Reworking a legacy part for mass-reduction, performance and productivity

video: Reworking a legacy part for mass-reduction, performance and productivity

Published on August 25, 2020

Kevin Brigden, Renishaw

nTop is an incredibly powerful tool for enabling creativity, flexibility and productivity. In this presentation, we’ll see how a simple exhaust manifold can be adapted, light-weighted and prepared for additive manufacture. In the context of the wider software eco-system; including CAD and Renishaw’s build preparation software: QuantAM, we’ll look at using surface lattice structures to reduce mass and increase the performance of the component. As well as the slicing and export tools of Platform, we’ll see how that slice data is handled in QuantAM and how we prepare multi-modal, multi-laser build files.

Key takeaways:

- An exhaust manifold, adapted and prepared for multi-laser additive manufacture

- CAD preparation

- Primary and secondary supports

- Design of the final part geometry in nTop

- Exporting slice data

- Preparation of a multi-laser build

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

Lightweighting an impeller for additive manufacturing

- VIDEO

Sneak peek into the nTop + Autodesk Fusion 360 integration

- ARTICLE

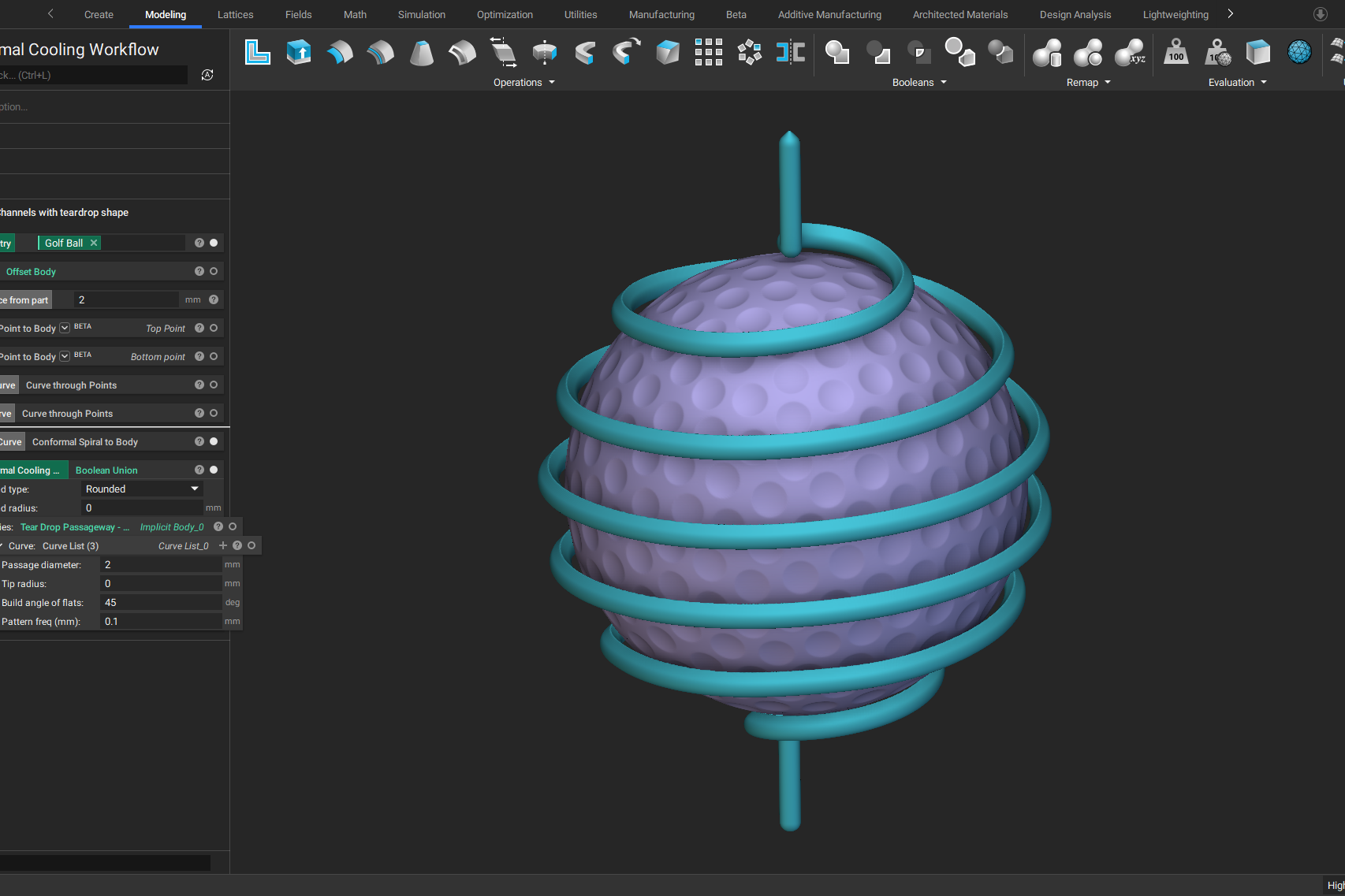

Optimizing thermal management with conformal cooling to extend operational life