Medical device design software

Minimize design time, automate validated workflows, and improve ergonomics with the most advanced medical device design software for additive manufacturing.

Leverage nTop’s advanced capabilities to design and develop revolutionary medical products for additive manufacturing.

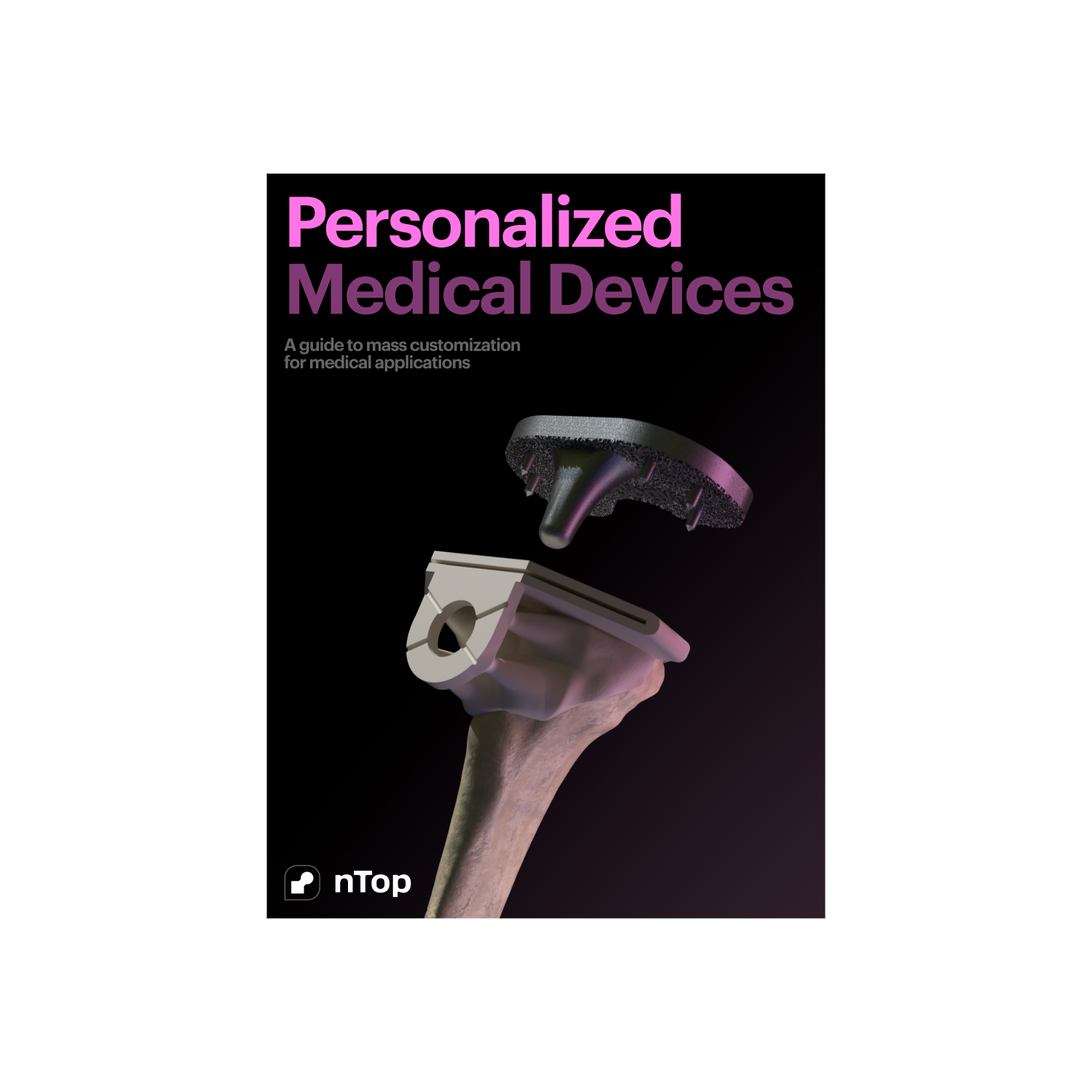

Get the Personalized Medical Devices Guide

Learn how mass customization for medical devices can be leveraged to reap many rewards for patients and medical practitioners.

