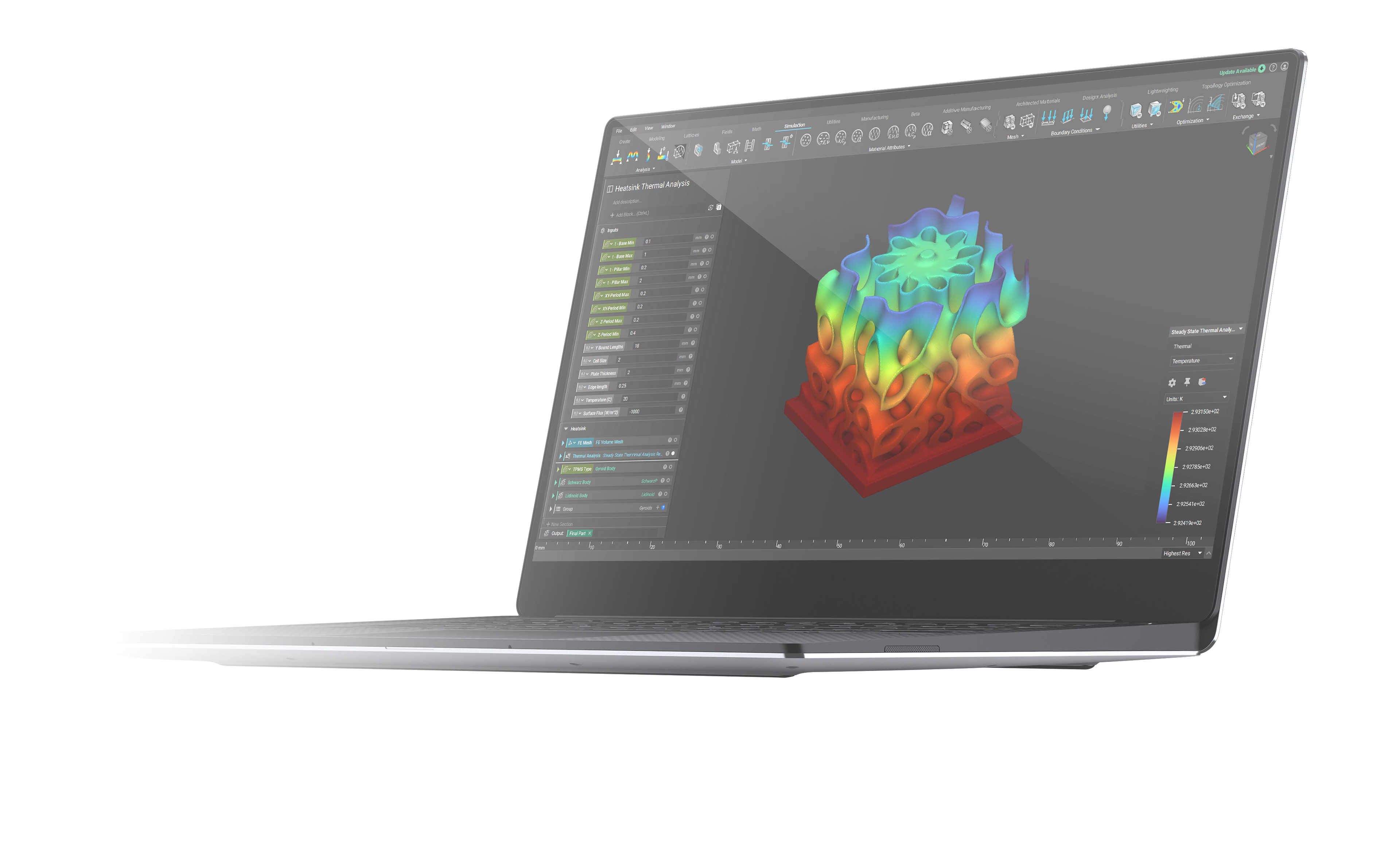

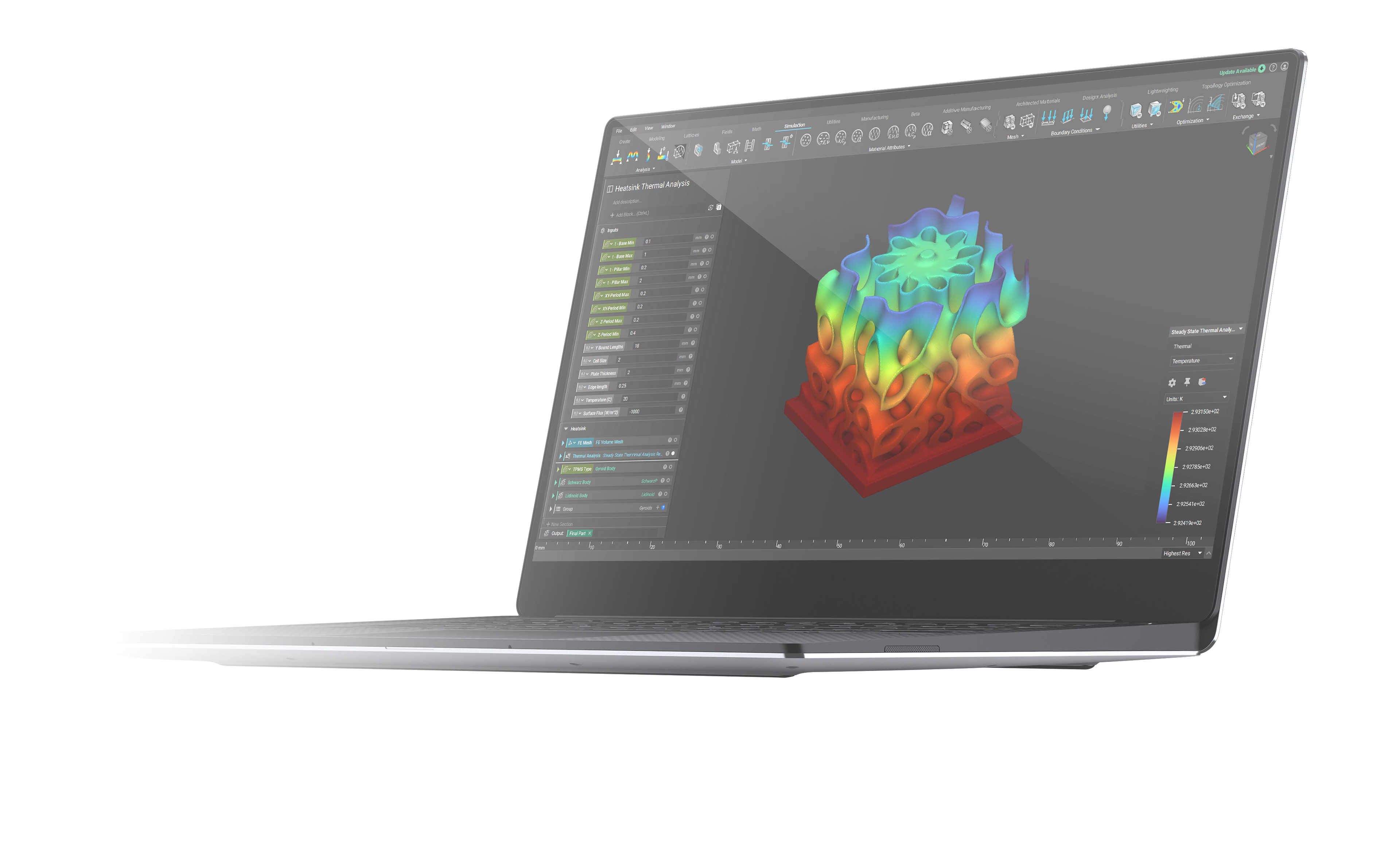

Engineering simulation software

Integrate engineering simulations and build automated analysis workflows to design processes, not just parts.

Why use nTop for simulation?

