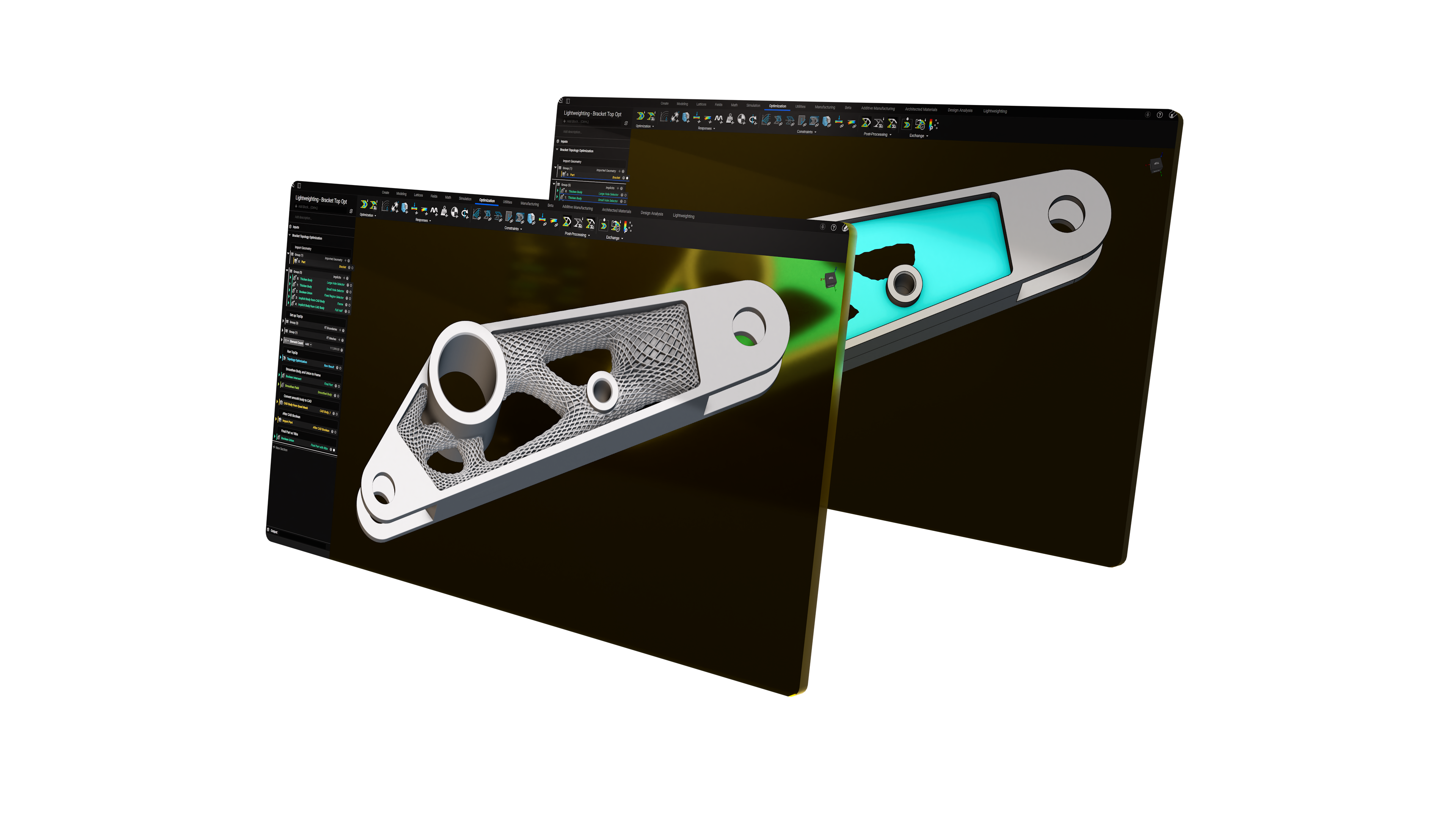

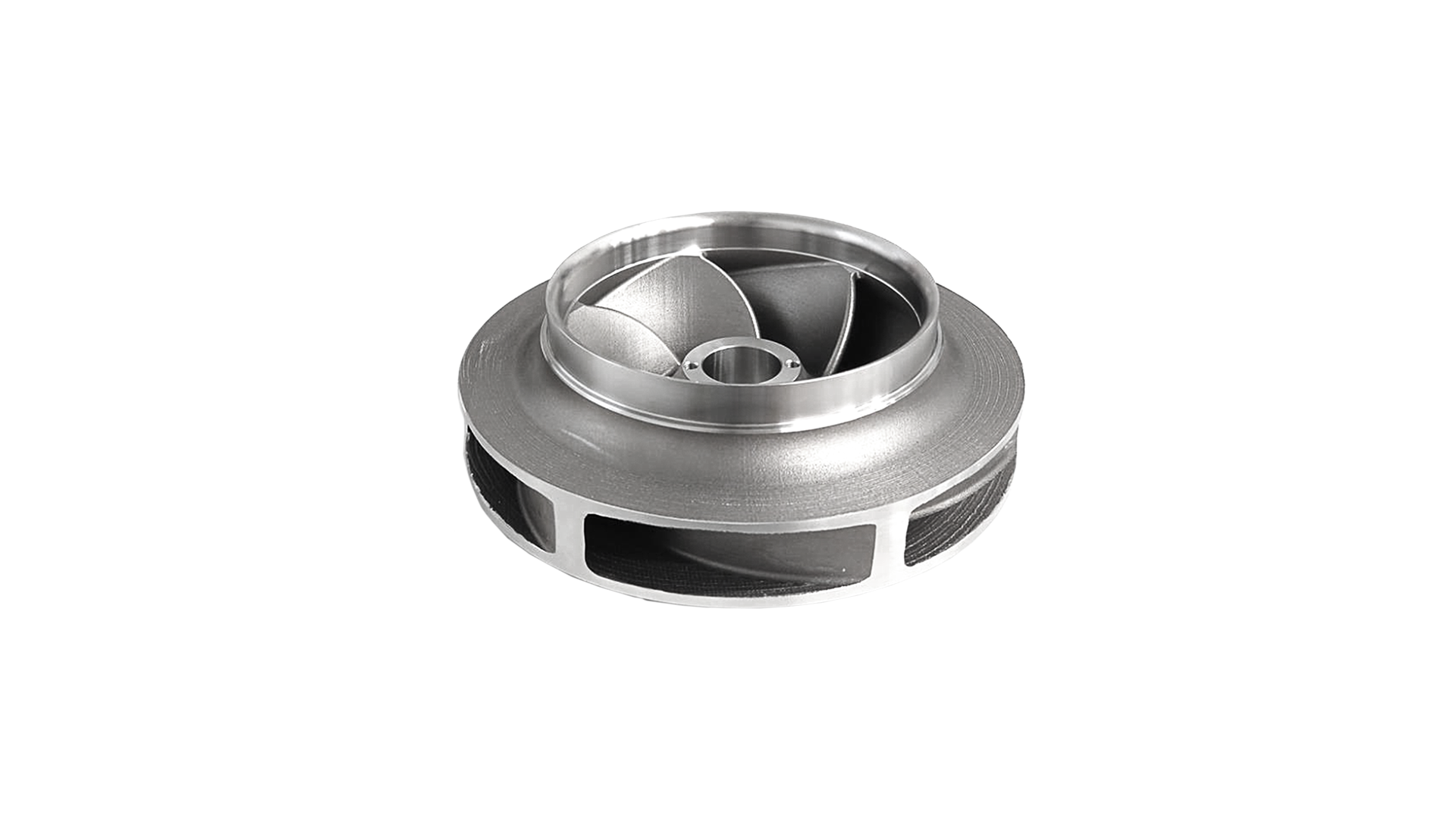

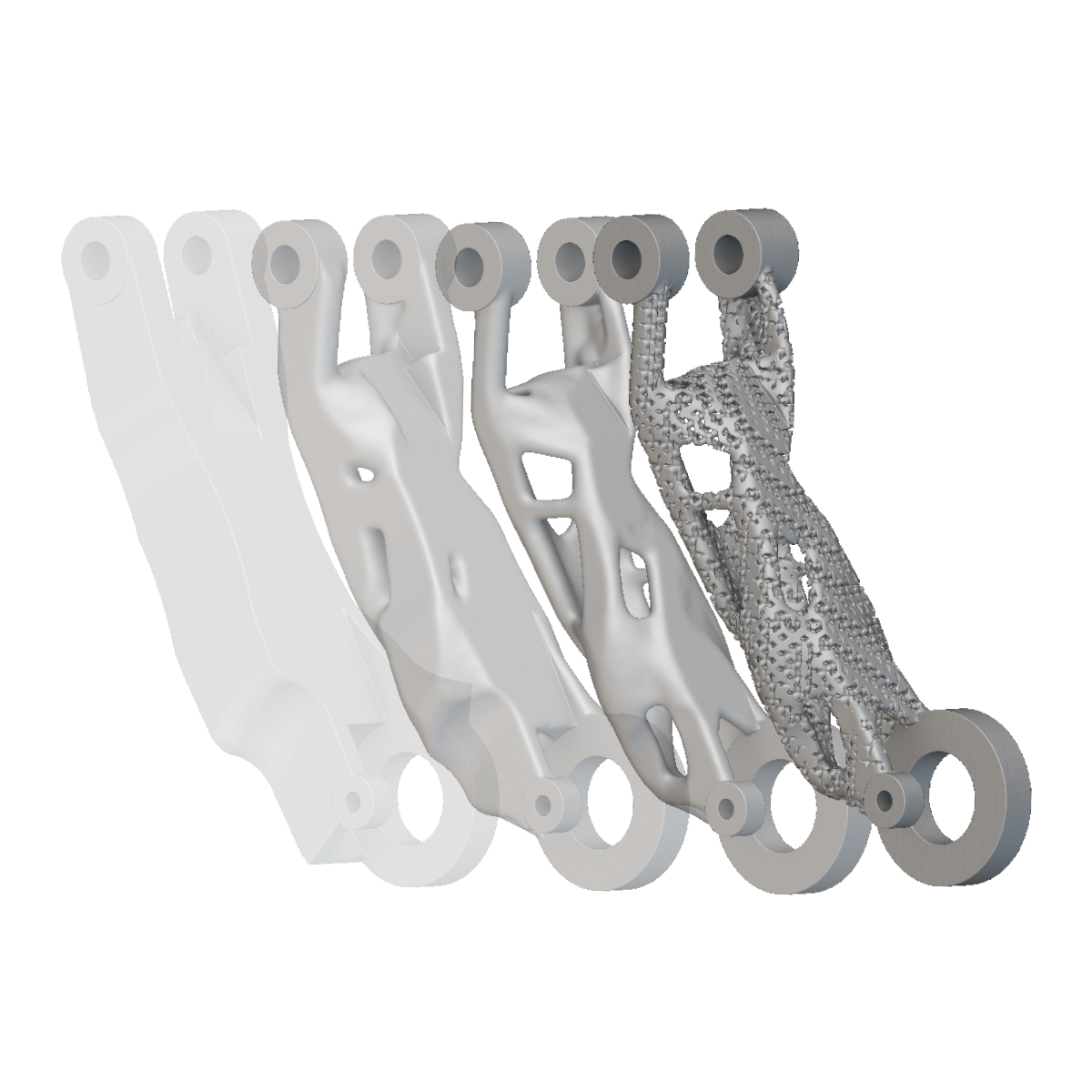