Medical applications

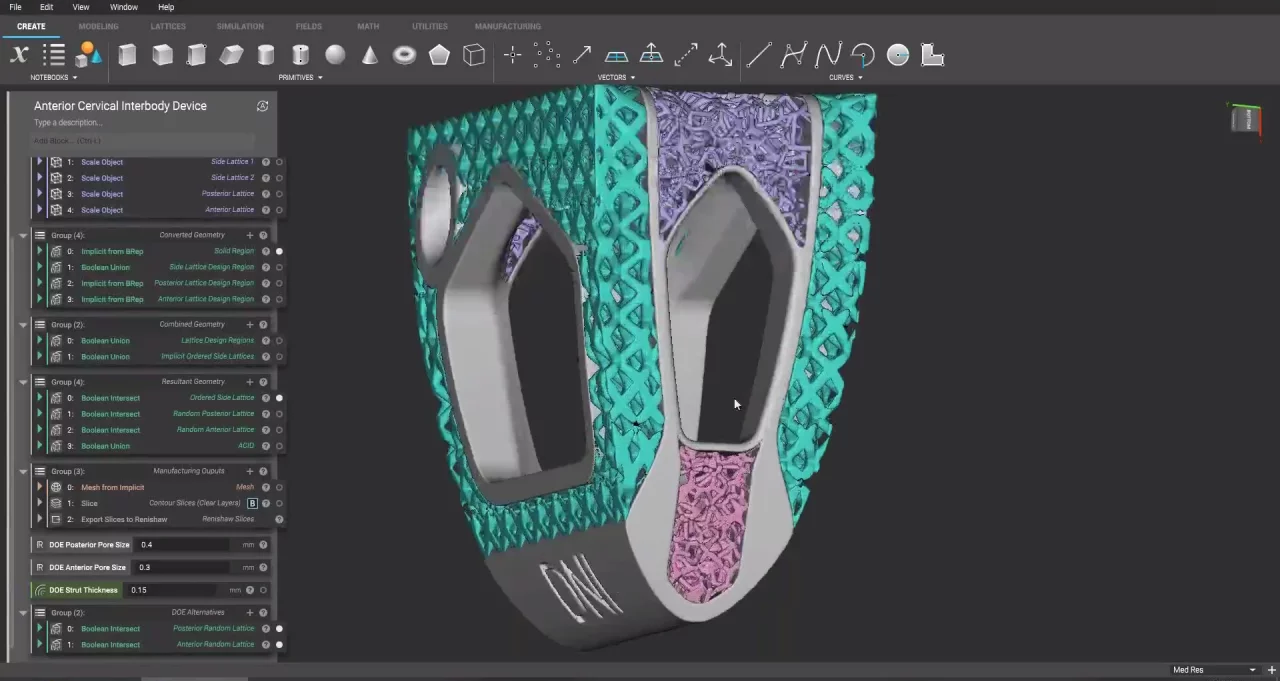

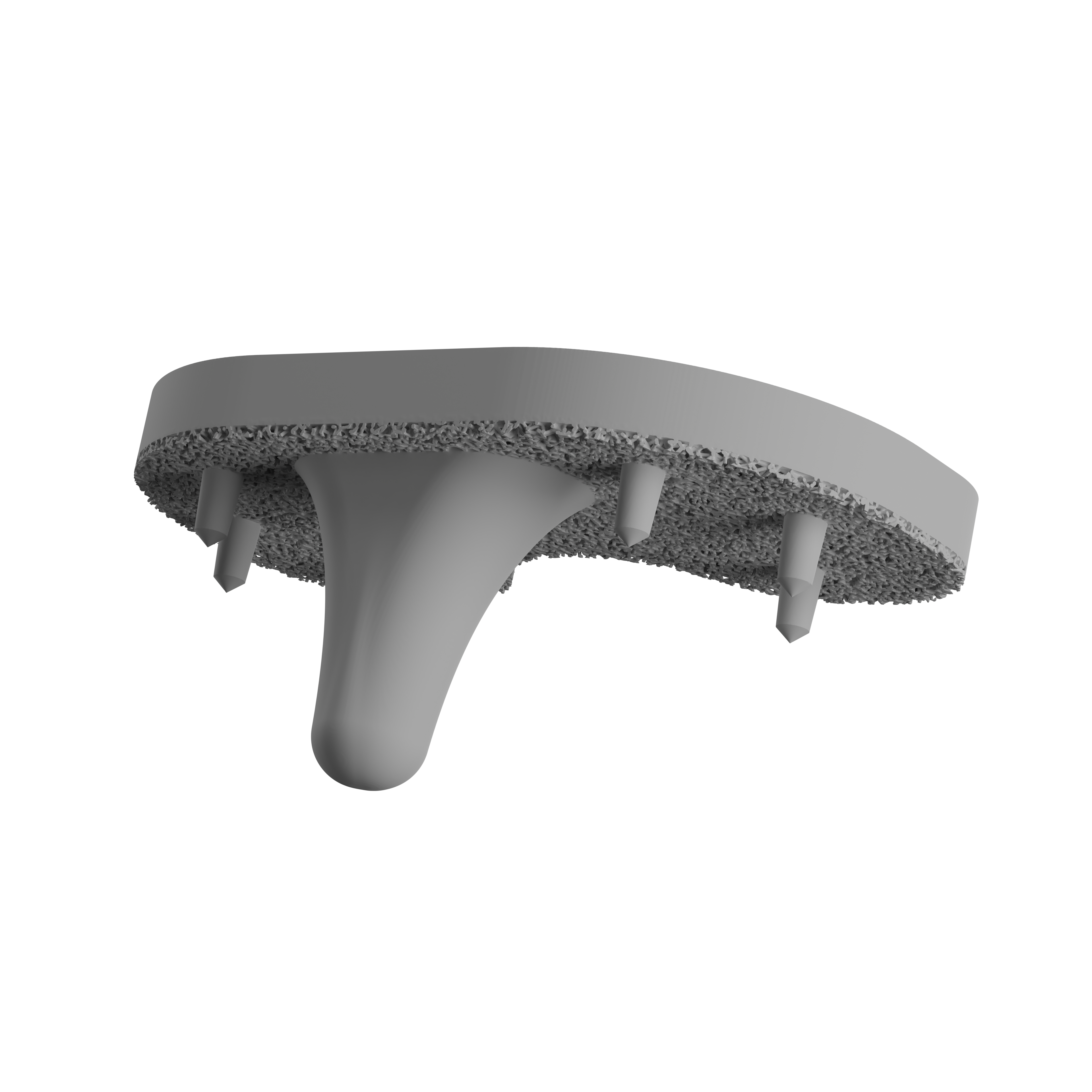

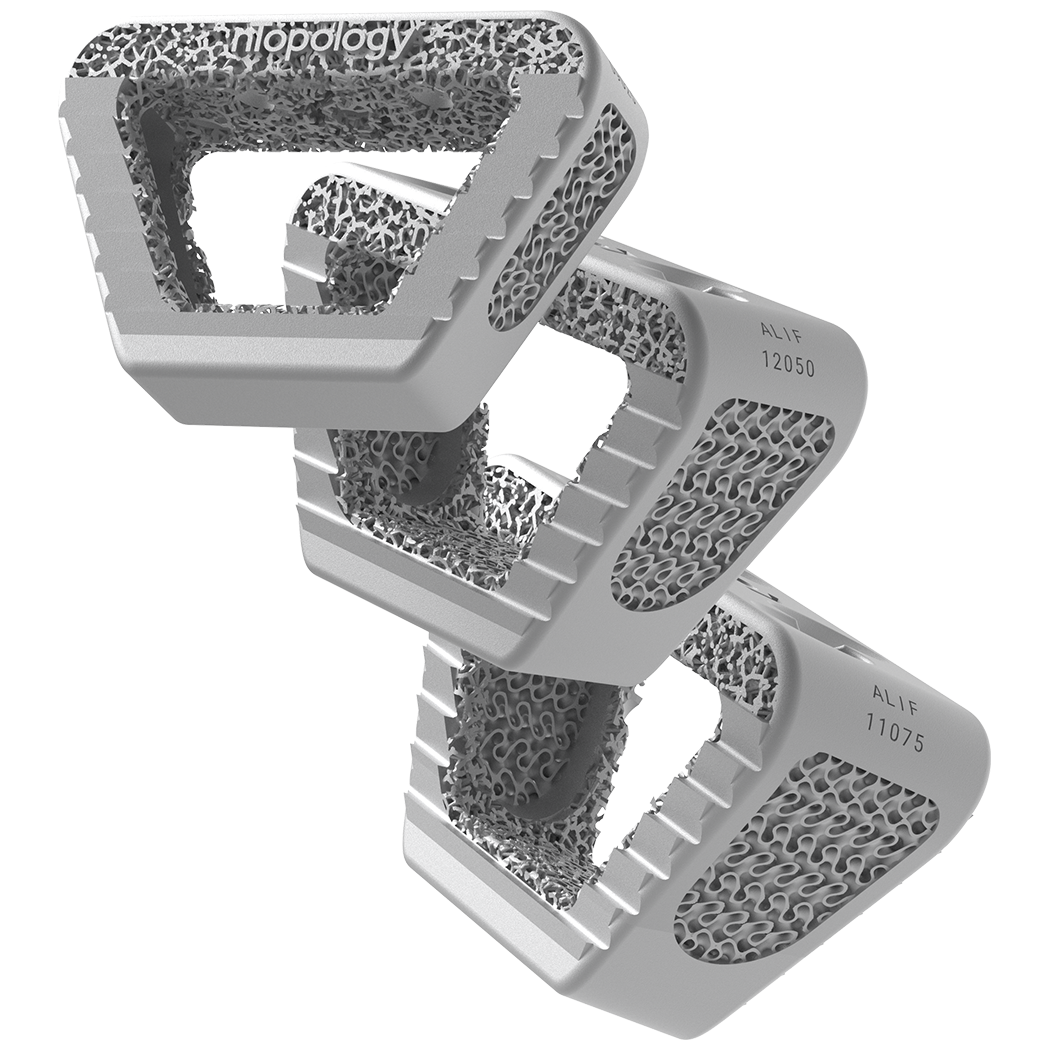

