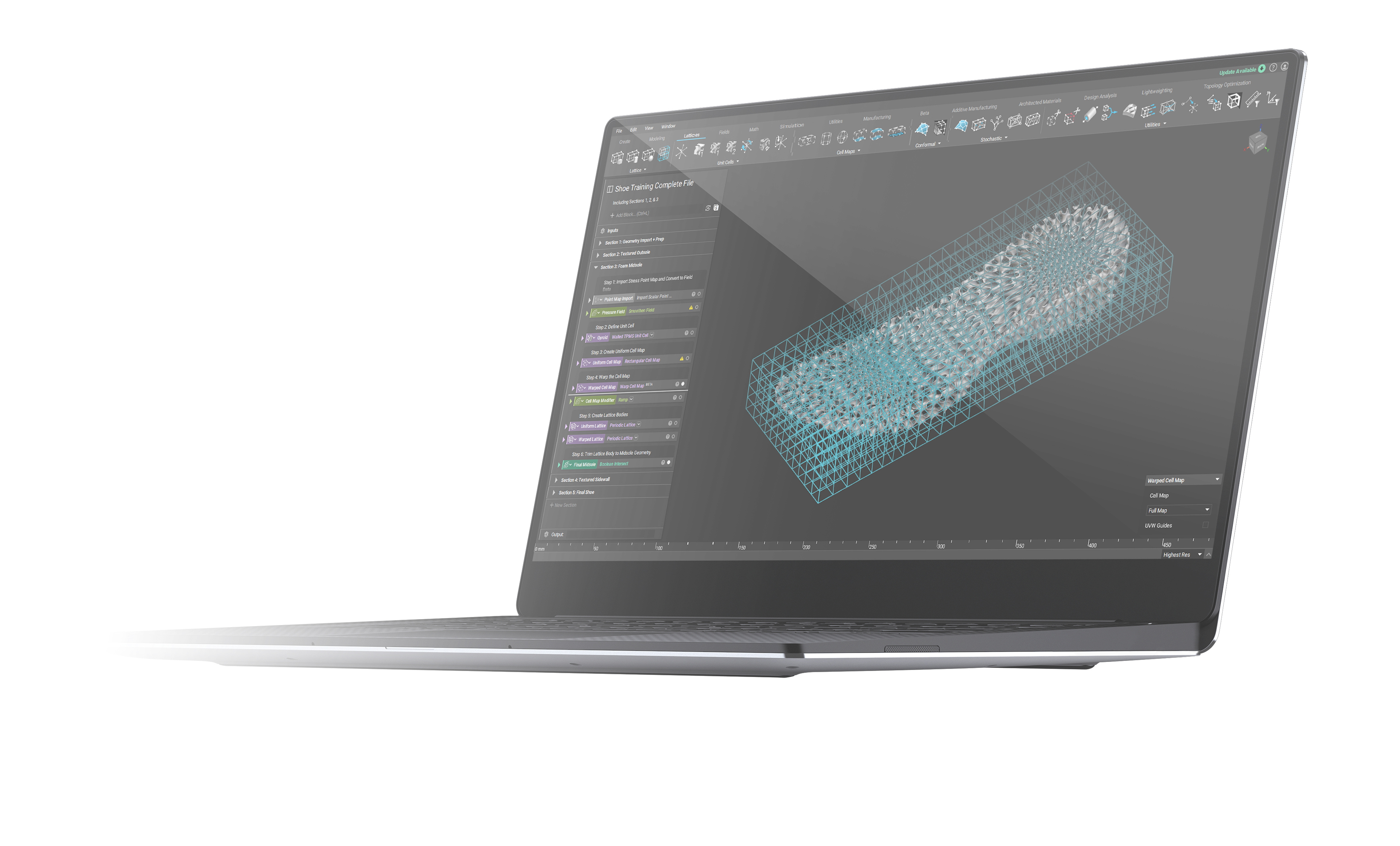

Lattice generation software

Achieve next-level performance with the most comprehensive toolset for lattice design and optimization.

Why use nTop for lattice structures?

