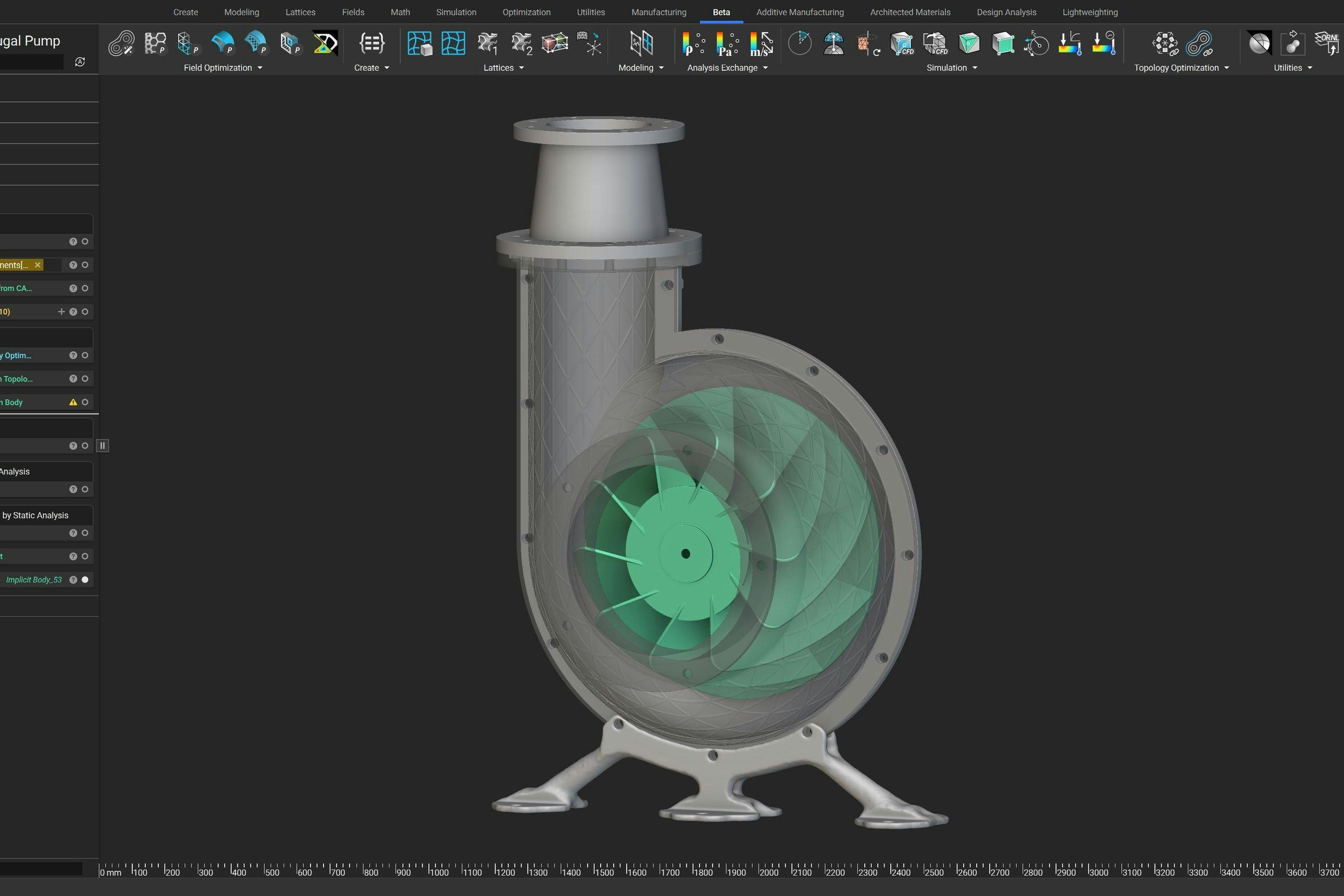

Topology Optimization Design for Cast and Injection-Molded Parts

Topology Optimization Design for Cast and Injection-Molded Parts

Published on April 4, 2024

Applications

Key Software Capabilities

- Topology optimization

Creating lightweight components through topology optimization can be challenging when the part becomes more complex, making it difficult to use traditional manufacturing methods such as metal casting and injection molding.