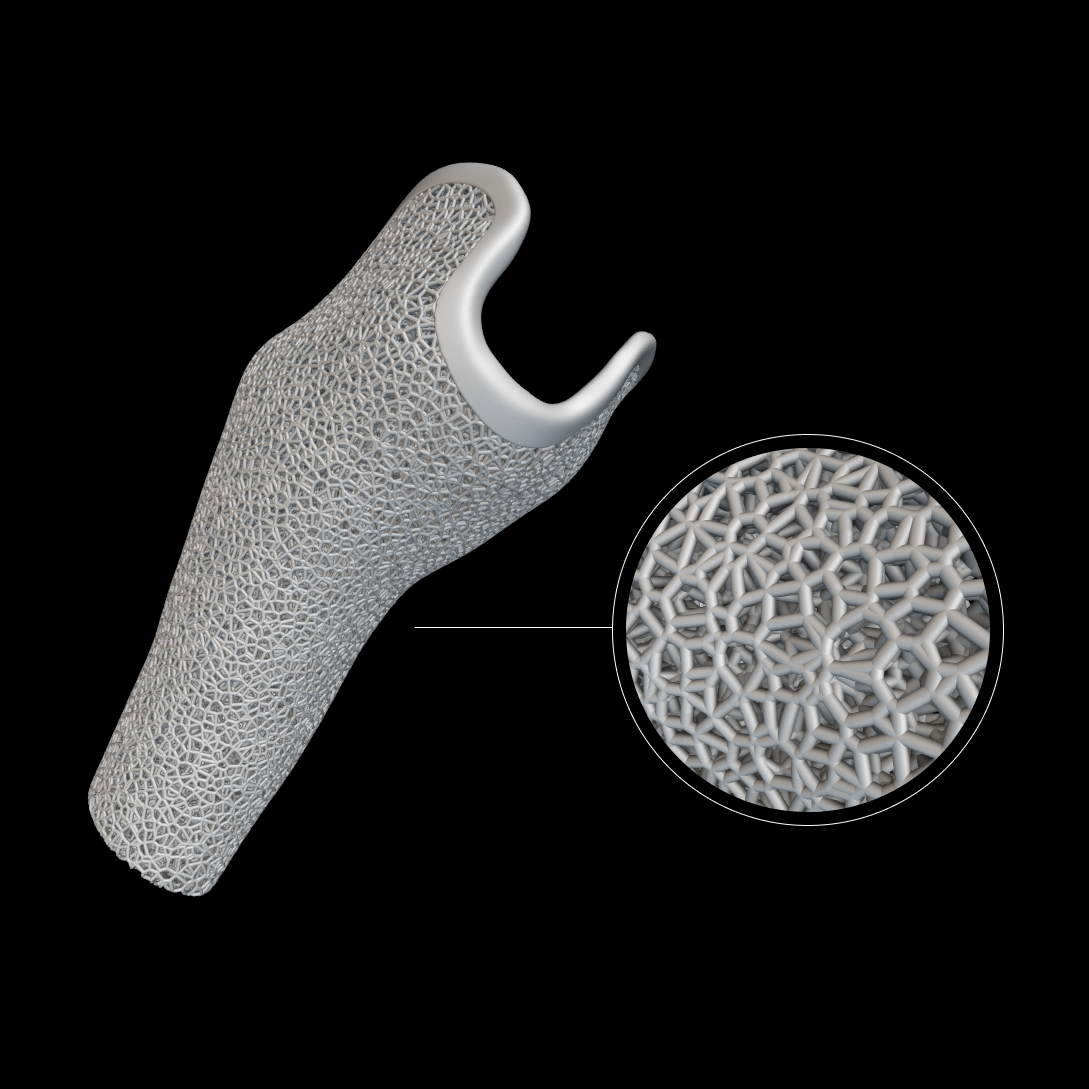

Implantable orthopedic devices

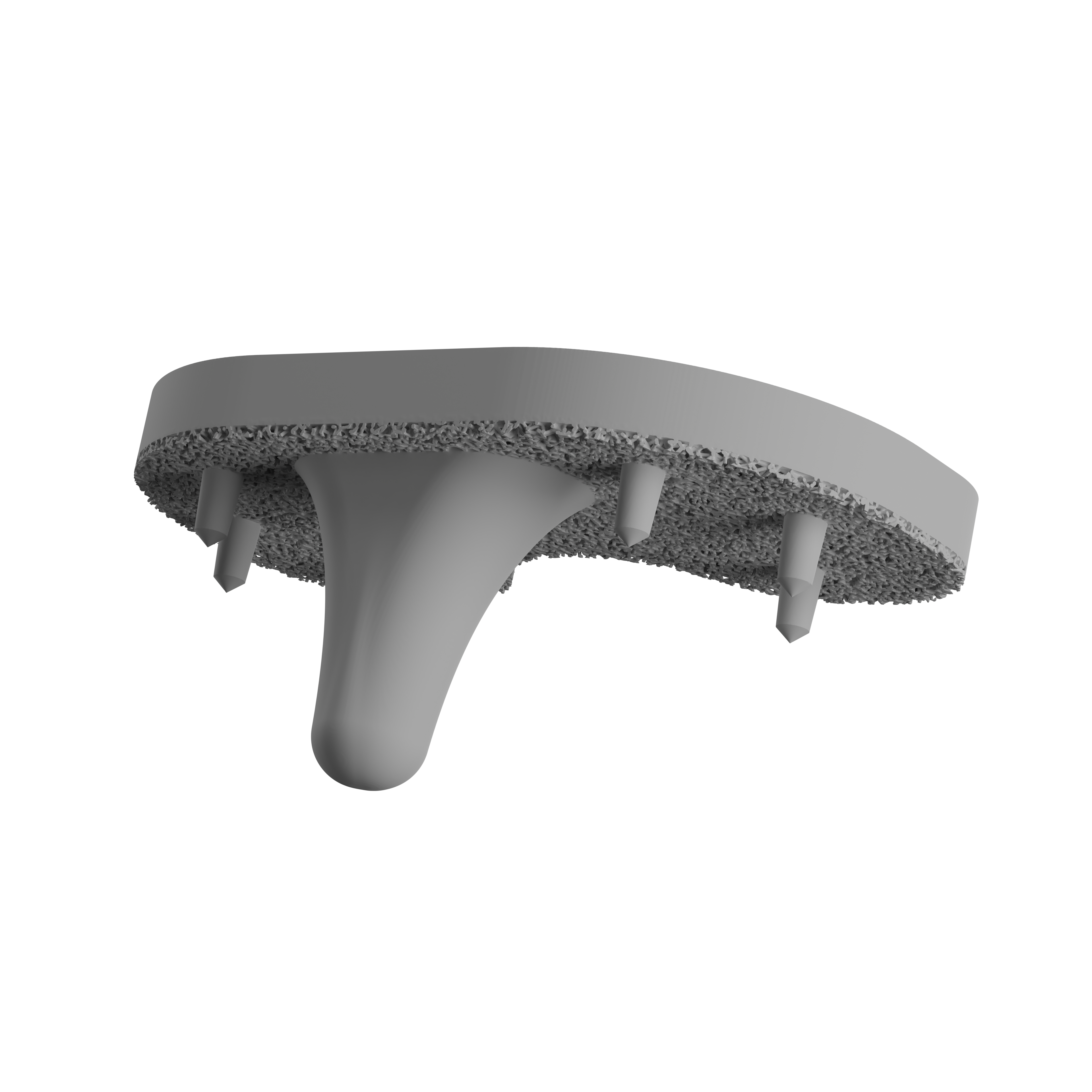

Promote osseointegration by using nTop’s unrivaled lattice generation tools to create complex structures that mimic the properties of bone.

