Aerospace engineering software

Develop lighter, better performing, more innovative parts that take full advantage of additive manufacturing.

When requirements are strict, leverage nTop’s advanced capabilities to create more efficient parts with the performance you need.

Design high-performance parts

Unlock the full potential of additive manufacturing with structural lightweighting and multifunctional optimization.

Capture and reuse engineering knowledge

Standardize best practices, empower collaboration, and jumpstart projects easily with reusable workflows.

Streamline and automate processes

Automate workflows and processes, improve efficiency and reduce repetitive tasks with notebooks and command-line tools.

Integrate with digital thread

Import and export CAD files seamlessly to integrate with your existing software stack.

Aerospace and defense applications

Structural lightweighting

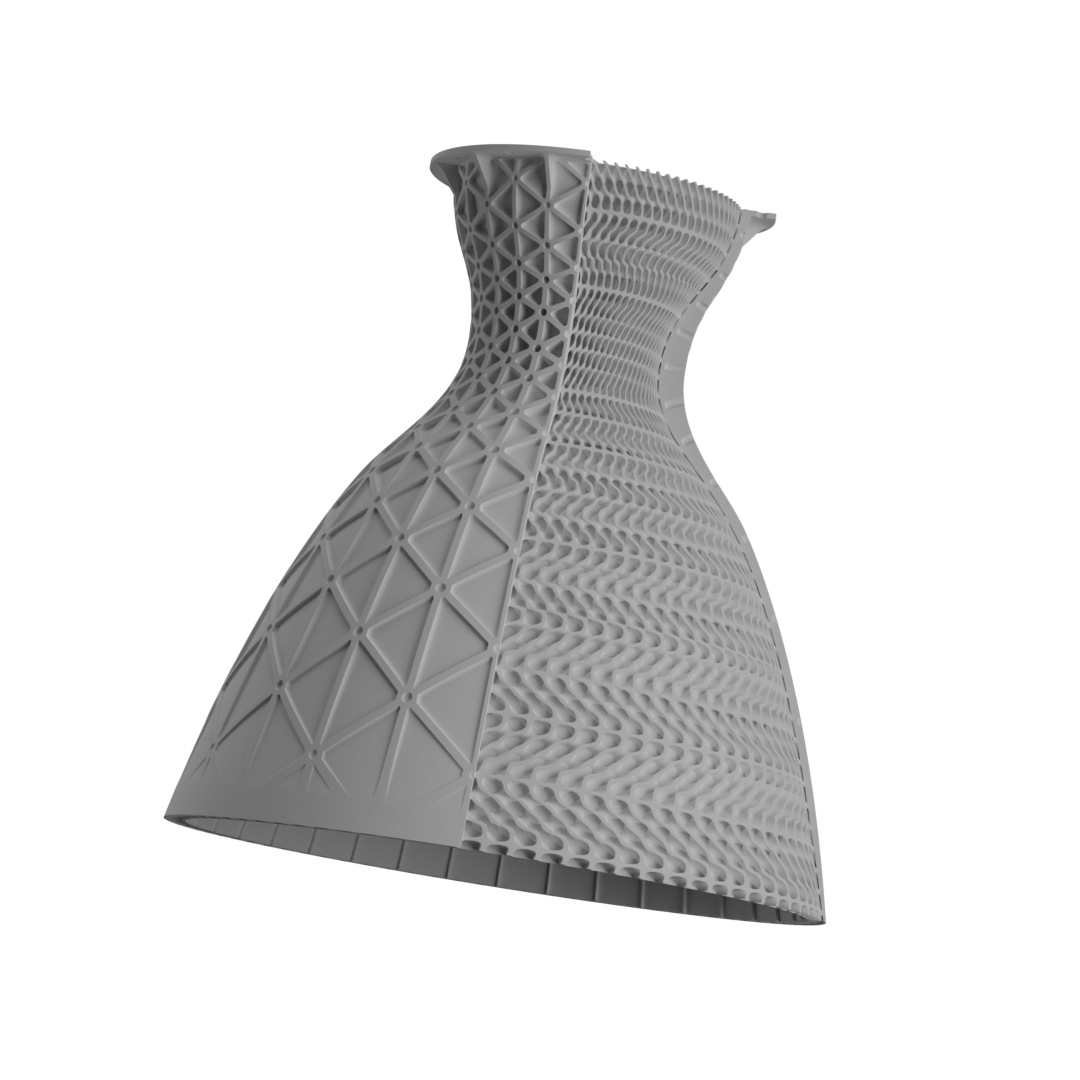

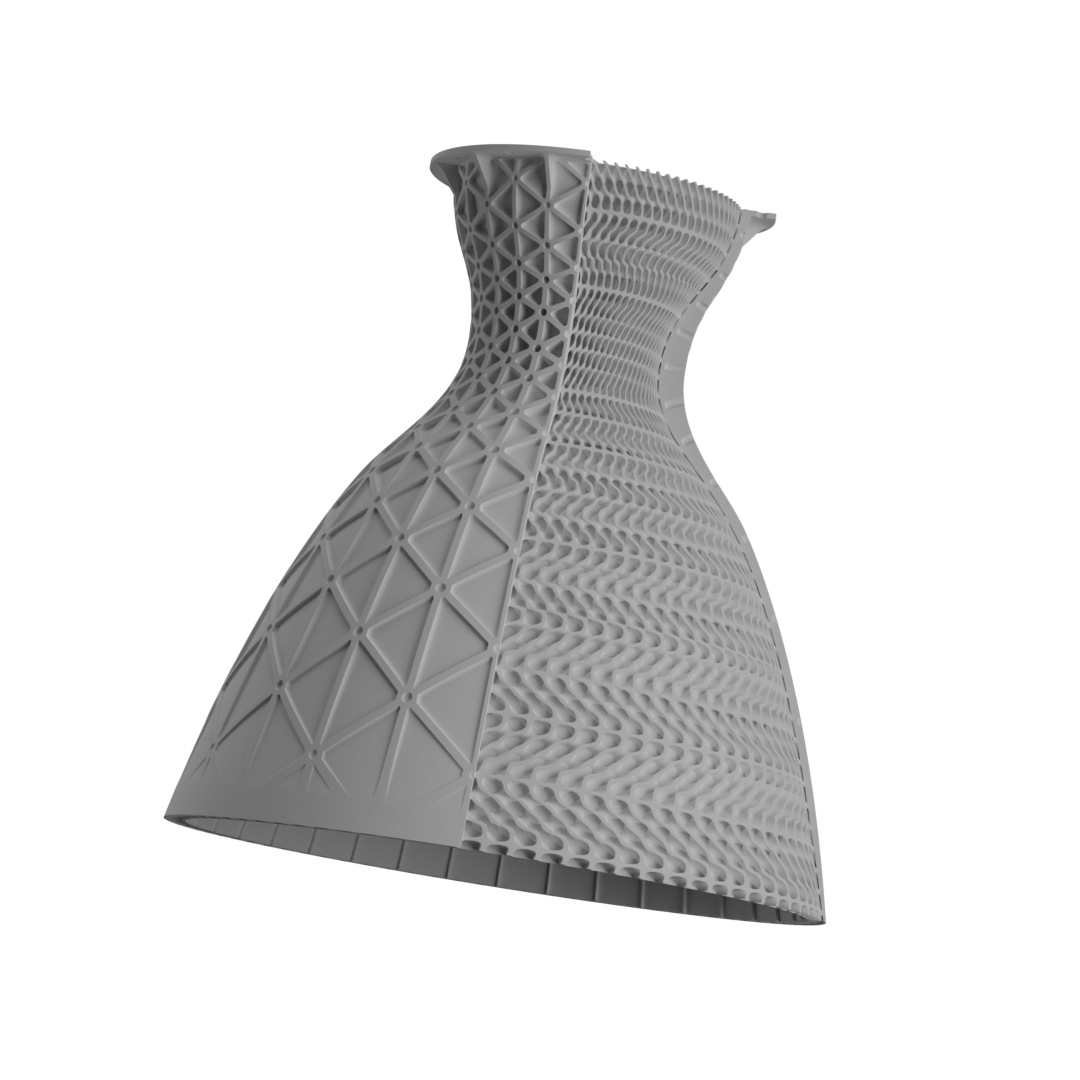

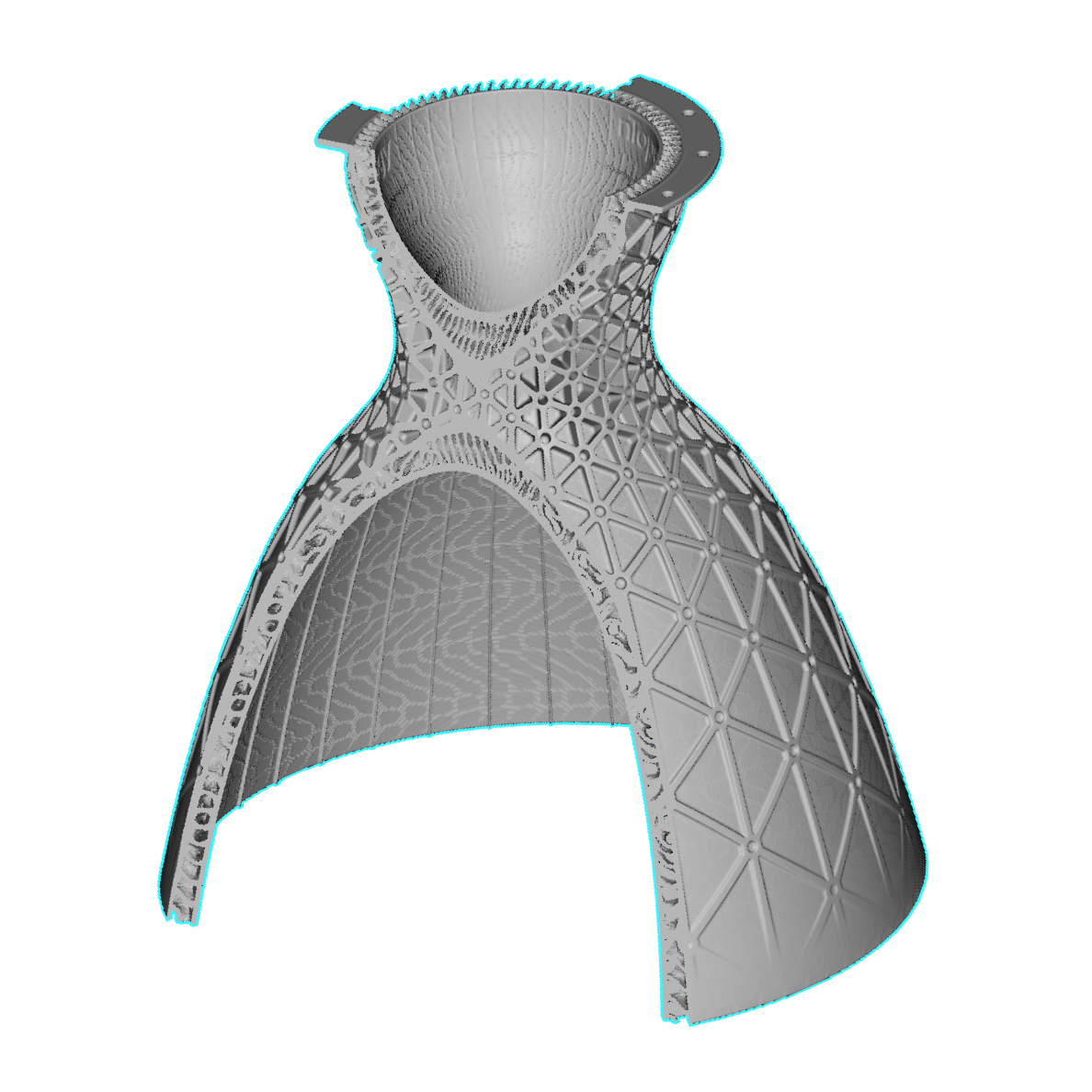

Make your aerospace parts lighter and more efficient with an extensive set of design tools like topology optimization, lattice and gyroid structures, perforation patterns, variable shelling, and isogrid ribs.