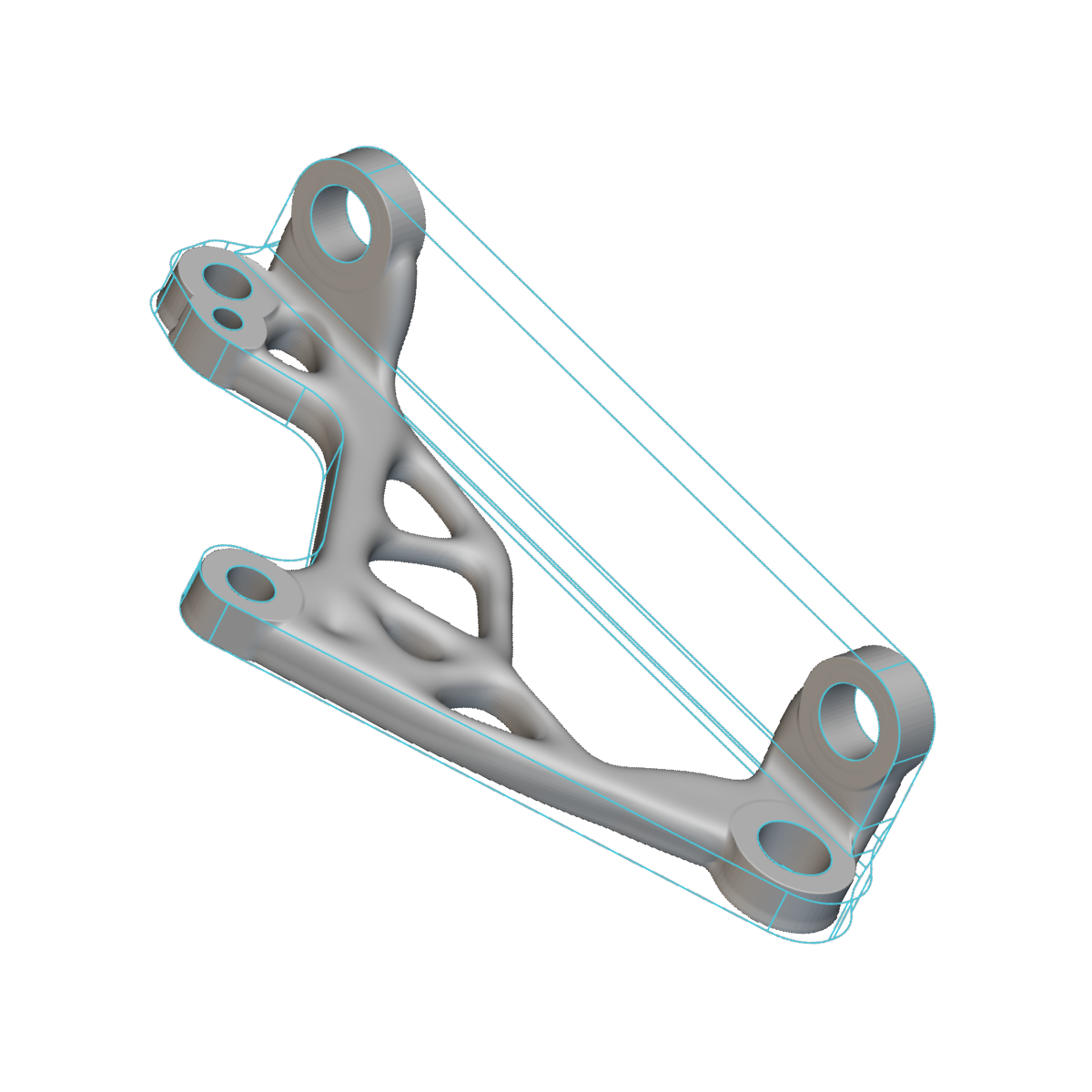

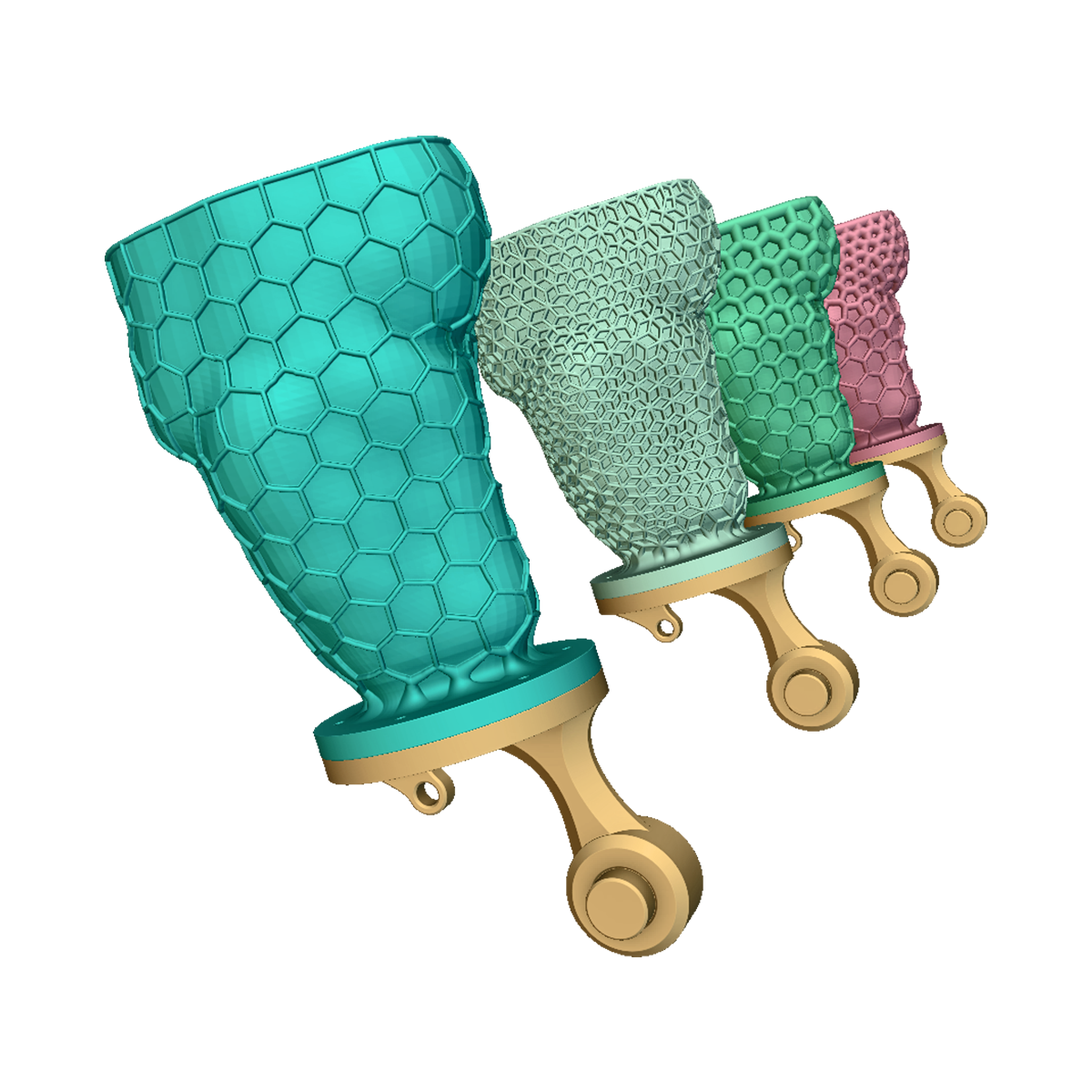

