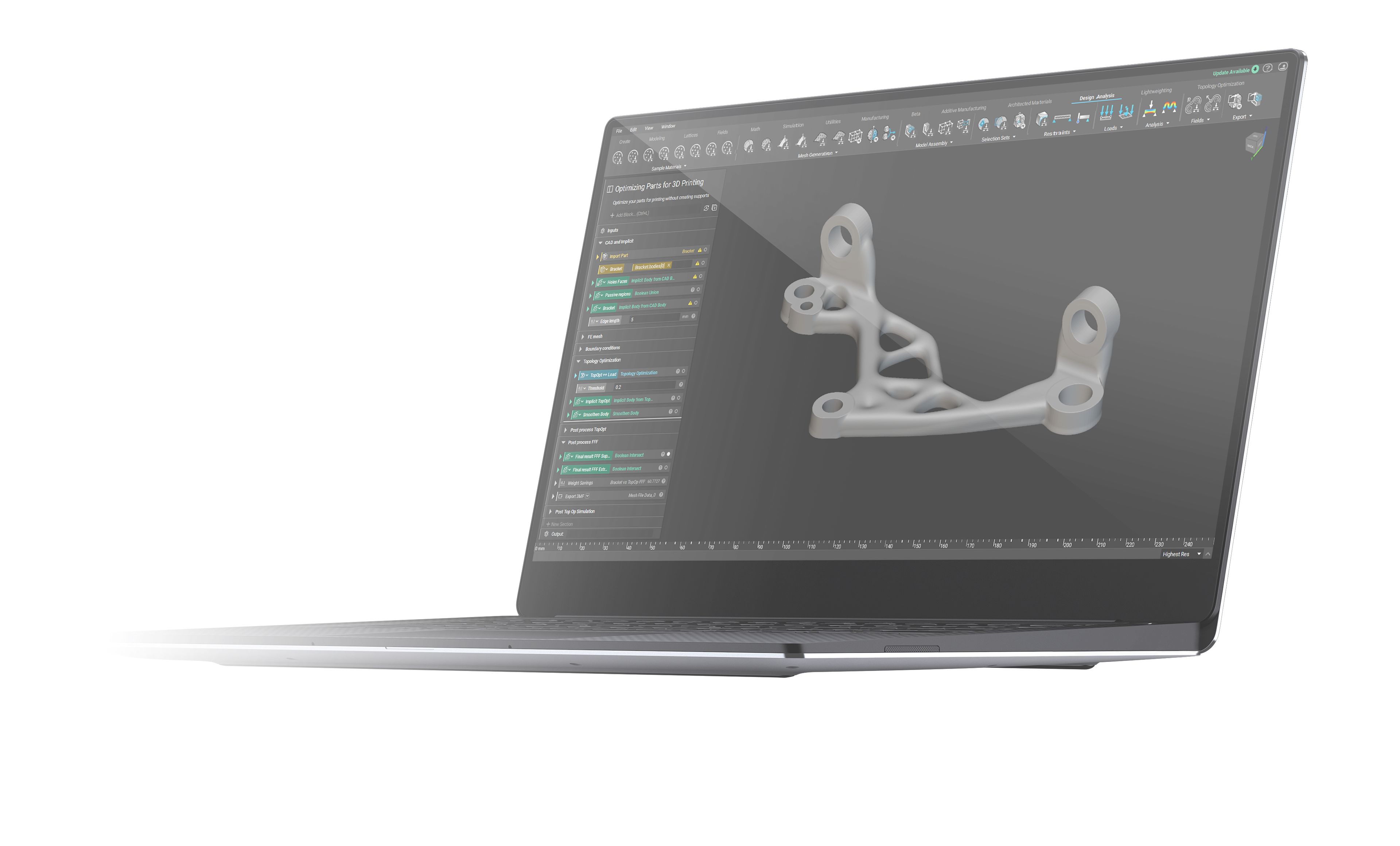

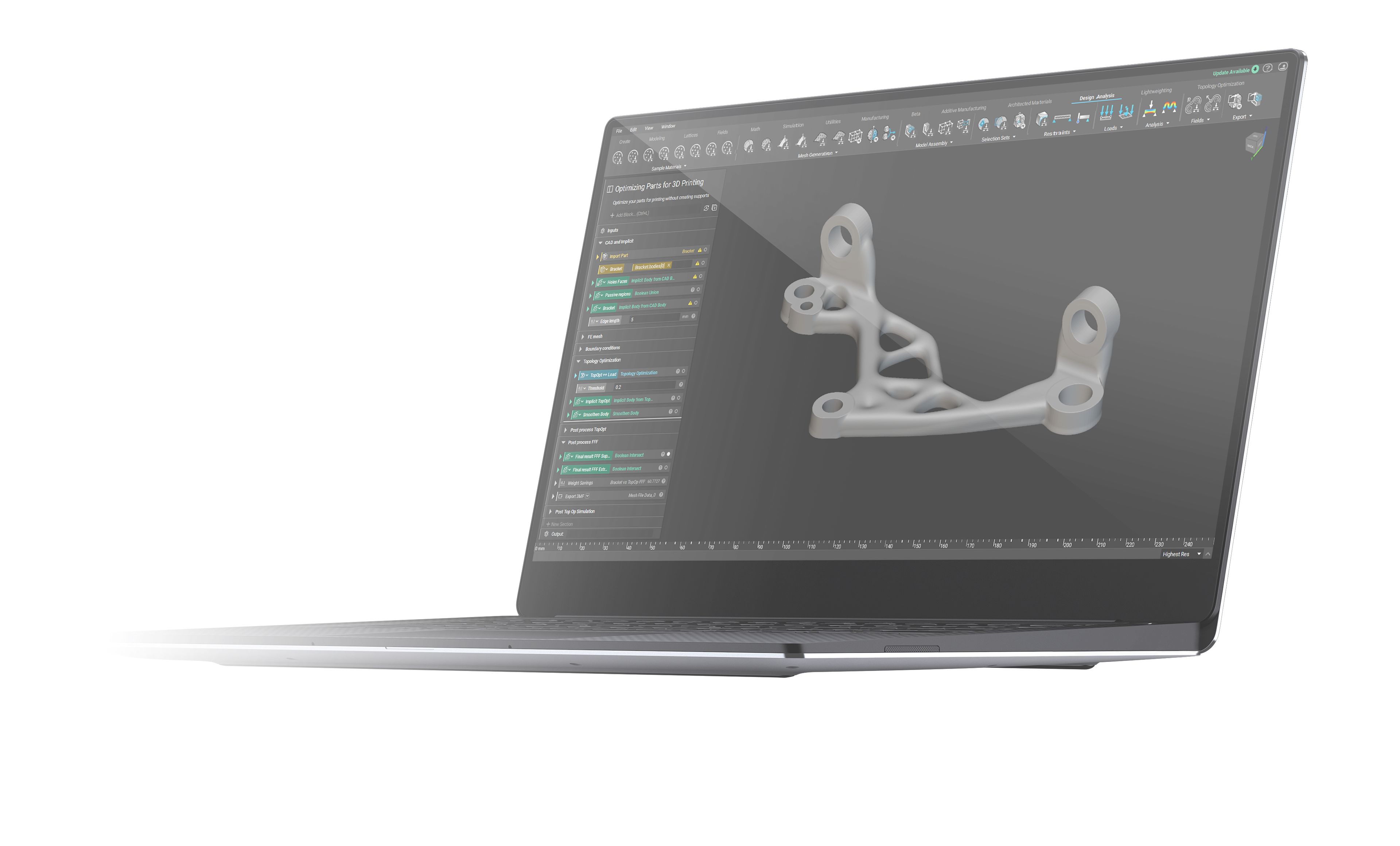

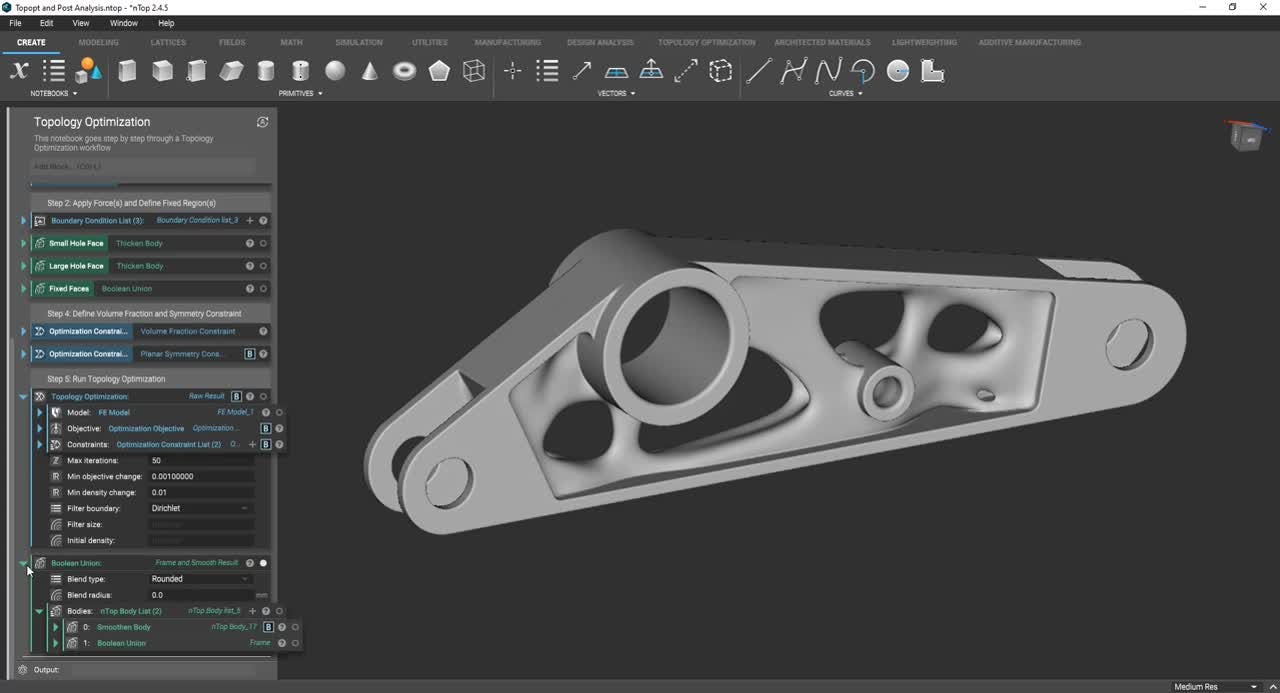

Topology optimization software

Exceed performance targets by completely controlling design parameters and automatically reconstructing optimization results.

Why use nTop for topology optimization?