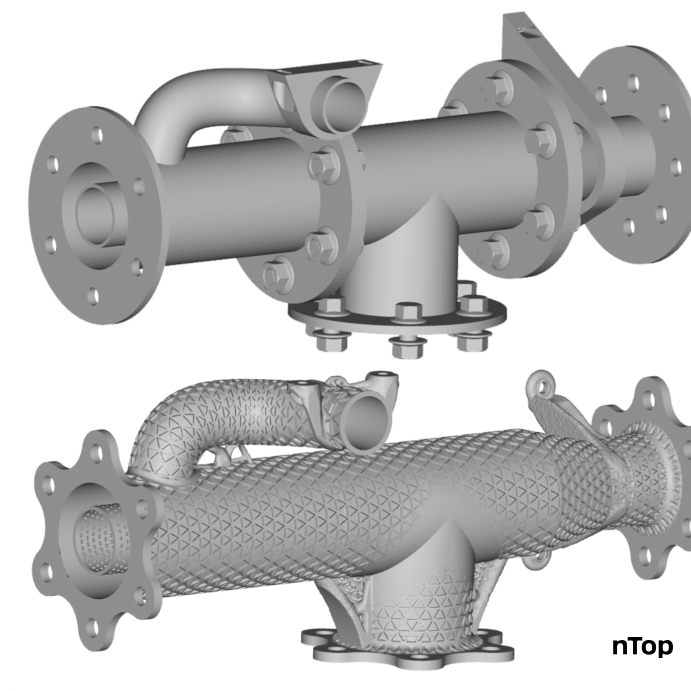

Part consolidation

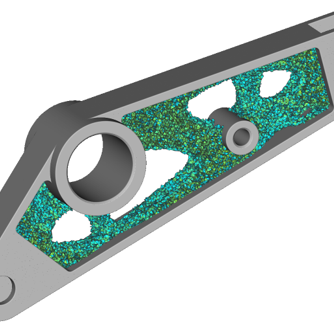

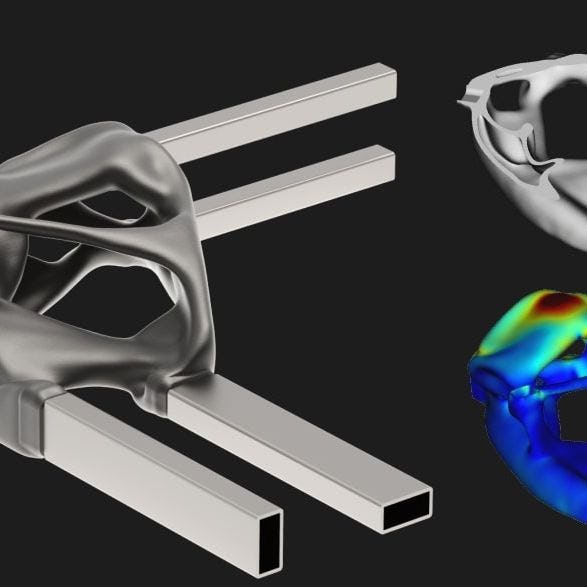

Topology optimization

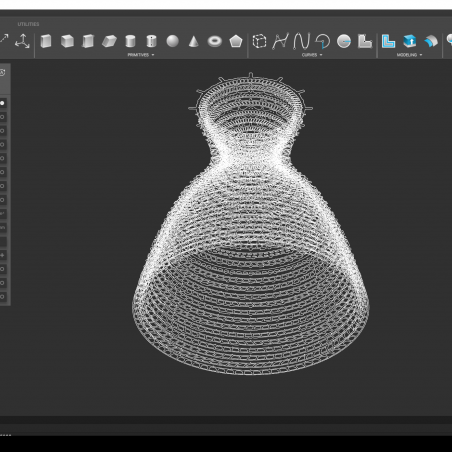

Lattice infills

Variable shelling

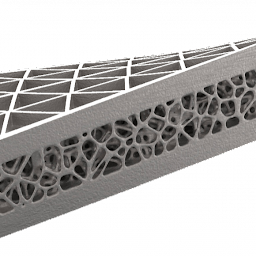