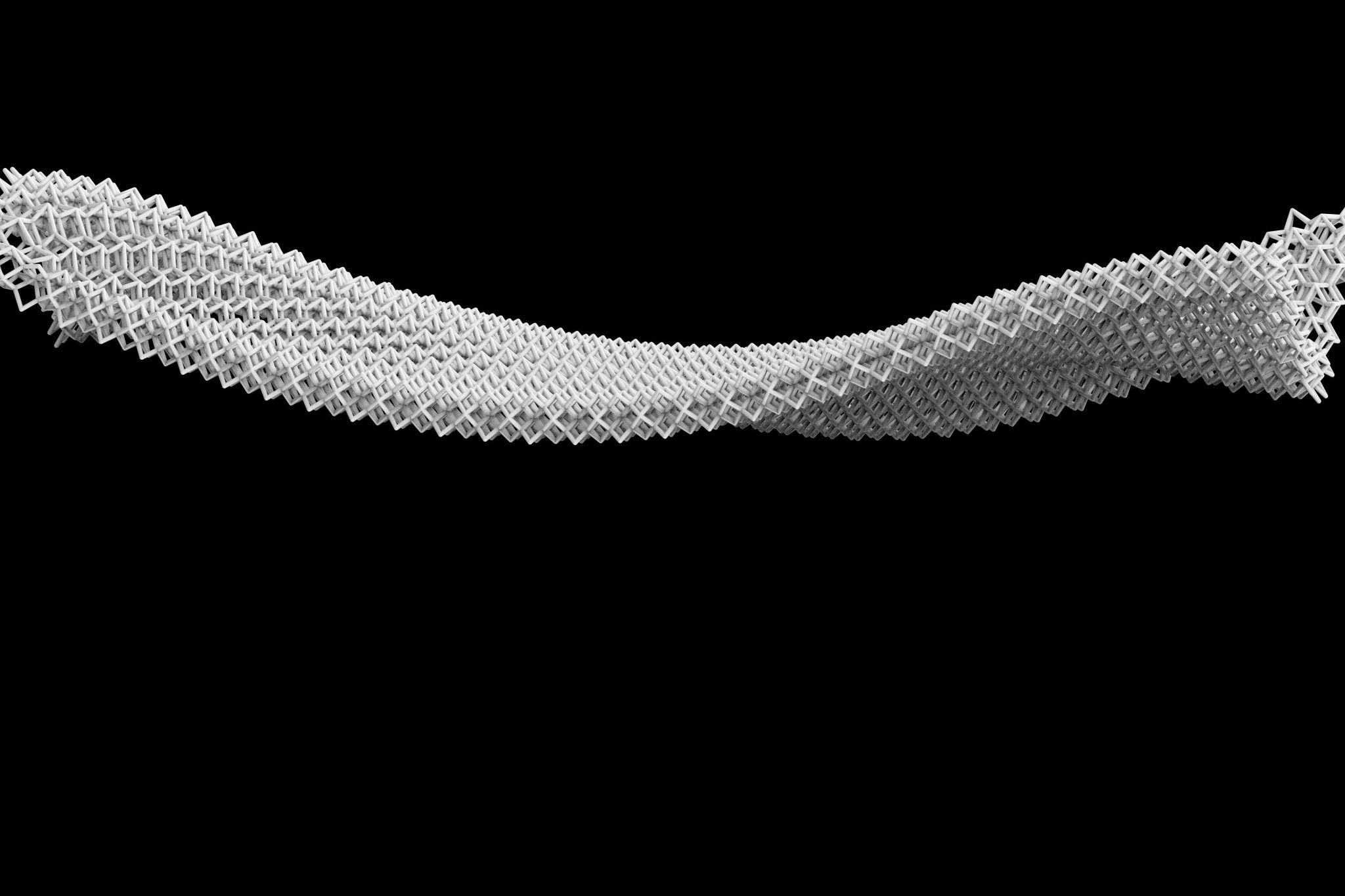

Lightning-fast lattice generation

Generate complex, scalable lattice structures, with variable thickness and smooth transitions, in seconds.

Complete control over lattice design

Control and fine-tune lattices for performance or aesthetics using field-driven design.