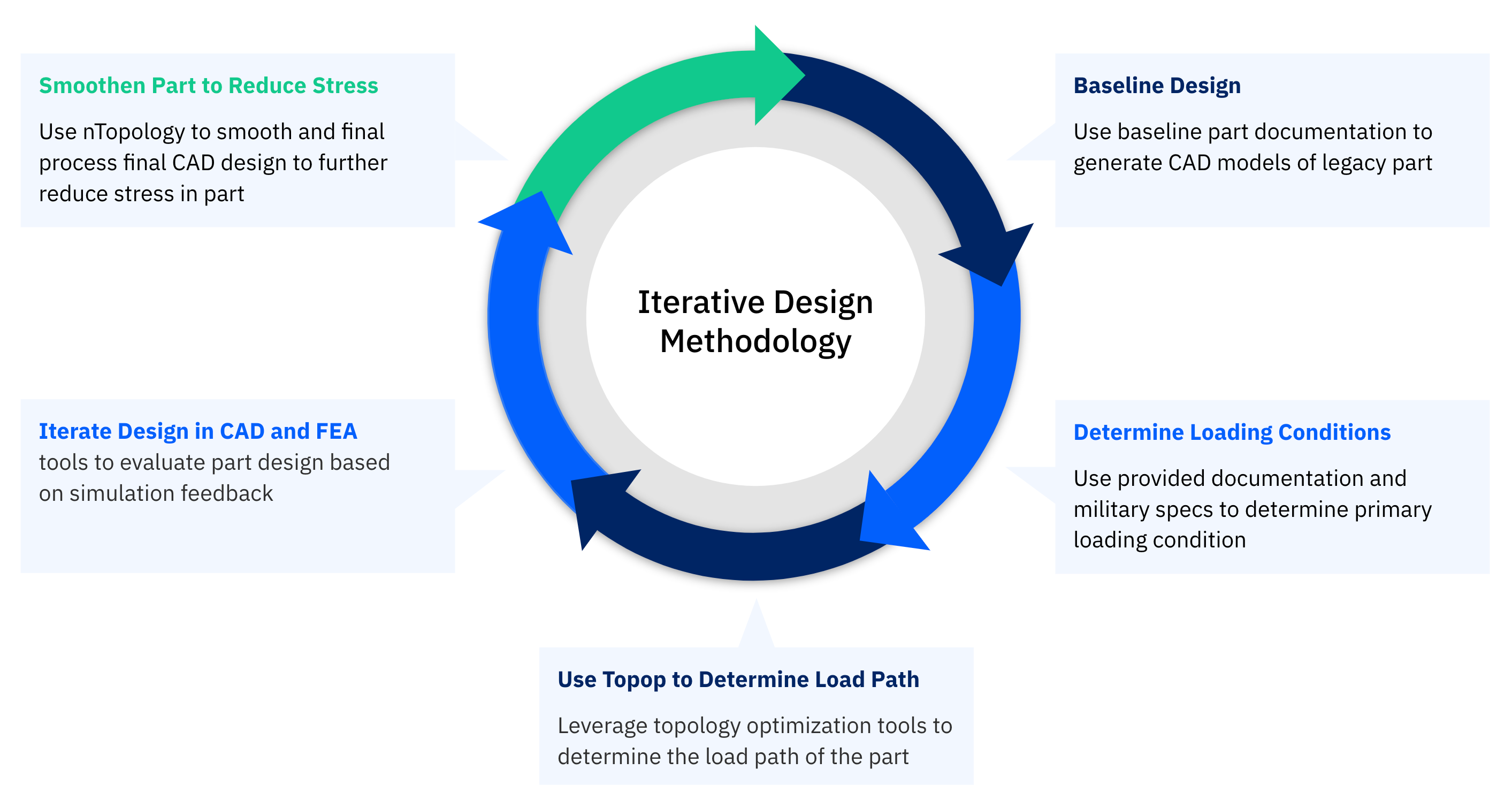

Simulation-driven design process

Make more informed decisions by moving simulation to the beginning of the design process.

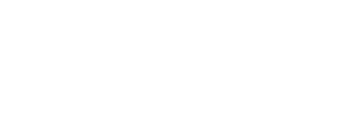

Built-in finite element analysis (FEA) software tools

Couple design generation with design analysis to reduce the time it takes to optimize products.

Augment your simulation workflows

Expand the capabilities of your CAE stack with robust integrations for nTop’s unbreakable geometry generation workflows.

Applications of simulation

Engineers use simulation across many applications to design innovative, high-performance products.