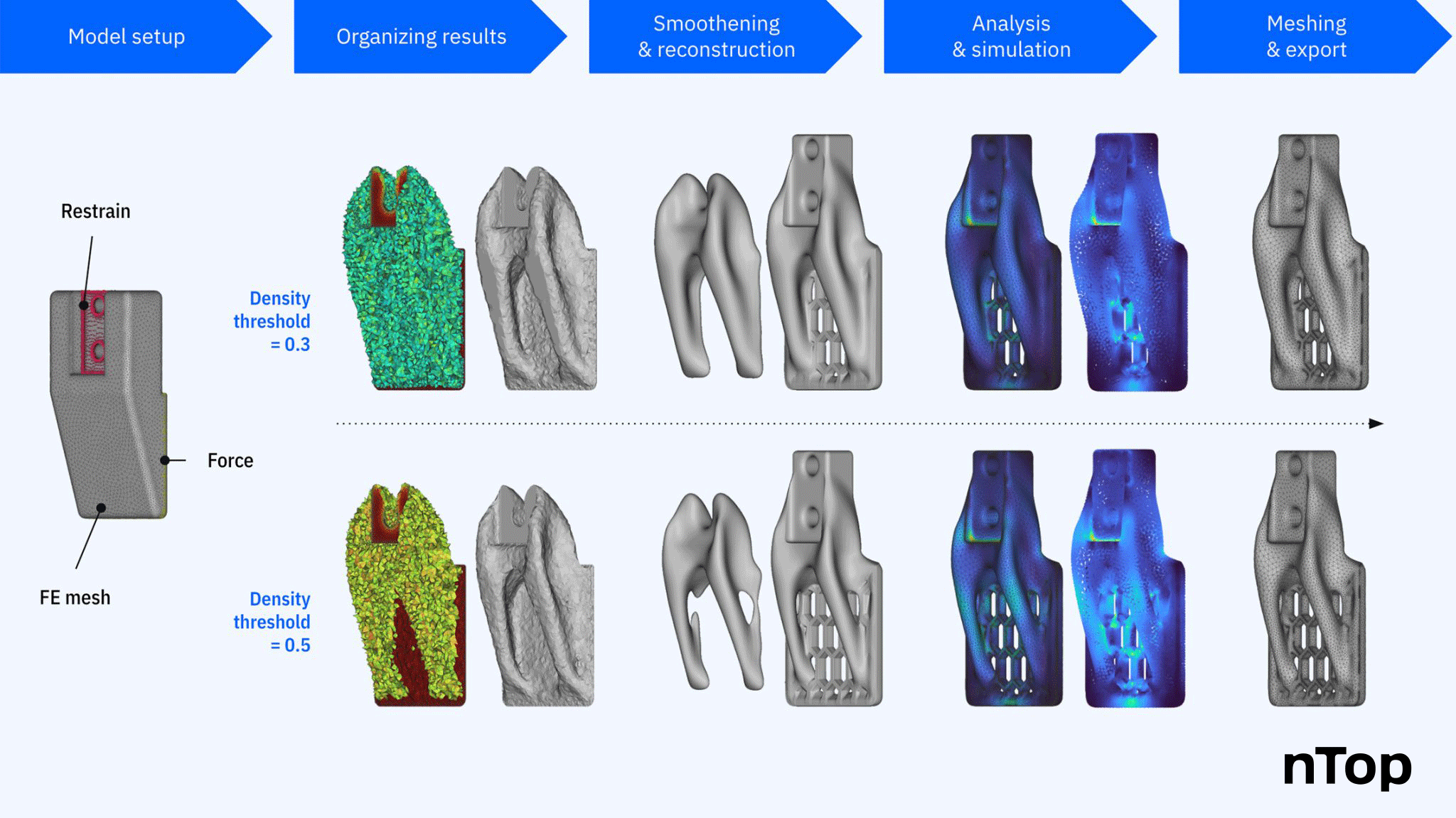

Automated geometry reconstruction

Apply automated smoothening to create clean, editable geometry and bypass time-consuming manual reconstruction.

