Fluid management

Improve flow and aerodynamic performance while cutting weight and manufacturing costs using nTop’s powerful design software.

Benefits of fluid management with additive manufacturing

Using additive manufacturing for fluid management solutions can unlock more efficient, reliable parts that perform better.

Industry applications of fluid management

Additive manufacturing helps create lighter, smaller, specialized parts for high-performance fluid management applications across industries.

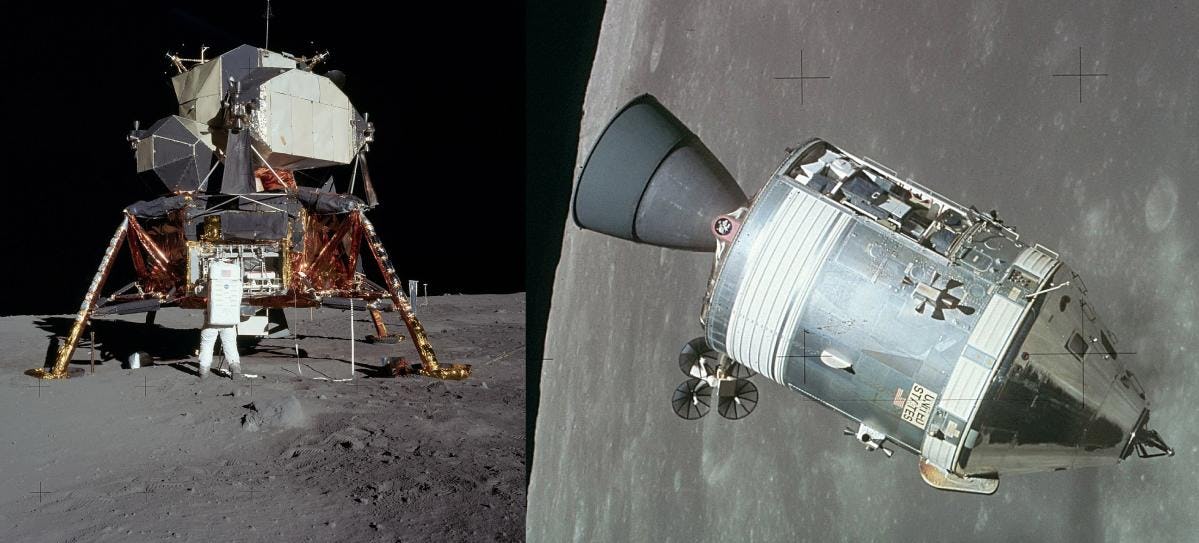

Aerospace

Fuel manifolds, nozzles, and turbomachinery within primary engines and auxiliary power units can be made lighter, smaller, and better-performing with AM.

Automotive

Automotive engineers can use AM to deliver more efficient engine manifolds, air ducts, piping, and housings that meet their requirements.