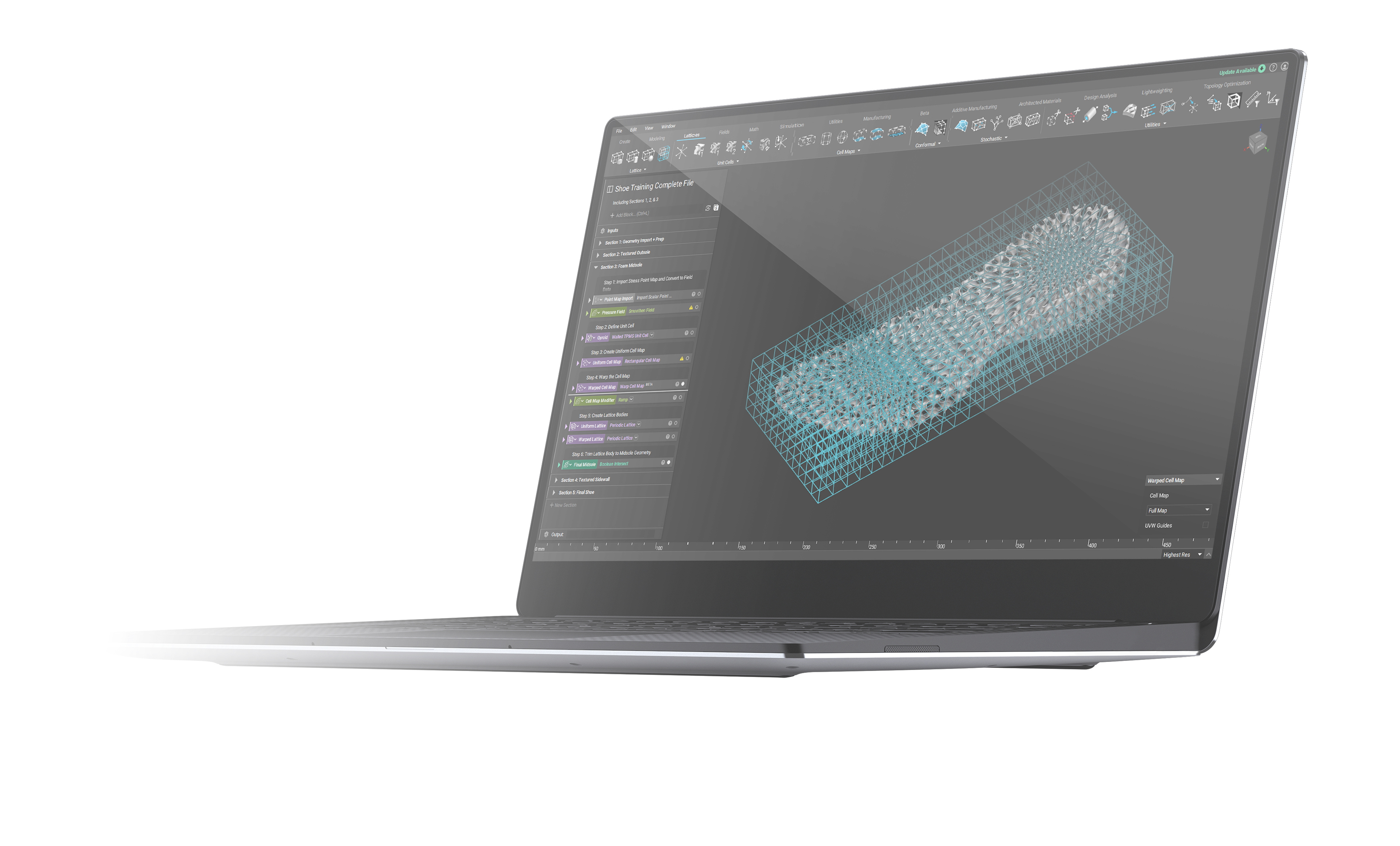

Robust and reusable design processes

Reuse and automate design workflows to accelerate your process and scale.

