Thermal management

Design the next generation of heat exchangers with the most powerful design software for additive manufacturing.

Benefits of 3D-printed heat exchangers

Additively manufactured thermal management solutions can be safer, more efficient, longer lasting, and more reliable.

Get the Thermal Management Guide

Learn how to design heat exchangers with higher performance, more compact size, and increased reliability.

Industry applications of thermal management

Additive manufacturing helps create more efficient, longer-lasting thermal management solutions across a variety of industries.

Automotive industry

3D printing heat exchangers in the automotive industry can help engineers improve efficiency and overcome the challenges associated with designing electric vehicles.

Aerospace industry

3D-printed, high-performance heat exchangers can help aerospace engineers balance heat transfer performance with weight and size requirements.

Industrial heat exchangers

Additively manufactured heat transfer systems can increase efficiency for the energy production, precision manufacturing, and semiconductor industries.

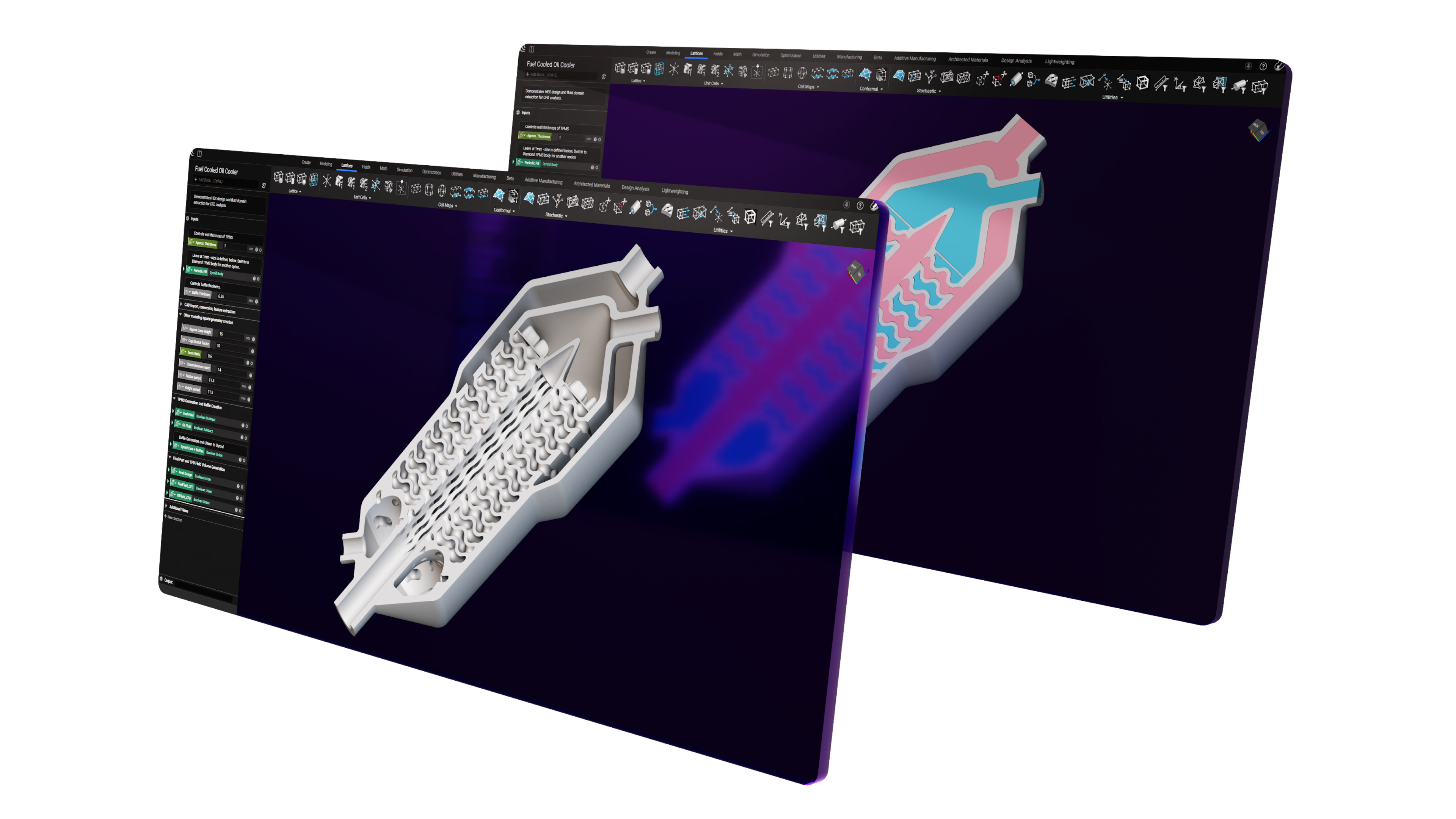

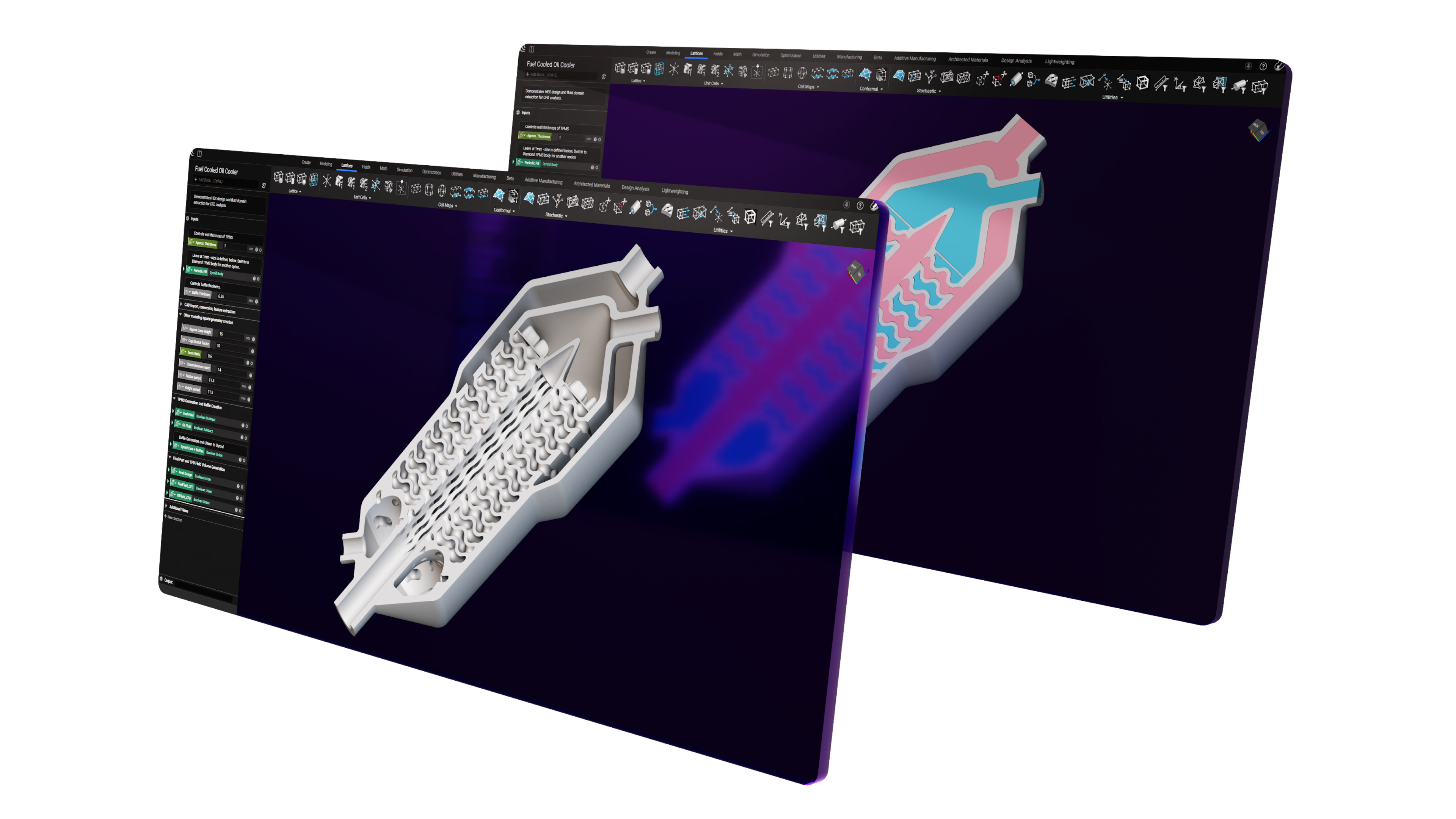

nTop’s critical tools for thermal management with additive manufacturing

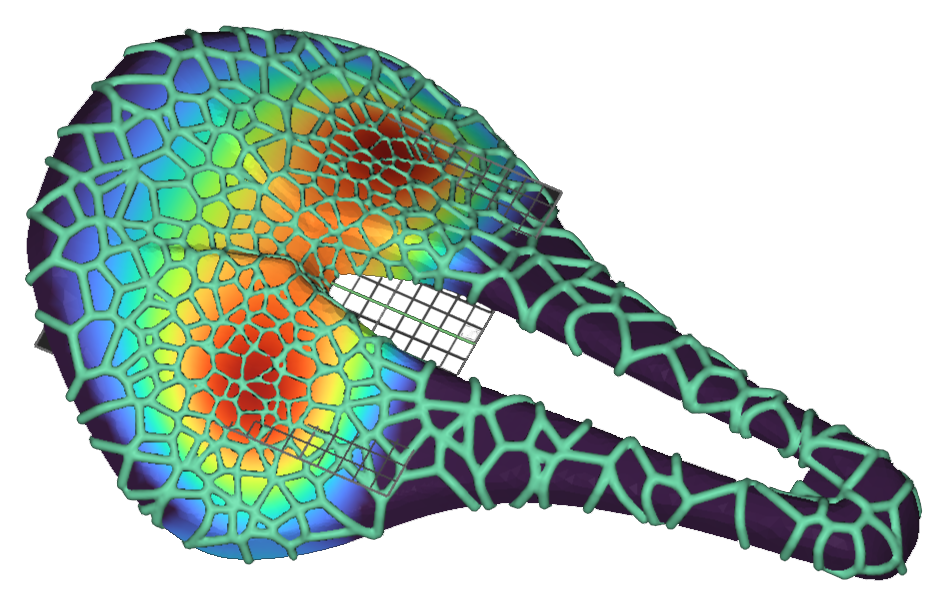

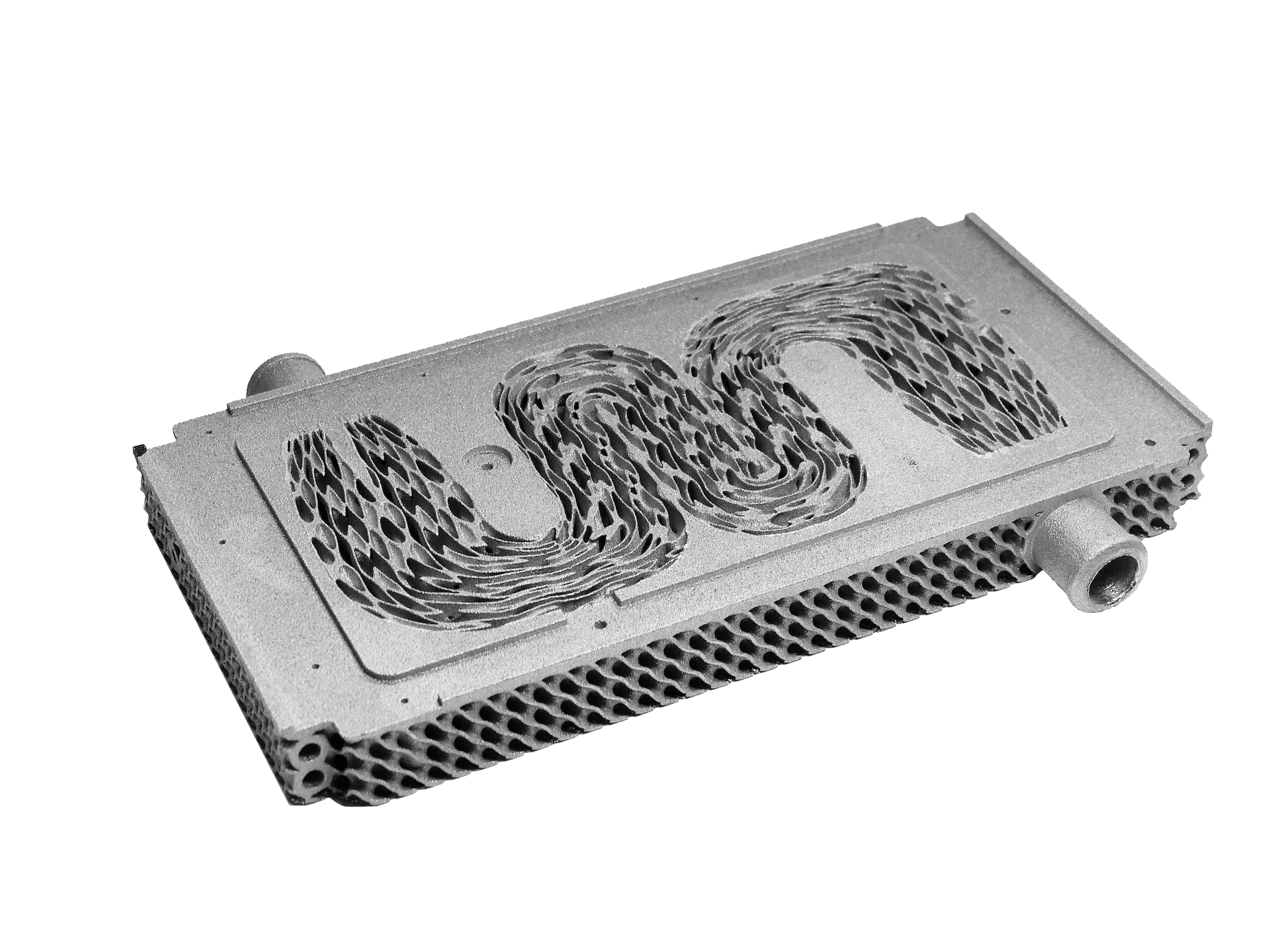

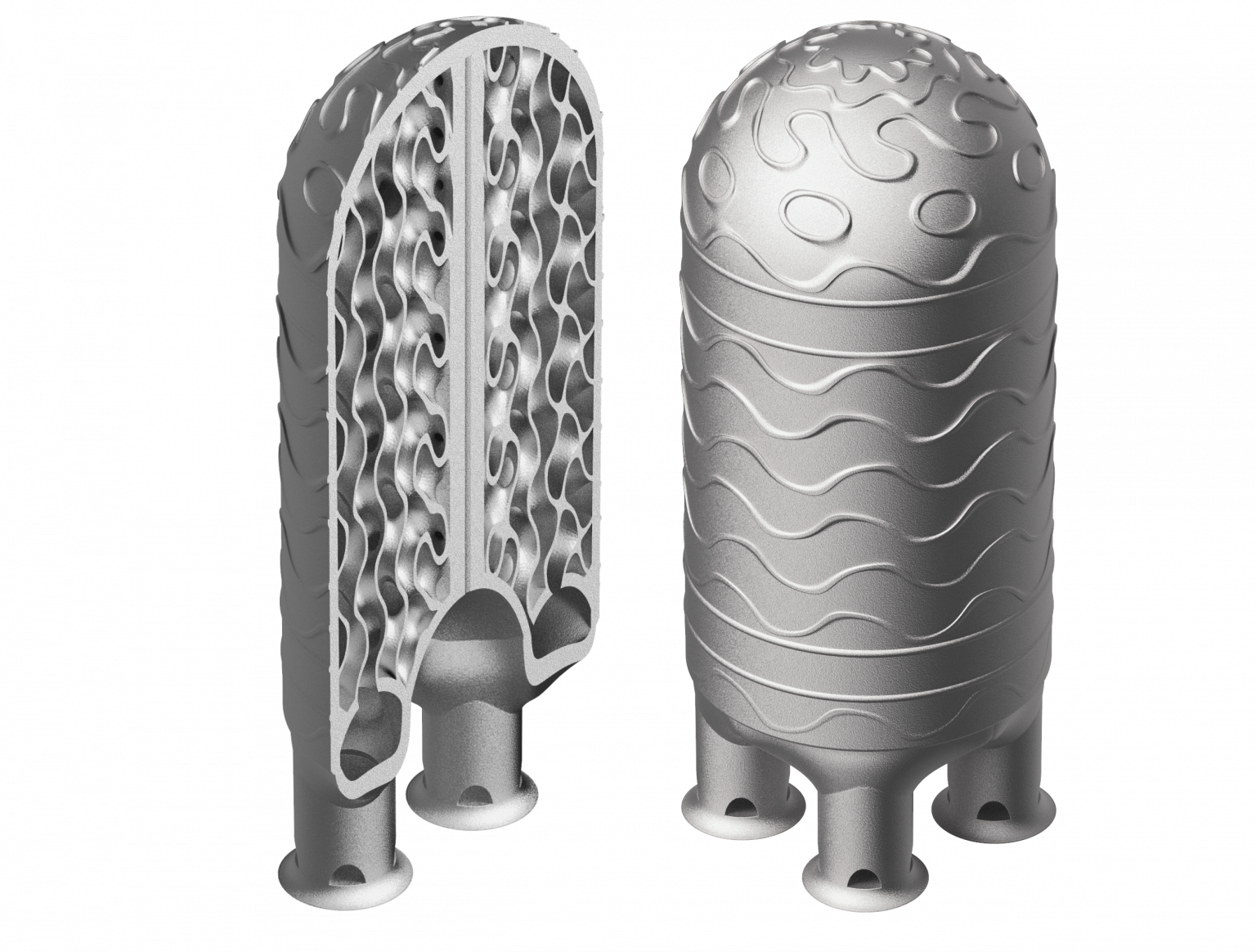

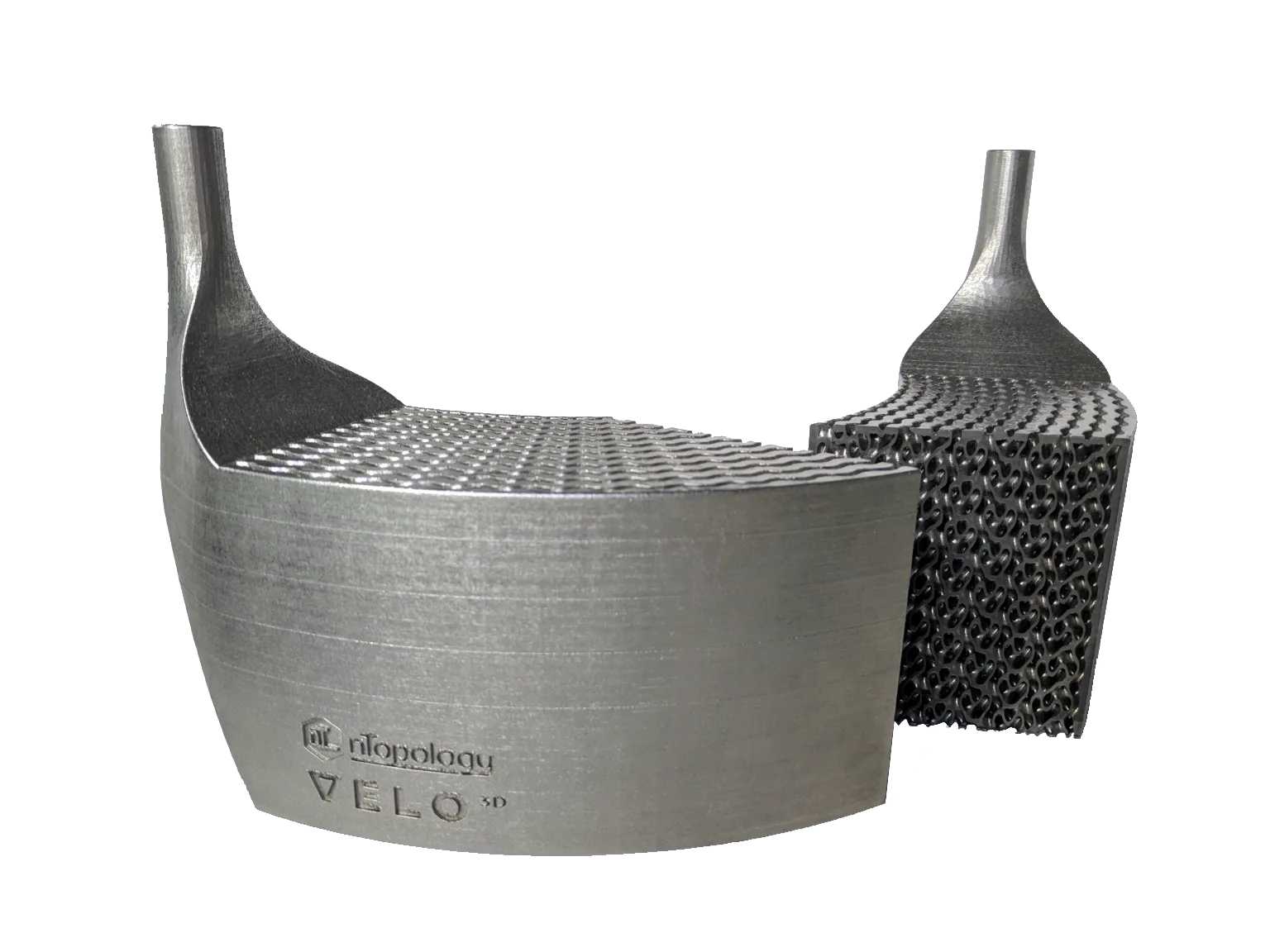

TPMS and lattice structures

Generate complex, scalable lattice structures, with variable thickness and smooth transitions, in seconds.