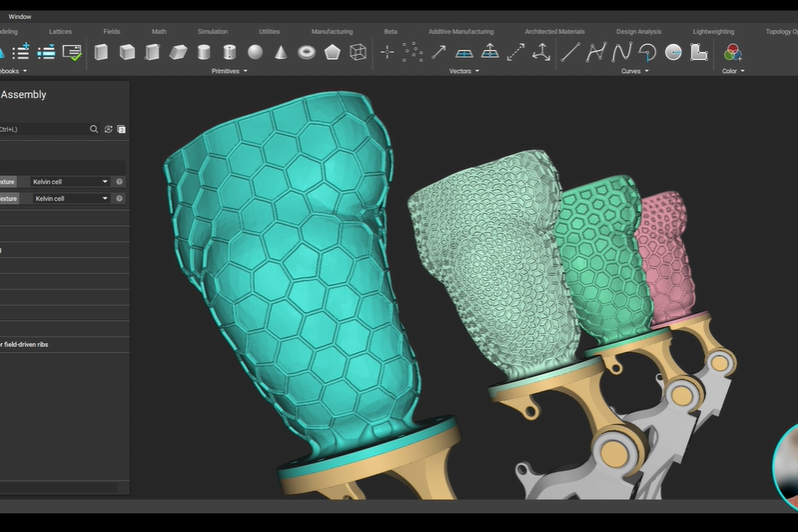

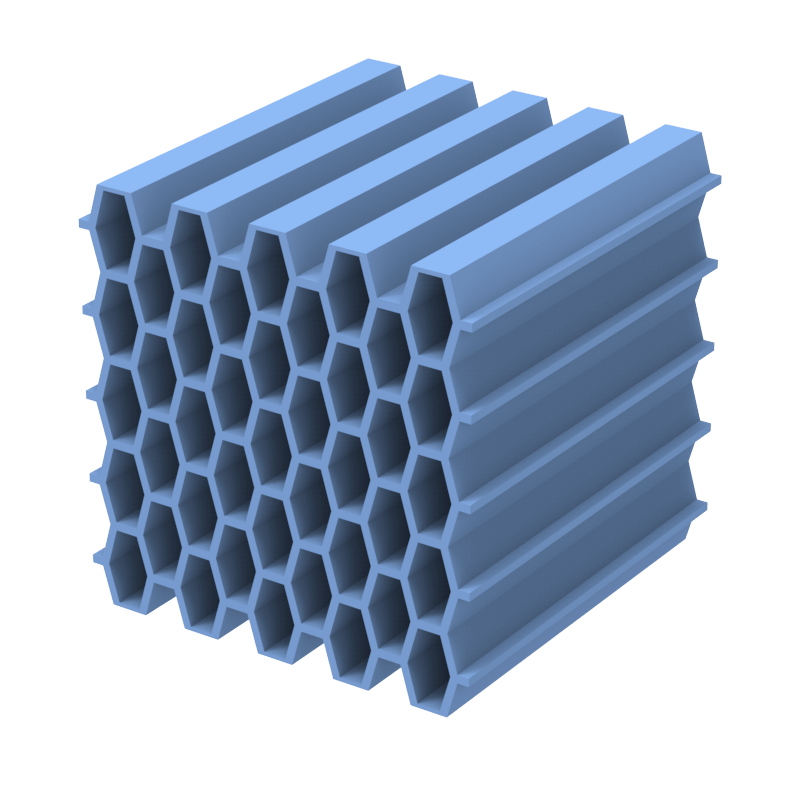

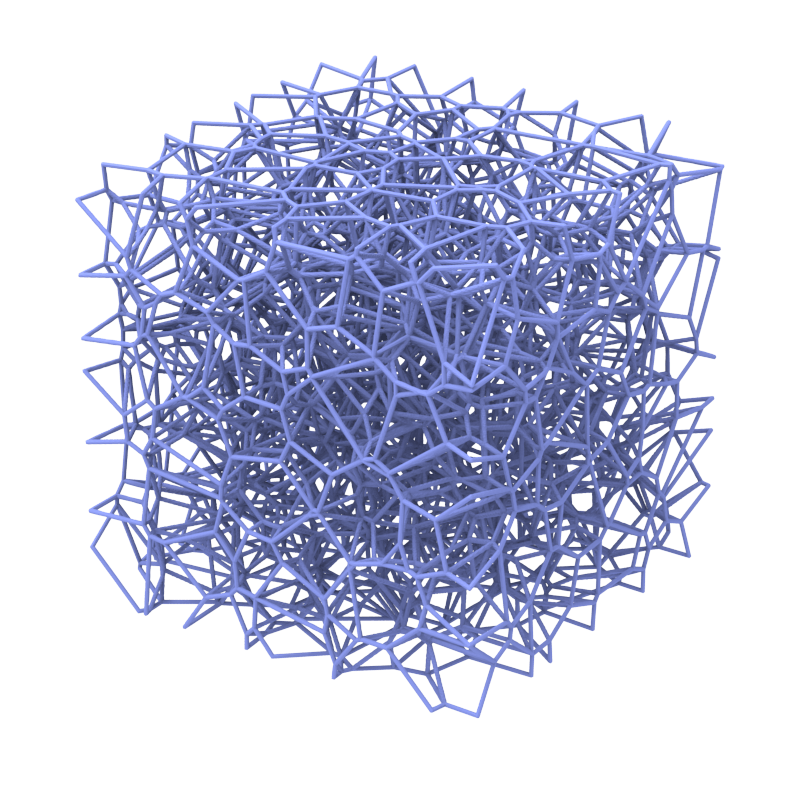

Osseointegrative surface lattices

Periodic lattice structures

Stochastic lattice structures

