What are 3D-printed medical devices?

Written by nTop

Published on January 10, 2023

3D printing medical devices offers many benefits, but it also has its limitations. With the right design software, you can grasp the full benefits of additive manufacturing for medical devices.

What is medical 3D printing?

Medical 3D printing involves creating physical copies of anatomical structures for the direct or indirect production of medical devices. You can use MRI, X-Ray CT, and other 3D imaging processes to create digital models of structures for printing.

In recent years, this process has become increasingly popular for clinical and research-based healthcare activities. A significant benefit of 3D printing is that it can produce small batch sizes quickly and relatively cost-effectively.

The use of medical 3D printing is expected to continue to grow in the coming years as the technology becomes more accessible and affordable. This growth is likely to lead to increased use of 3D printing in both clinical and educational settings, clearer regulatory guidance, and more competition among medical device manufacturers.

Unique capabilities of 3D printing medical devices

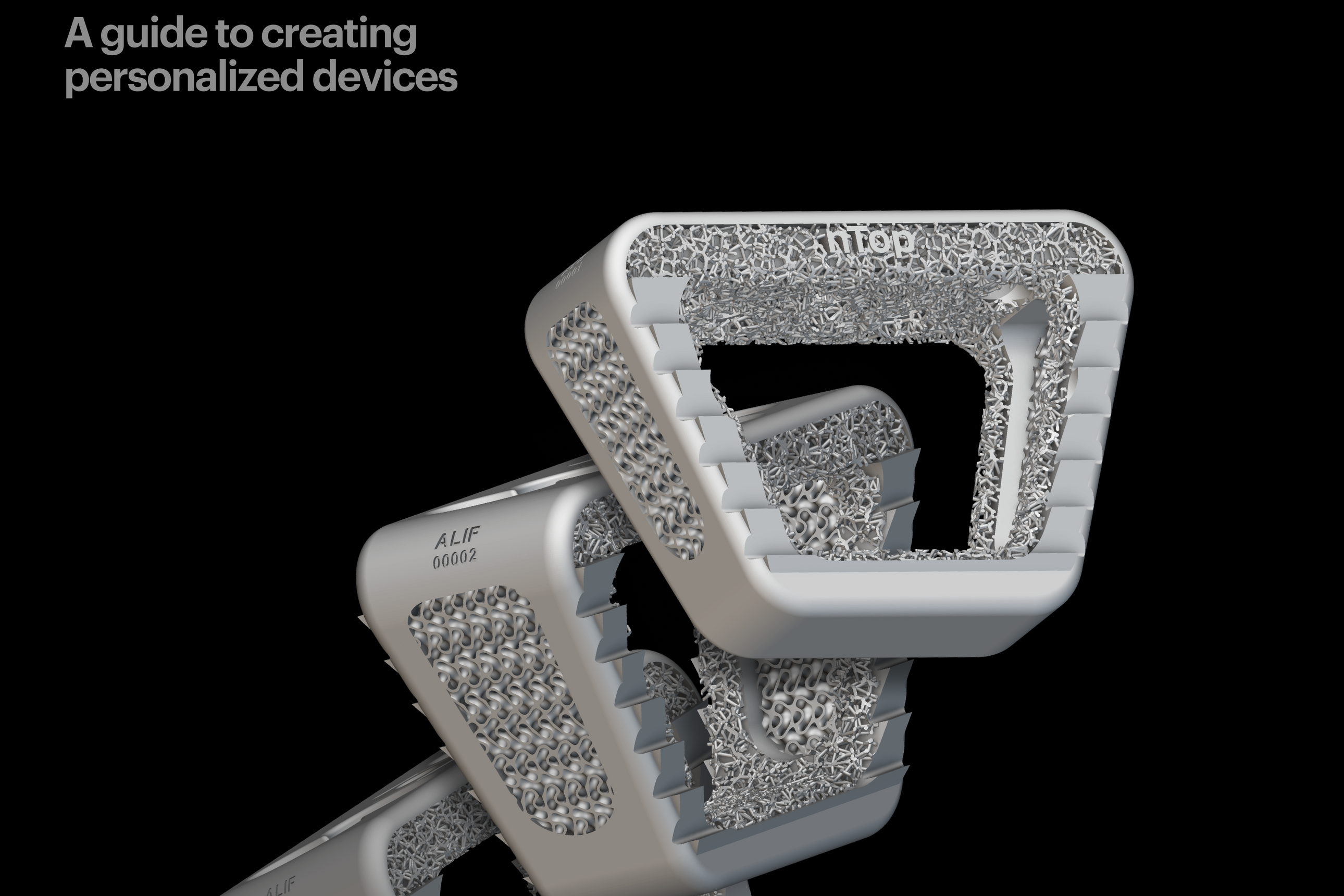

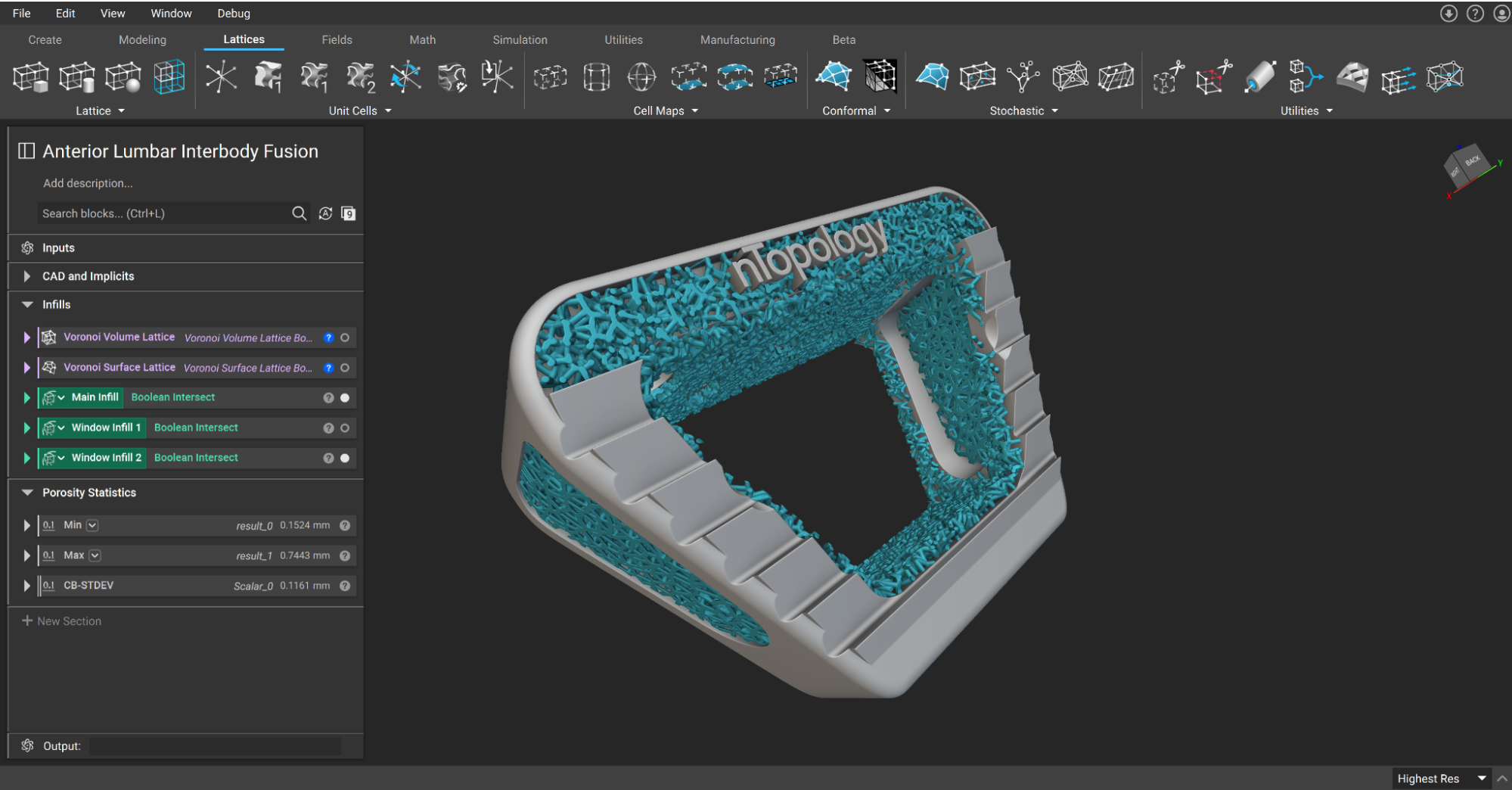

Anterior Lumbar Interbody Fusion (ALIF) spinal implants designed in nTop.

3D printing technology, also known as additive manufacturing (AM), has numerous applications in the medical field. With highly customized medical devices now possible, 3D printing is changing how we think about patient care. Some of the unique capabilities of this technology are listed below.

Personalized devices

Clinical studies have shown that personalized medical devices improve patient outcomes and reduce the cost of care. This means that personalized medical devices have the potential to significantly advance reconstructive surgery, orthopedics, prosthetics, orthotics, dentistry, and veterinary medicine — in a similar way to how personalized cancer treatments revolutionized oncology.

Medical device manufacturers can now develop patient-matched devices more affordably and effectively, thanks to the convergence of several technologies. 3D printing, in particular, enables healthcare providers to create innovative personalized medical devices for their patients.

Unlike traditional mass production methods, 3D printing permits more extensive personalization of devices, enabling you to tailor them to each patient’s specific needs and physiology. This results in patient-matched devices better suited to the individual and their unique anatomy.