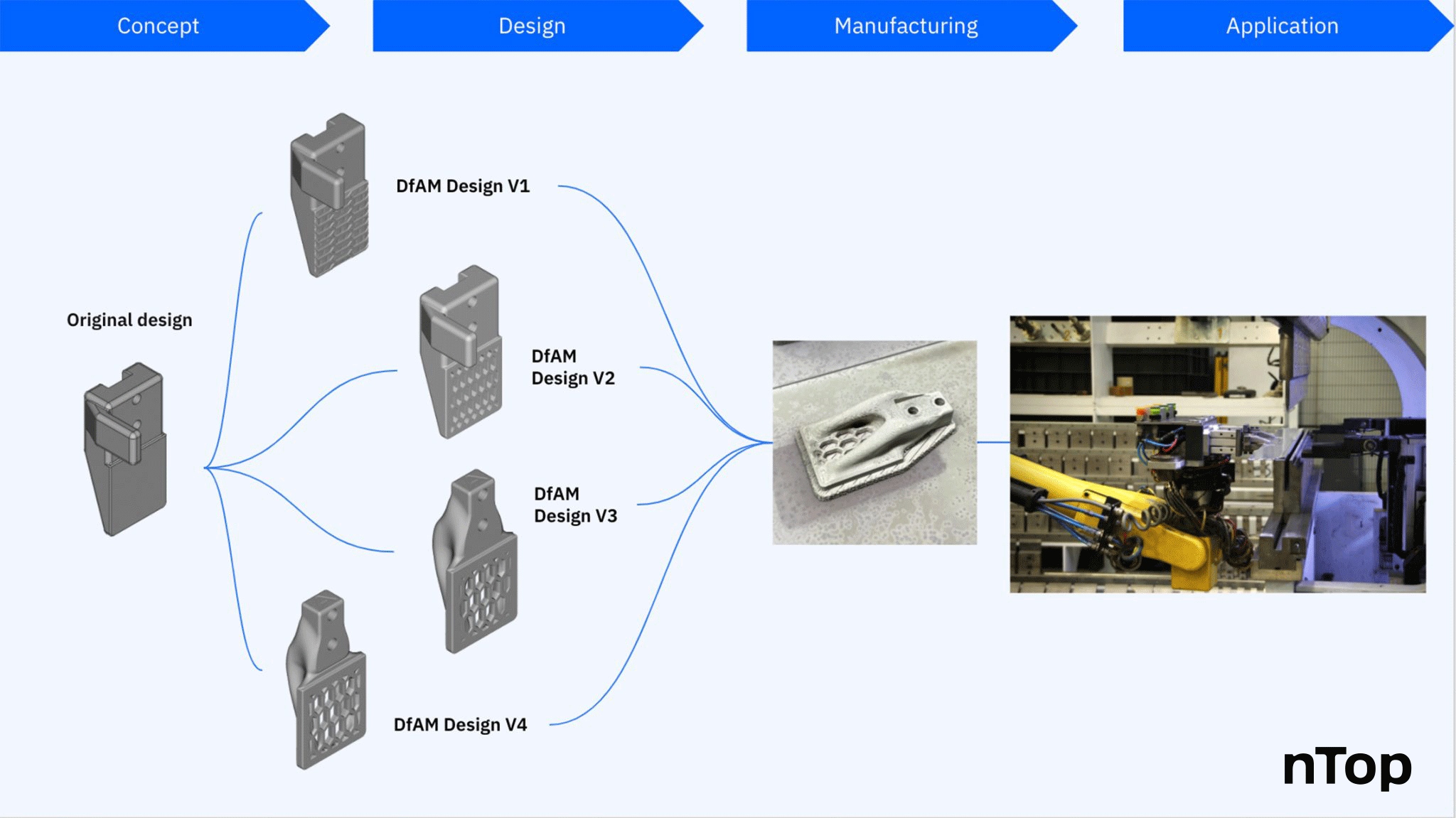

Design for additive manufacturing

Minimize material usage and production costs by factoring in additive manufacturing constraints early.

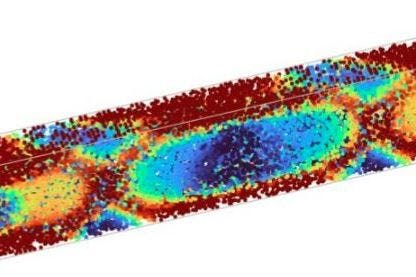

End-to-end optimization

Control your workflow from start to finish by using integrated simulation tools and connecting to external software.