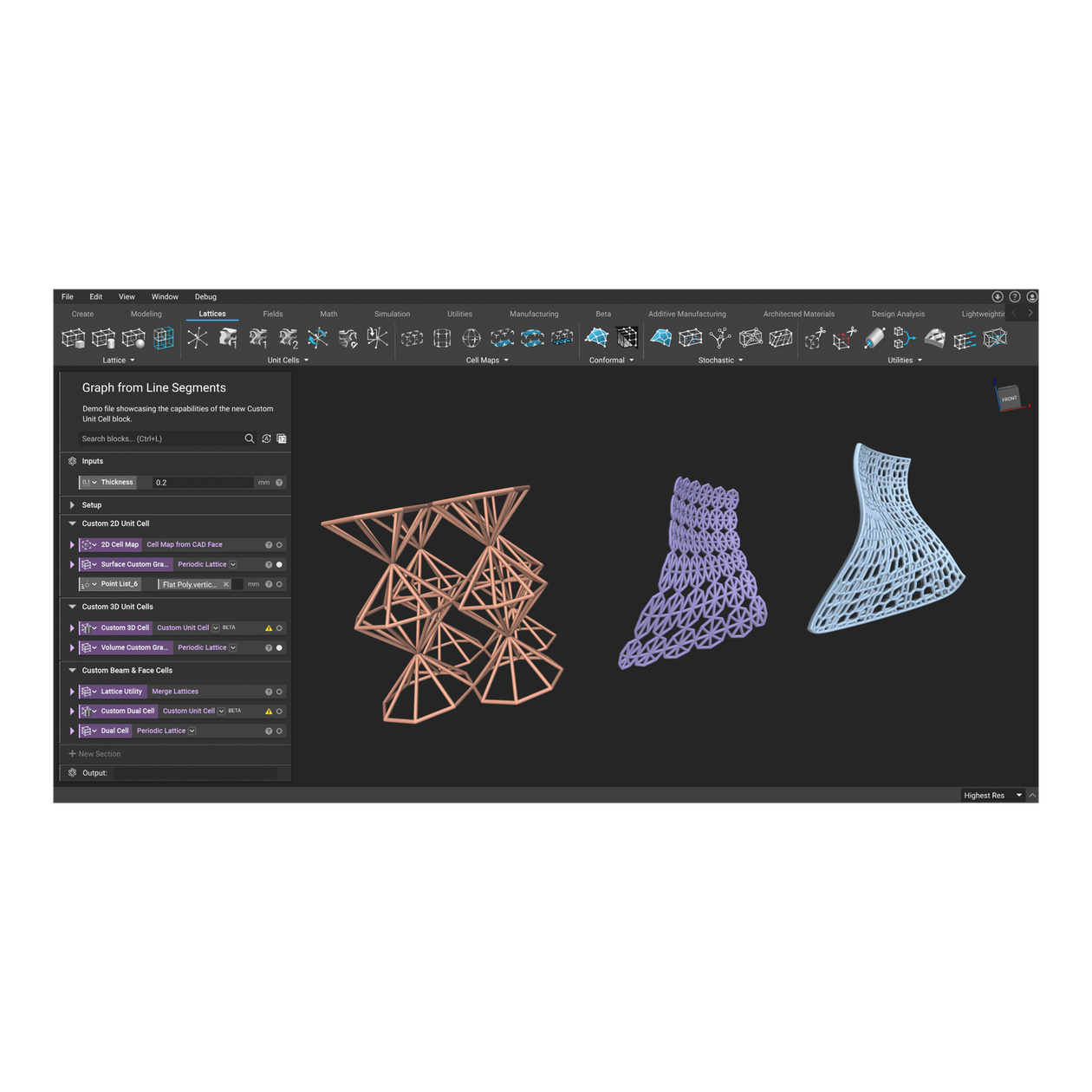

Custom lattice unit cells

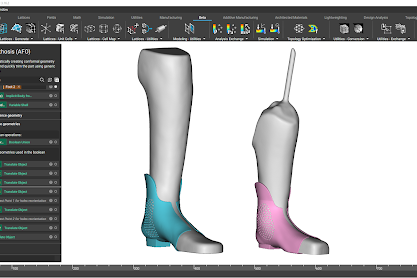

Patient-specific solutions

Improve outcomes by leveraging patient-specific data to automatically generate customized devices.