For example, medical devices personalized to the patient include:

- Orthopedic implants that adapt to the contour of the bone

- Prosthetic leg sockets with adjustable stiffness according to the patient's body mass index and lifestyle

Personalized medical devices offer many benefits to patients, including improved aesthetics, faster procedures, and reduced pain. As such, they will play an essential role in the future of healthcare.

Biologically relevant structures

3D printing personalized medical devices allows you to leverage architected materials, offering enhanced performance opportunities. Architected materials are structures with targeted performance properties, which enable you to engineer physical characteristics such as stiffness or impact absorption and treat them as design variables.

Medical device use cases for 3D printing include osseointegration, mechanical biocompatibility, and 3D-printed foams — each of which can offer performance benefits.

Osseointegration

Osseointegration is crucial for implant stability and long-term clinical success because it provides a direct functional and structural connection between living bone and the surface of an implant.

3D-printed medical devices often include porous metal foams, which can accelerate osseointegration because you can carefully fine-tune their porosity, shape, pore size, and distribution. These implants don't require cement and often reduce the time spent in the operating room by 25%.

Mechanical biocompatibility

An important aspect of creating personalized medical devices is mitigating the risk of "stress shielding," which occurs when metal implants are used to repair fractures or in joint replacement surgery. Stress shielding can cause complications in the long term, but it can be reduced by ensuring that an implant's mechanical properties, such as compressive strength and Young's modulus, match the bone's properties.

TPMS, stochastic, and graph lattices are ideal for designing porous metal scaffolds, which are an alternative solution to autologous bone grafts. The properties of these lattice structures can be precisely tuned and optimized locally to prevent implant failure and achieve the desired effect.

3D-printed foams

Polymer lattices can also be tuned to generate structures that have foam-like behavior. Unlike traditional foams, additively manufactured foams offer greater control and excellent impact absorption and cushioning properties. 3D-printed foams for medical devices are often used in prostheses to create sockets with unique, dynamic behavior.