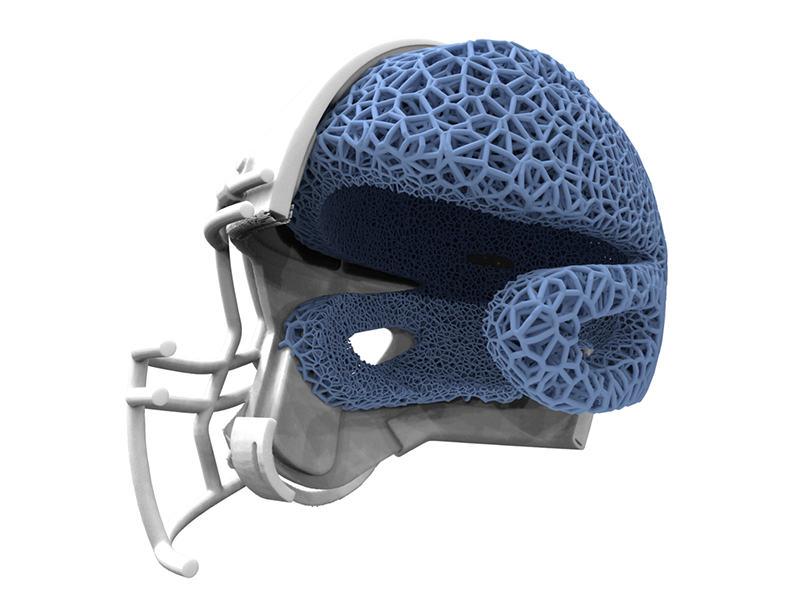

Applications of lattice structures

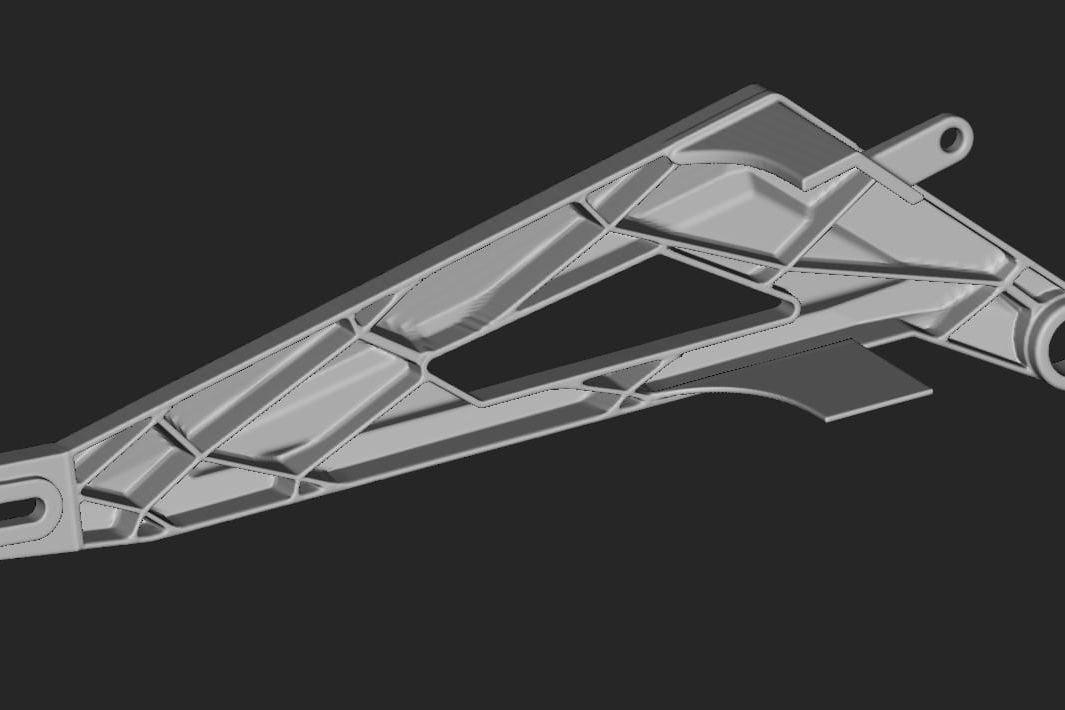

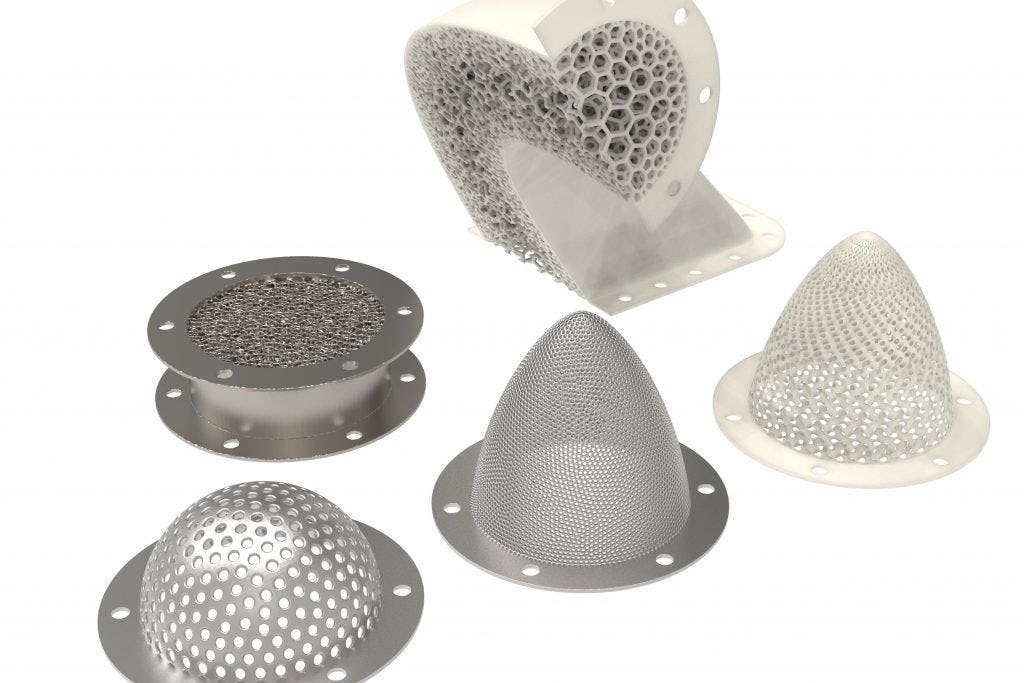

Engineers use lattice structures across many applications to design innovative parts with tailored mechanical or thermal properties.

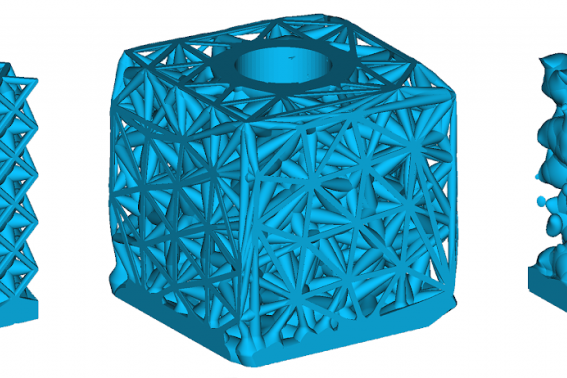

Types of lattice structures

There is a wide range of unit cell types, from graph to surface-based lattice structures, each of which is appropriate for different applications.