Patient-specific scan data

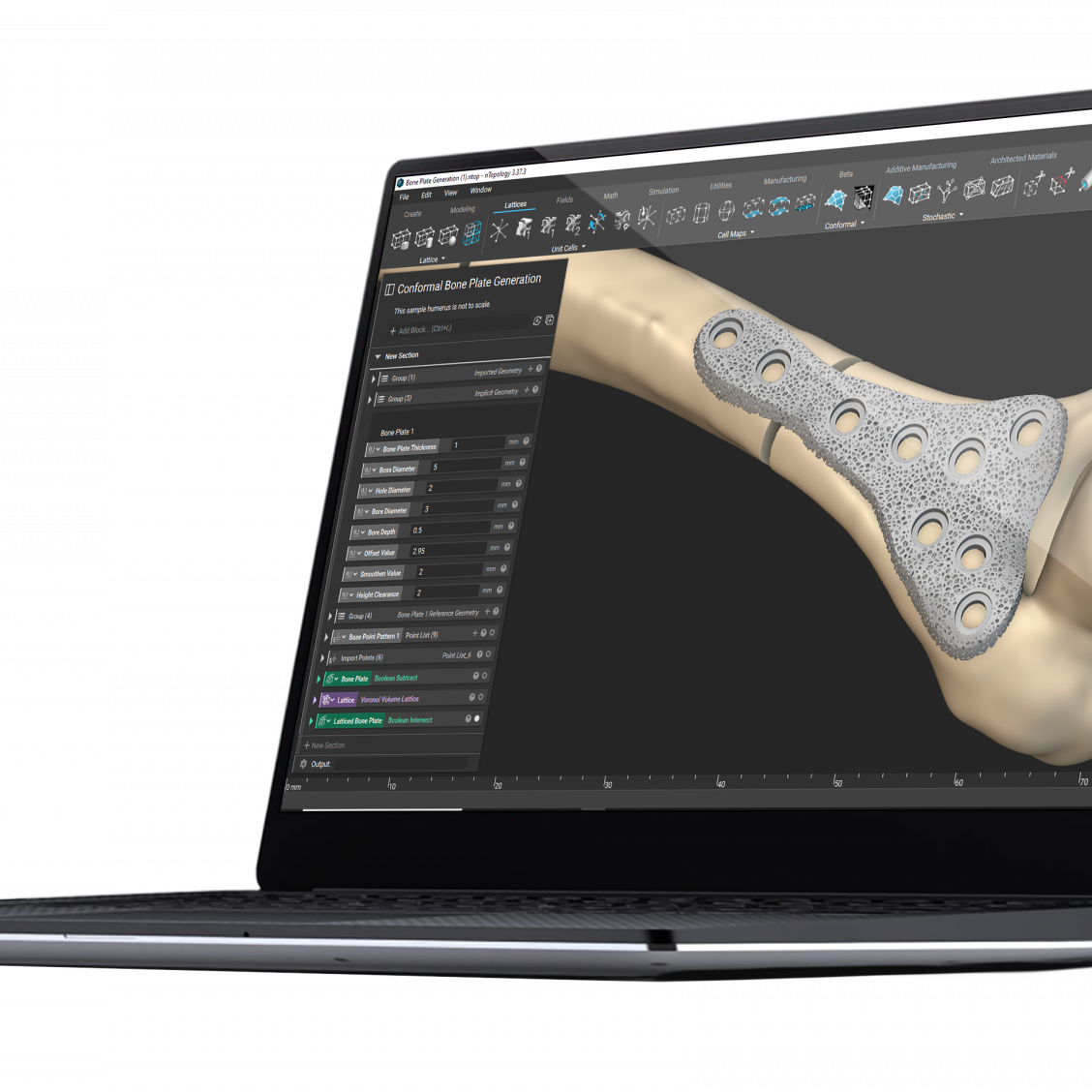

Conformal device design

Mass customization

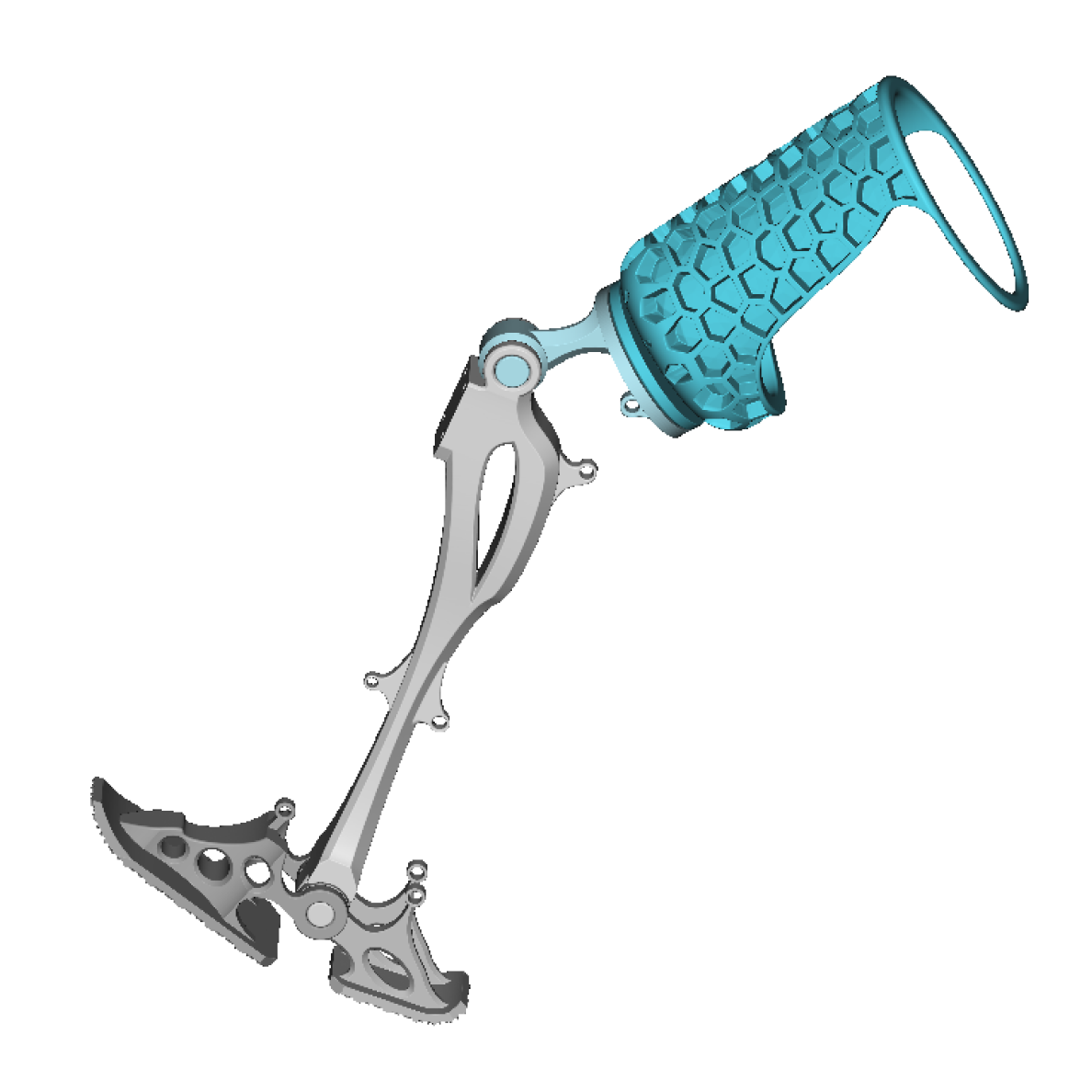

Ergonomics, comfort, and aesthetics

Design more comfortable, better-looking medical devices with nTop’s next-generation suite of tools.