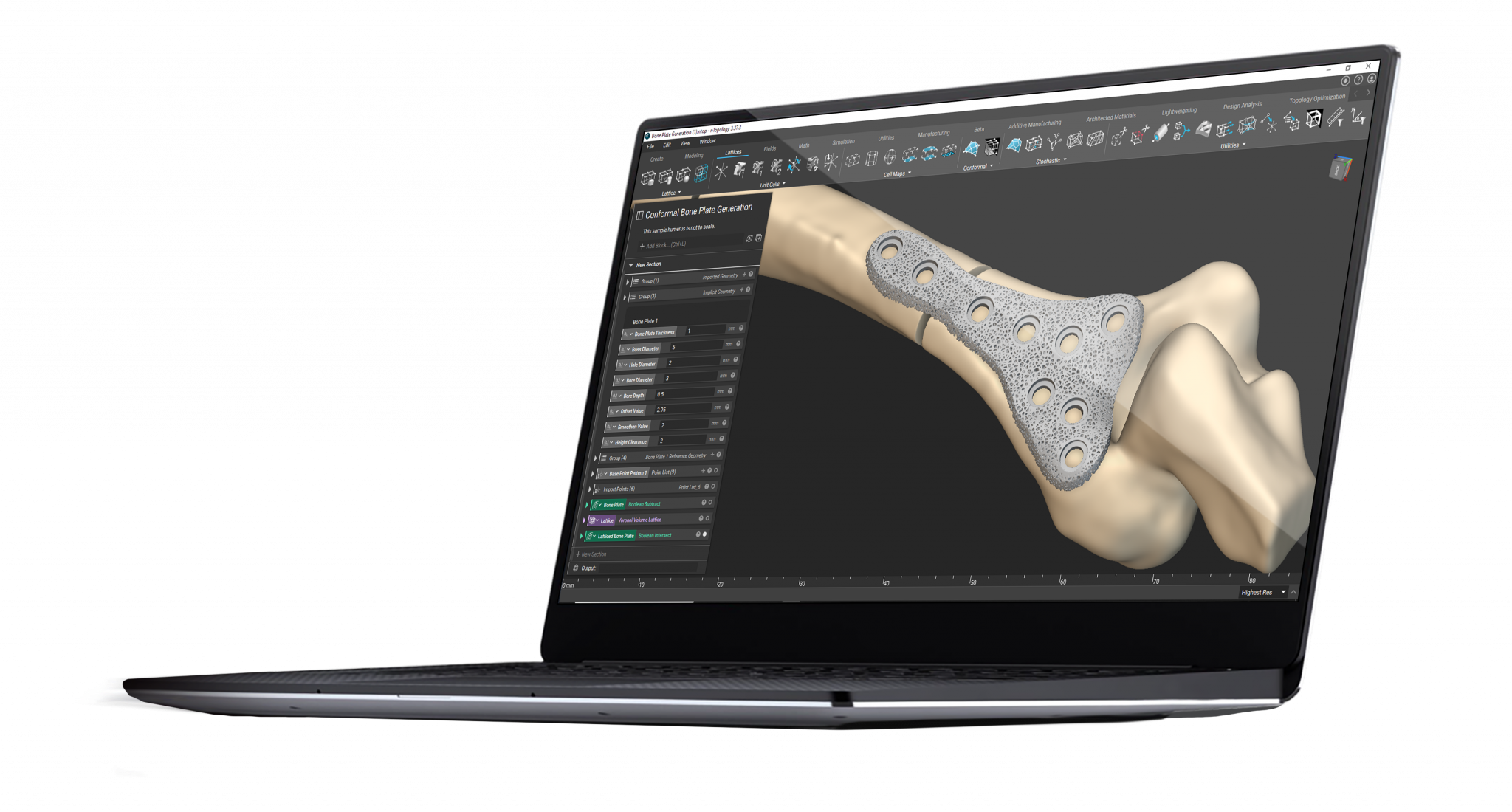

Design automation

Design automation is critical in developing 3D-printed medical instruments and devices. It enables rapid exploration of the available design space, the lock-in of critical parameters, and the identification of the most important design variables. By creating an automated design workflow, you will typically only need to provide new inputs to generate a new pre-validated design.

Automating the design process in this way helps to ensure reproducibility and consistency in the final product, resulting in significant time and cost savings.

Benefits and limitations

Additive manufacturing offers several advantages over traditional manufacturing technologies that make the production of personalized medical devices viable and economical. However, there are some limitations to consider when using additive manufacturing for personalized medical devices.

Benefits

- Marginal cost of customization. Additive manufacturing allows you to create scalable, automated, end-to-end workflows for custom products — from design to production.

- Biologically relevant structures. 3D printing will enable you to create accurate organic structures and unique design features that are impossible with traditional methods.

- Accelerated product development. Once you have established the initial process, you can easily replicate it across different devices.

Limitations

- Limited range of materials. Although additive manufacturing is limited in terms of available materials, you can leverage its ability to create complex structures to expand the scope of available applications.

- Engineering cost of customization. The cost of customization for additive manufacturing production is marginal, but the cost of customization during the design process is considerable.

- Regulatory approval and compliance. Receiving regulatory clearance and ensuring compliance is a highly scrutinous process. Traceable design processes can help you overcome this limitation.

Applications

3D-printed medical devices are revolutionizing the healthcare industry by providing bespoke solutions to patients and surgeons. There is a wide range of 3D-printed medical device applications, from orthopedic surgery to veterinary medicine.

Orthopedic surgery

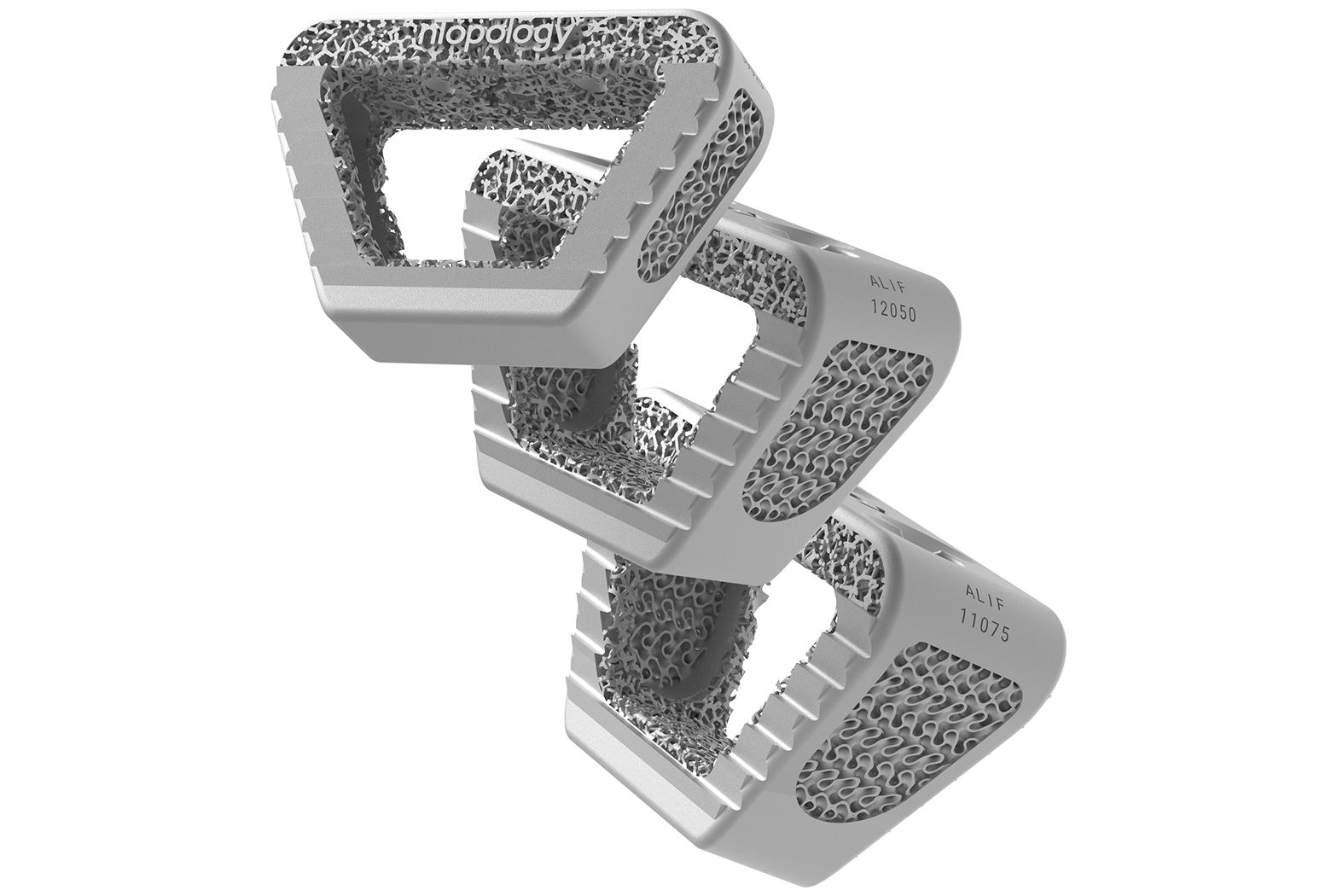

ALIF spinal implant featuring porous trabecular structures for cementless fixation.