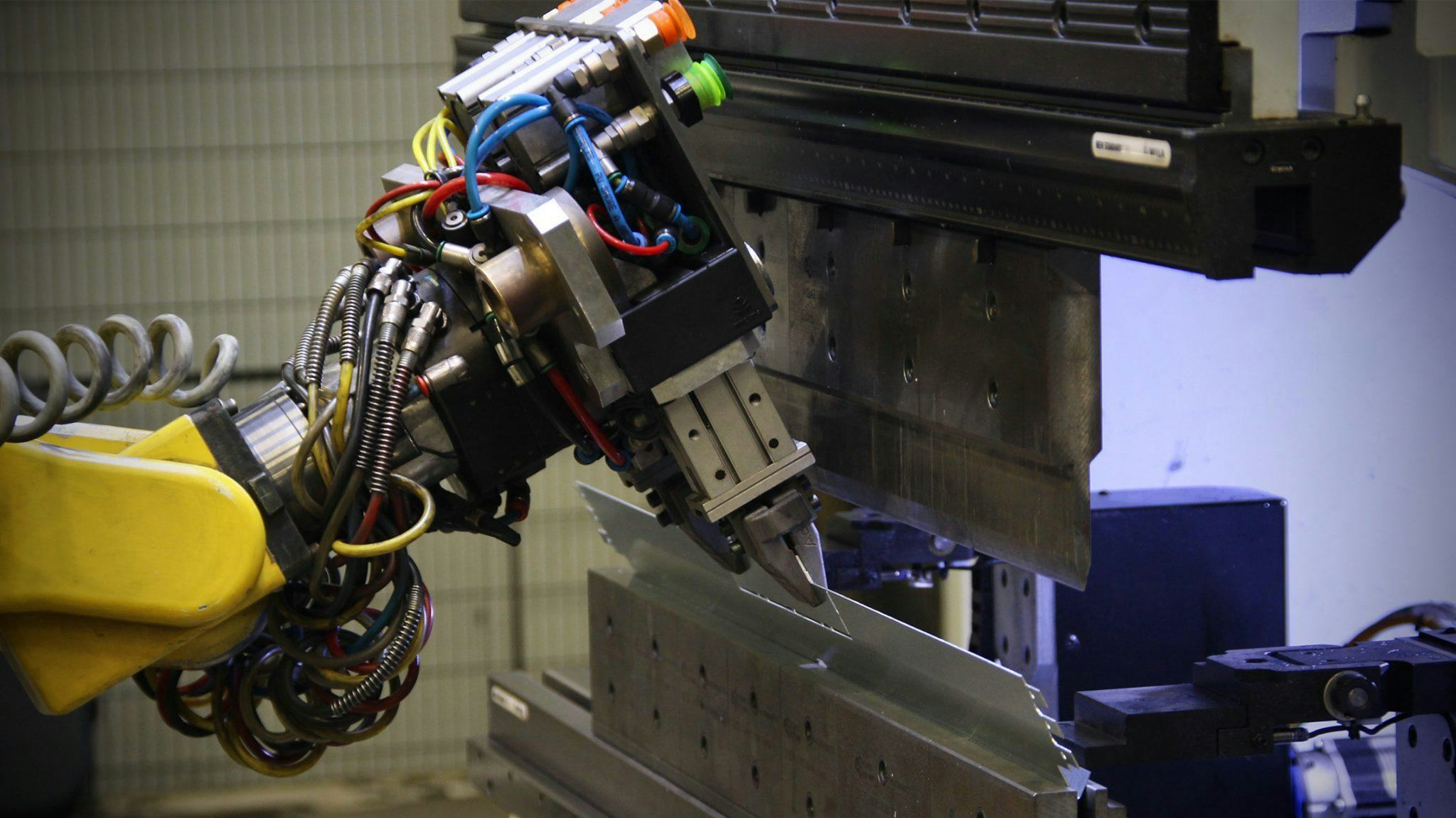

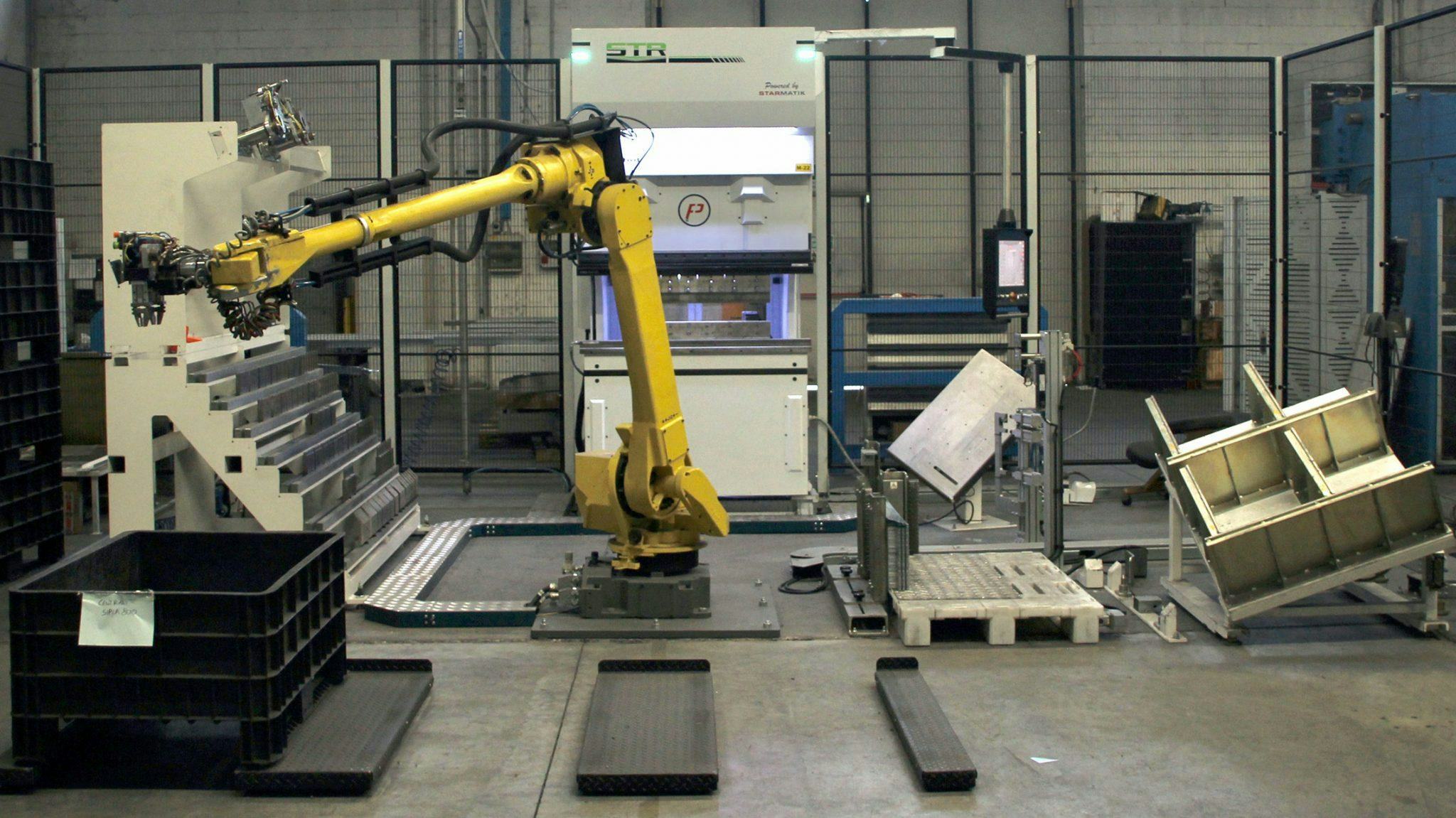

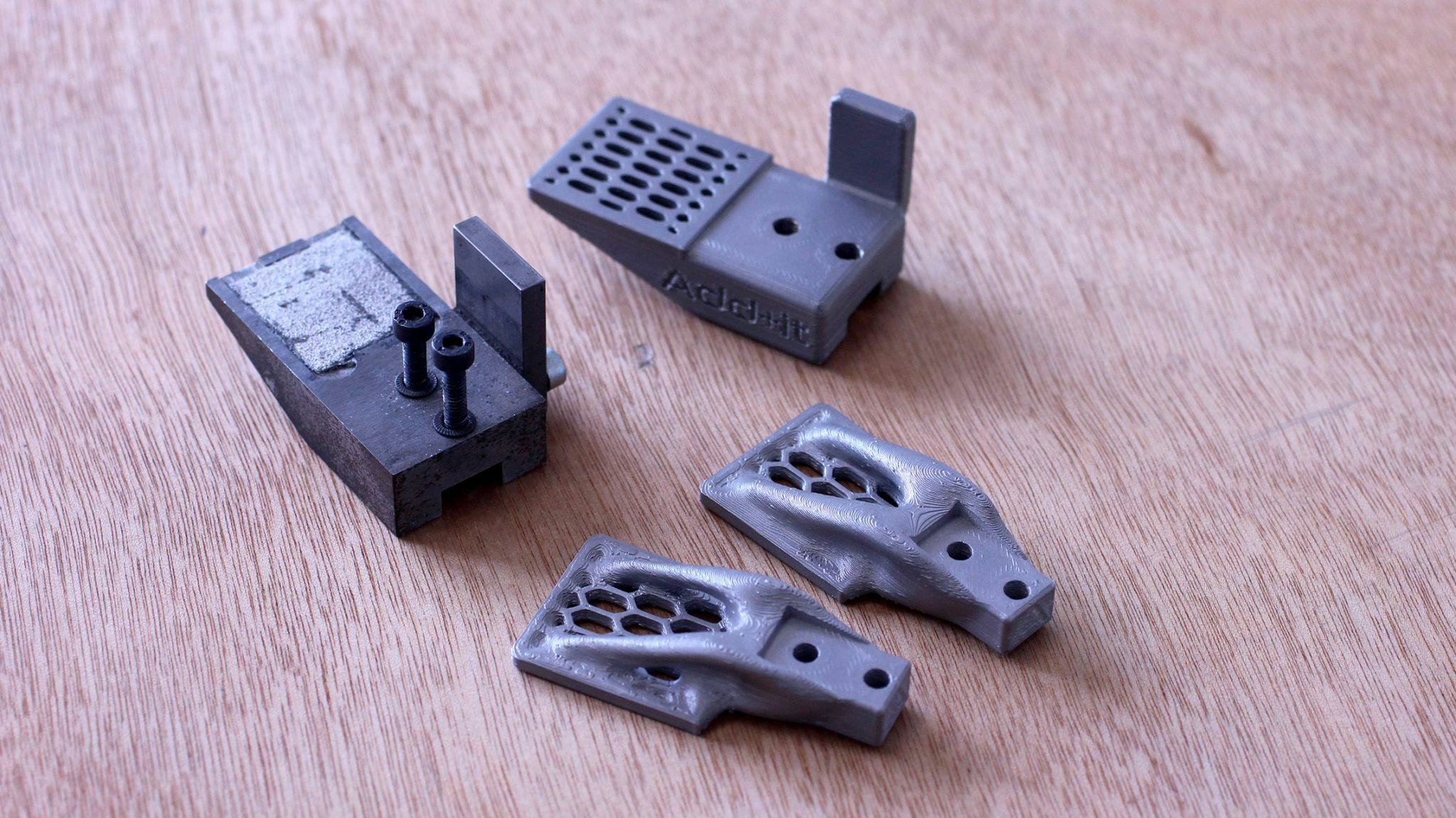

Preziosa Francesco

Preziosa Francesco SRL and Add-it redesigned their robot grippers for metal 3D printing, reducing costs, time, and weight by 32-40%.

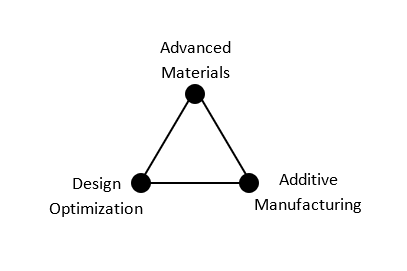

Is your software ready for additive manufacturing?