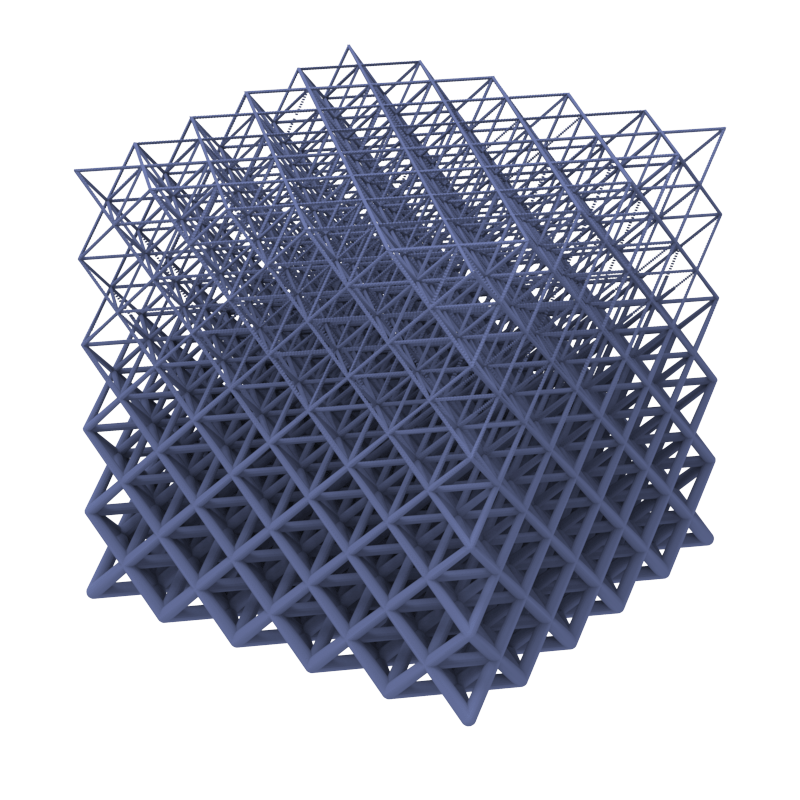

Beam

For lightweight structures with excellent strength-to-weight ratio.

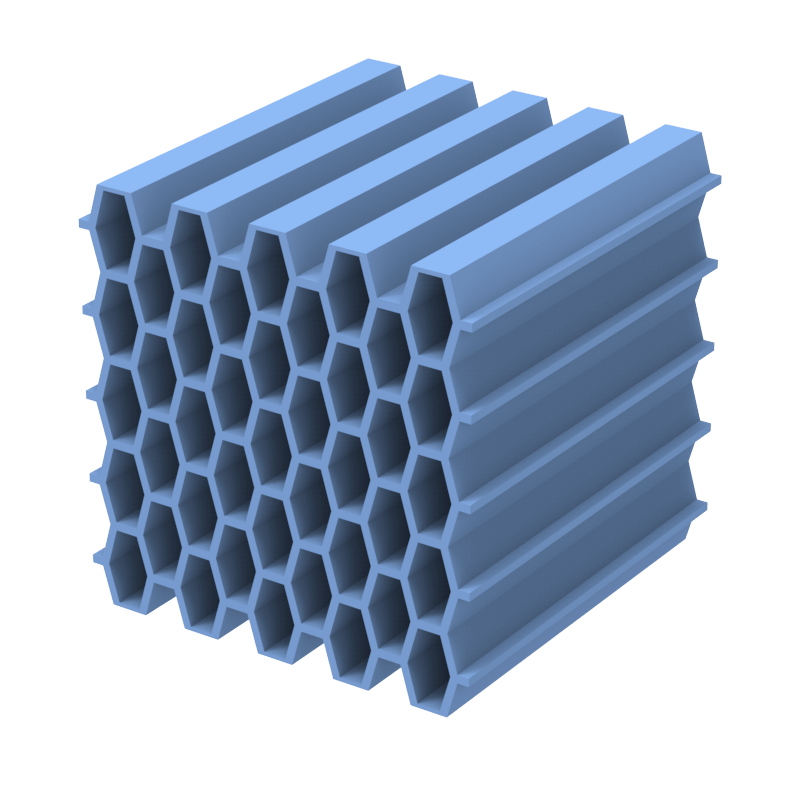

Honeycombs

For structures with high compression strength and directional stiffness.