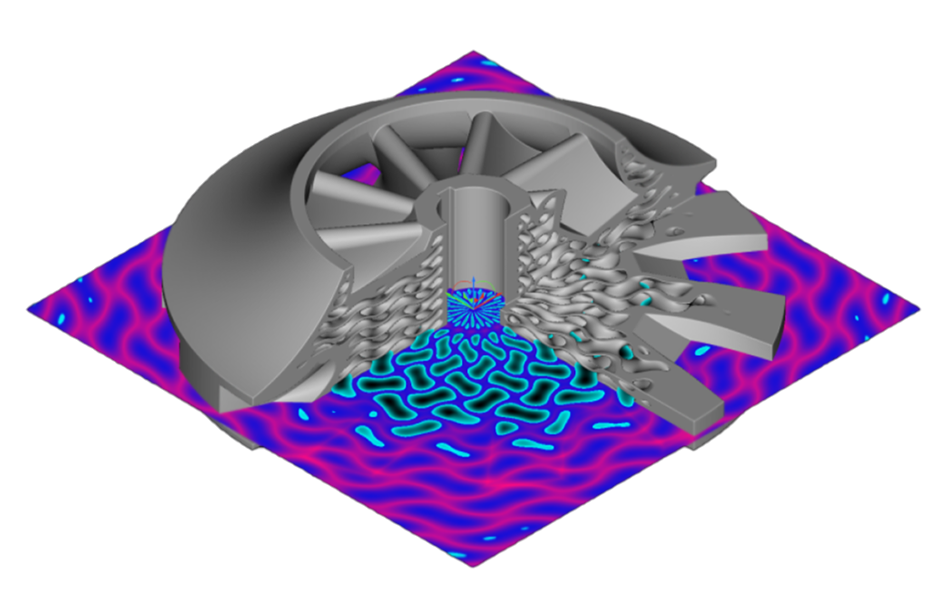

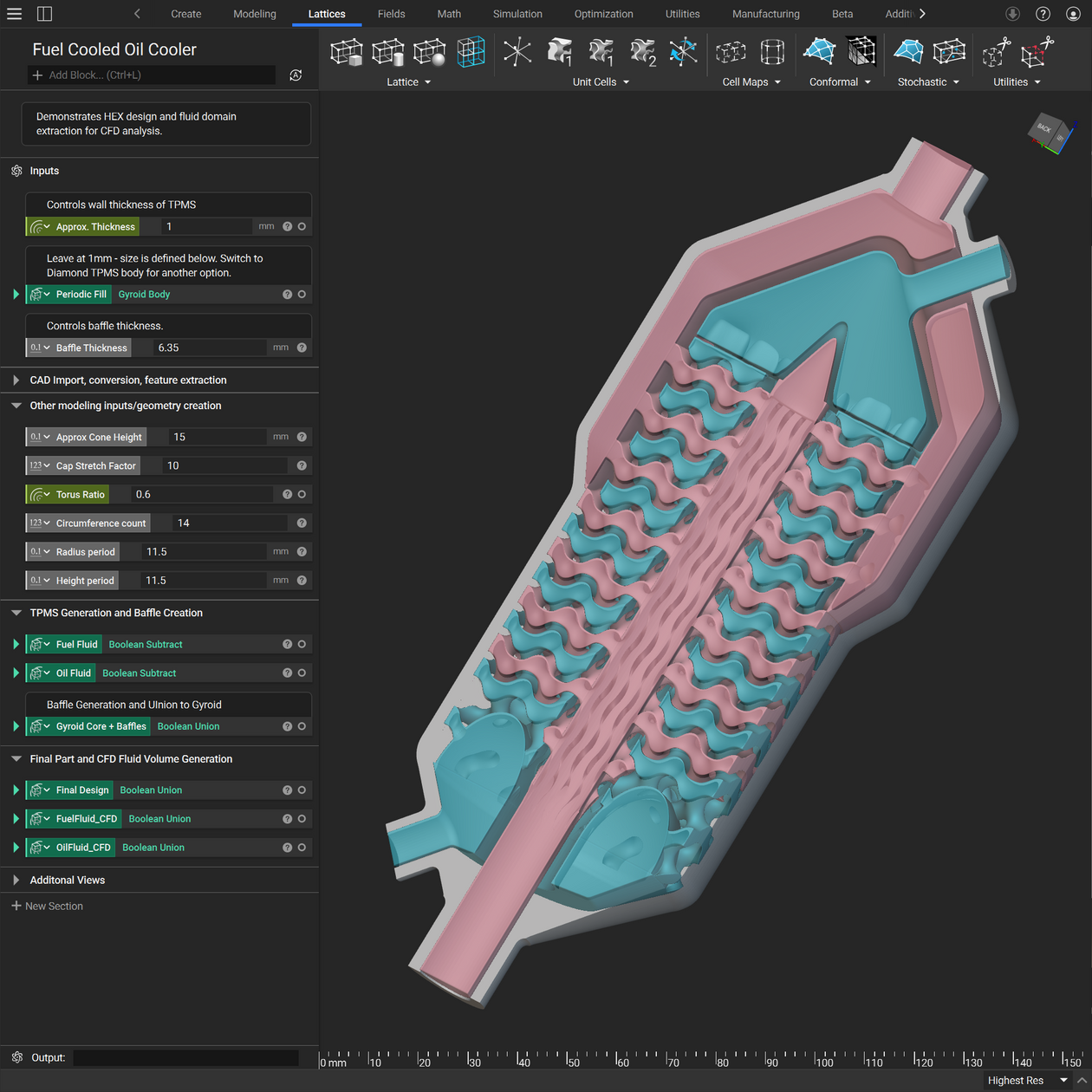

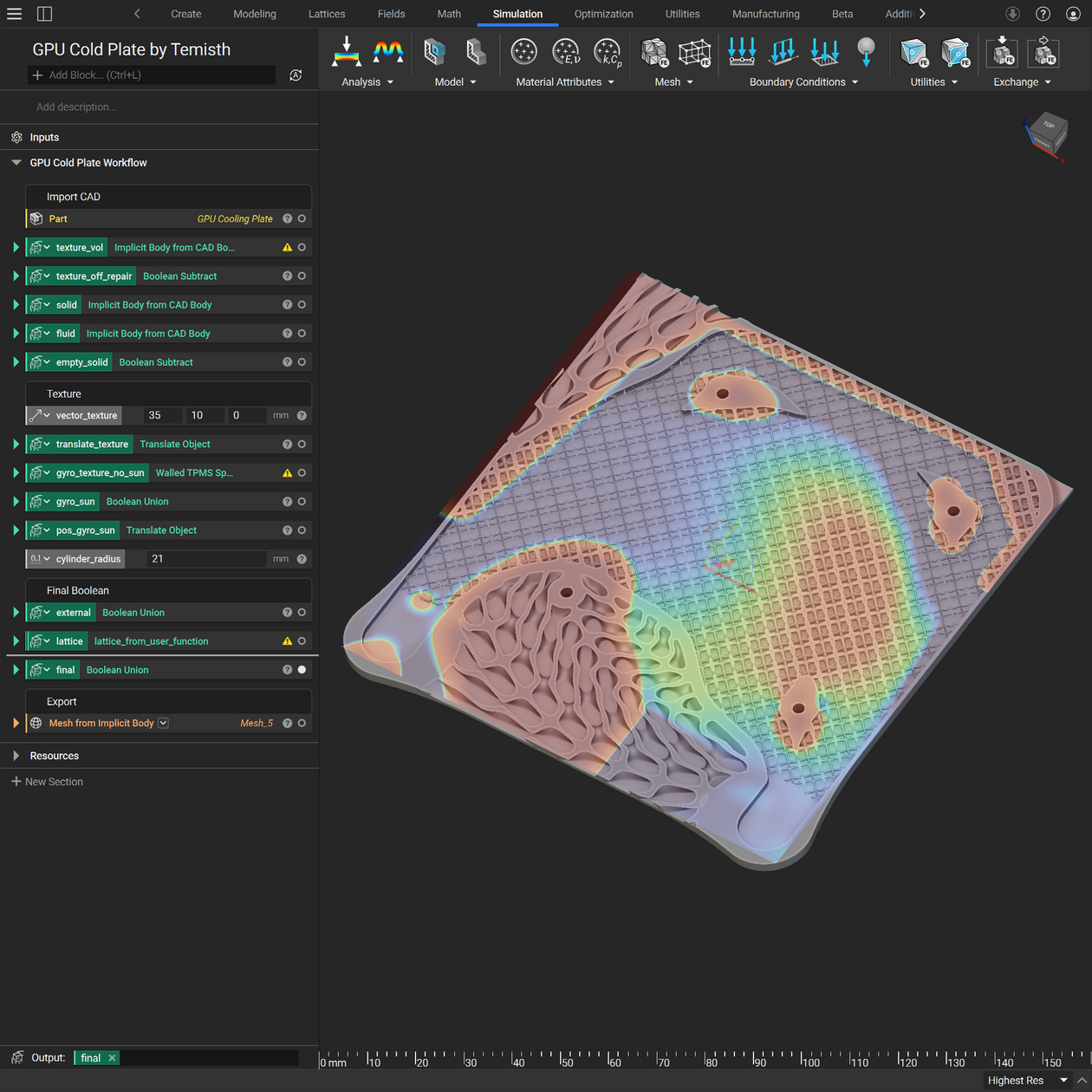

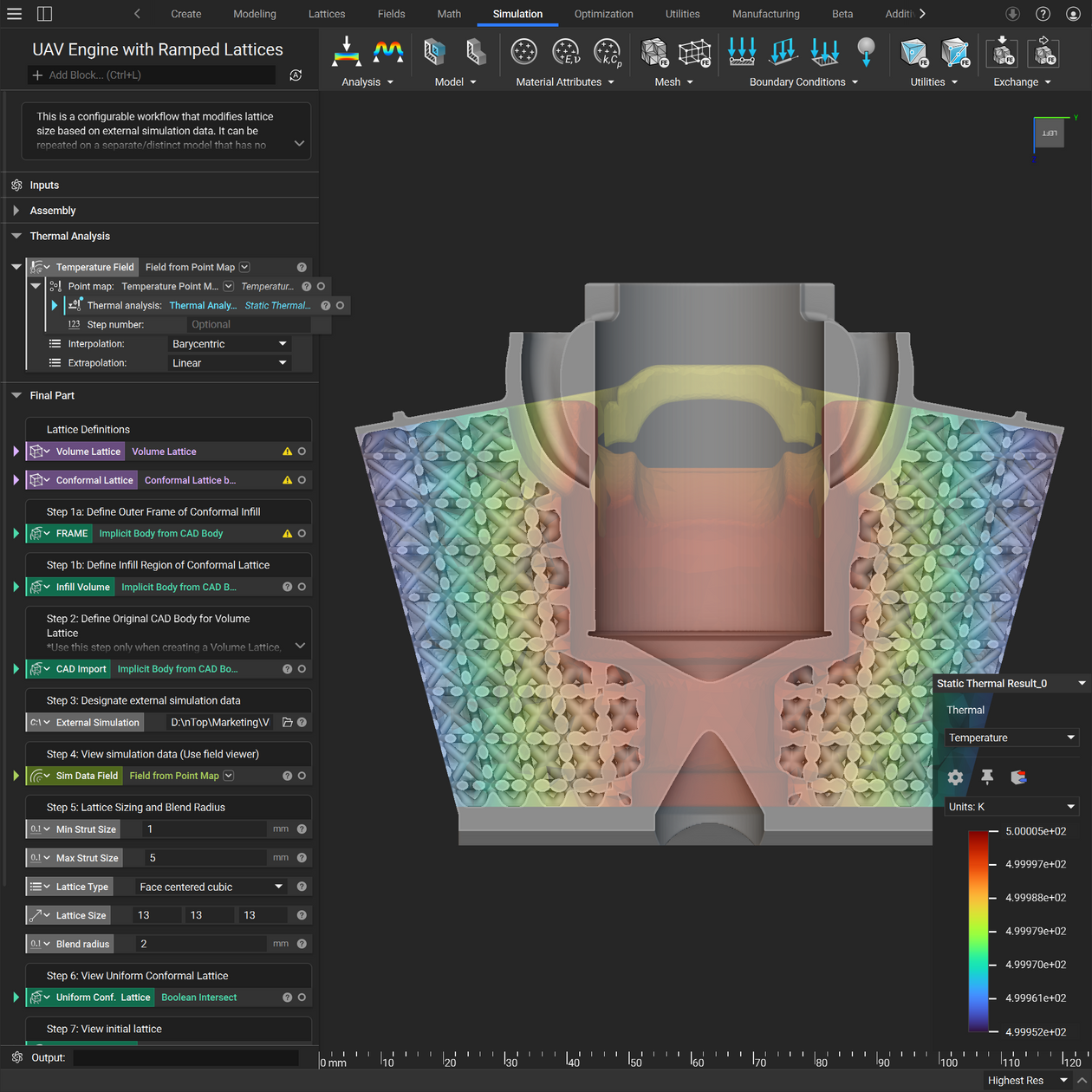

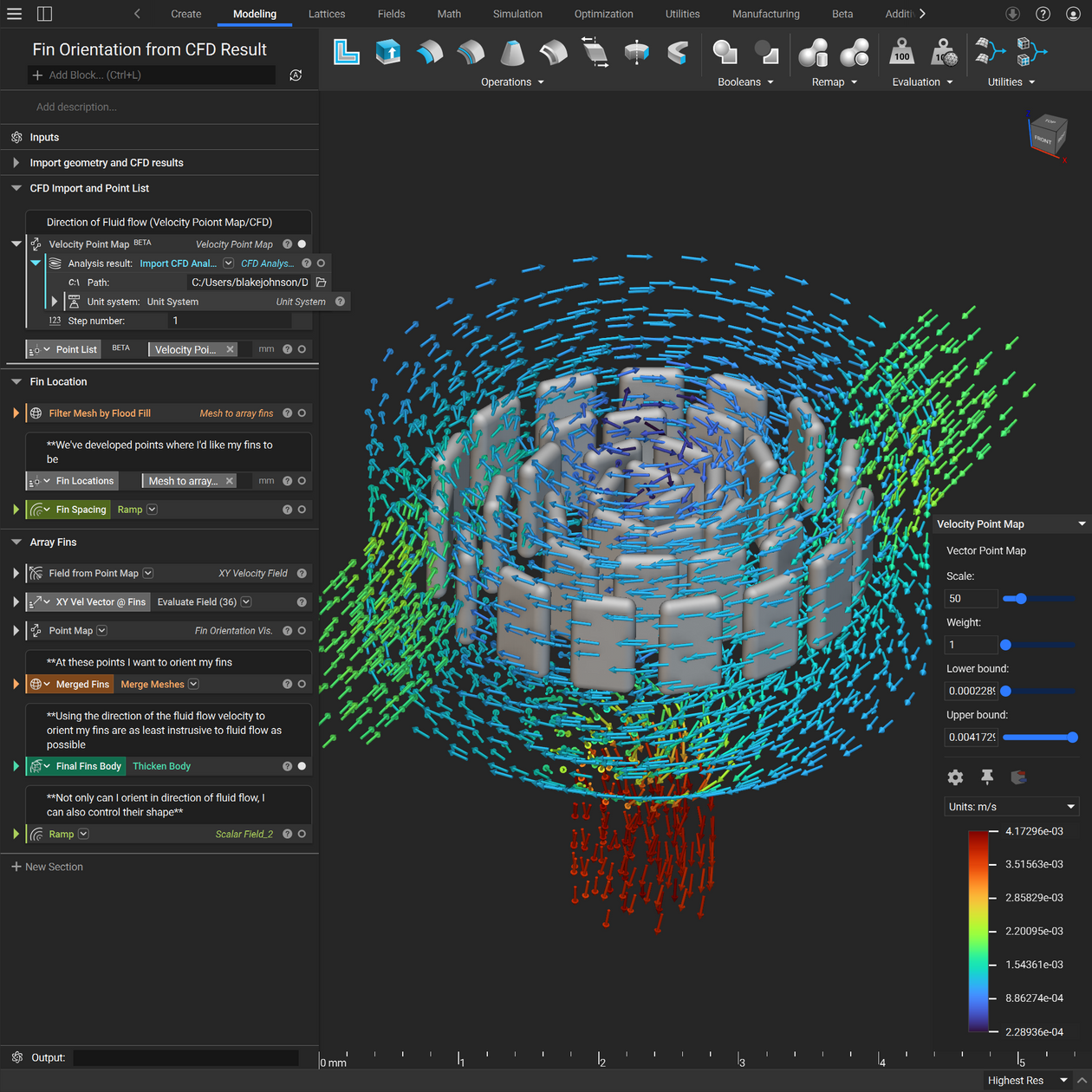

Simulation-driven design

Control the location, density, and orientation of flow and thermal guides with thermal maps and flow fields.

Integrated thermal FEA

Rapidly assess thermal performance with linear, non-linear, thermal stress, and transient thermal analysis tools.

CFD and MDO interoperability

Generate new designs, mesh, and send to CFD for virtual validation or simulation software for rapid iteration.