Industrial technology

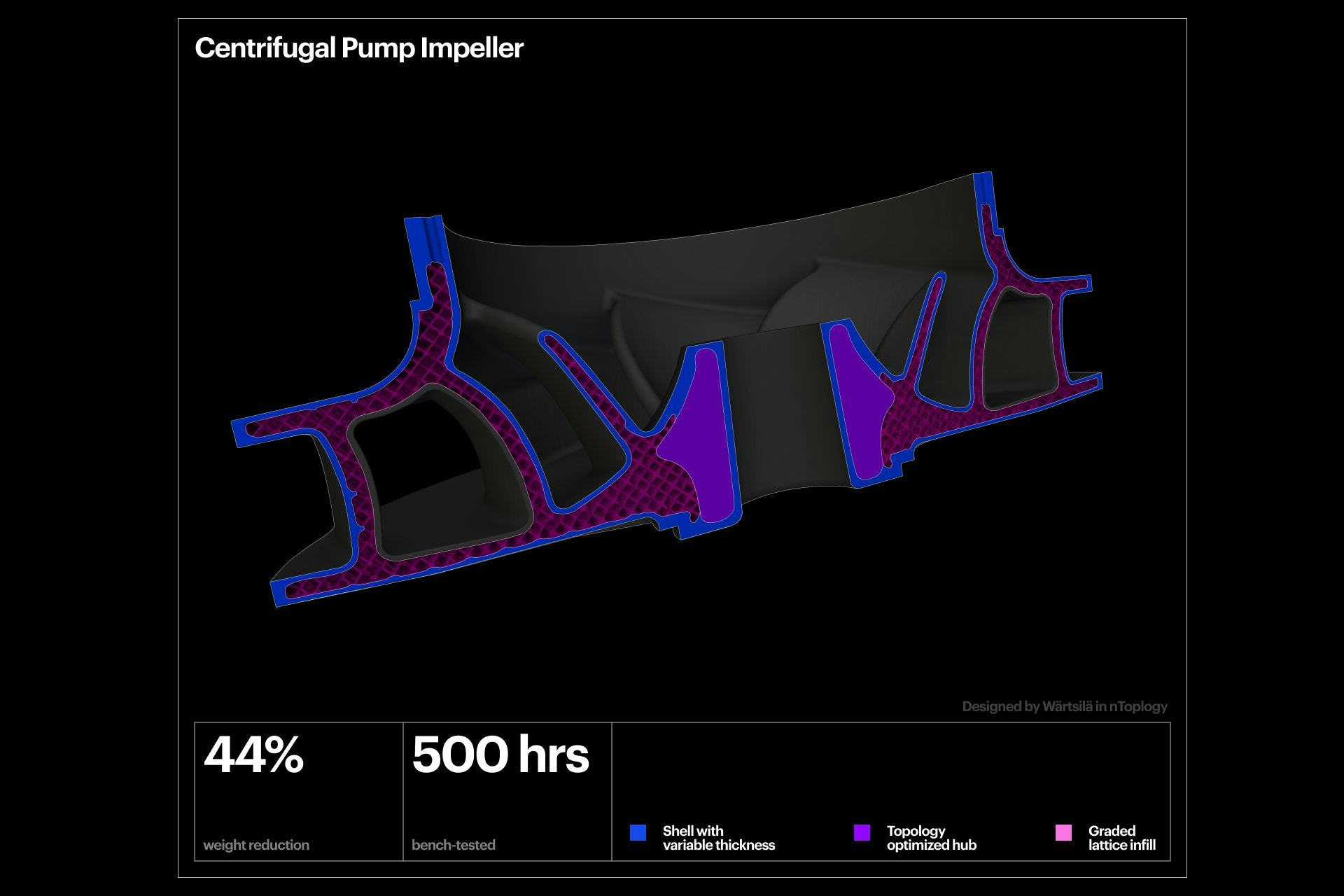

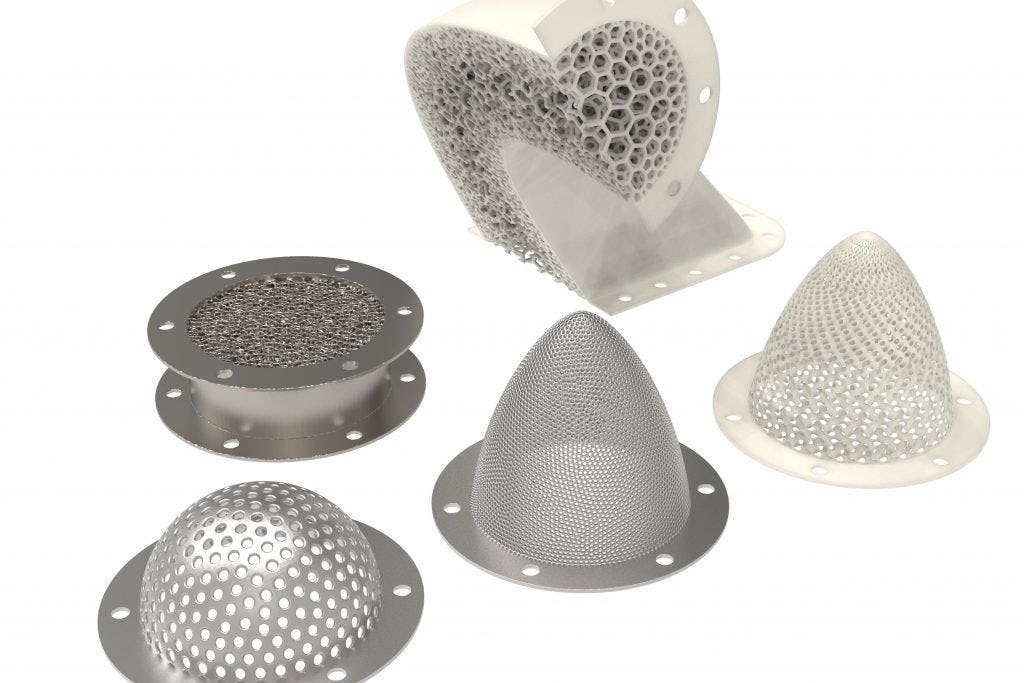

3D printing can improve operational efficiency by creating specialized, low-volume components for compressors, pumps, and filters for high-performance applications for oil and gas and other industries.