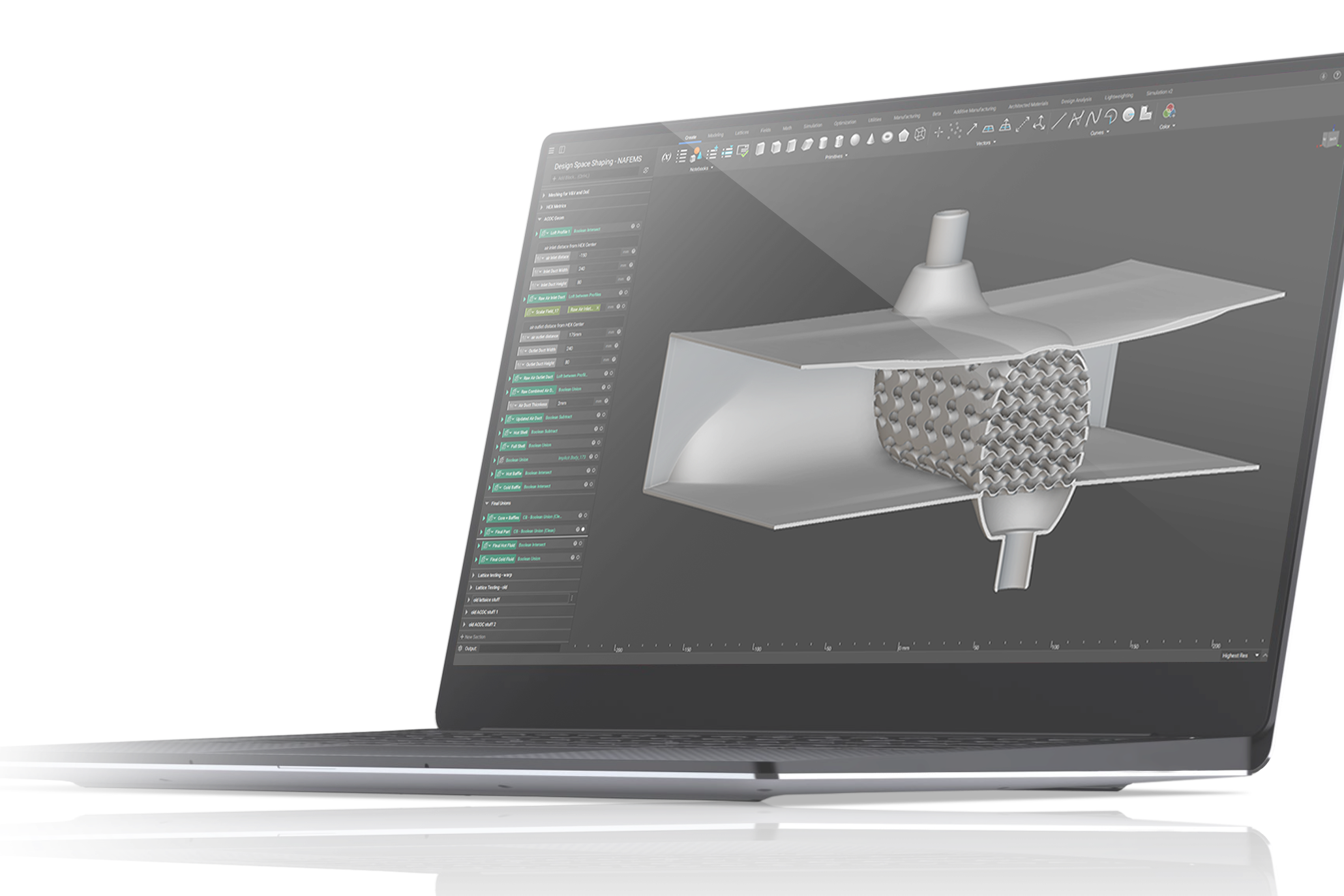

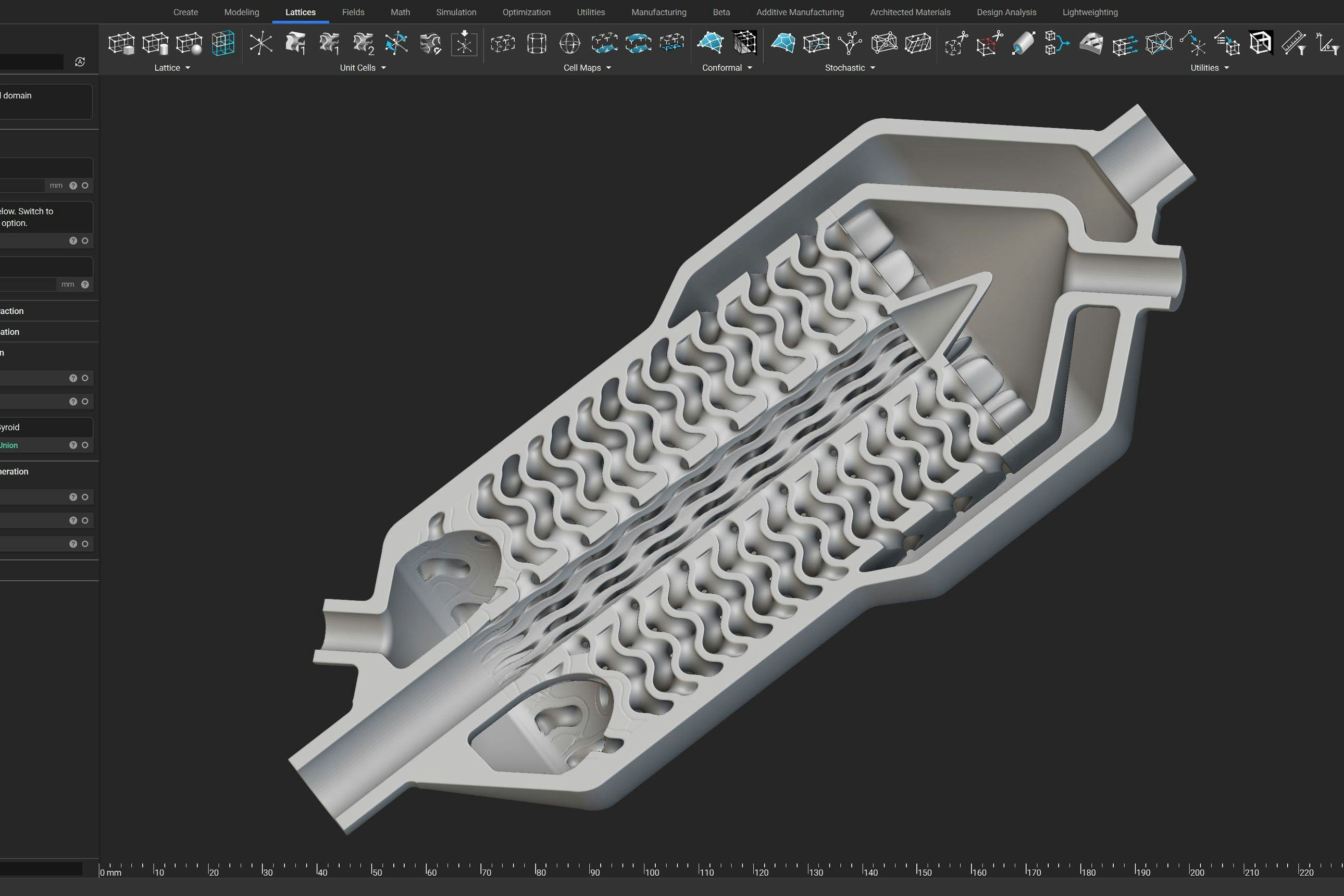

In nTop, we’ve introduced new constraints that can help you reduce the mass of parts that need to be cast or molded.

In this video, Yuki Okada, Technical Marketing Specialist at nTop, shows you how to set up a topology optimization using the new de-molding constraint. He will also show you how to use the inputs within the constraint to create a single-draw, split, or custom-draw mold.

Watch and learn how to:

- Set up topology optimization with the de-mold constraint.

- Create a single-draw, split, or custom-draw mold.

- Add draft to the final part and export.

Level: Intermediate

Industry: Aerospace and Defense, Automotive, Heavy Industry

Applications: Lightweighting

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Lightweighting an impeller for additive manufacturing

- ARTICLE

Advancing structural performance of aerospace heat exchangers

- ARTICLE

Flow management innovations: reducing pressure drop and energy

- ARTICLE

Efficient thermal and fluid management strategies for aerospace heat exchangers