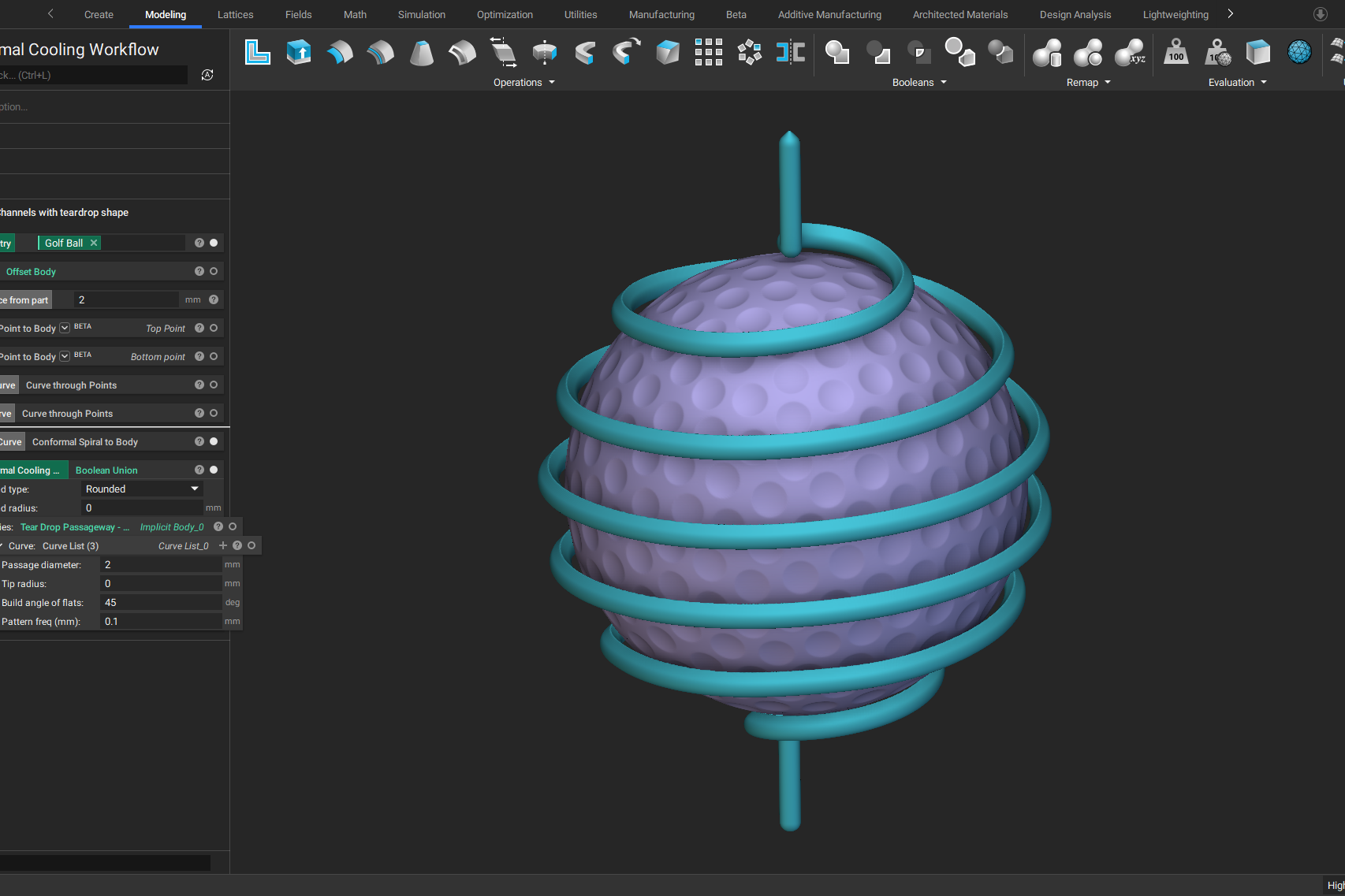

Generate cooling channels with fins for 3D printed injection molds

video: Generate cooling channels with fins for 3D printed injection molds

Published on May 28, 2021

Injection molding tooling produced with additive manufacturing offers many advantages over traditional molds. One of the benefits is the ability to incorporate conformal cooling channels into the mold that reduce cycle time and extend the life of the mold.

In this nTop Live, Evan Pilz, Application Engineer at nTop, shares best practices on how to design cooling channels for your 3D printed molds. He creates channels that can only be manufactured additively with internal fins that guide the flow and increase cooling performance and improve manufacturability.

Watch and learn how to:

- Design molds with cooling channels that can only be produced with 3D printing

- Create reusable design workflows that generate high-performance conformal channels

- Reduce the cost of additive tooling and improve injection molding performance

Download the files

Recreate the steps that Evan followed in this nTop Training. To download all the necessary files for this training, please see this link.

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

Lightweighting an impeller for additive manufacturing

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

Optimizing thermal management with conformal cooling to extend operational life