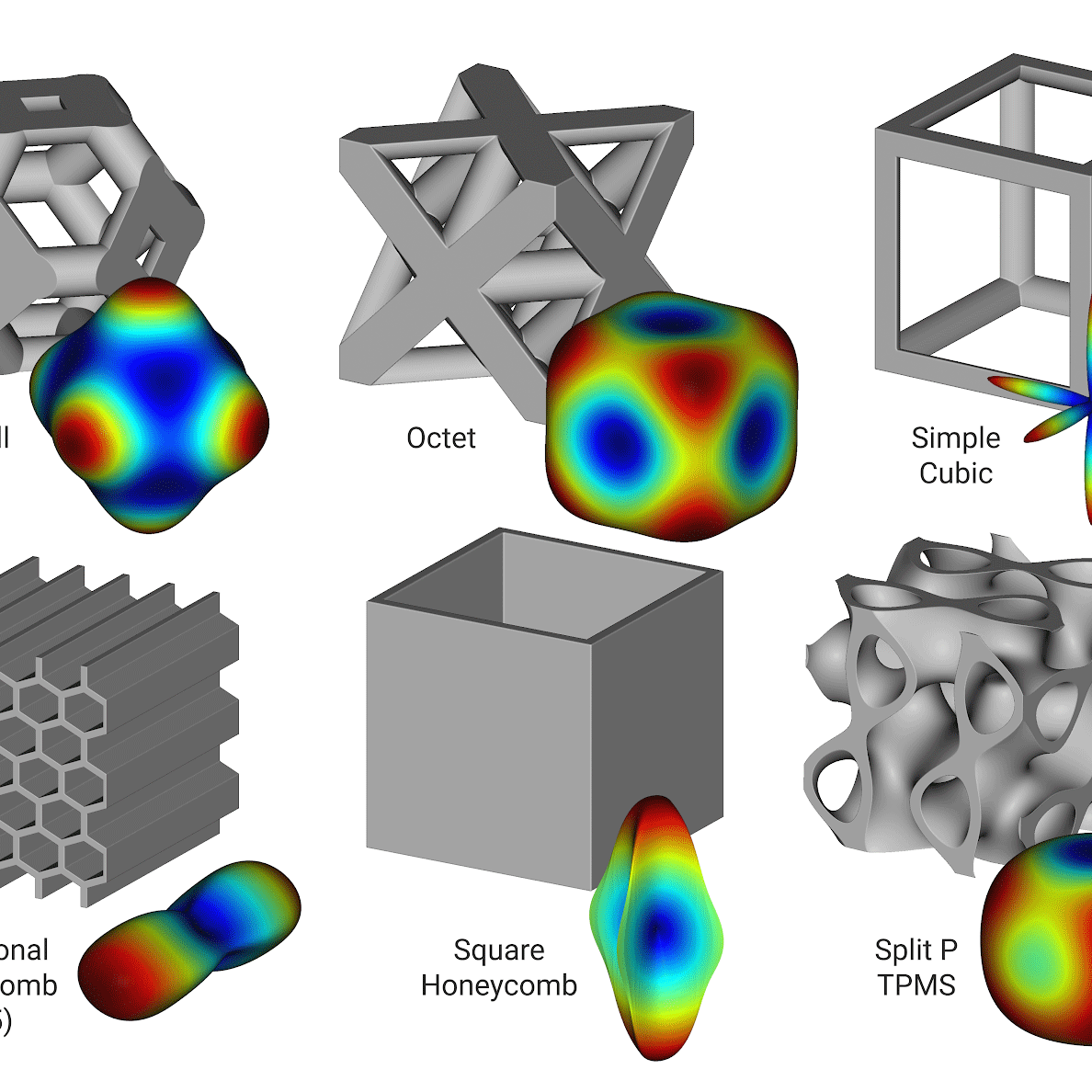

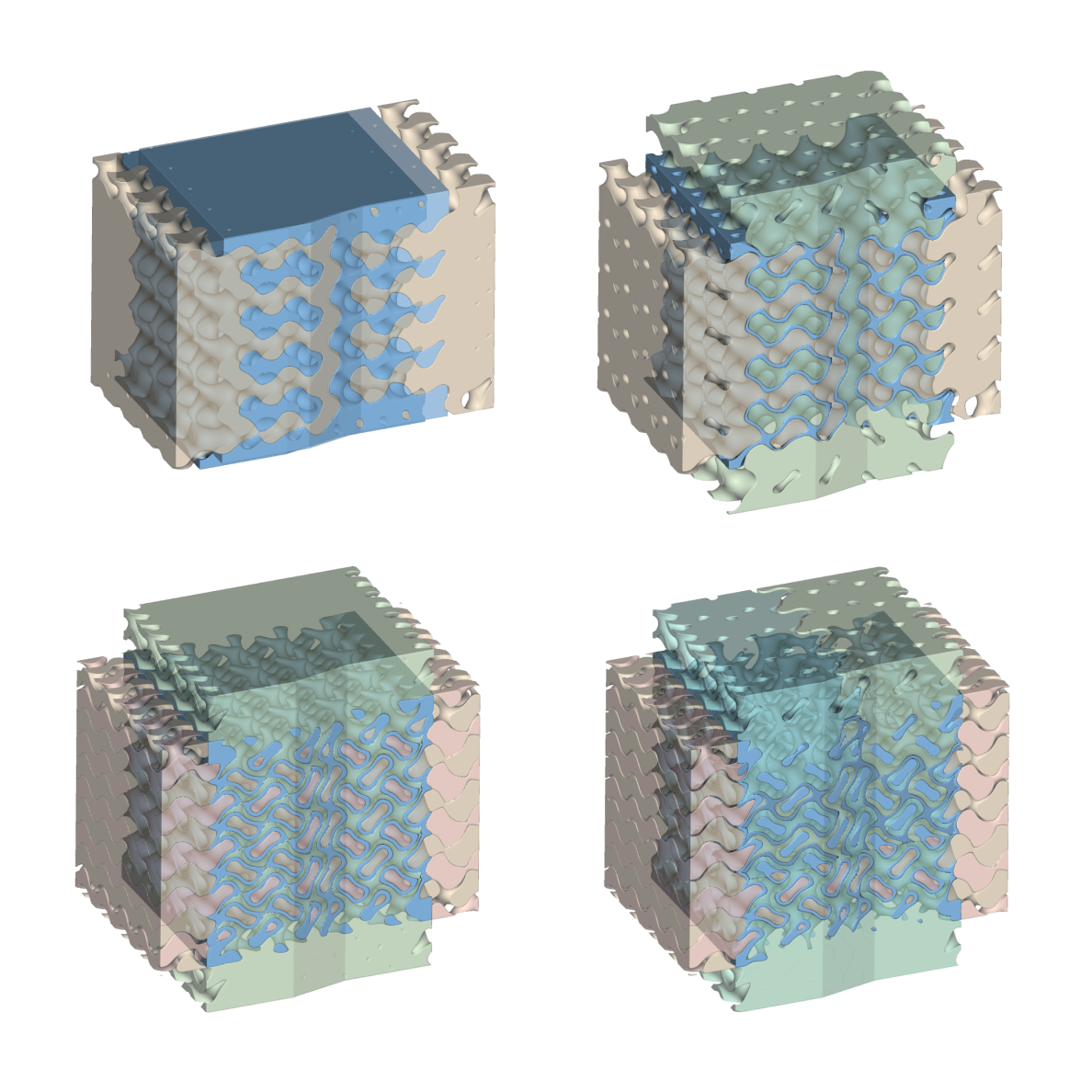

Architected materials

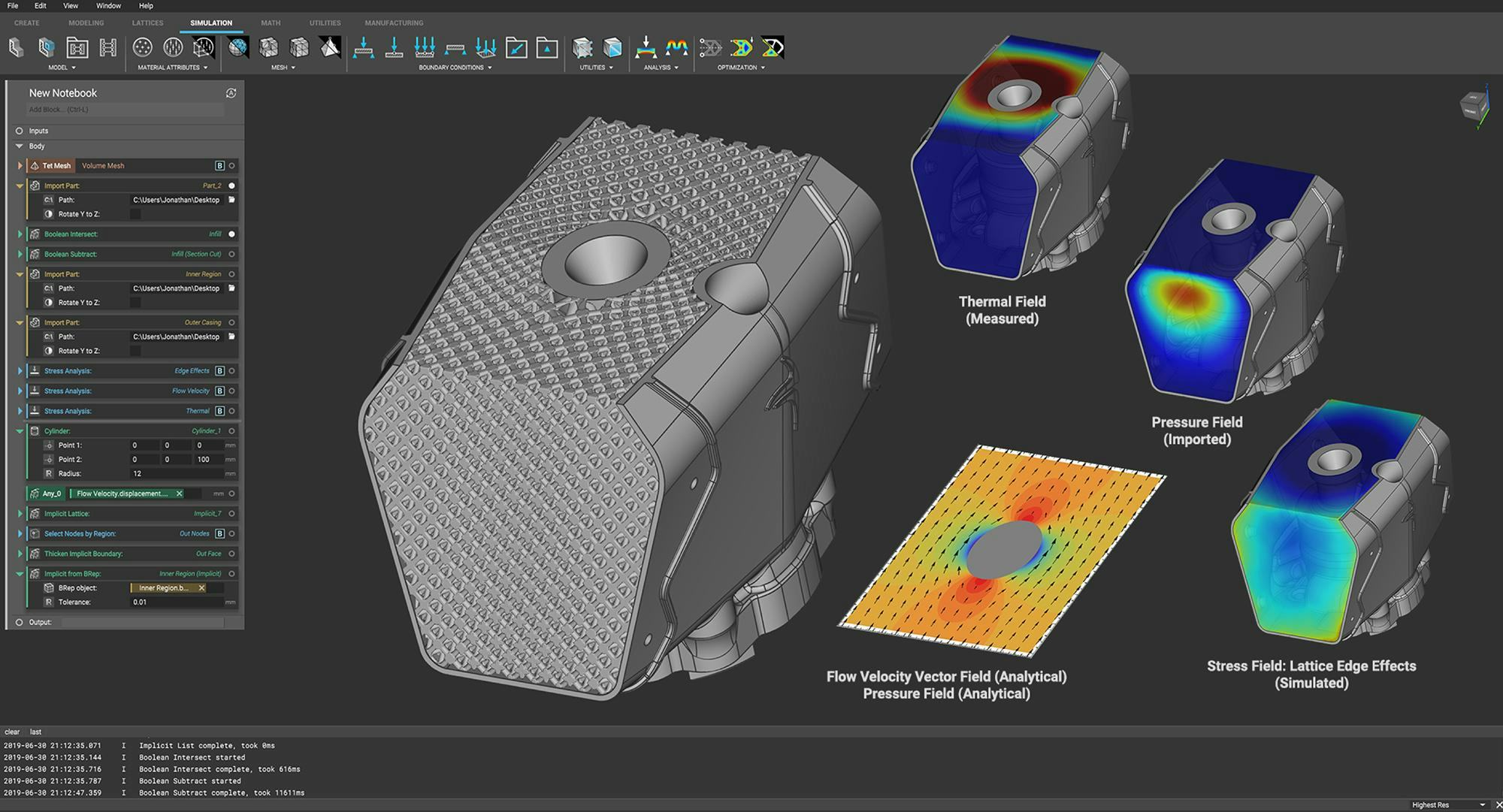

Tailor your part’s mechanical, thermal, or electromagnetic characteristics through complex geometries that could only be manufactured with 3D printing.

Tailored material properties

High stiffness sandwich structures

Multifunctional design

Rapid design exploration

Quickly generate, iterate, and optimize intricate designs that would be impossible with traditional CAD software.