Orthopedic surgery is one of the most common applications for 3D-printed surgical instruments. You can design customized implants to match a patient's unique anatomy and precisely manufacture them using specific techniques. These personalized implants can offer better coverage and alignment, as well as features that promote osseointegration and match the mechanical properties of the bone. In addition, you can use patient-matched bone plates to treat complex cases or promote healing.

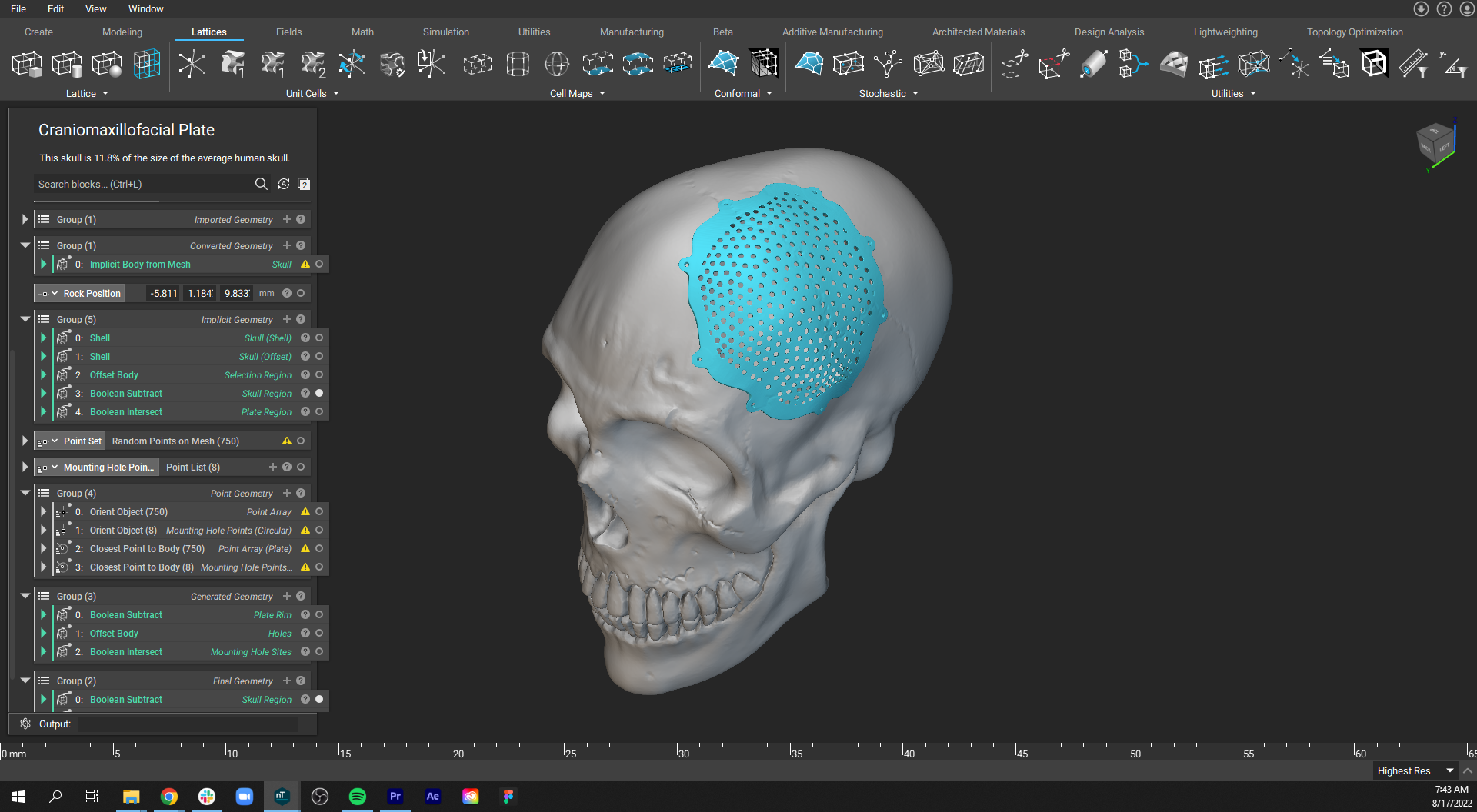

Plastic and reconstructive surgery

Patient-specific cranial bone plate with shape that mirrors the undamaged part of the skull.

You can use several types of 3D-printed medical devices in plastic and reconstructive surgery. One of the most common patient-specific implants can restore both form and function to patients suffering from deformities or traumas.

Additively manufactured implants made from biocompatible materials show promise as an alternative to autologous bone grafts. Early clinical results indicate that they are safe and effective. These implants can be customized to each patient's specific needs, providing a perfect fit and minimizing the risk of postoperative infections.