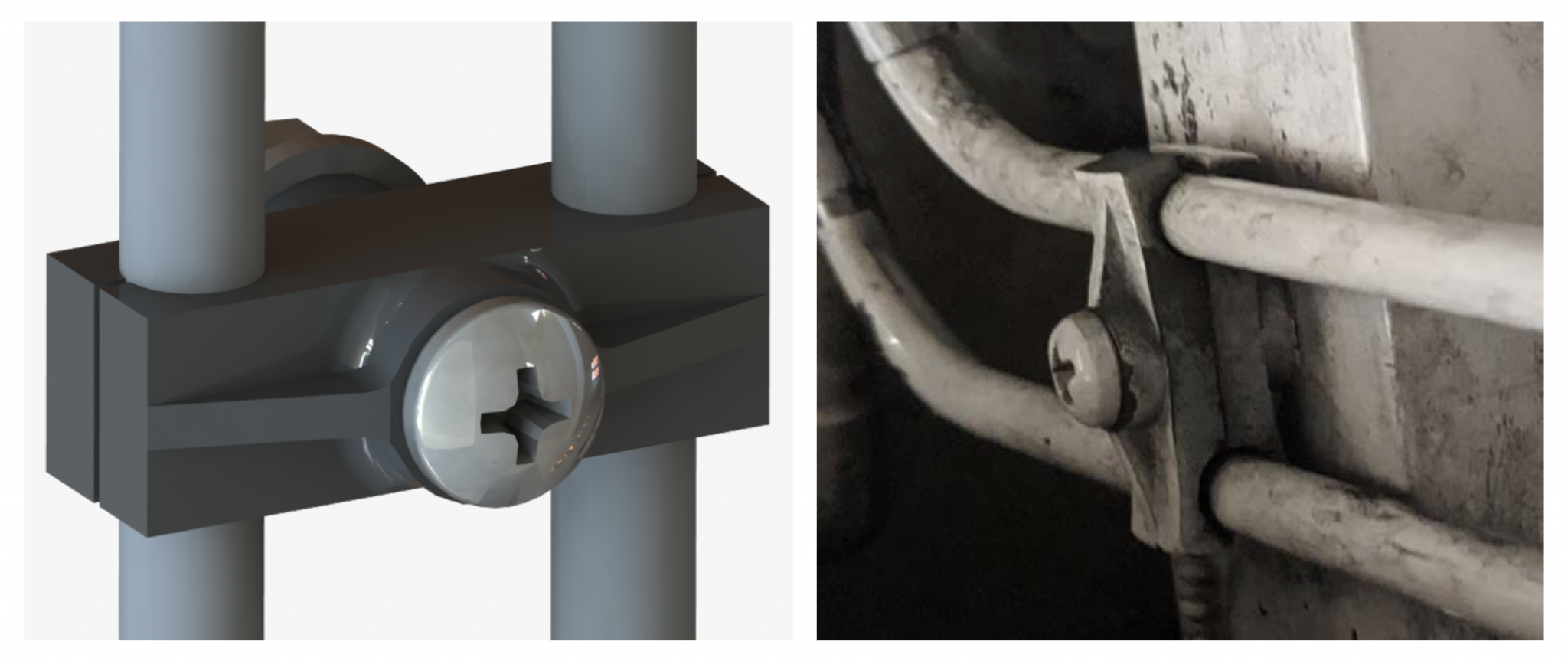

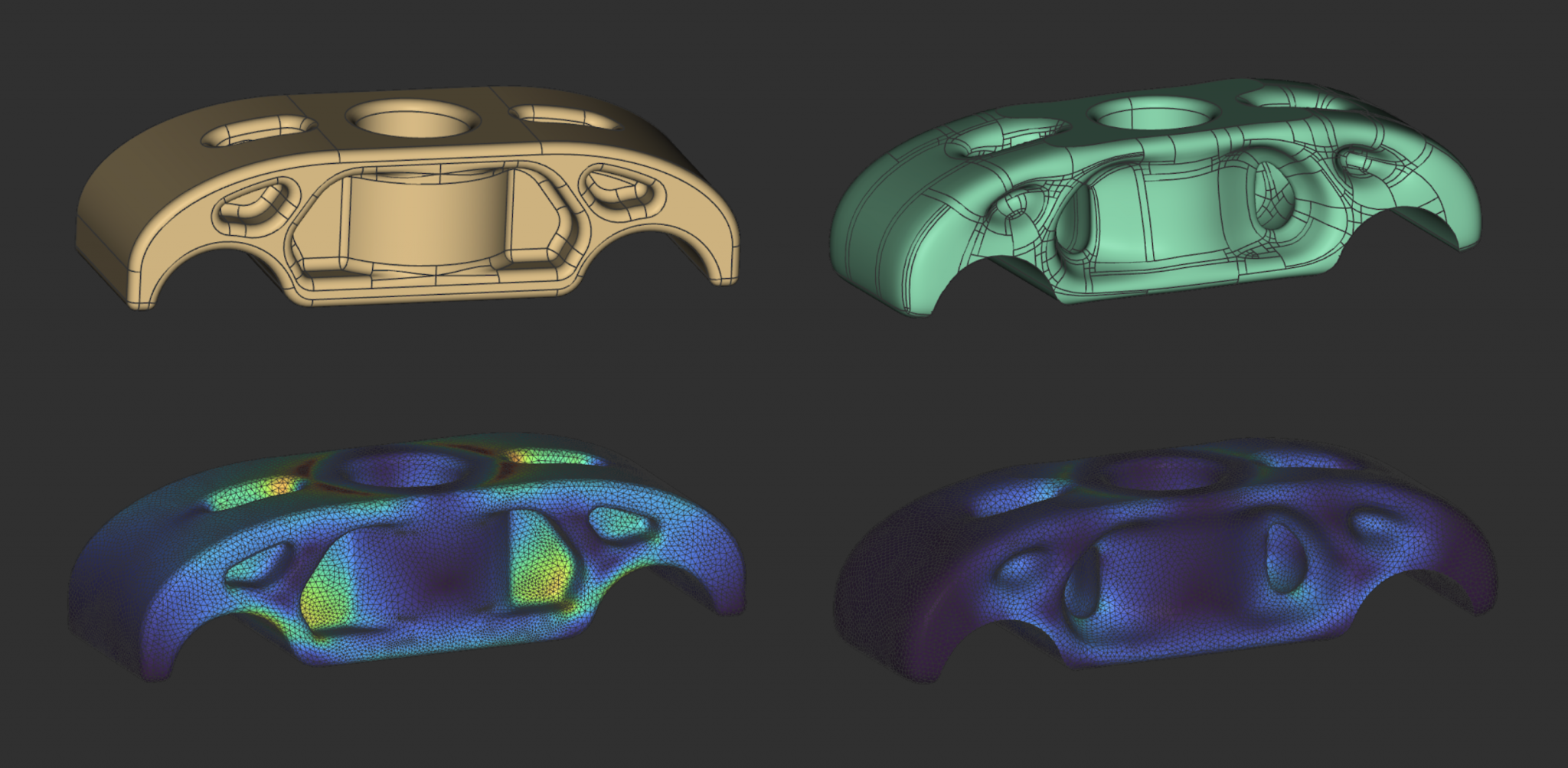

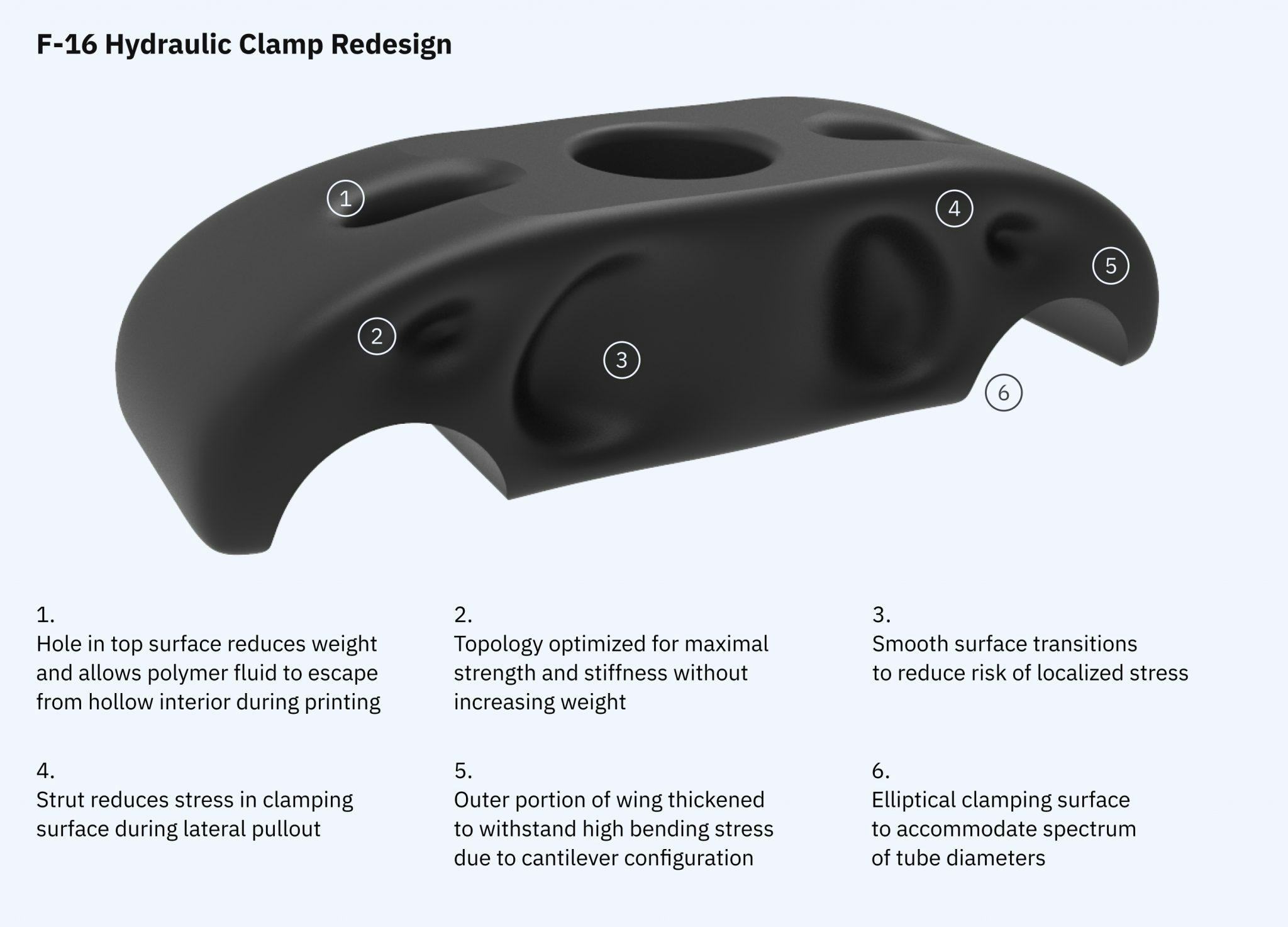

Full-flight qualification for F-16 aircraft spare part in just 30 days

nTop, Origin, and Stress Engineering Services used nTop to redesign a family of F-16 aircraft hydraulic tube clamps for AM as participants in an advanced engineering competition. They used a design-optimize-build-test approach with cutting-edge design and simulation, and the final part was 2x stiffer and manufacturable on demand.

Is your software ready for additive manufacturing?

Traditional software isn’t built to take full advantage of new opportunities for engineers. Maximize the benefits of additive manufacturing with the best simulation tools available.