Unlock faster innovation and better performance with advanced computational design software.

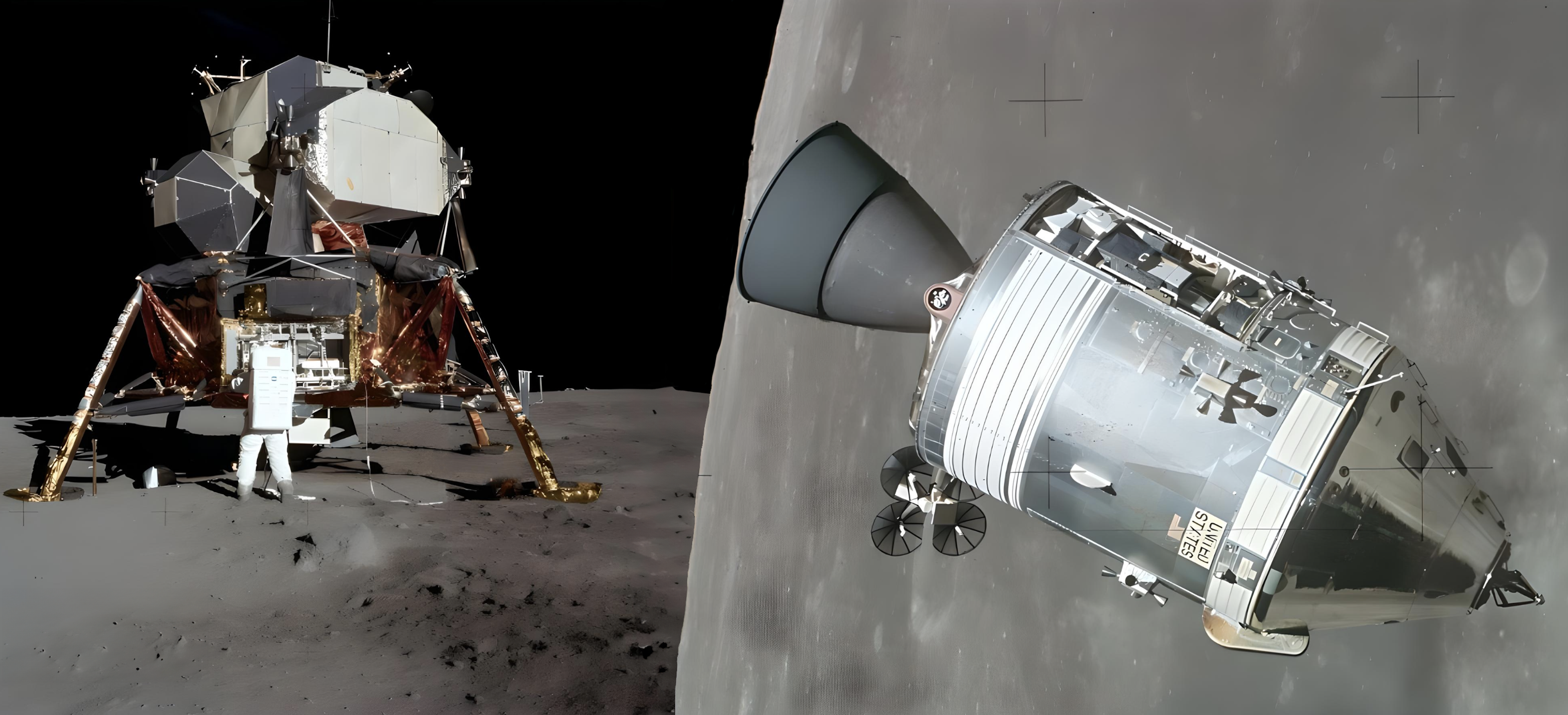

Trusted by leading engineering teams

Join the cutting edge of your industry.