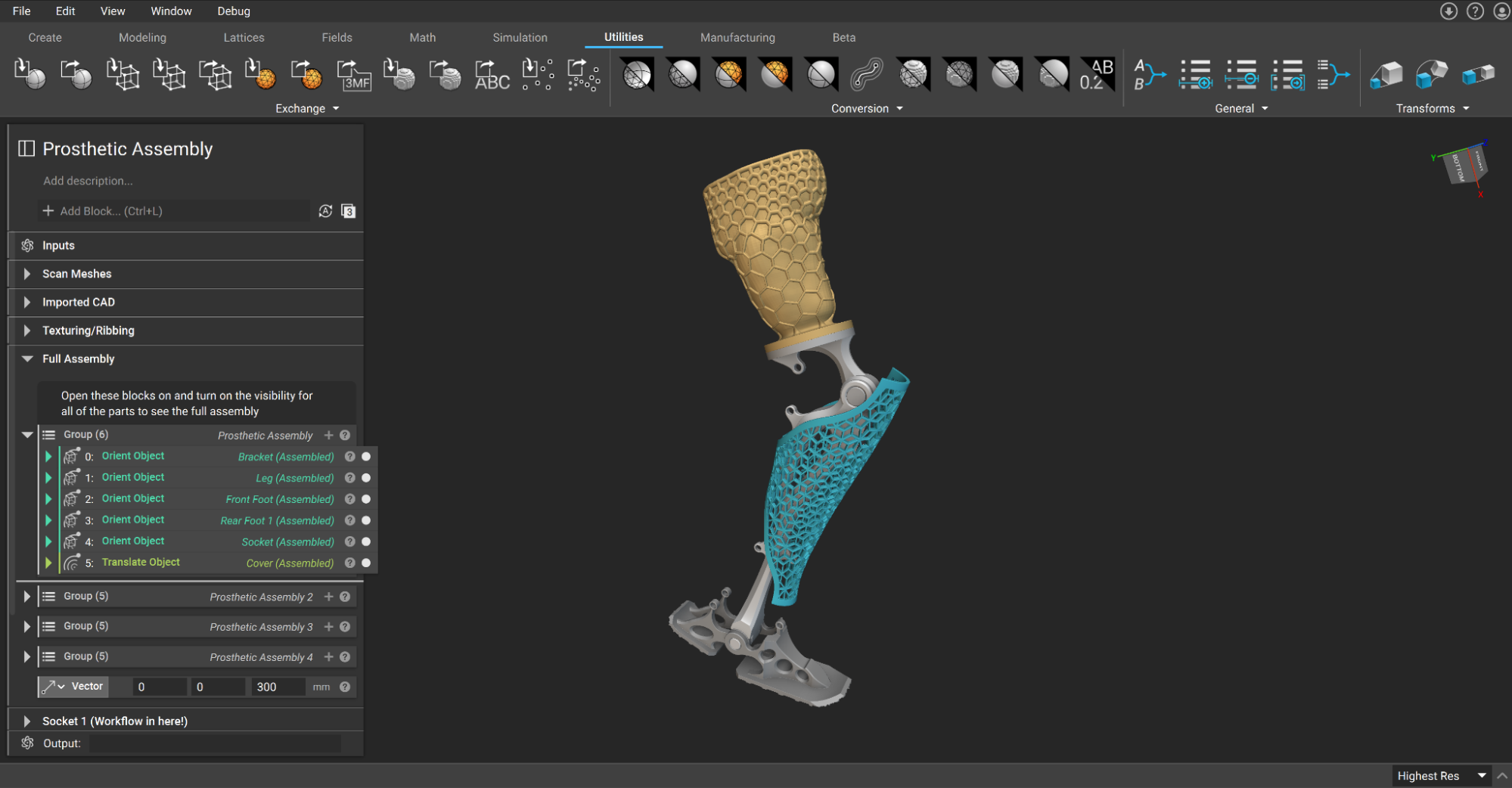

Prostheses

3D-printed arm prostheses concept designed by Jade Myers in nTop.

3D printing offers opportunities to create prostheses that are more comfortable and better fitting than those made with traditional methods. The ability to customize prosthetic sockets using 3D scanning and additive manufacturing also offers economic benefits, making them well-suited for children and teenagers who require frequent socket replacements during growth.

From a design perspective, 3D printing allows for the creation of prostheses with unique features that are not possible with traditional manufacturing methods. For example, the socket can be stiff where needed and more flexible in other areas, allowing for a better fit and greater comfort.

Orthoses

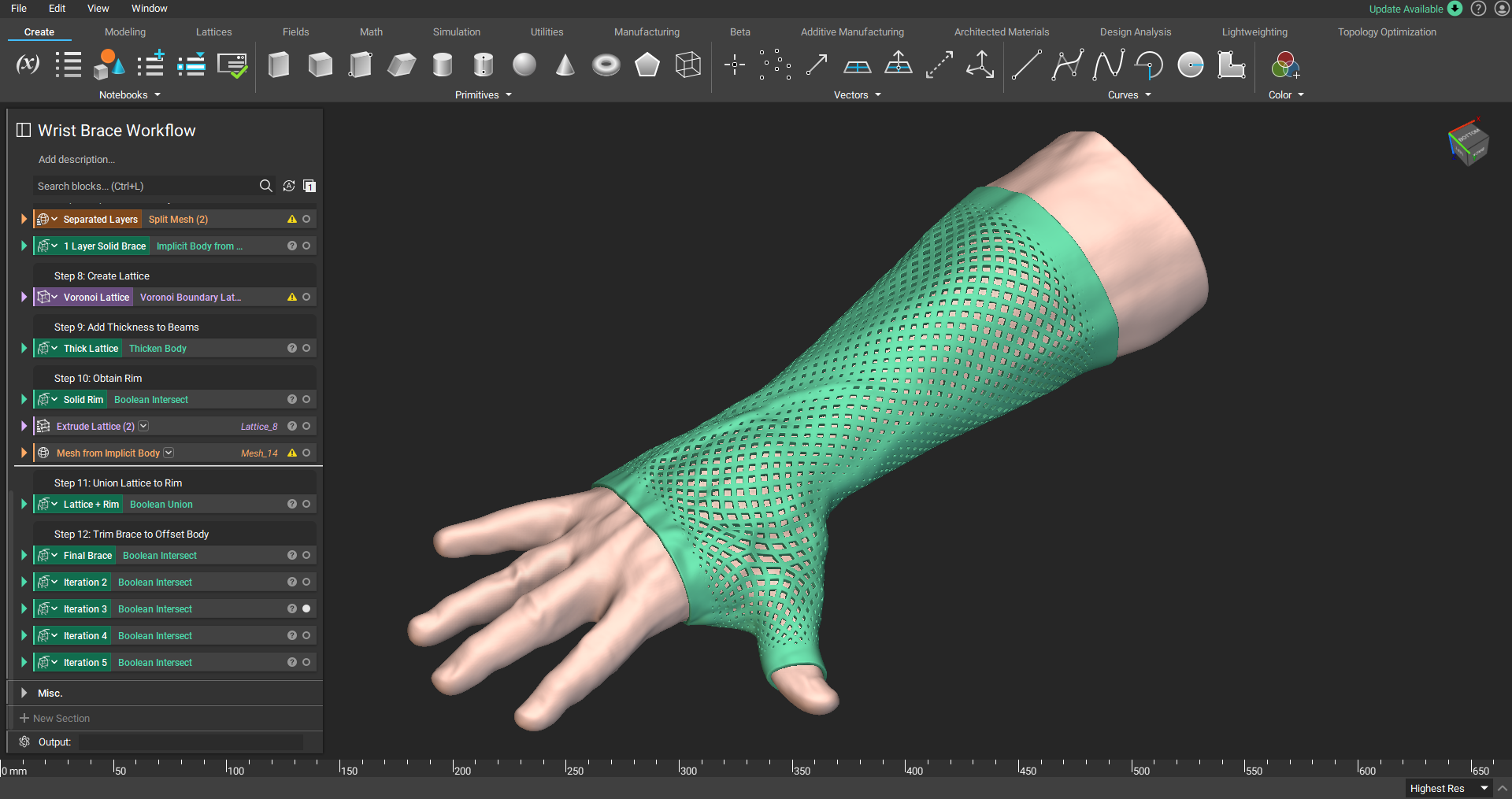

Patient-specific wrist-hand orthosis.