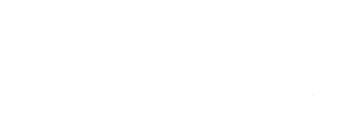

nTop’s critical tools for fluid management with additive manufacturing

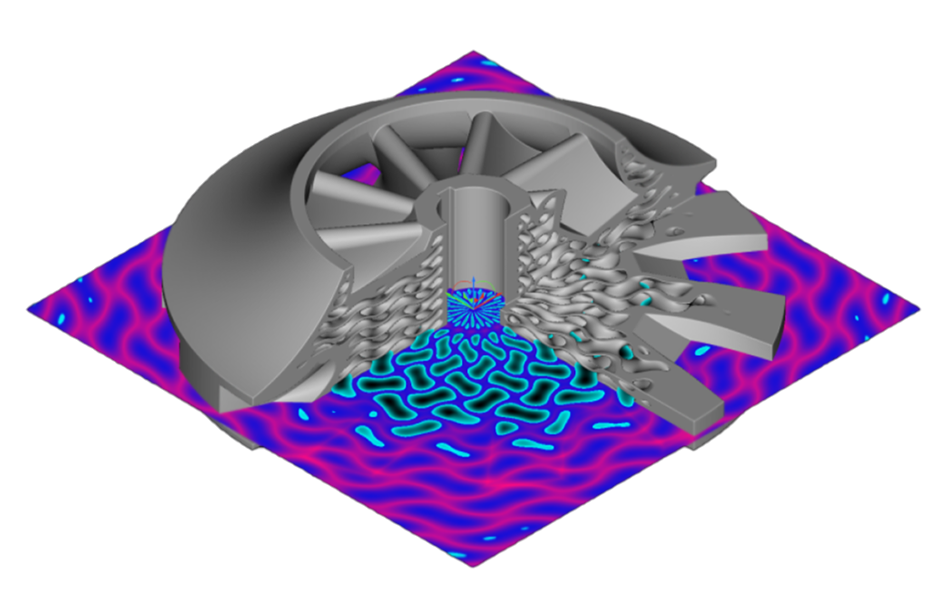

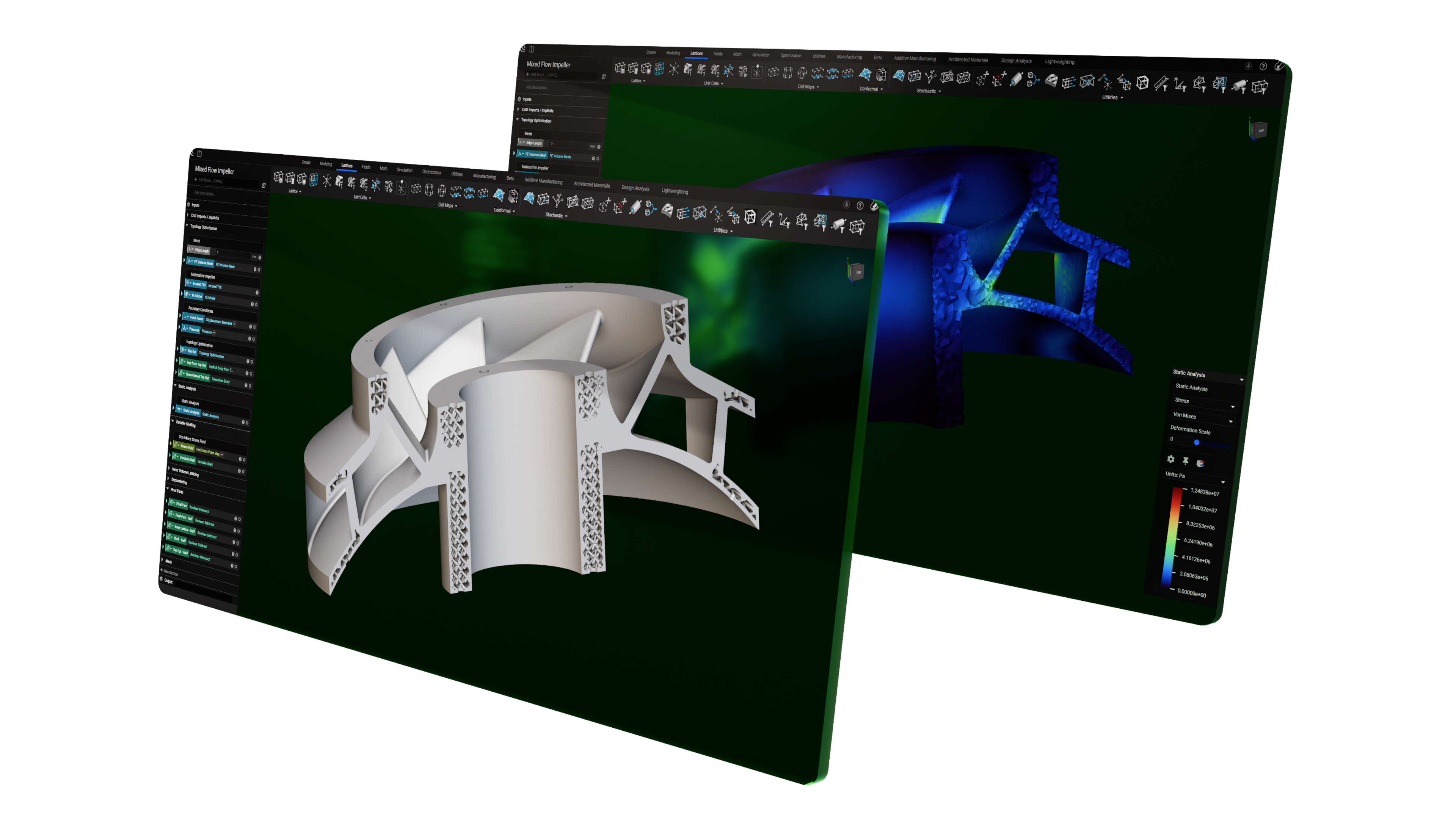