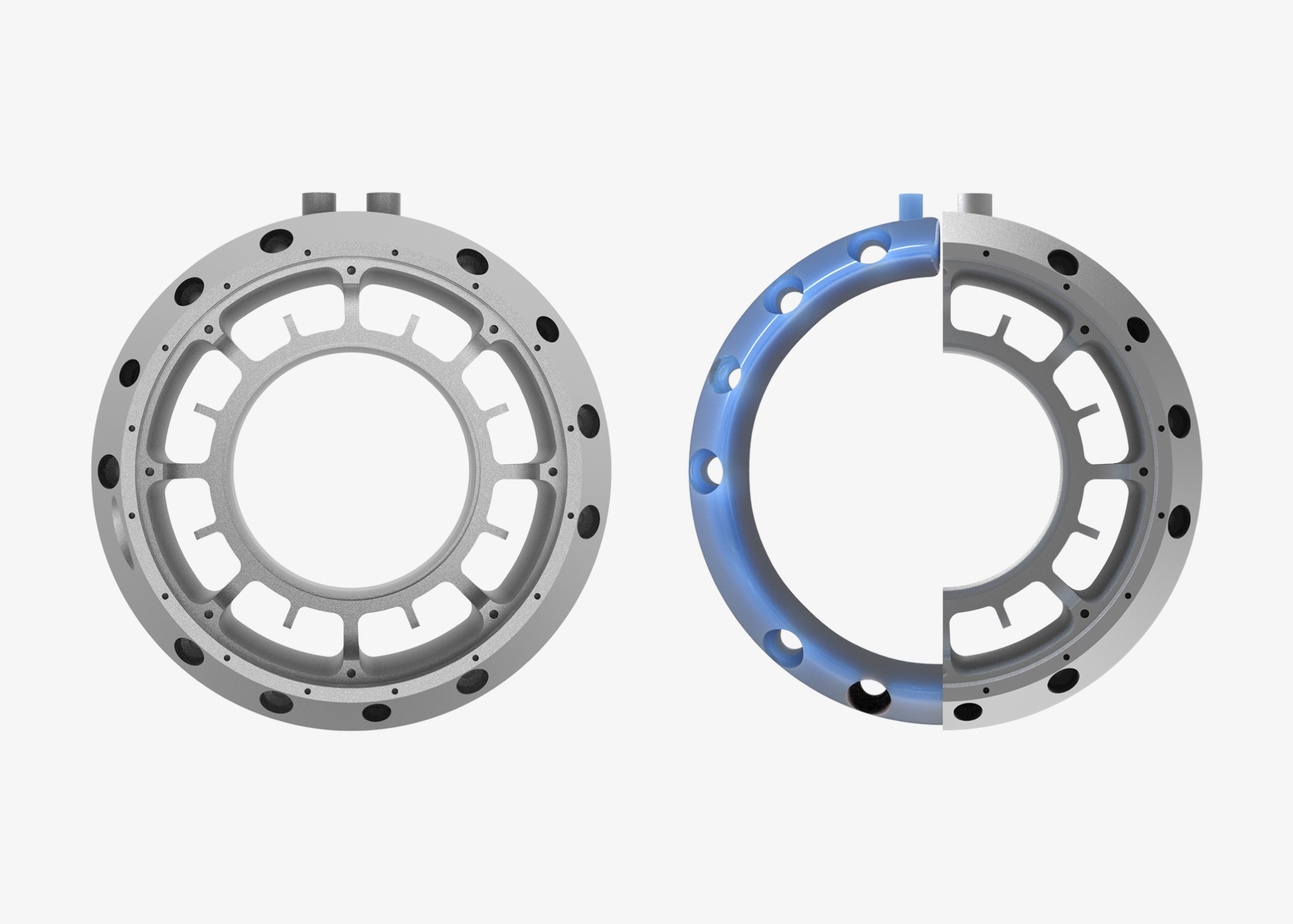

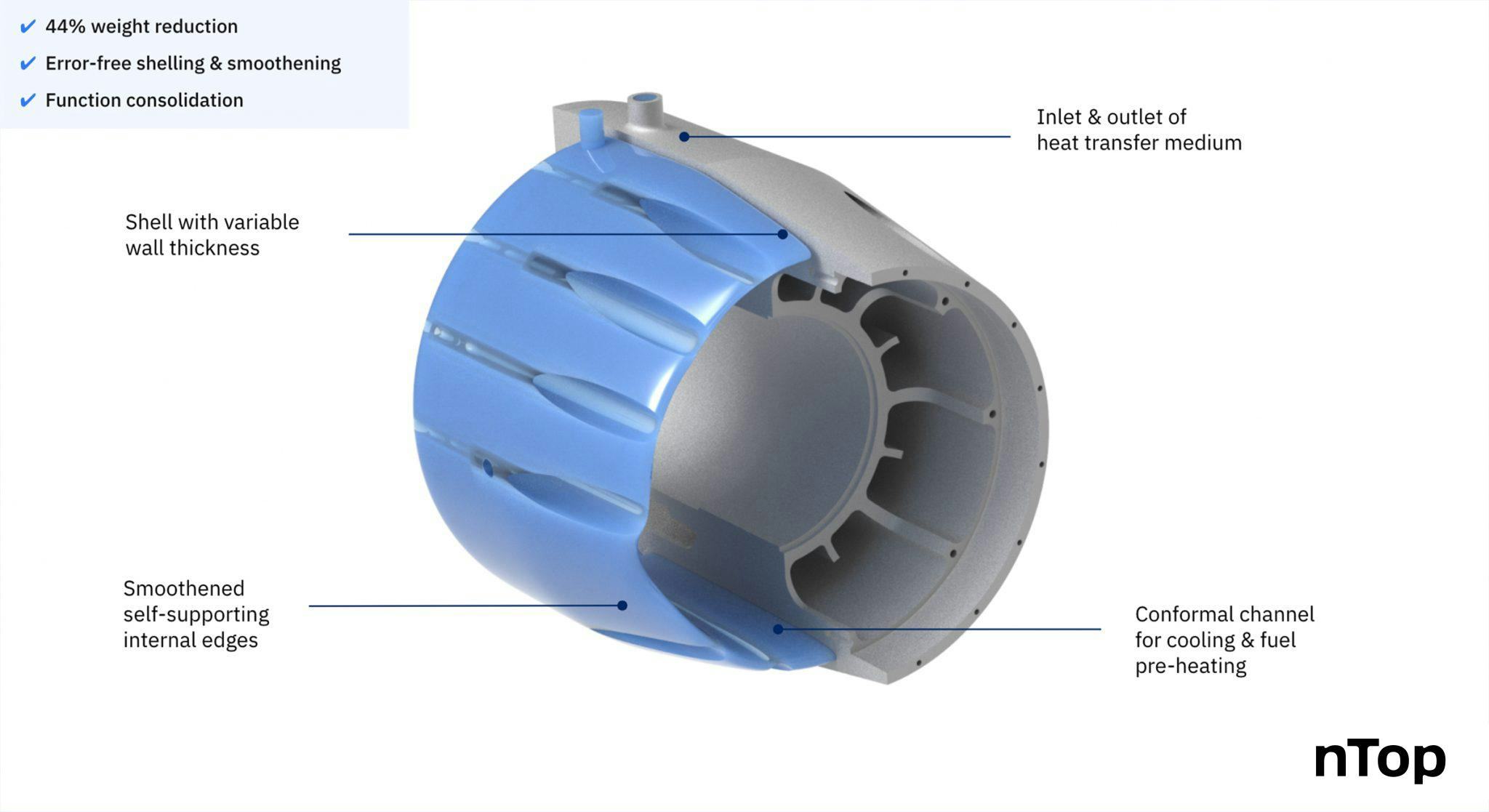

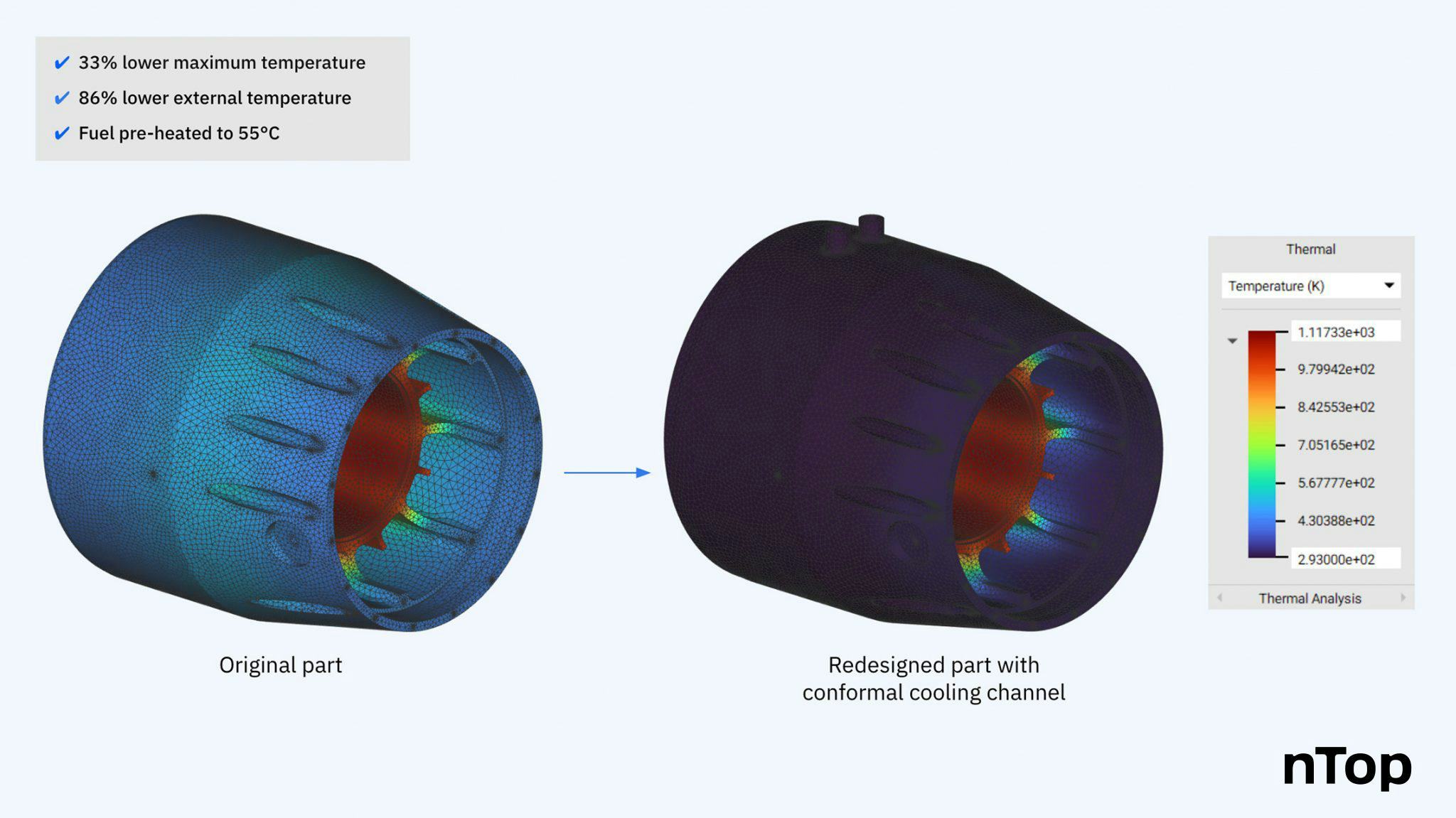

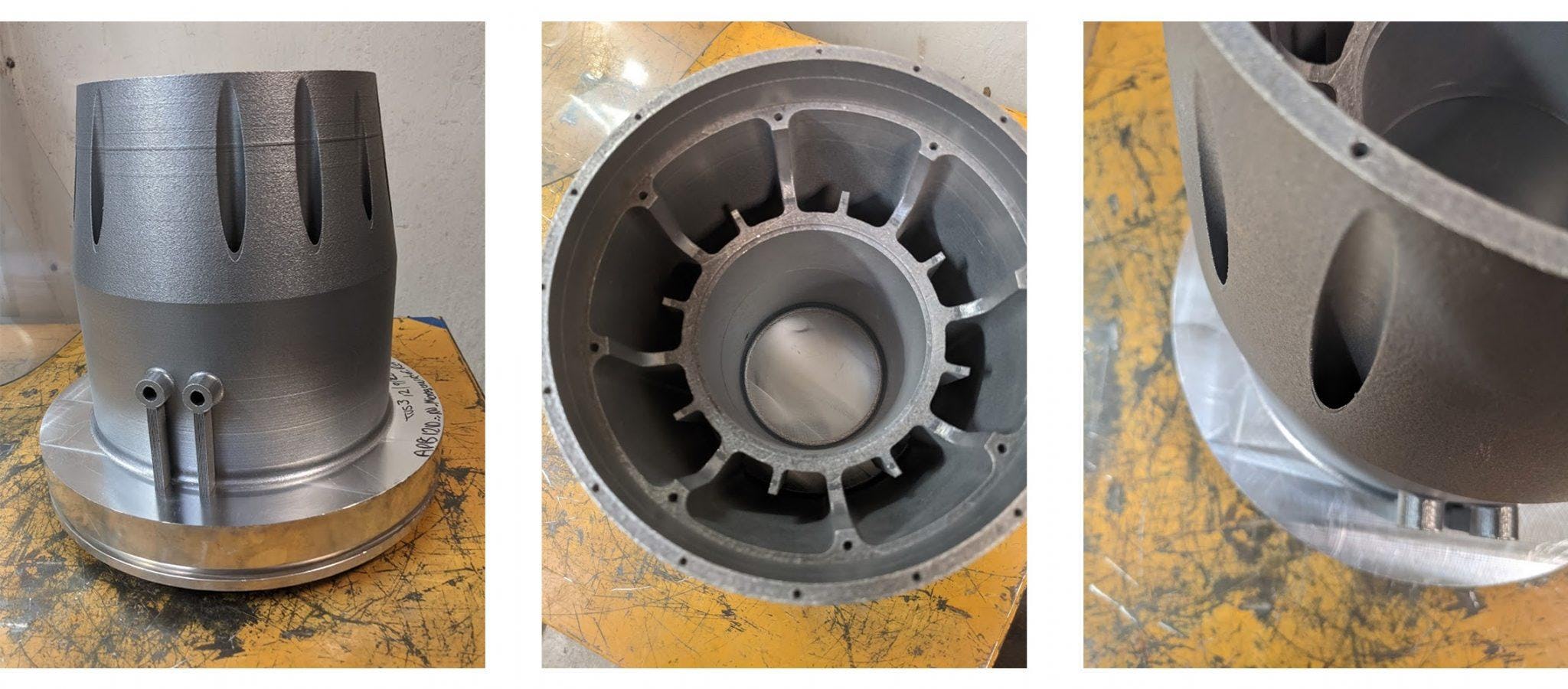

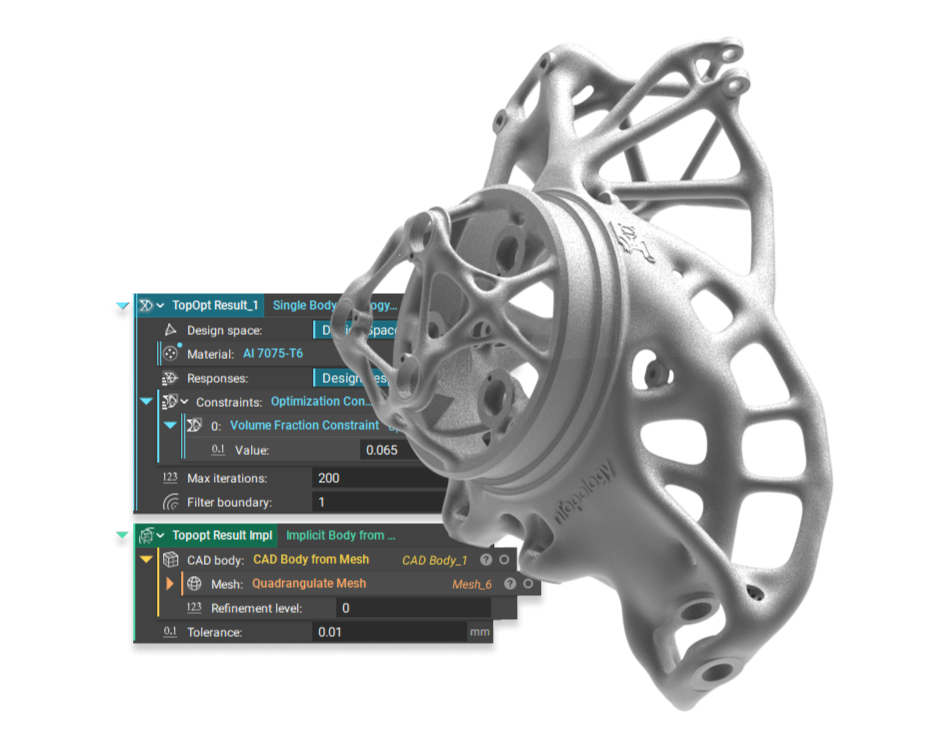

KW Micro Power

Simulation and field optimization create a lighter microturbine housing with embedded cooling channels