Lightweighting

Surface texturing

Foam replacement

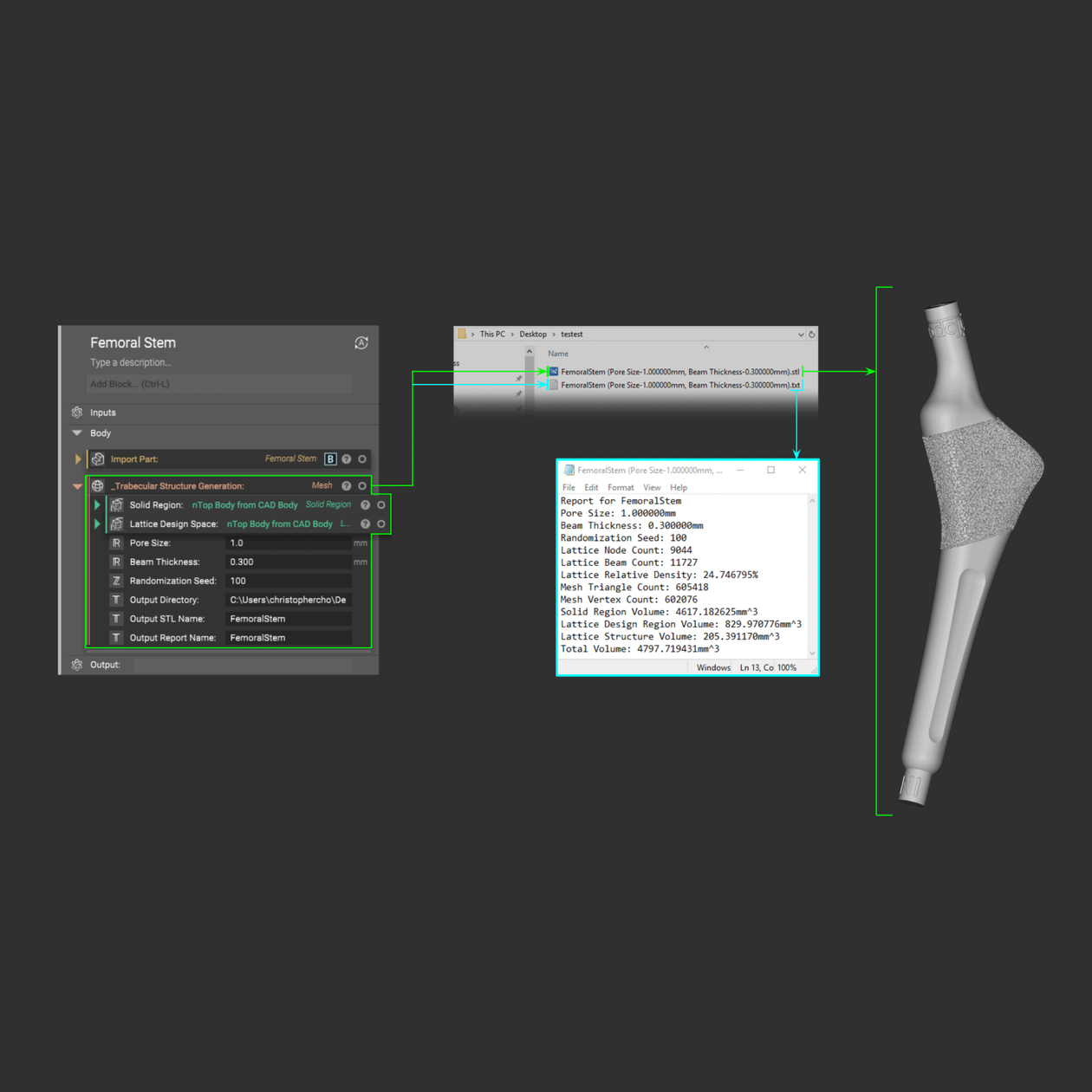

Workflow automation

Create repeatable workflows that can be batch processed to save engineering time and eliminate manual errors.

Design of experiments

Batch processing

Process reporting

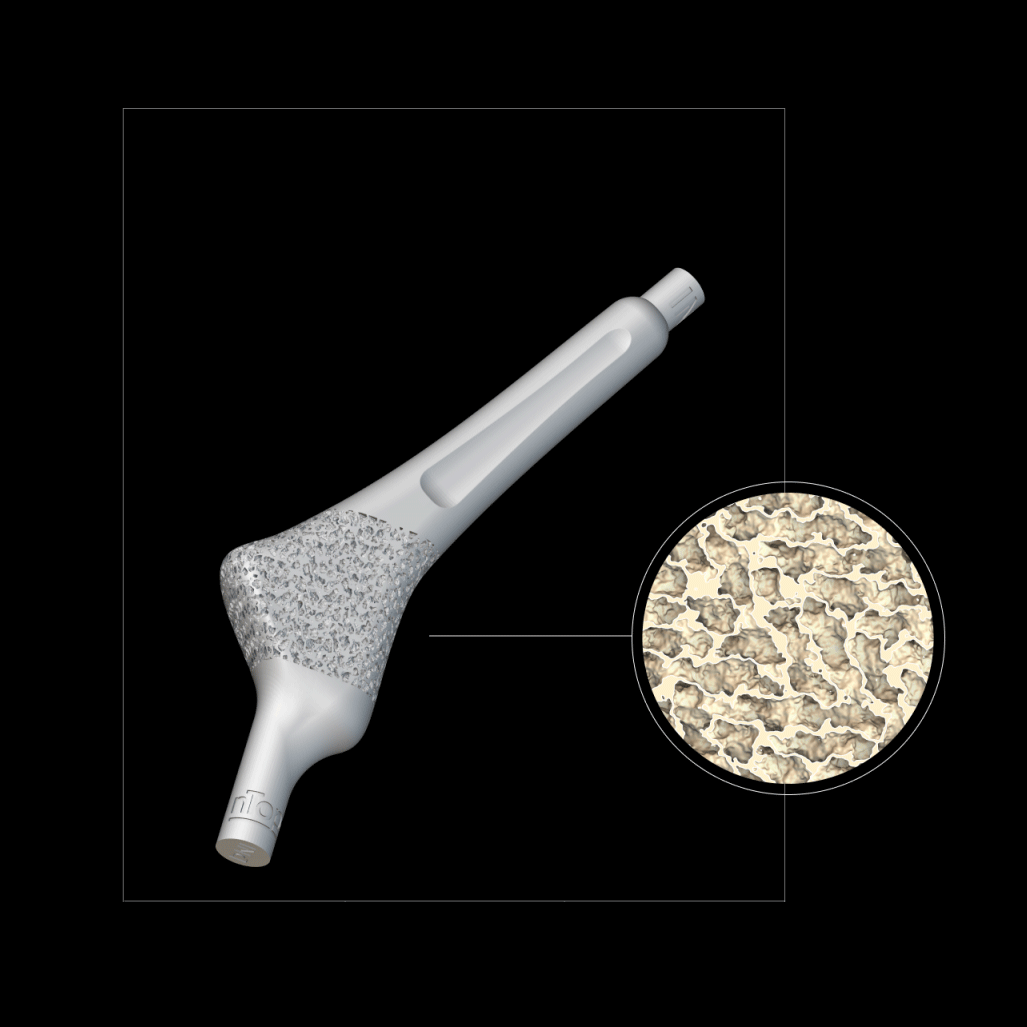

IMR and Renishaw streamline the additive manufacturing of spinal implants

The engineers of Irish Manufacturing Research (IMR) and Renishaw used nTop to develop a new additive spinal implant that uses a porous lattice design to promote osseointegration. The implant is easier to print thanks to field-driven design and reusable workflows.

Related resources

Ready for the next step?

See for yourself why leading companies in the medical devices industry have chosen nTop as their engineering design software solution.