FAQs

Simulation resources for engineers and designers

- VIDEO

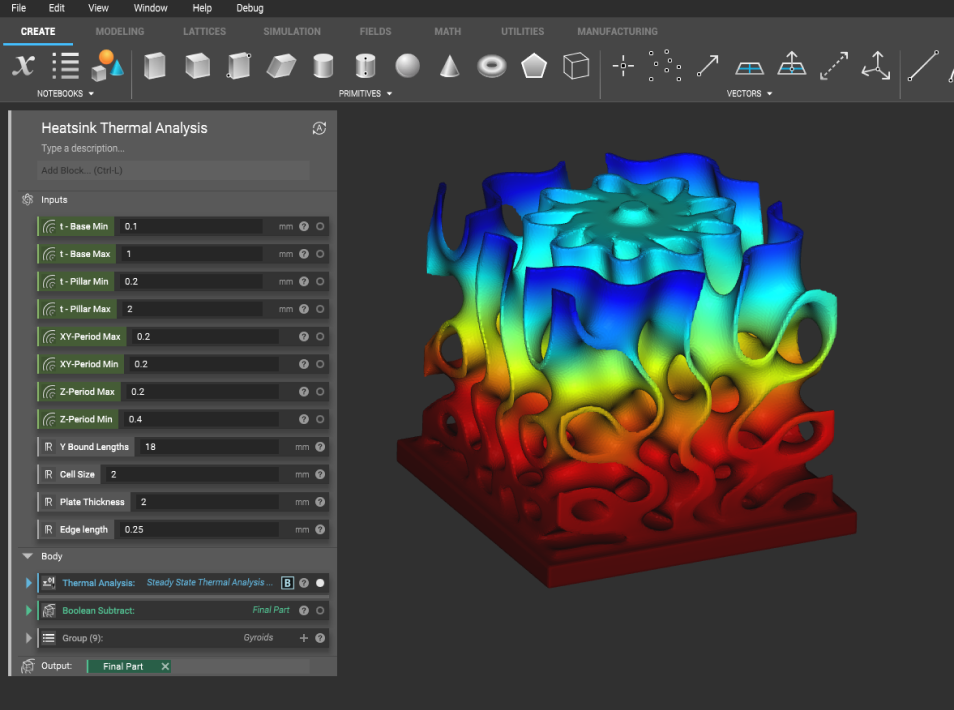

Automated simulation workflows for design analysis

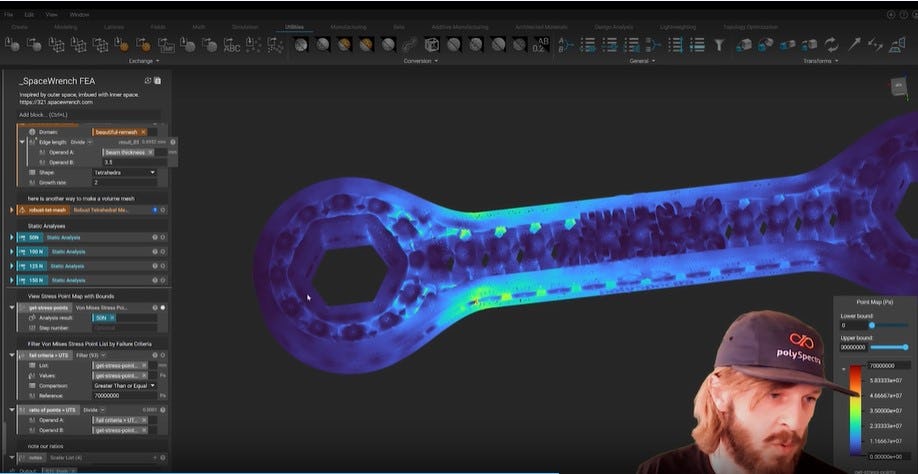

- VIDEO

Simulation series - Finite element to failure: Simulation and experimental fracture analysis of lightweight aerospace components