KW Micropower used nTop to redesign the housing of their aerospace-grade, high-power-density, compact turbogenerator for metal additive manufacturing. Using field optimization and shelling, they reduced the housing’s weight by 44% and reduced the temperature by 33%.

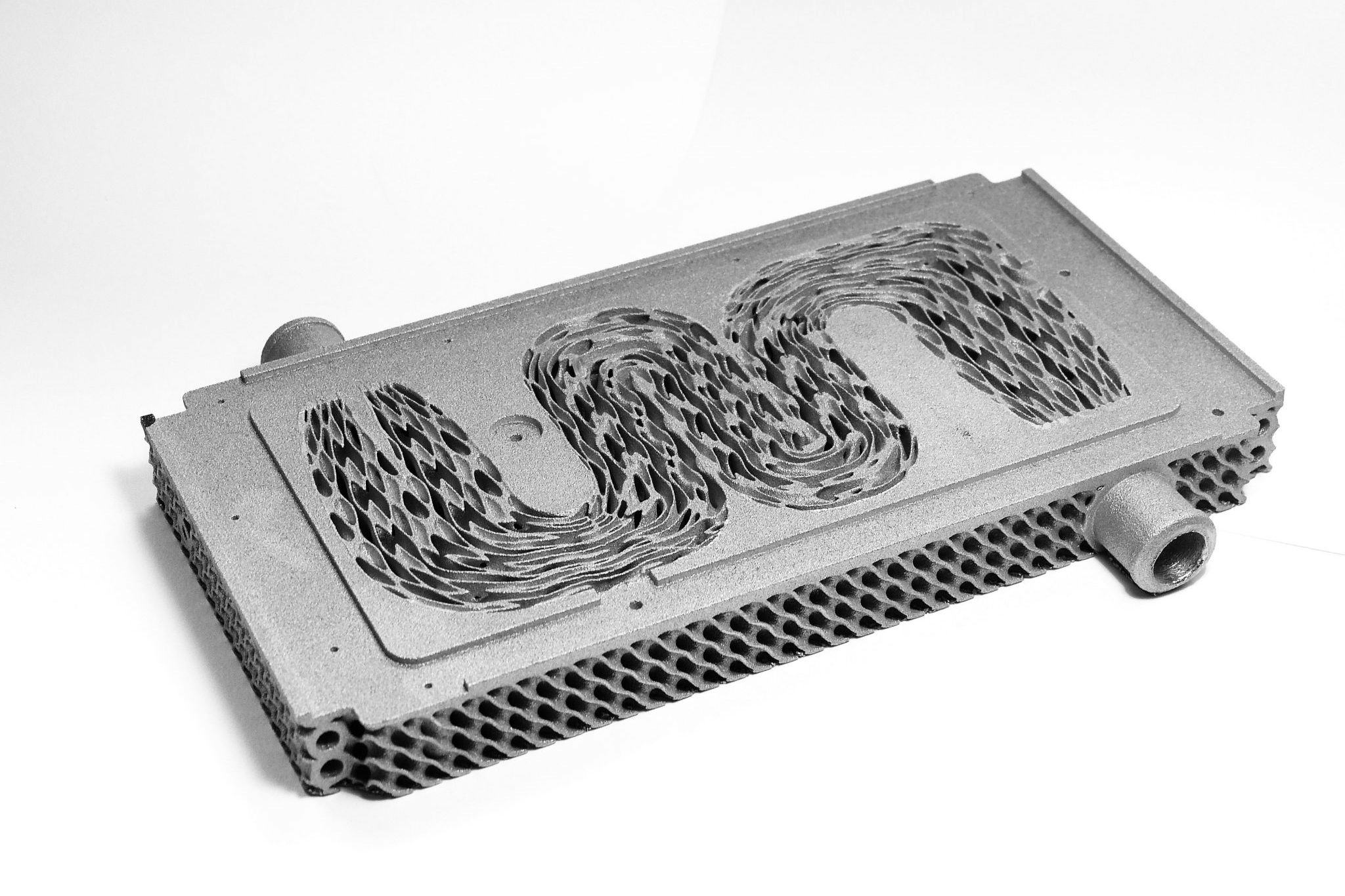

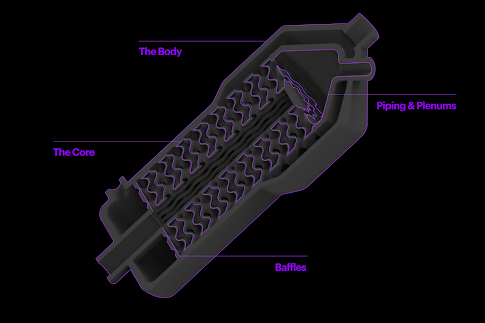

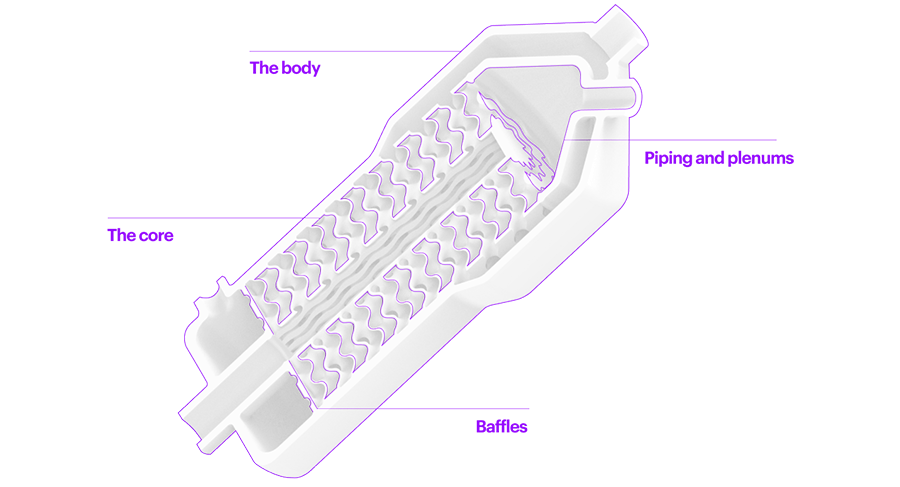

The anatomy of a 3D-printed heat exchanger

Heat exchangers may vary in type, shape, and size, but their basic layout is the same. Here are the essential elements of an additive manufactured heat exchanger.

Software built on transformative technology

Thermal management resources for engineers and designers

Ready to improve your heat exchanger design?

nTop has the tools you need to maximize the benefits of AM.