Conceptual design phase iterations

Heat exchanger design and optimization

Performance-driven design

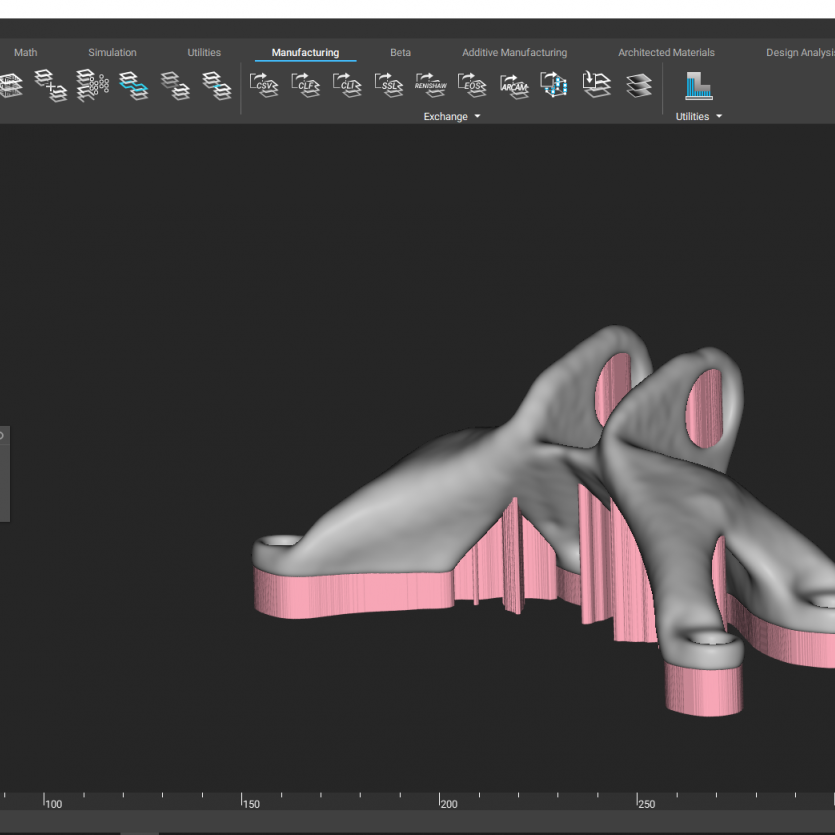

Advanced manufacturing

Improve the efficiency of additive manufacturing operations with nTop’s capabilities, from Implicit Interop to automated design for fixturing and tooling.