Orthoses can be customized using 3D scan data for better fit and support. Like prostheses, 3D-printed orthoses can have a more dynamic behavior than traditional designs. For example, the design might have areas of stiffness and areas of flexibility, as well as perforation patterns that improve breathability and hygiene.

Studies have shown that custom-made orthoses for the wrist, hand, foot, and ankle offer similar or better results in biomechanical and kinematic parameters than standard braces.

Dentistry & orthodontics

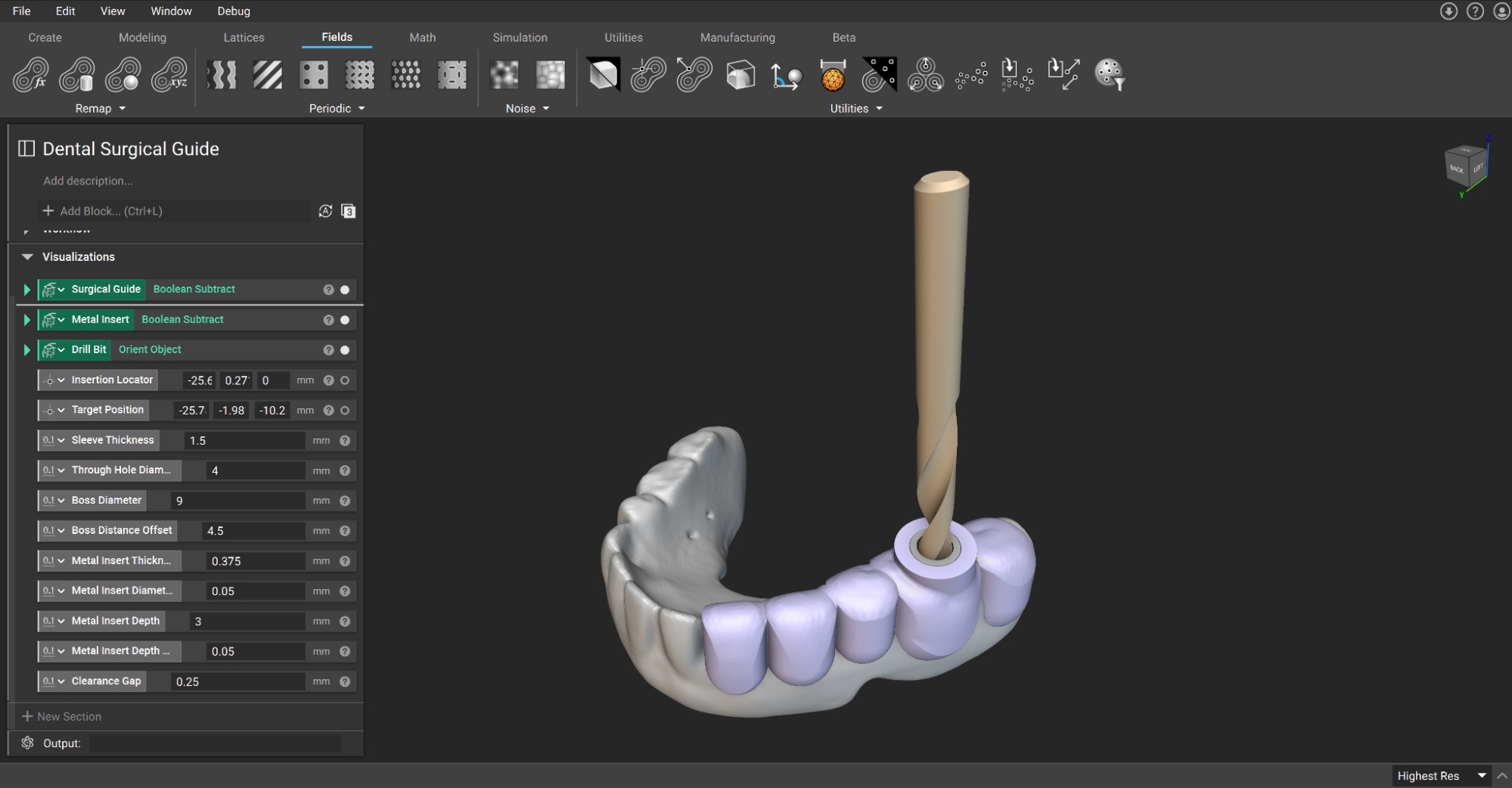

Patient-specific dental surgical guide.

The dental and orthodontic field is one of the most digitized medical fields today. 89% of large orthodontic labs use 3D printing technologies to produce at least one type of patient-specific device. This prevalence is because dental devices require a high degree of customization but also a high volume of production. You can streamline operations and increase throughput by using digital design and manufacturing workflows.