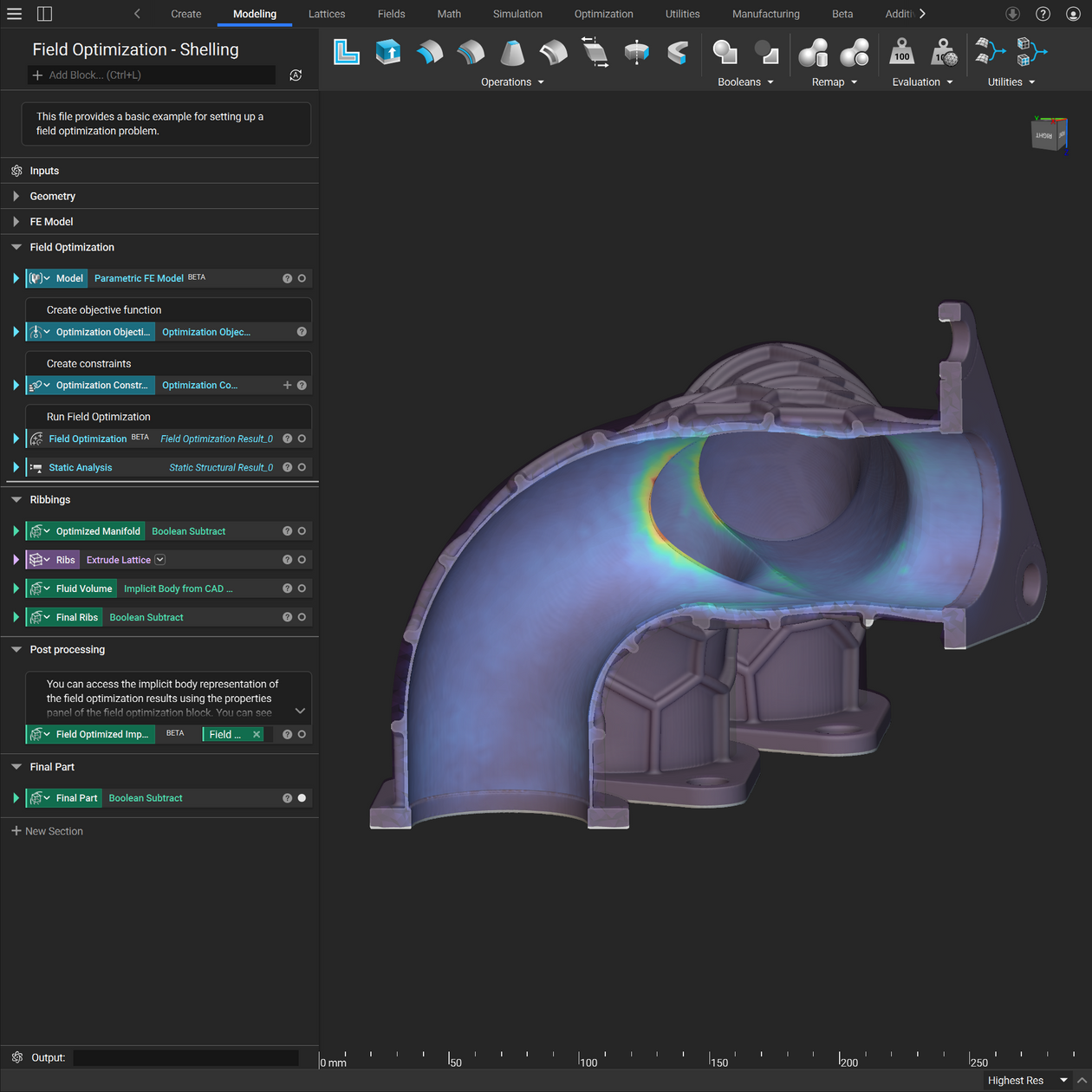

Field Optimization

Generate highly engineered parts with a multi-scale design tool that extends nTop’s Field-Driven Design, optimization, and latticing capabilities.