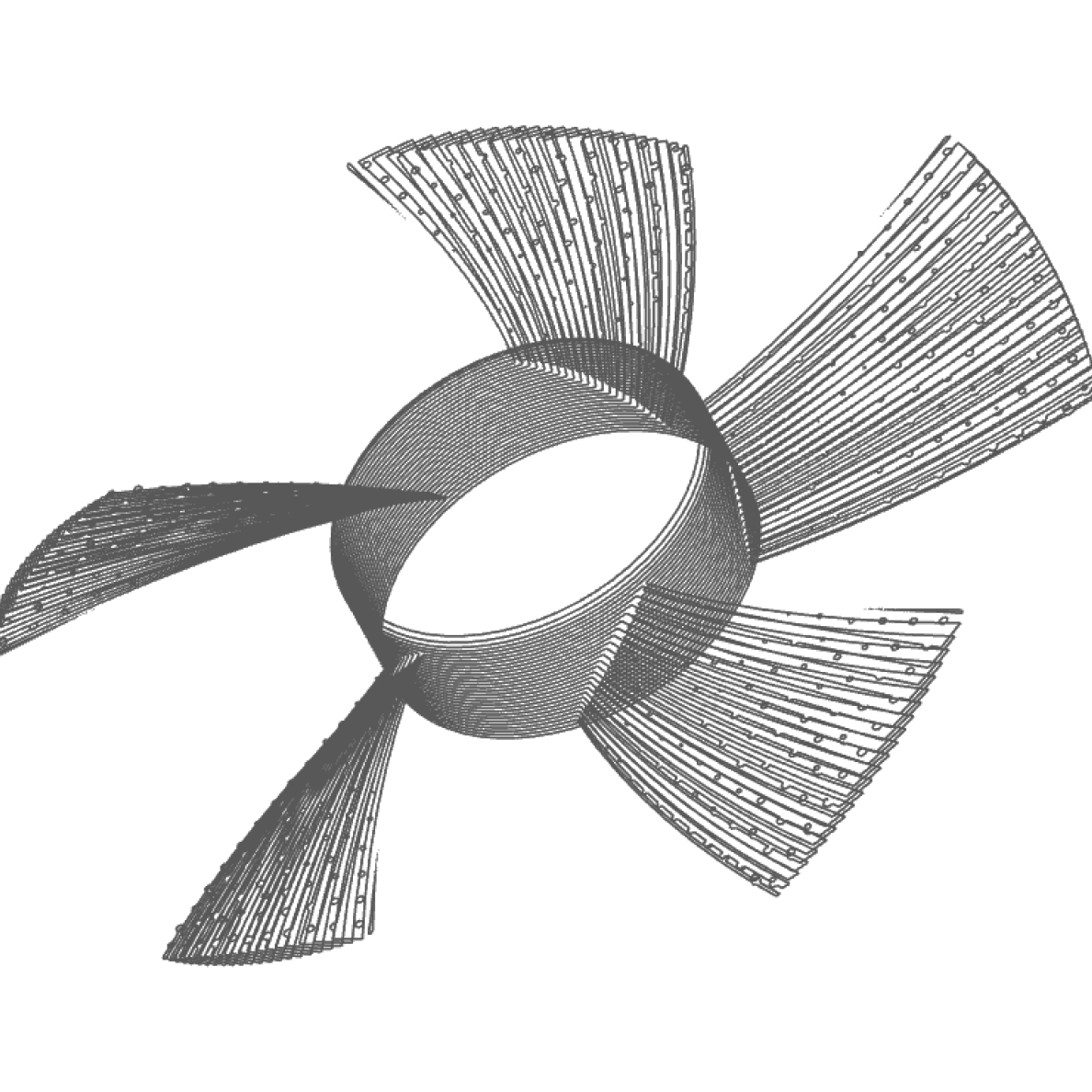

Automated composite design

Support structures

Slicing

Jig and fixture design automation

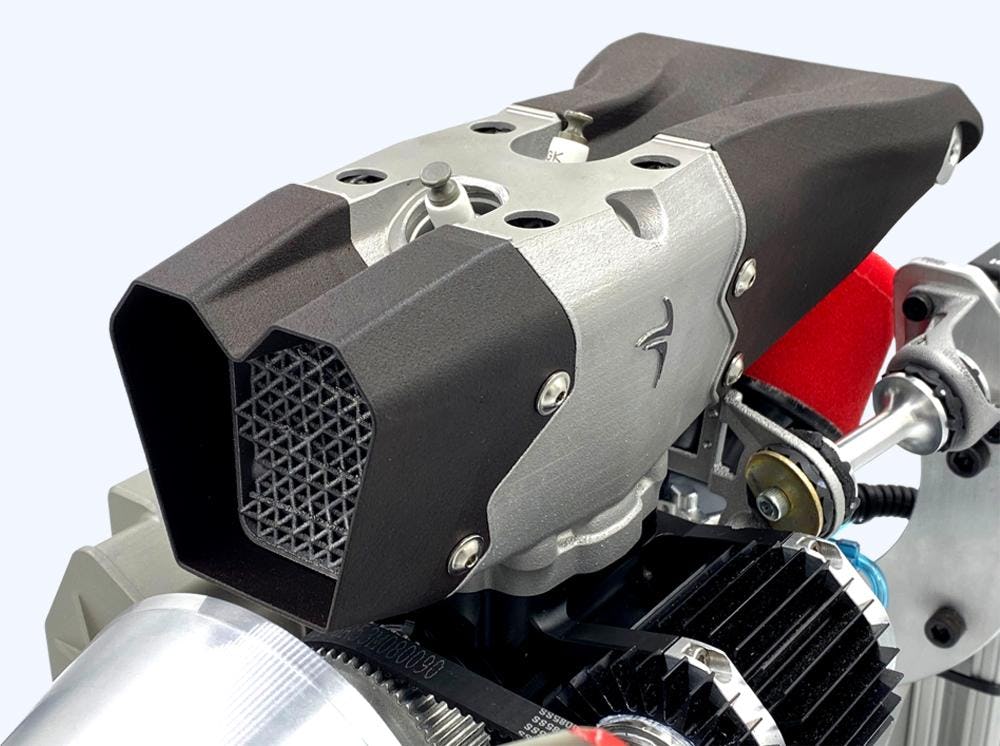

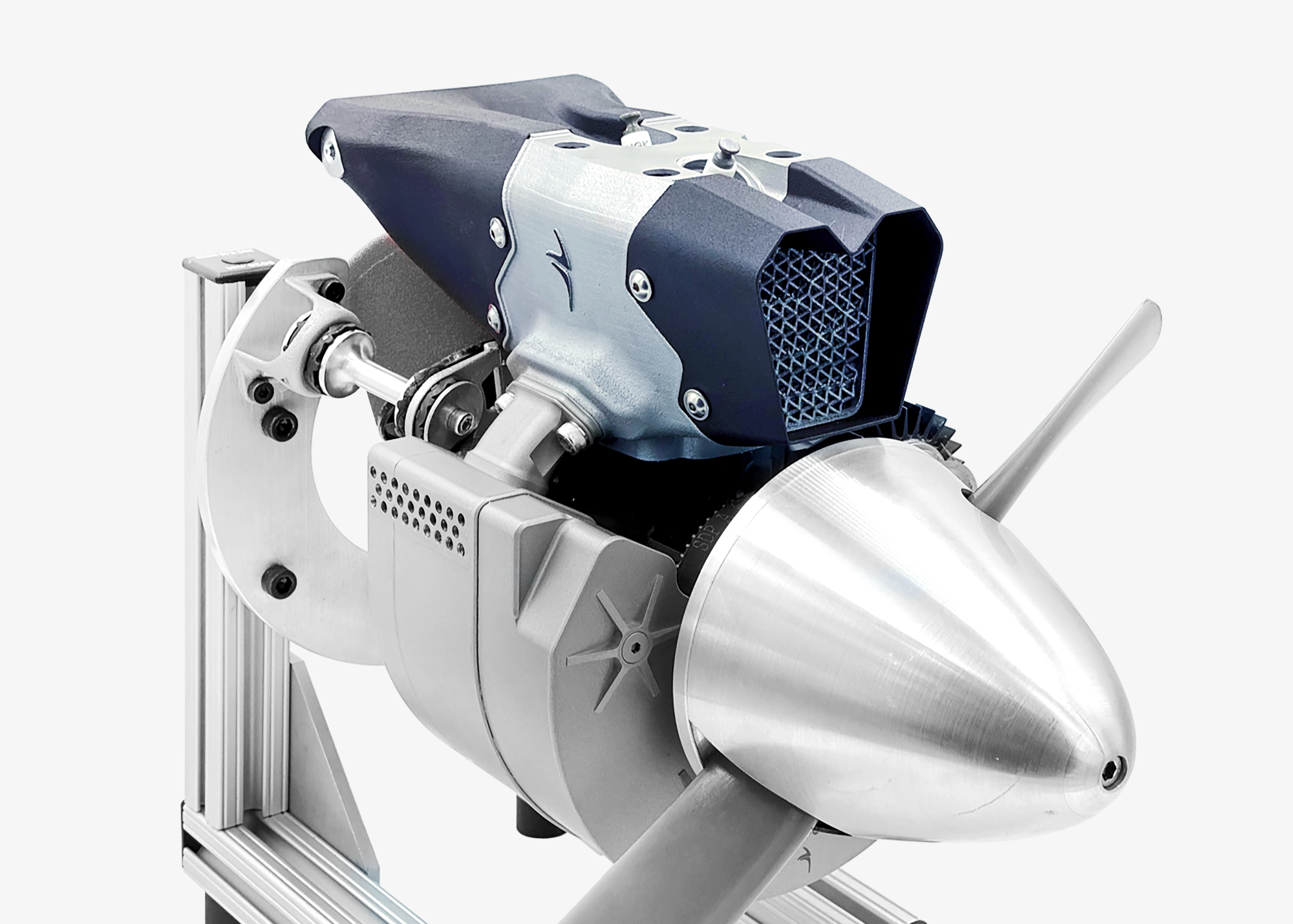

Cobra Aero reduced air-cooled cylinder weight by 50% with nTop

Cobra Aero used nTop to redesign the air-cooled cylinder of their UAV drone engines for additive manufacturing. Using conformal lattice structures, they developed an engine cylinder that is manufacturable in one piece and weighs only 420 grams.

Ready for the next step?