- VIDEO

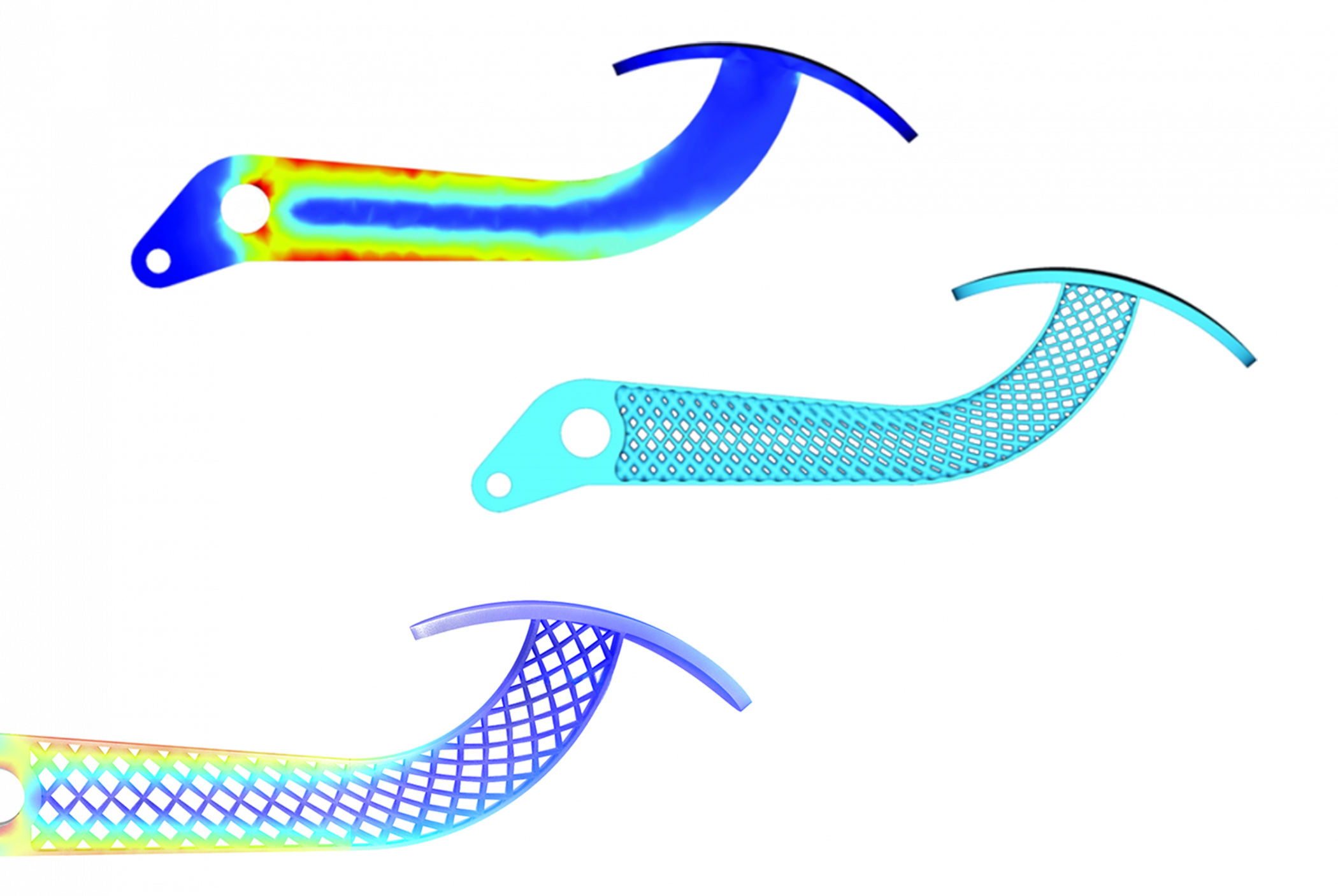

Structural optimization of a bracket with field-driven design and simulation data

- VIDEO

Designing for the harsh temperature gradients of space

- VIDEO

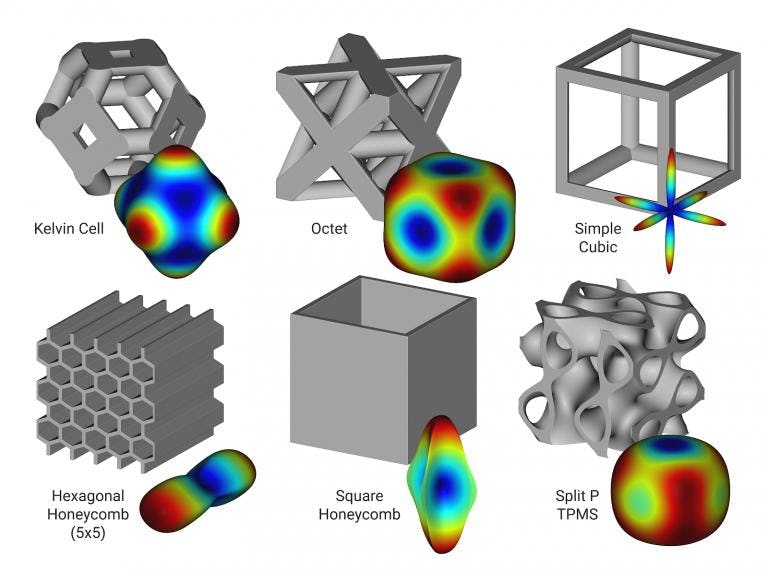

Modal analysis of lattice structures for damping external vibrations