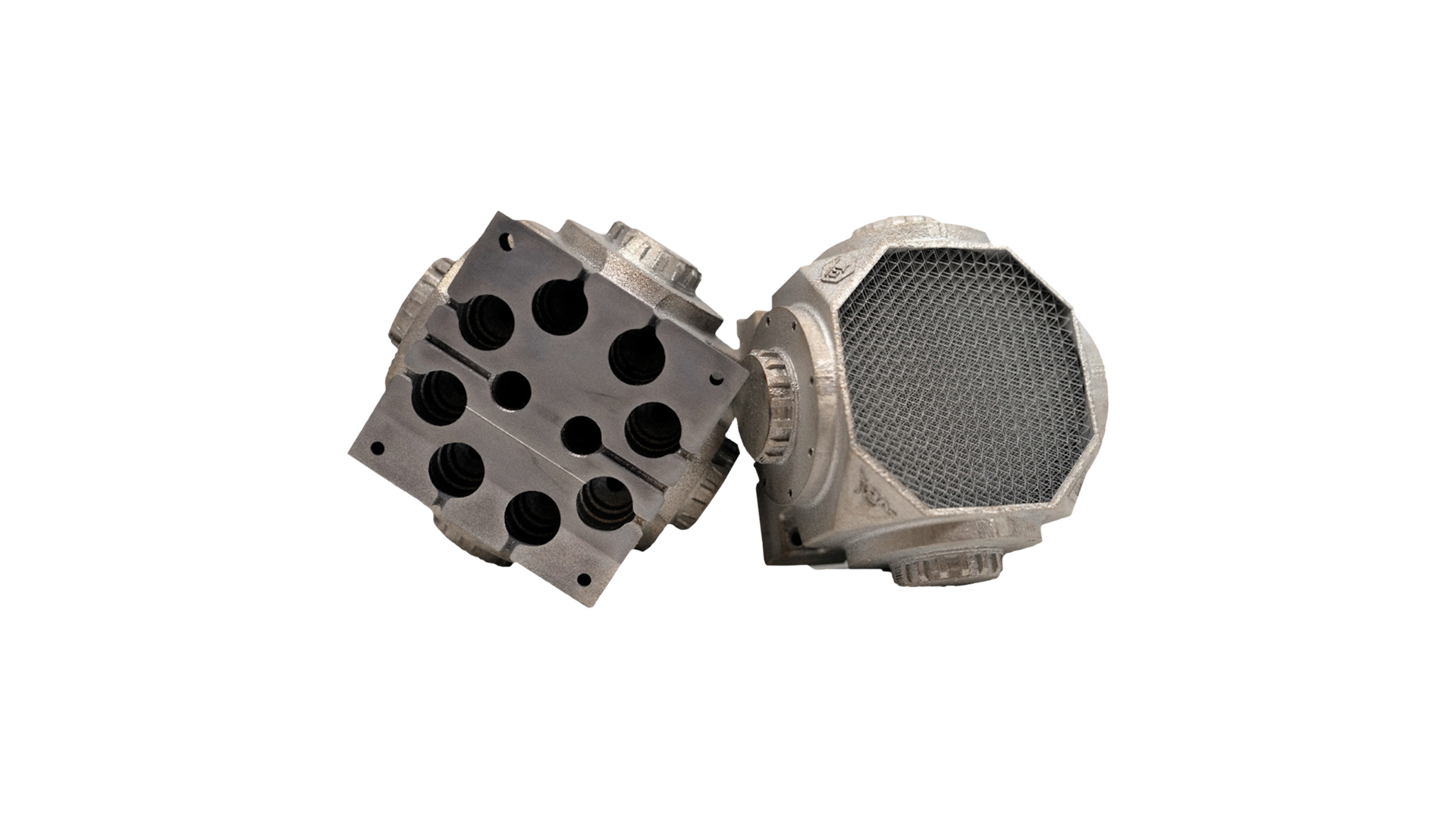

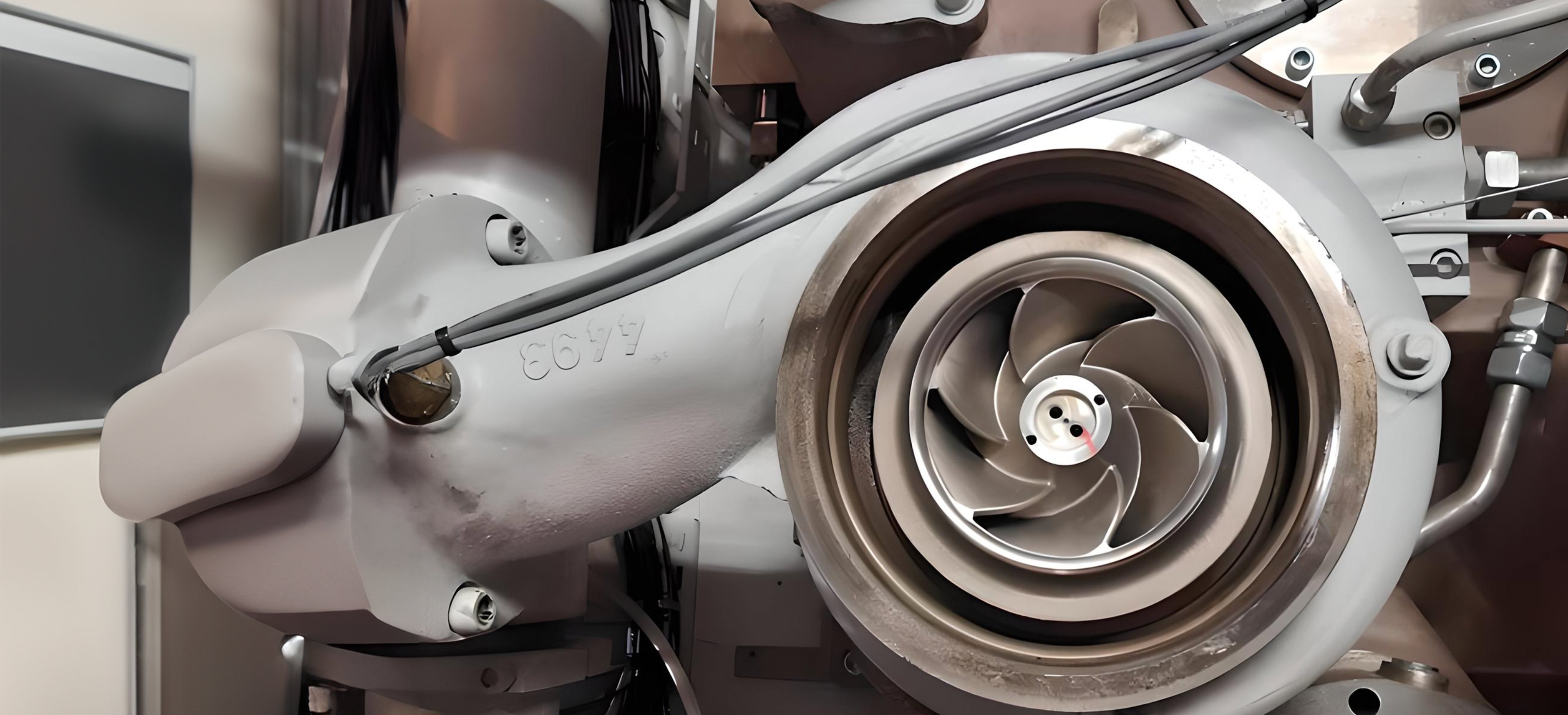