Traditional software isn’t built to take full advantage of new opportunities for engineers. Maximize the benefits of additive manufacturing with the best advanced latticing tools available.

FAQs

Topology optimization resources for engineers and designers

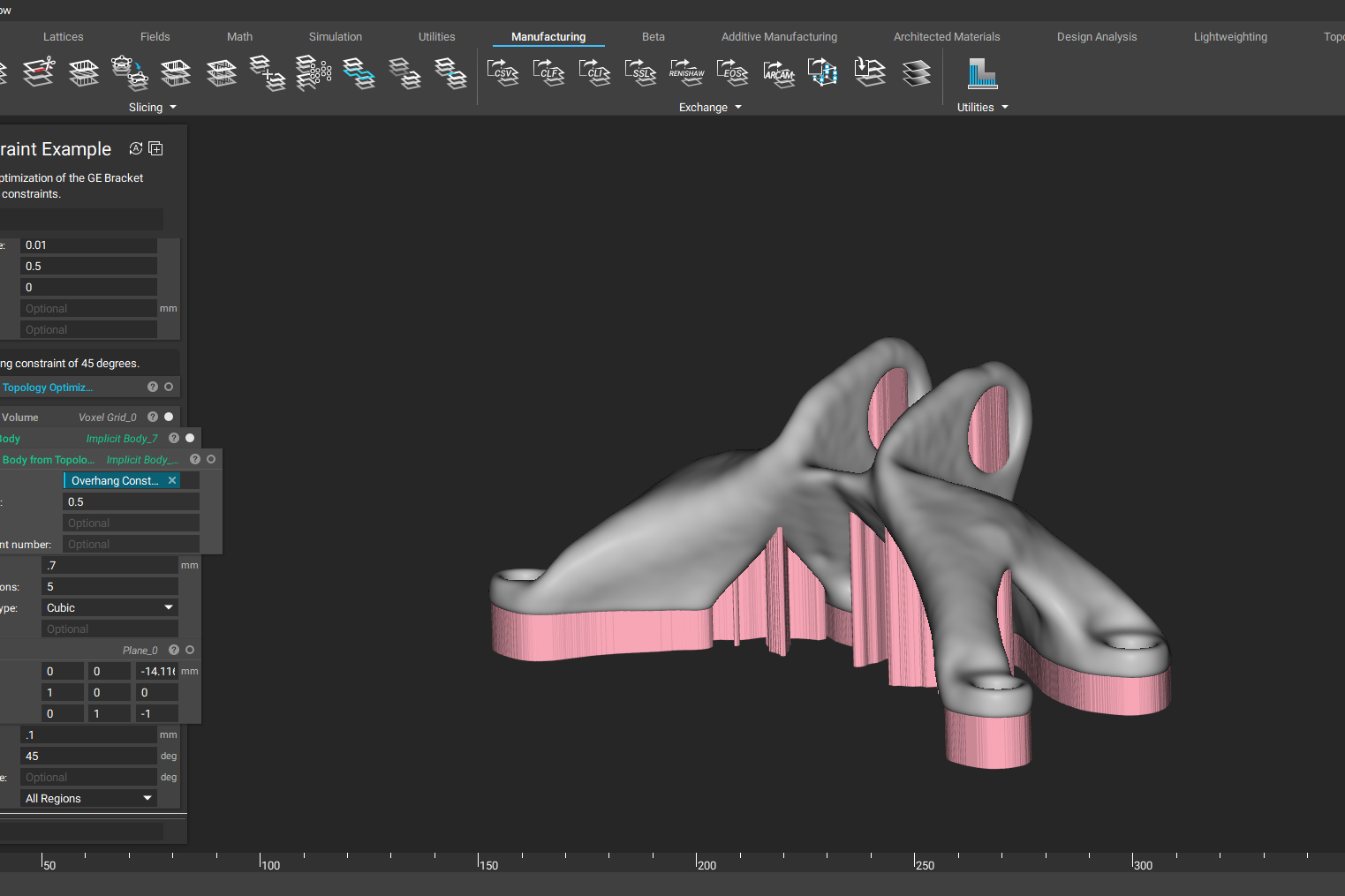

- PRODUCT UPDATE

Topology optimization additive manufacturing constraints in nTop

- VIDEO

Topology optimization 101: How to setup a basic workflow in nTop

- ARTICLE

Yamaha pairs topology optimization with graded lattices

- ARTICLE

Fracture mechanics analysis of topology-optimized parts

Blog - ARTICLE

Topology optimized carbon fiber polypropylene parts are "taking-off"!