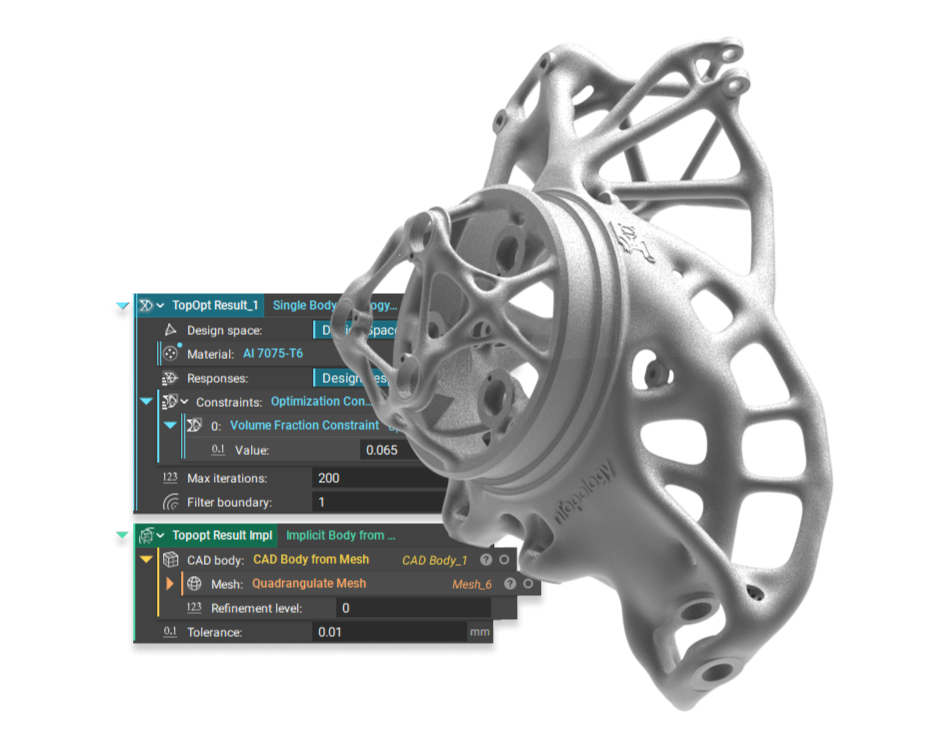

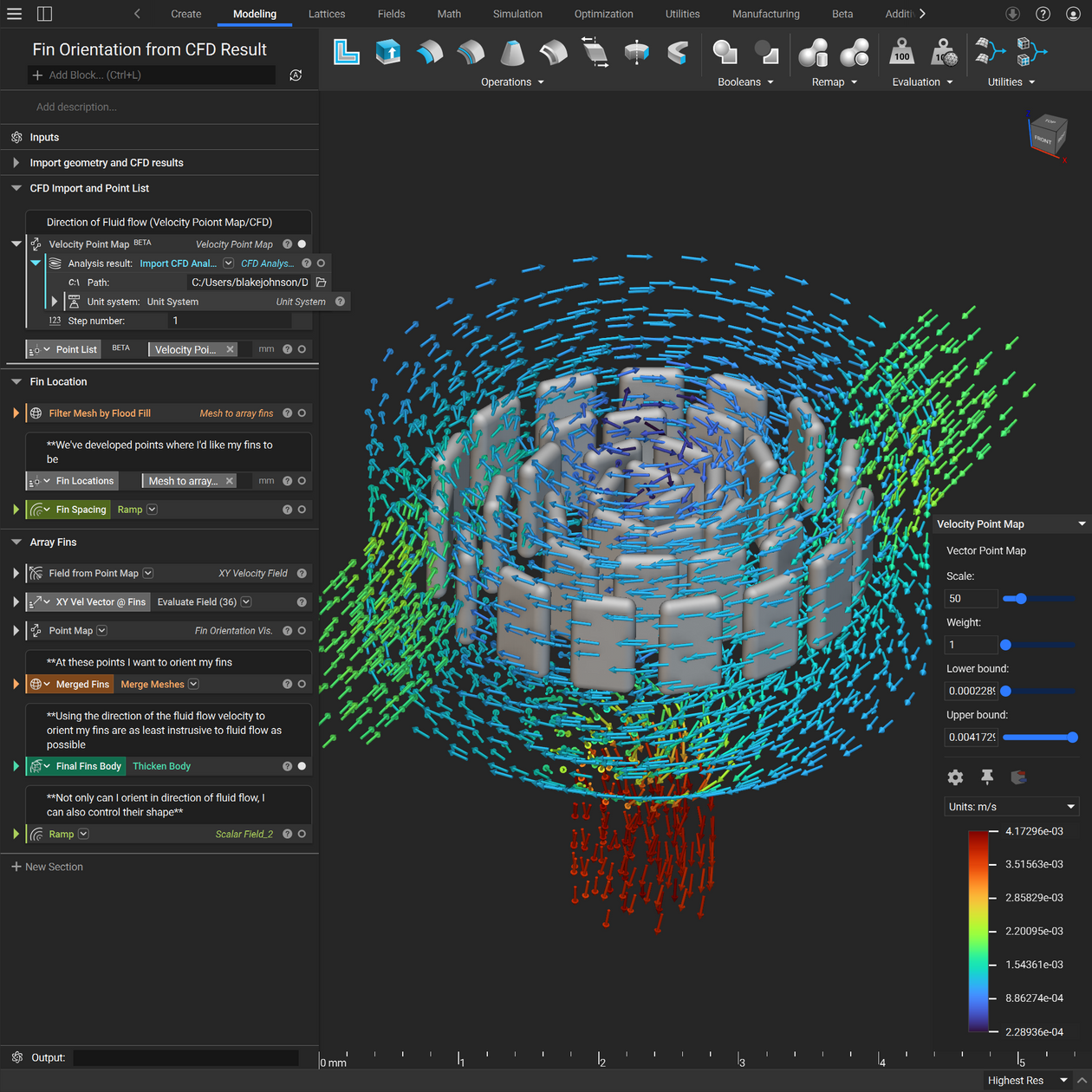

Design optimization

Drive designs directly from simulation data to iterate faster. Set up automated parametric optimization processes to identify the best-performing results.