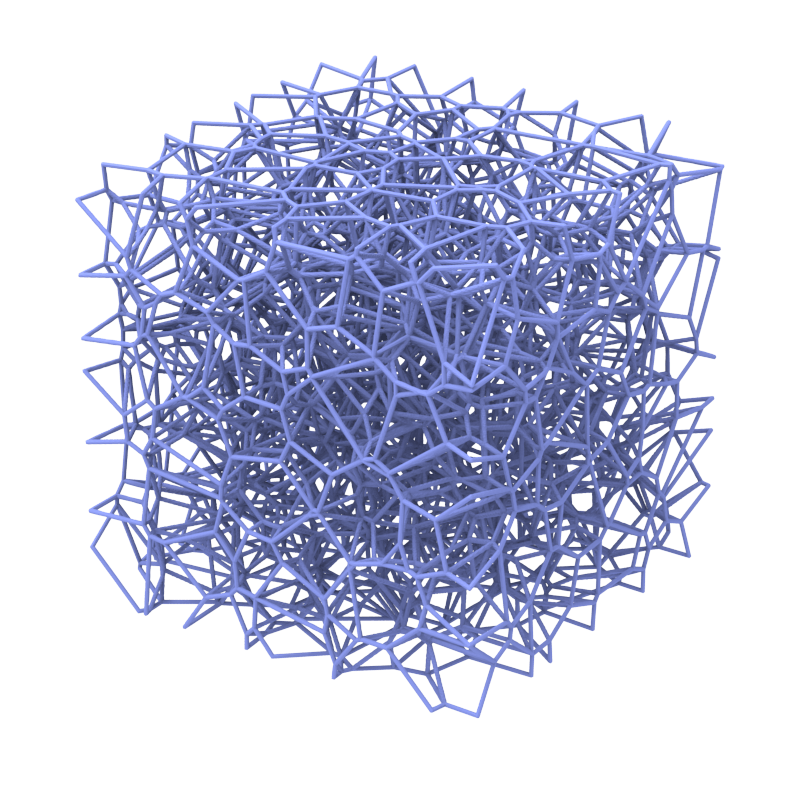

Stochastic

For porous foam-like structures that approximate isotropy at larger sizes.

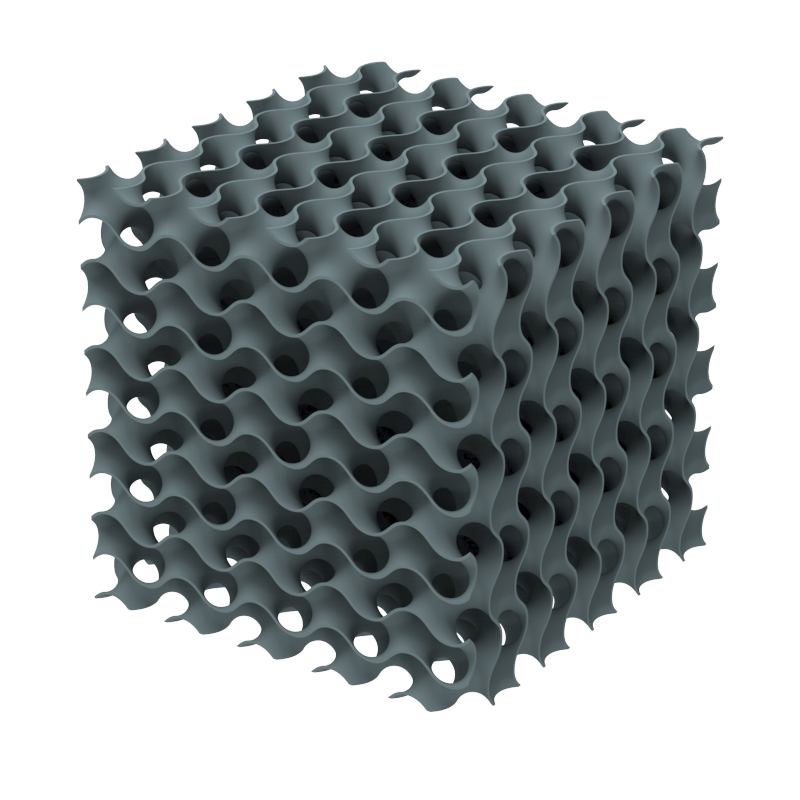

TPMS

For structures with large surface area, high stiffness, and excellent manufacturability.