See for yourself why leading companies in the aerospace, automotive, medical, and consumer industries have chosen nTop as their engineering design software solution.

Related content

- VIDEO

Landing gear optimization for additive manufacturing

- VIDEO

Efficient plate-fin heat exchanger design driven for aerospace applications

- VIDEO

Select the right lattice structure using automated simulations and ranking

- VIDEO

Webinar: Rapid design of a polymer component for flight qualification

- ARTICLE

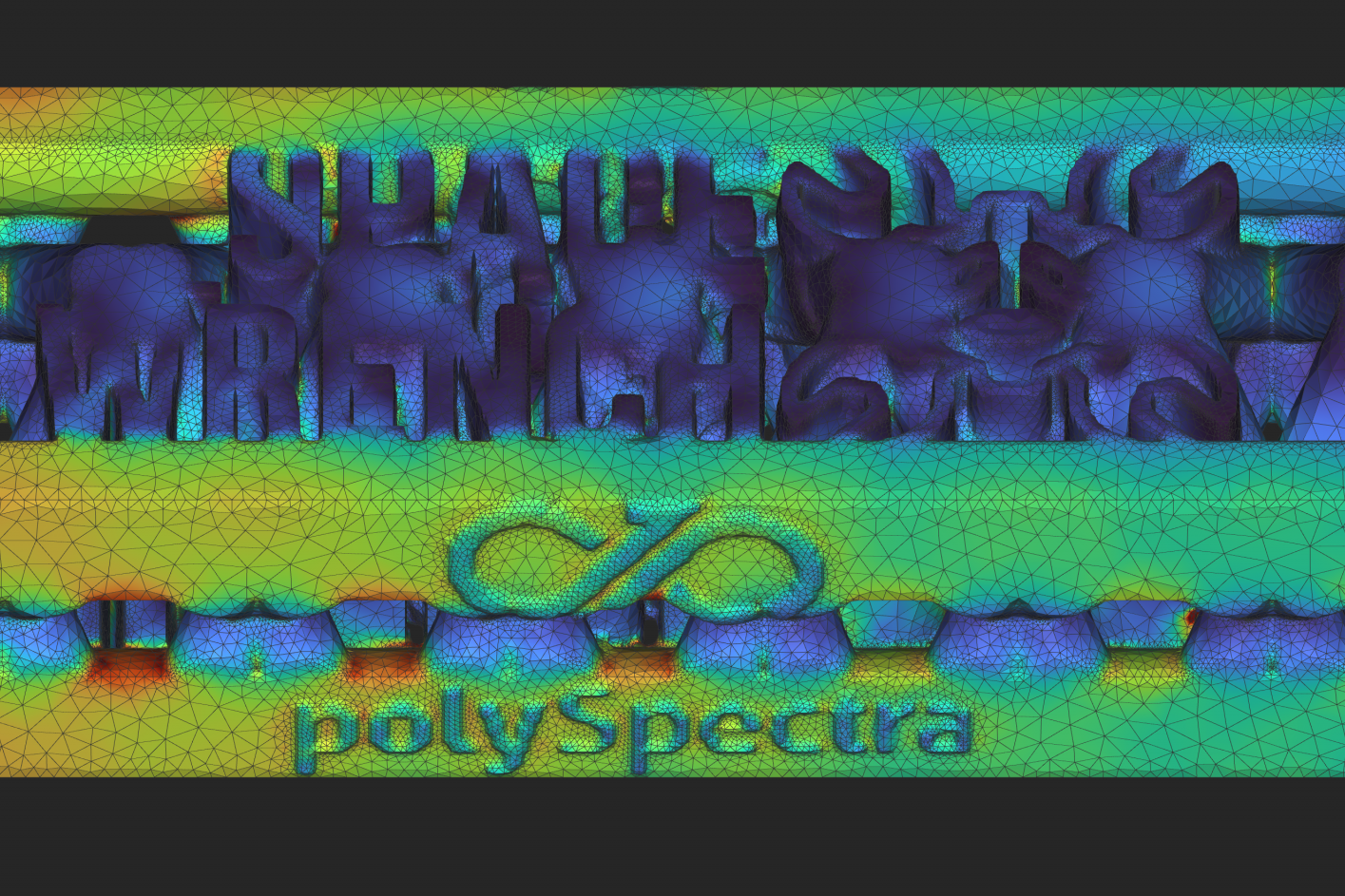

How strong is a space wrench? Finite element to failure: High-performance, real-world parts