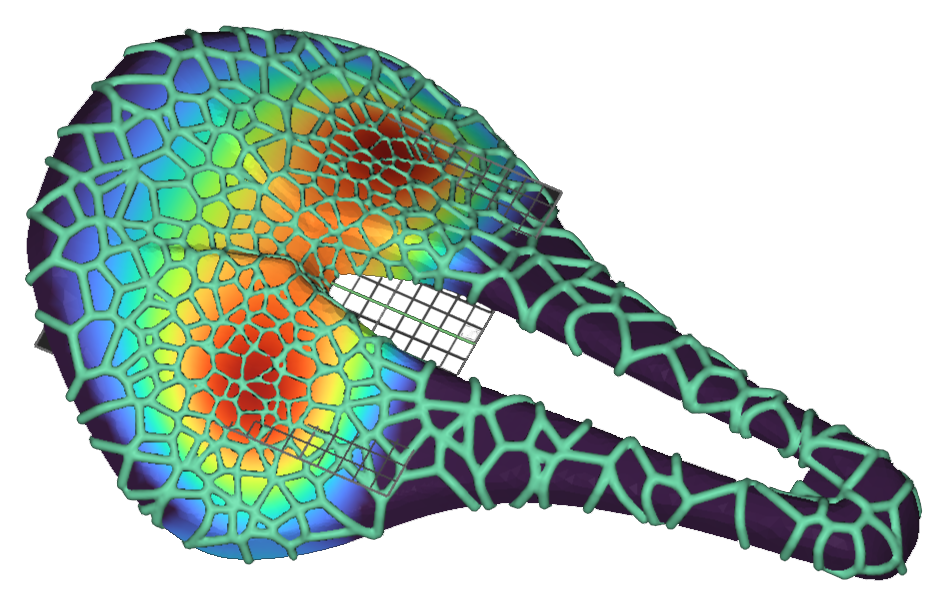

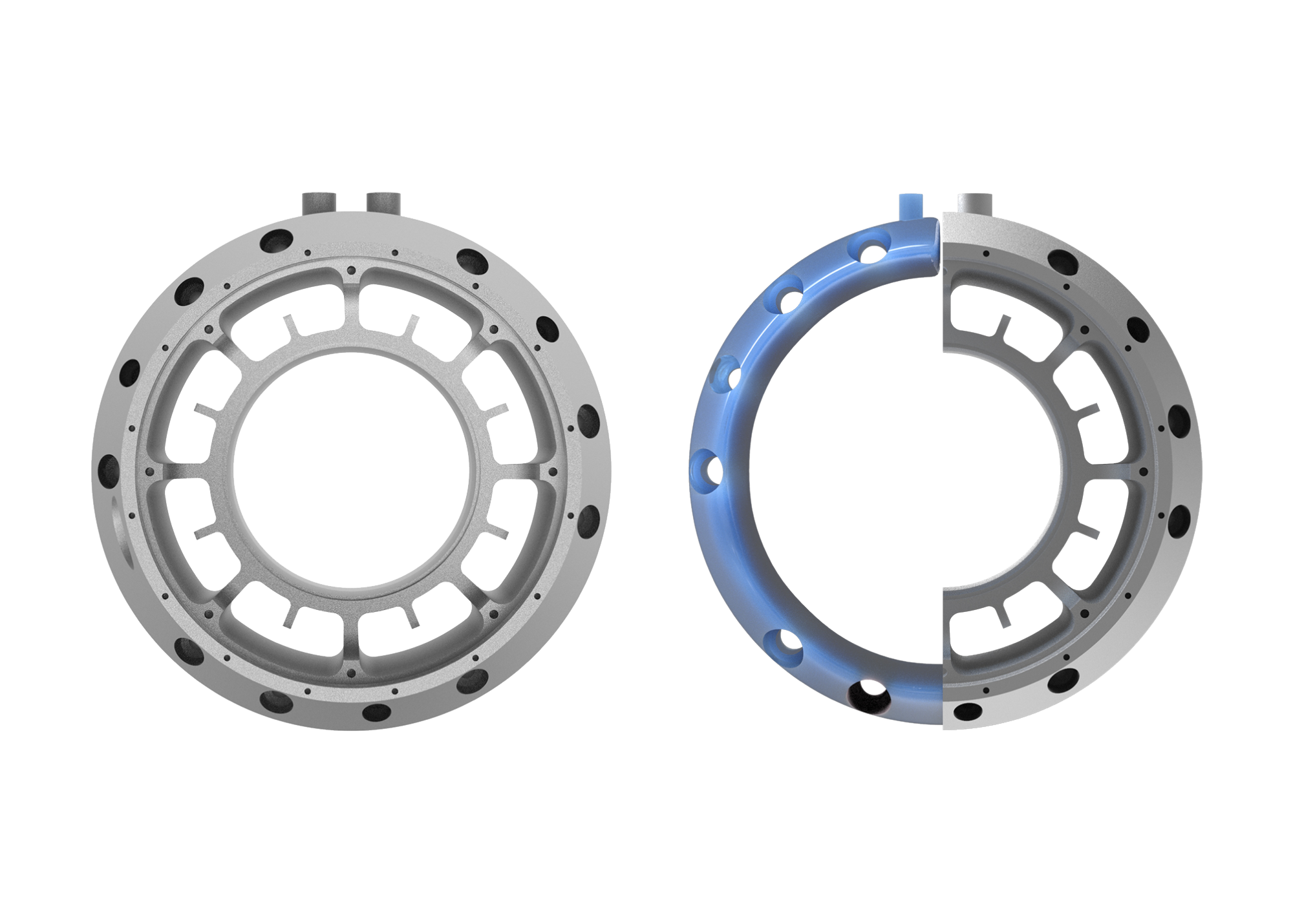

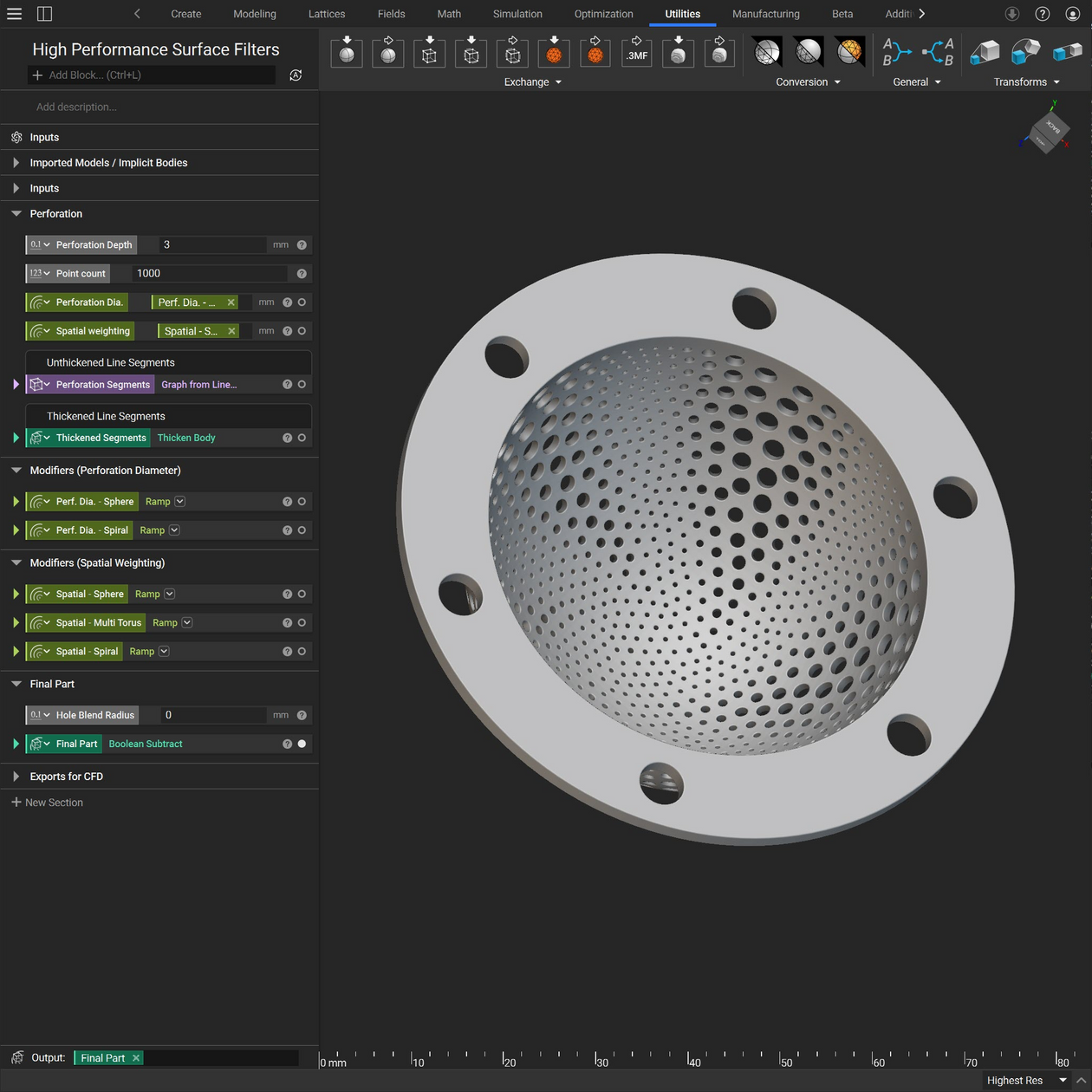

Perforations

Generate perforation patterns with thousands of elements on the surface of any part. Control the hole shape, size, spacing, and direction.

Integrations

Transfer data easily between nTop, CAD, CAE, CAM, and PLM systems. Import and export data in a variety of file types and sources.