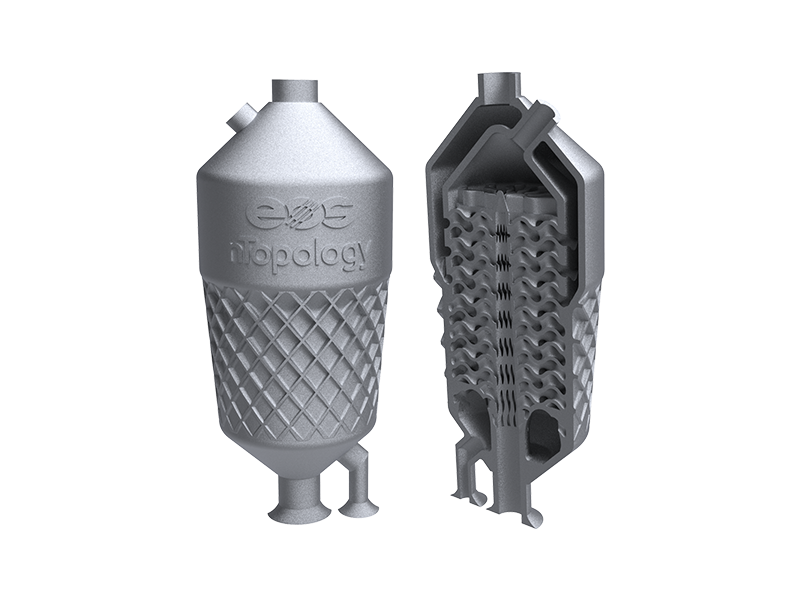

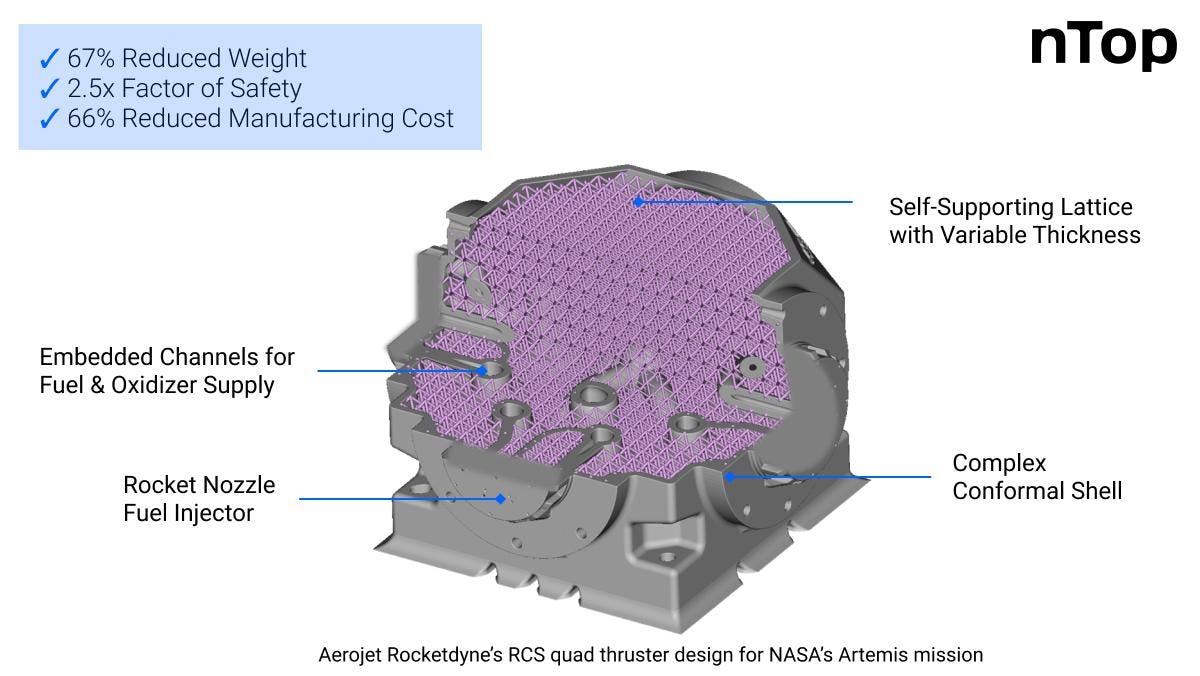

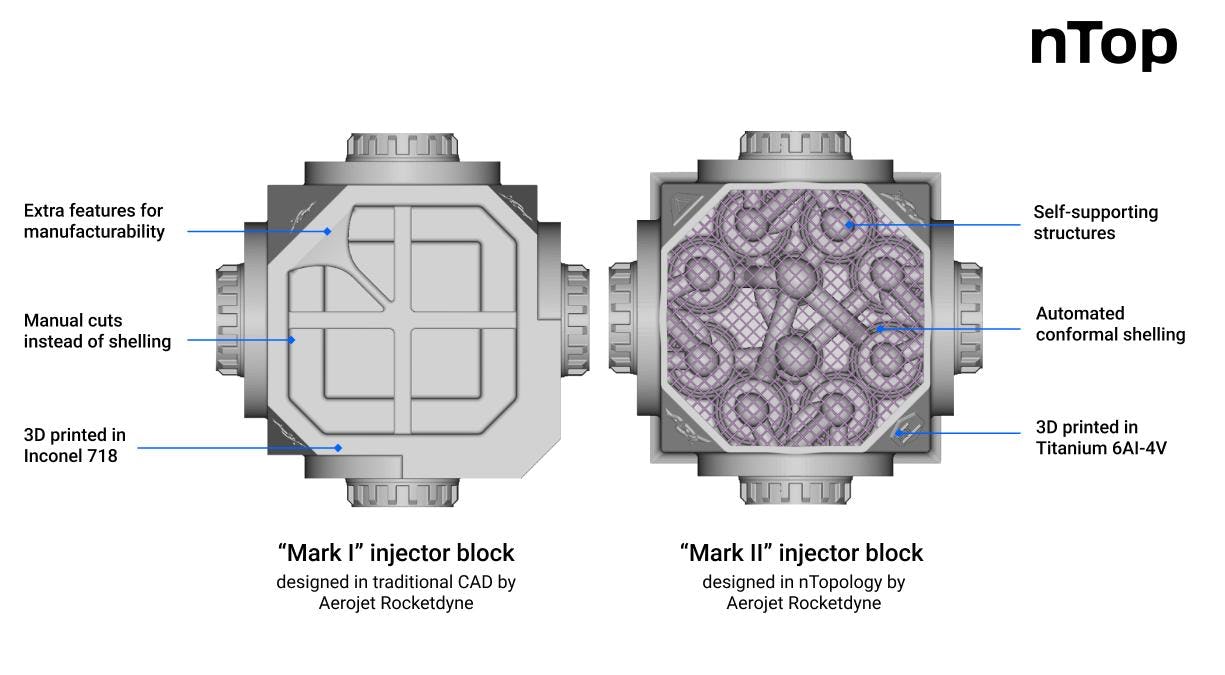

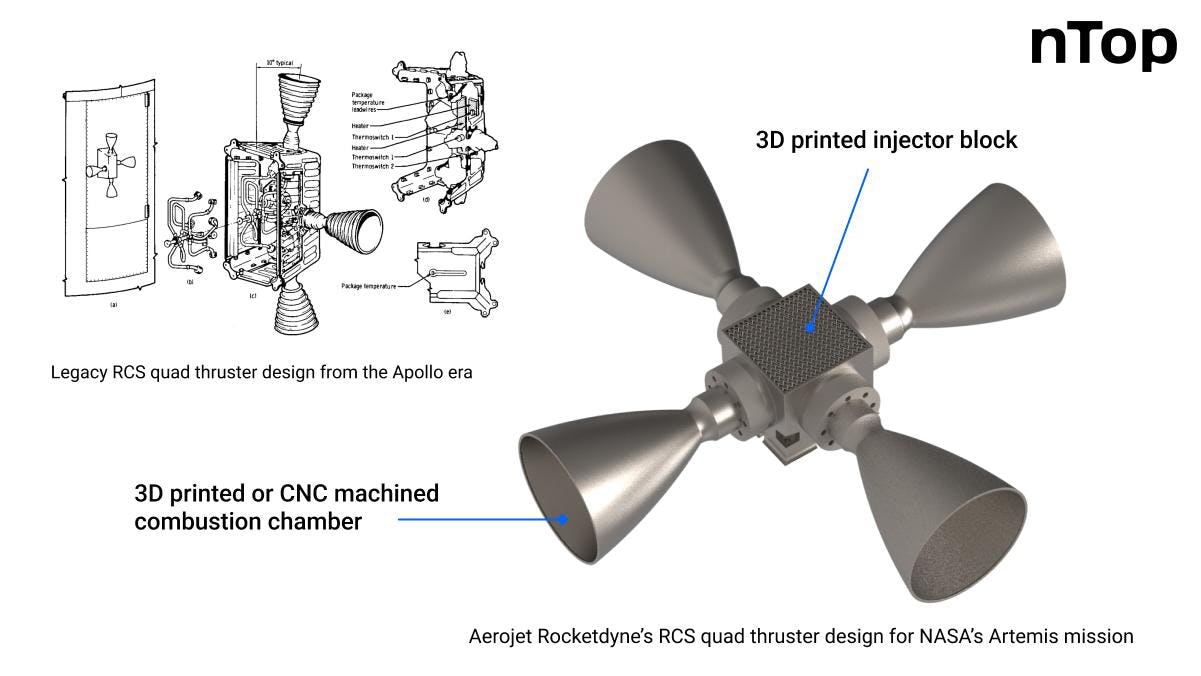

Aerojet Rocketdyne

Light, reliable quad thruster enables low-cost space exploration

Aerojet Rocketdyne used nTop’s shell-and-infill latticing capability to develop a RCS quad thruster that is 67% lighter and 66% less expensive than competing solutions.

Is your software ready for additive manufacturing?

Traditional software isn’t built to take full advantage of new opportunities for engineers. Maximize the benefits of additive manufacturing with the best advanced latticing tools available.