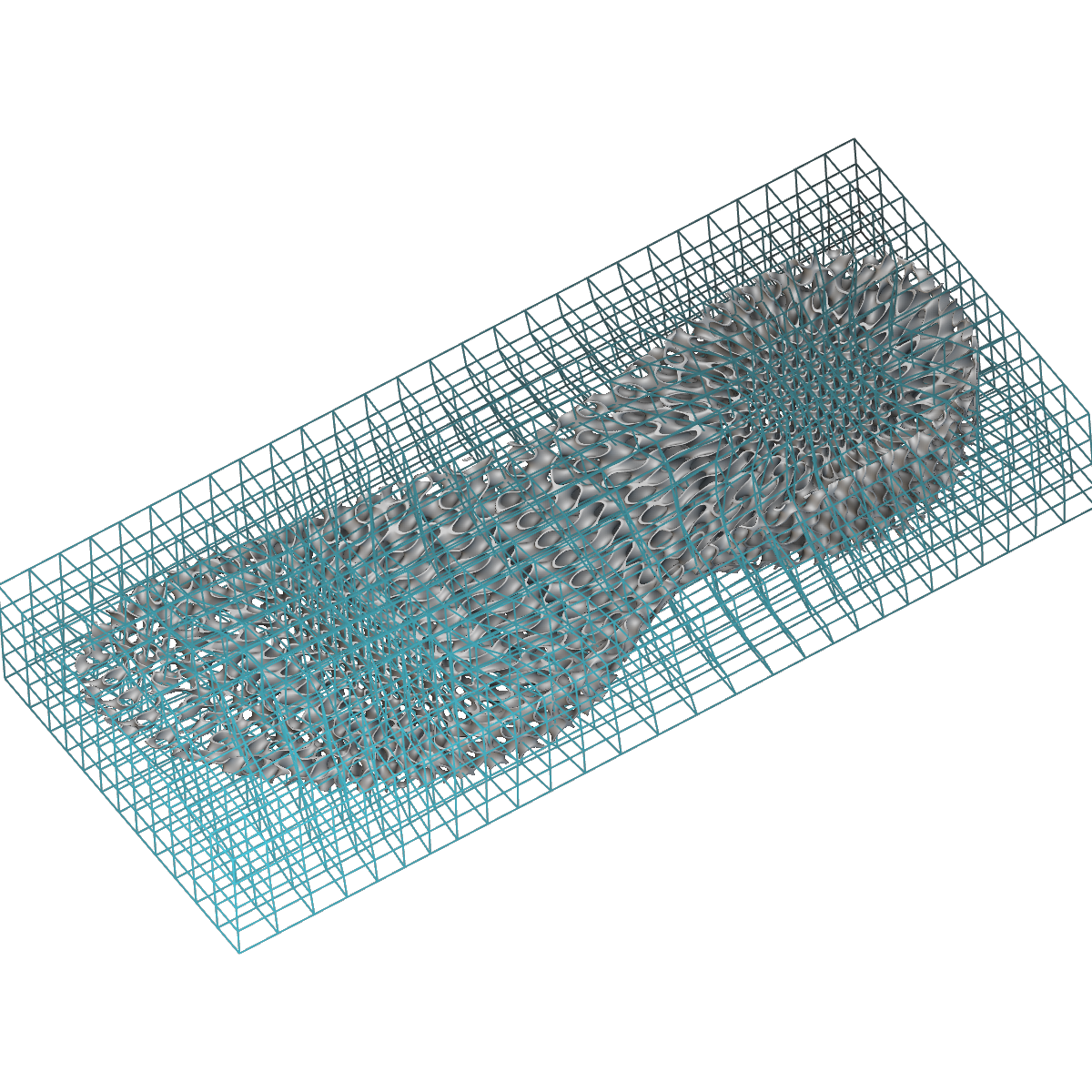

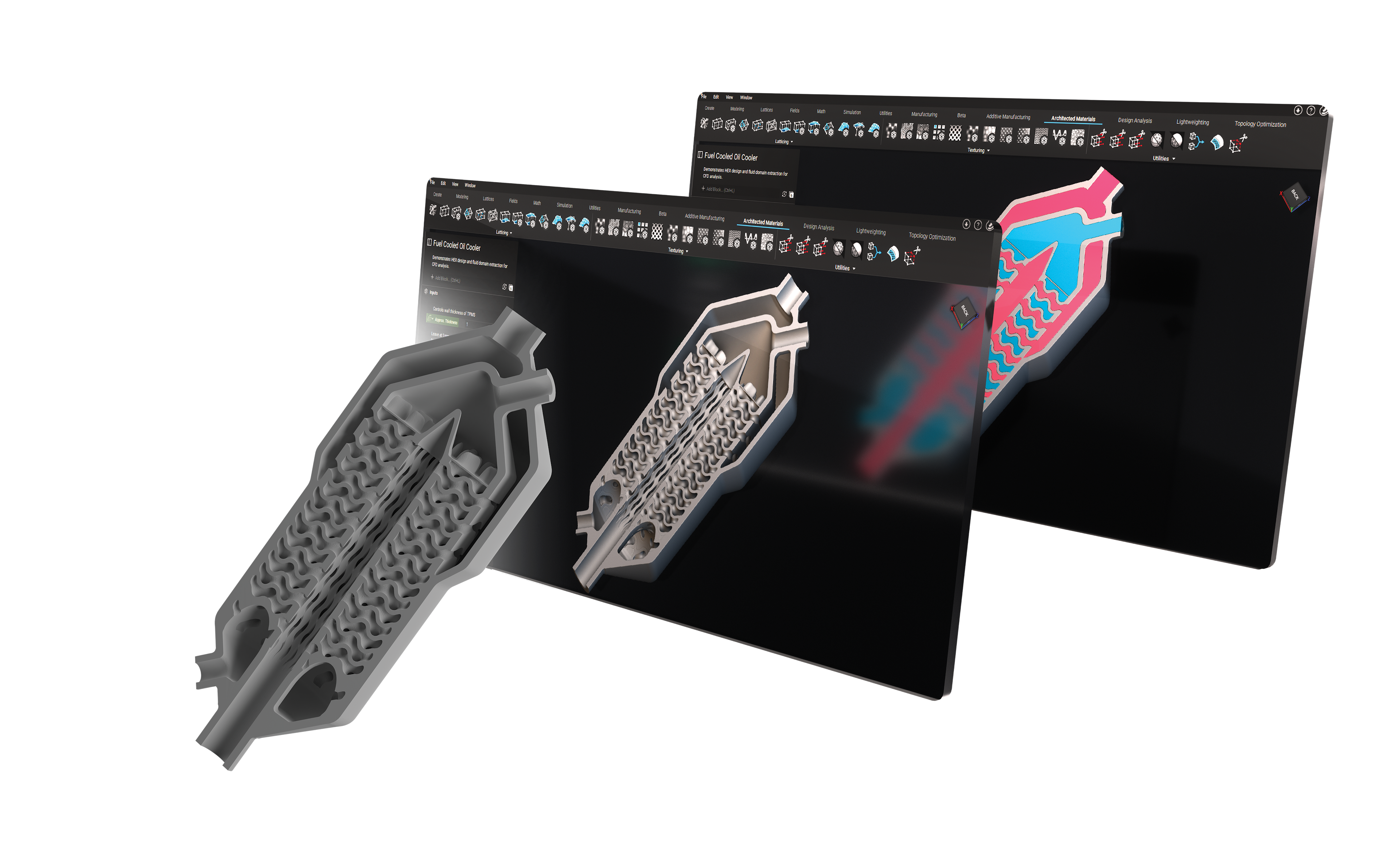

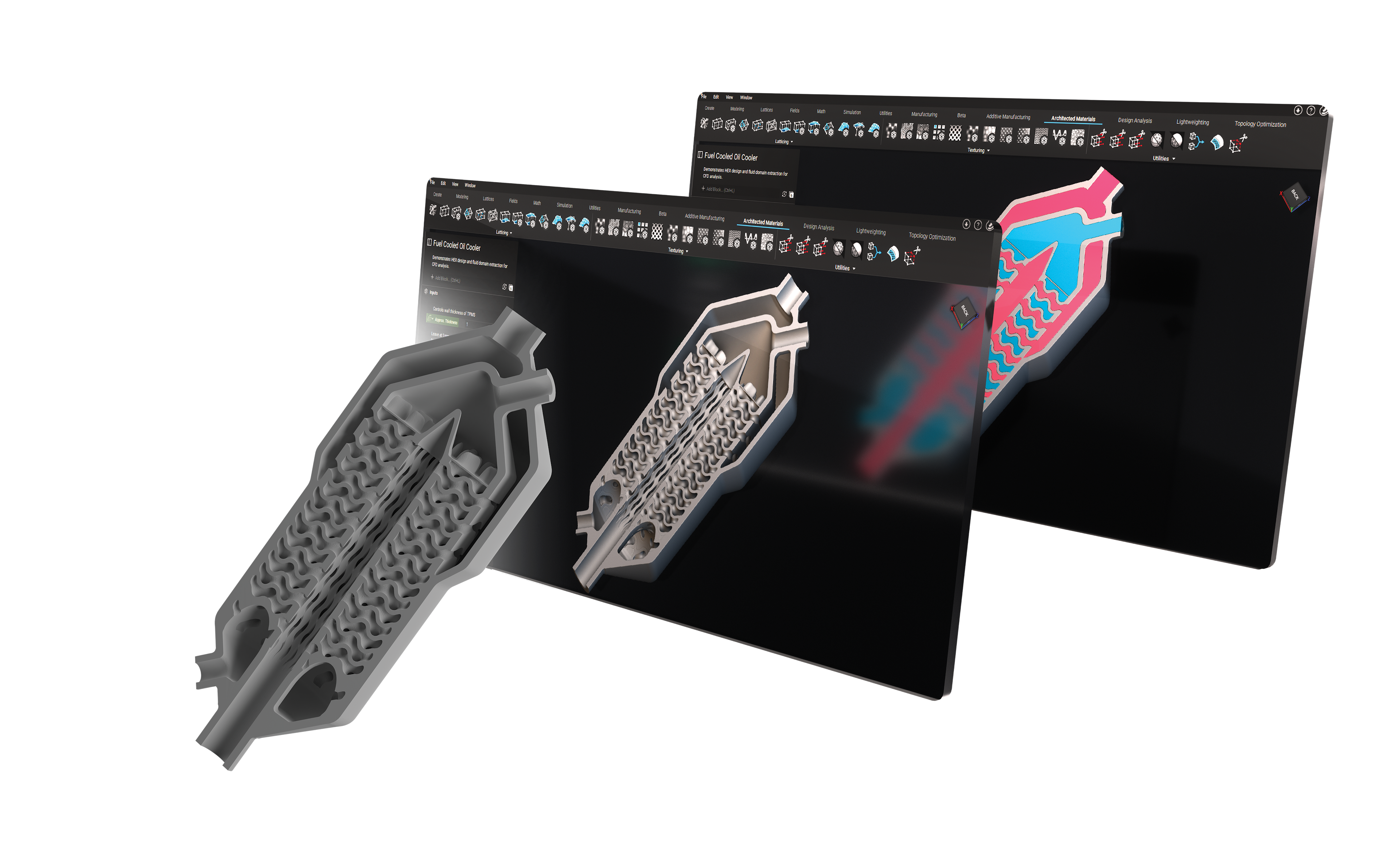