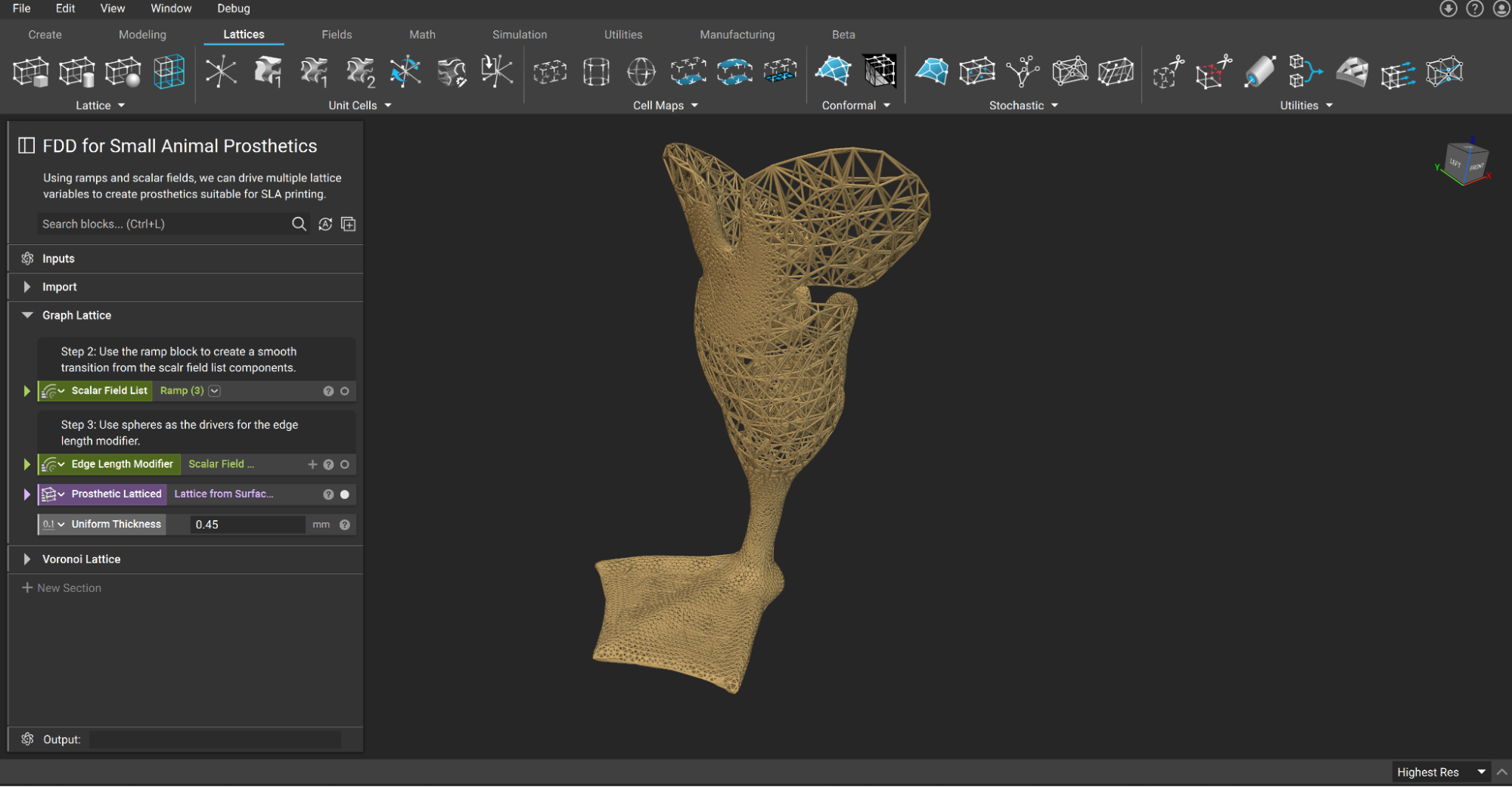

Veterinary medicine

Prosthetic leg for a small animal.

Additive manufacturing has been increasingly adopted in veterinary medicine to create custom, innovative medical devices for animal patients. Veterinarians use these personalized devices to treat pets effectively by restoring bone defects using custom implants and surgical guides and by creating custom prostheses. This technology is more affordable than traditional methods and is customizable to each animal patient's needs.

Case study: SI-BONE

Implantable orthopedic devices by SI-BONE, designed in nTop.

SI-BONE is a medical device company that has developed a novel osseointegrative lattice structure. This structure is used in minimally-invasive joint surgery and provides better support for the fusion of bones.

The company's engineering team was able to apply this structure to a product family of 70+ unique parts in under six hours while ensuring traceability. The main advantages of this new design are time savings and reduction in operational risk. The design is also more reliable and can be reproduced more accurately.

This new technology offers great potential for SI-BONE and other companies in the medical device industry, and it was awarded the Breakthrough Medical Device designation by the FDA.

Regulatory approval and compliance

Above-knee prosthesis with patient-specific socket with dynamic stiffness and customizable cover.

Personalized medical devices must undergo a rigorous approval process to be cleared for patient use. In most cases, this will involve working with regulatory bodies in the relevant country or region to ensure that the device meets all the necessary safety and efficacy standards.

The standard procedure for all medical devices includes two phases:

The first step is establishing a quality management system (QMS) that outlines all the policies, procedures, forms, and work instructions required to produce and sell medical devices. This QMS will form the basis for assessing whether your device complies with relevant regulations.

Once you have established your QMS, you also need to generate quality records demonstrating that you are correctly following policies and procedures and that your device meets all the required standards.

Personalized medical devices introduce an additional challenge; since the design is always changing, the medical device manufacturer must also ensure that the design process is traceable and that the generated designs fall within a specific design window. Recent regulatory guidelines in the US and other jurisdictions are making the certification process for personalized devices more streamlined.