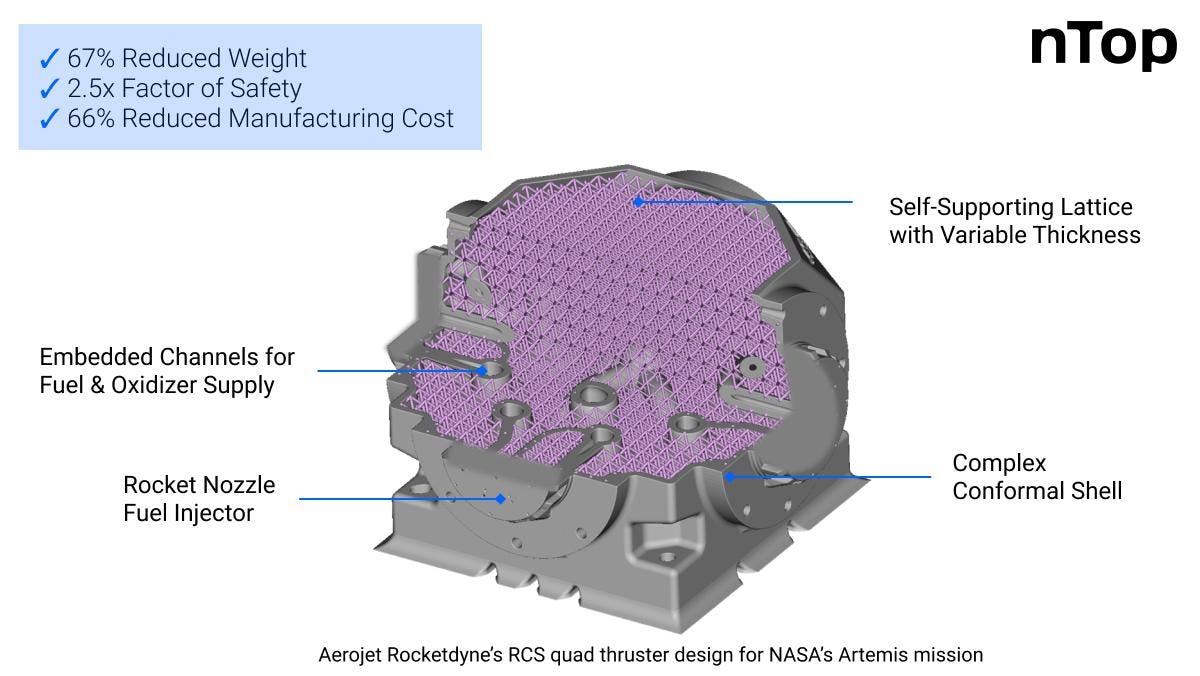

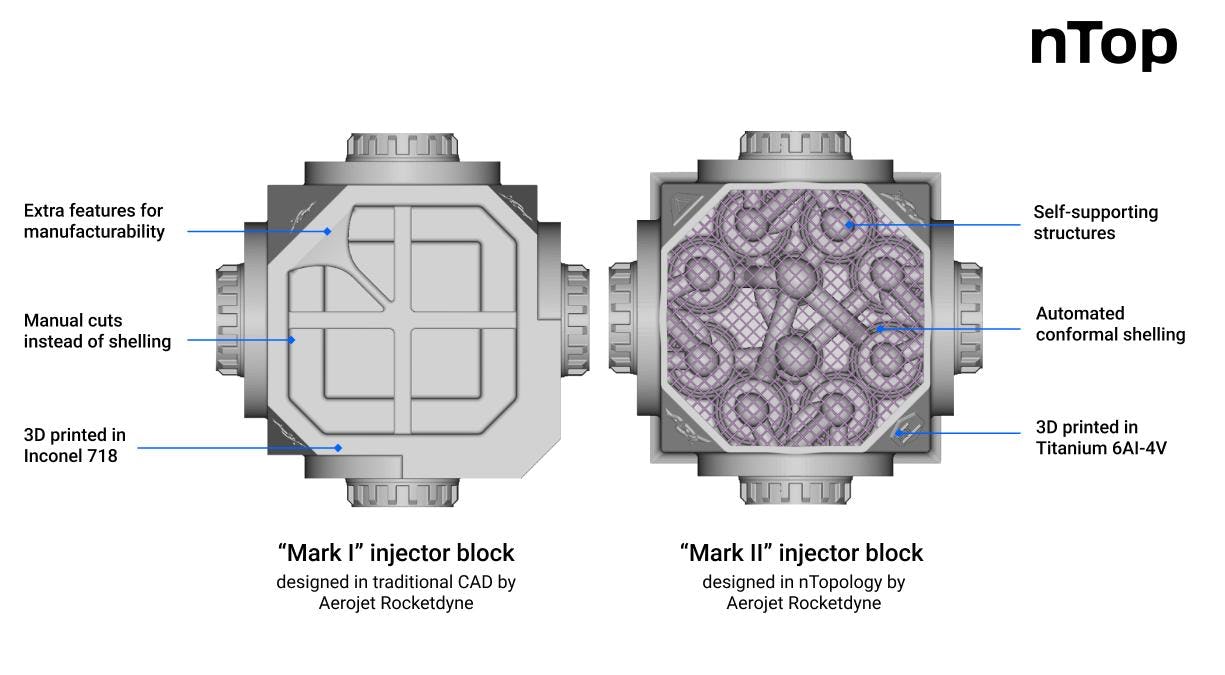

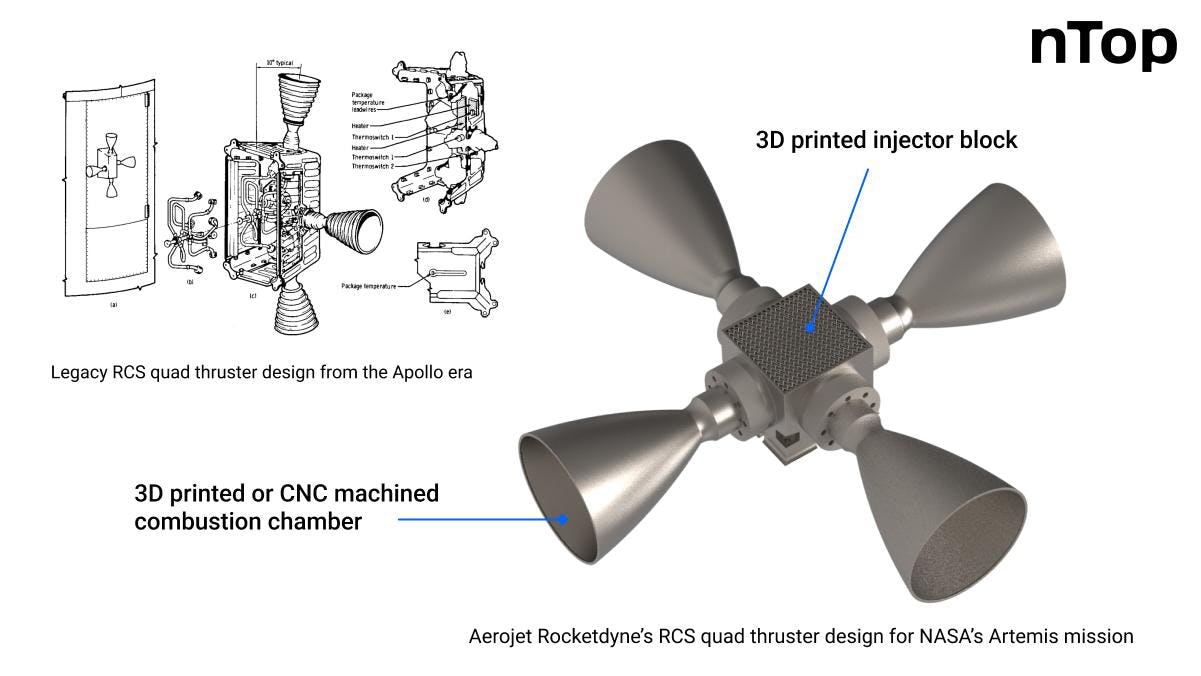

Aerojet Rocketdyne

Light, reliable quad thruster enables low-cost space exploration

Aerojet Rocketdyne used nTop’s shell-and-infill latticing capability to develop a RCS quad thruster that is 67% lighter and 66% less expensive than competing solutions.