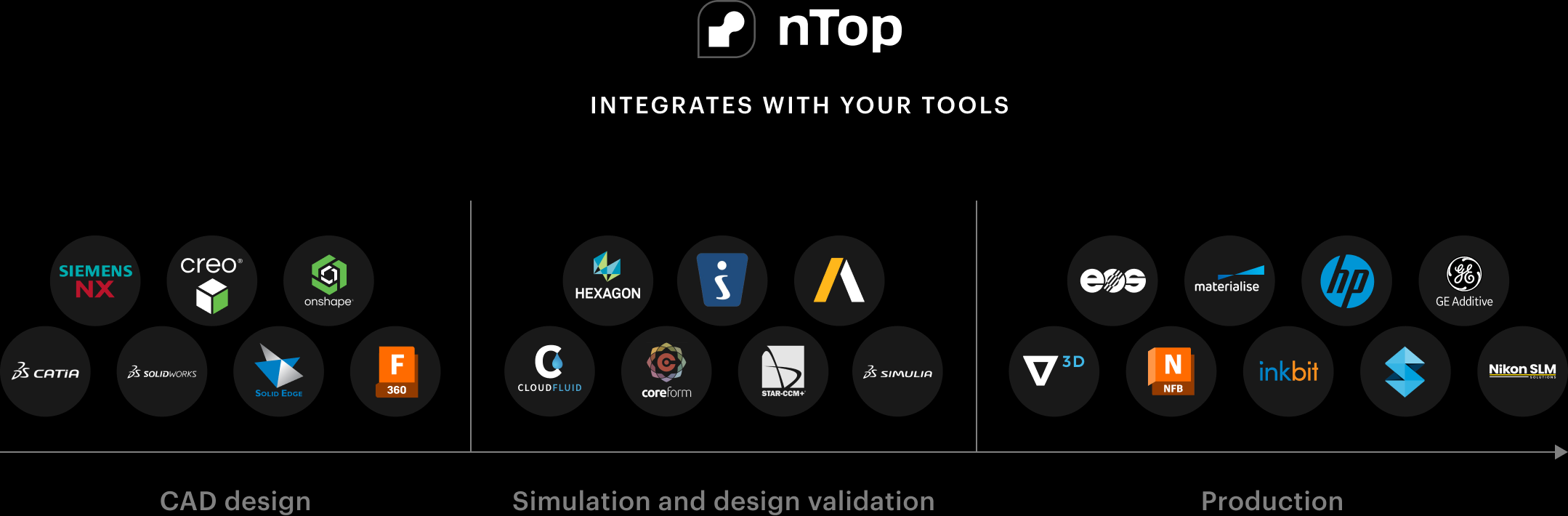

New powerful capabilities that work with your existing workflows and tools

Overcome your toughest design challenges.

See our capabilities in action.