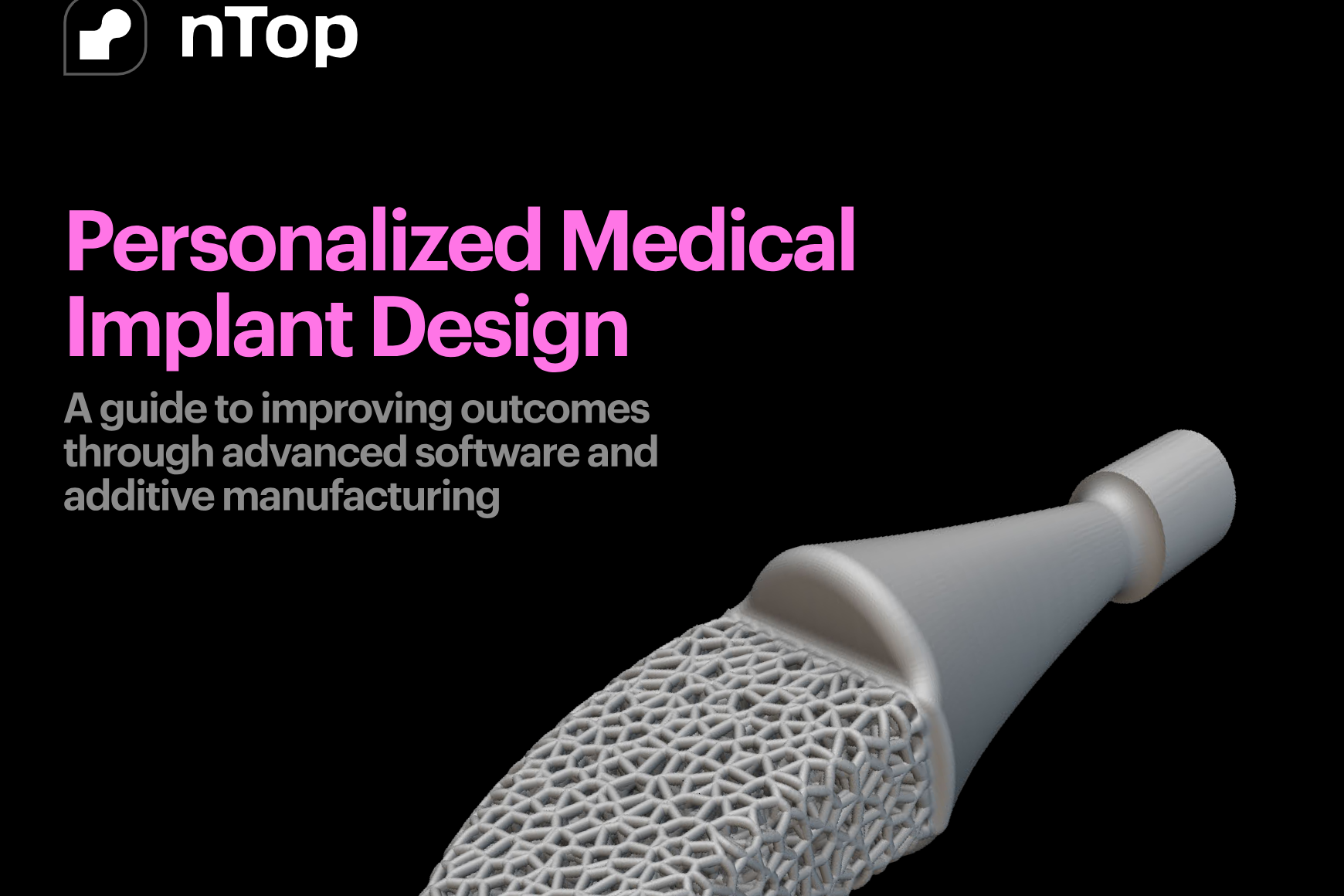

Design software for personalized medical devices

With the increasing popularity and widespread use of additive manufacturing, there is a rising demand for software that can take full advantage of its design freedom. nTop is a next-generation design software that enables engineers to create innovative medical devices that improve patient outcomes.

This advanced engineering design software gives you access to design tools to develop innovative medical devices that improve patient outcomes and provides a clear pathway for personalization at scale.

With nTop, you can quickly and easily design custom medical devices that meet the unique needs of your patients. Find out more about personalized medical devices in our comprehensive guide.

Key takeaways

- 3D-printed medical devices are becoming increasingly popular as additive manufacturing technology improves and costs decrease.

- There are many benefits to using 3D printing for medical devices, including the ability to create complex shapes with tailored physical properties that would be difficult or impossible to create using traditional manufacturing methods.

- With the increasing popularity of additive manufacturing, there is a rising demand for software like nTop that can overcome its limitations and help you take full advantage of its design freedom.

nTop

nTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Built on proprietary technologies that upend the constraints of traditional CAD software while integrating seamlessly into existing processes, nTop allows designers in every industry to create complex geometries, optimize instantaneously, and automate workflows to develop breakthrough 3D-printed parts in record time.

Related content

- VIDEO

Five ways to lightweight in nTop

- GUIDE

Download: Advanced design software and additive manufacturing for personalized implants

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

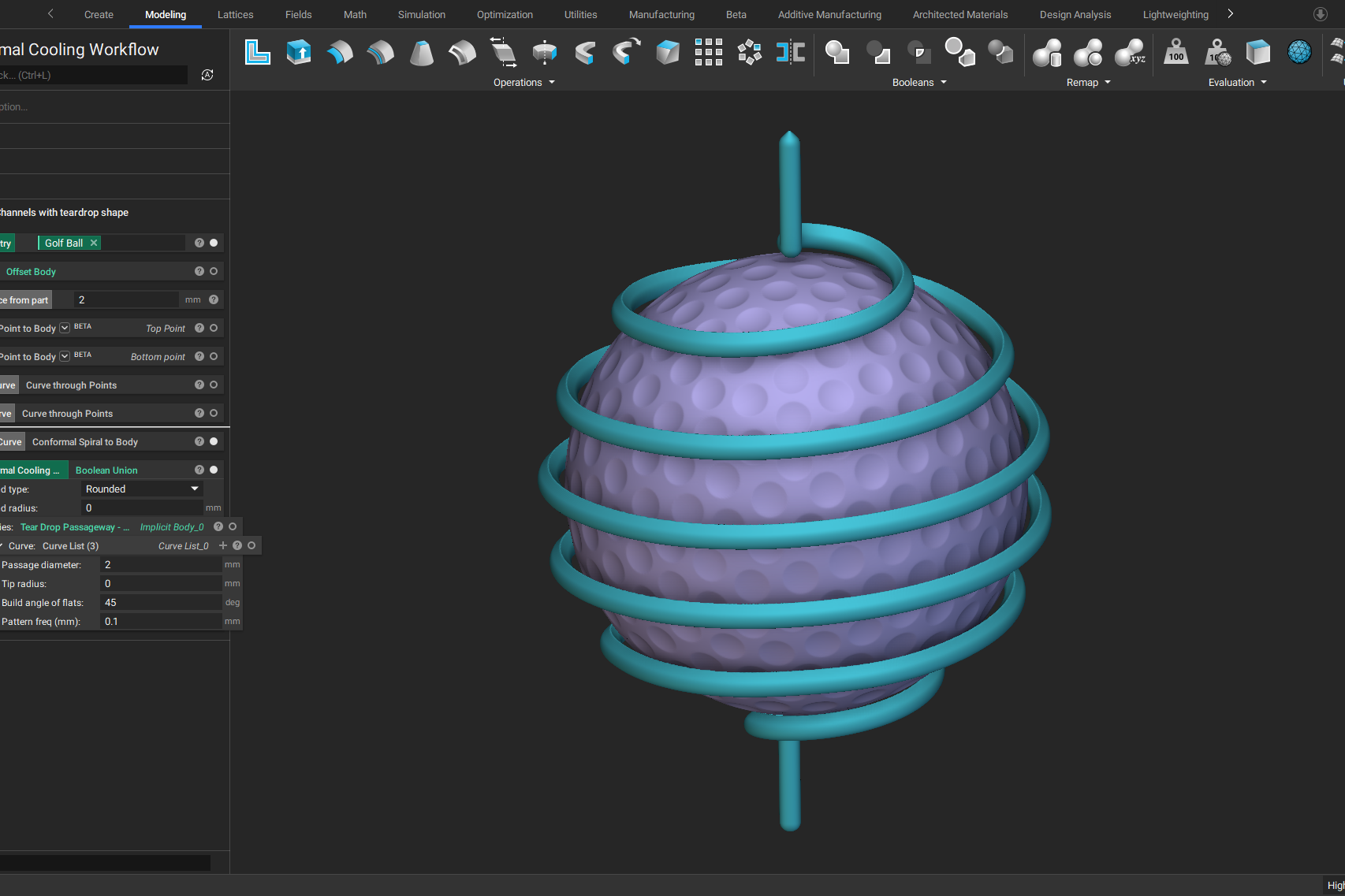

Optimizing thermal management with conformal cooling to extend operational life

- GUIDE

Download: Design Automation for Medical Devices