Software built on transformative technology

Tooling design resources for engineers and designers

- ARTICLE

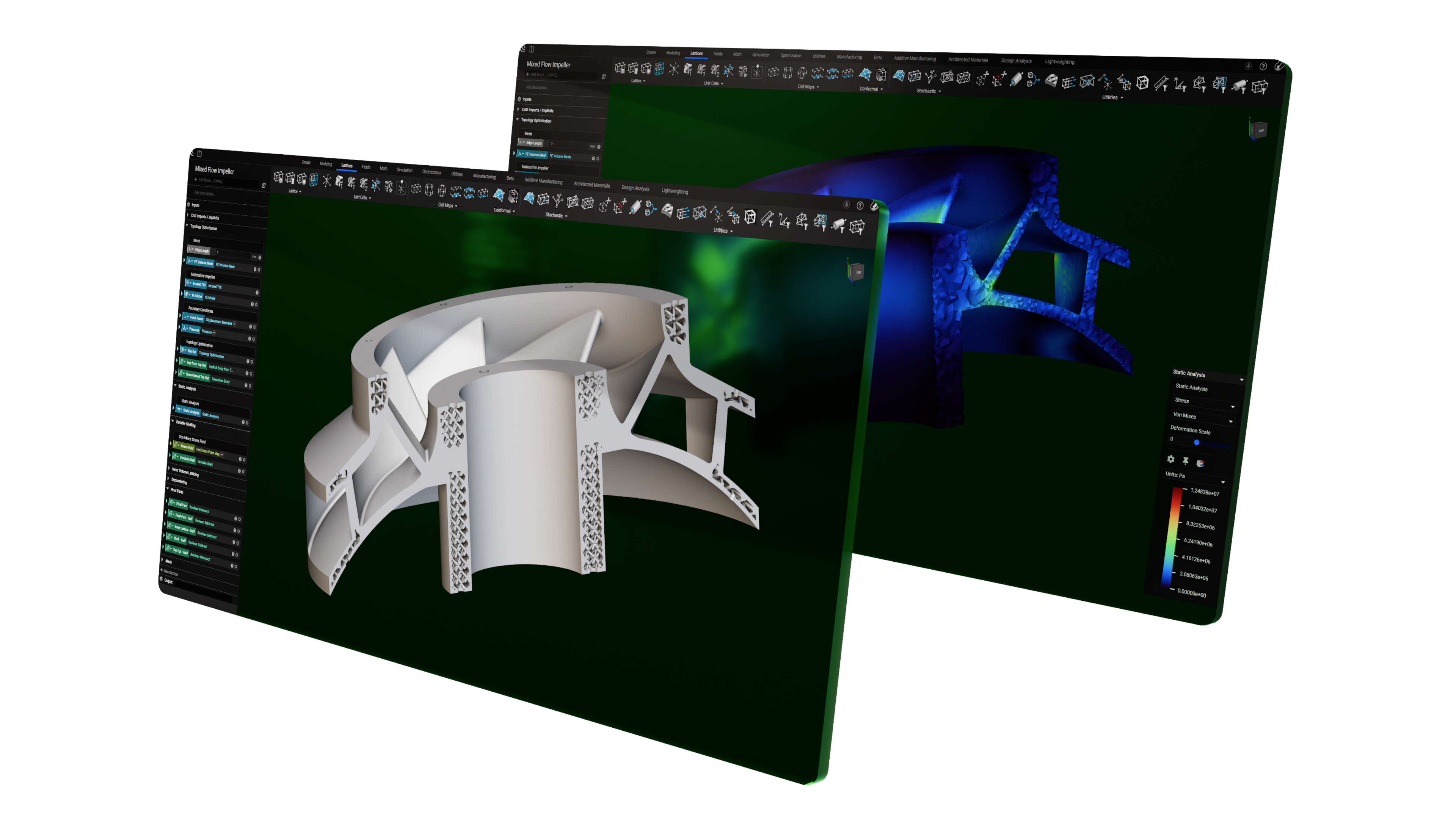

Wärtsilä optimizes industrial impeller for additive manufacturing

- VIDEO

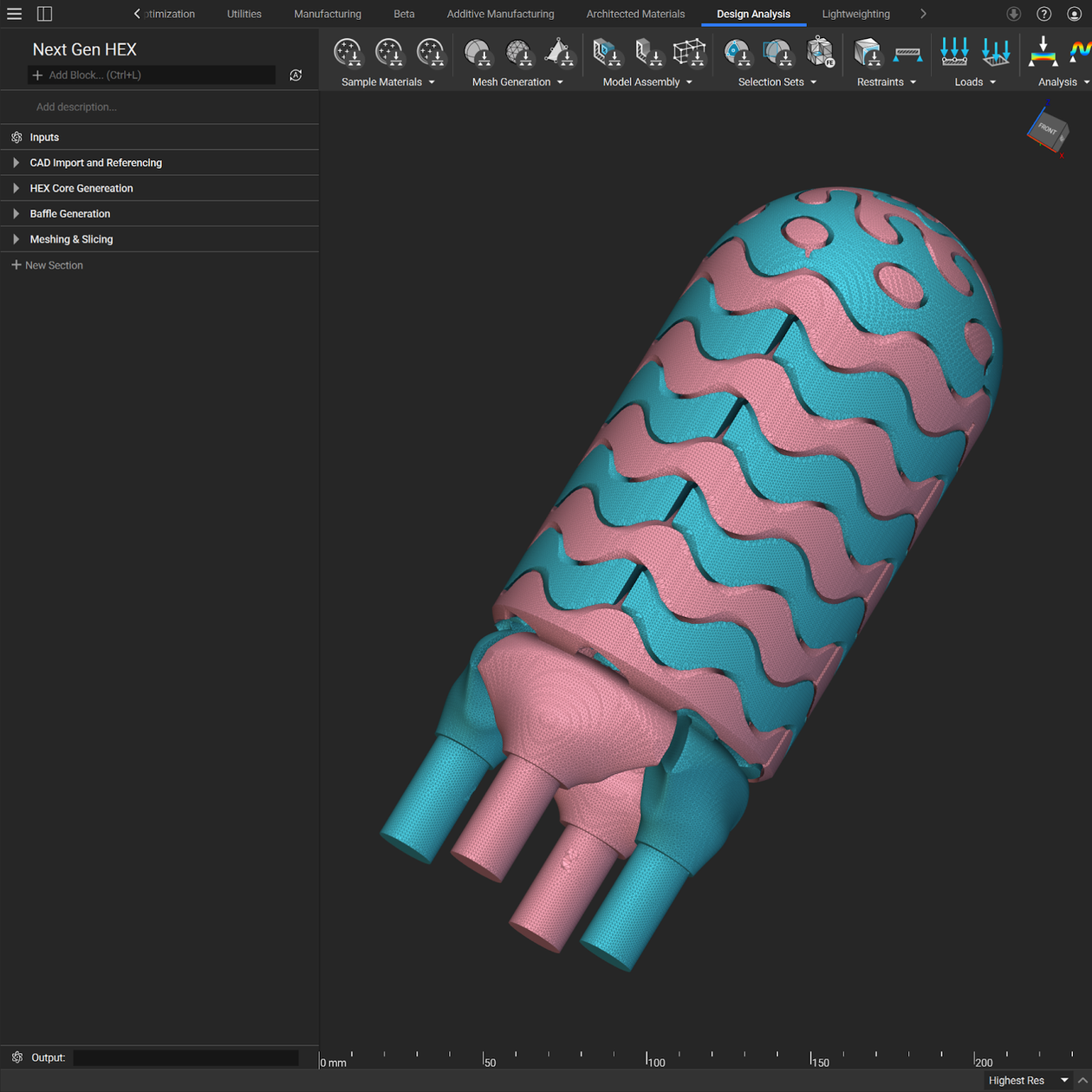

Conformal isogrid ribbing on low bypass turbofan engine casing

- VIDEO

Dimpled surfaces to increase air intake in air duct

- VIDEO

Generative design workflows from CFD fields

- ARTICLE

How to design high-performance filters for additive manufacturing

Ready to improve your fluid management applications?

Top has the tools you need to maximize the benefits of AM.