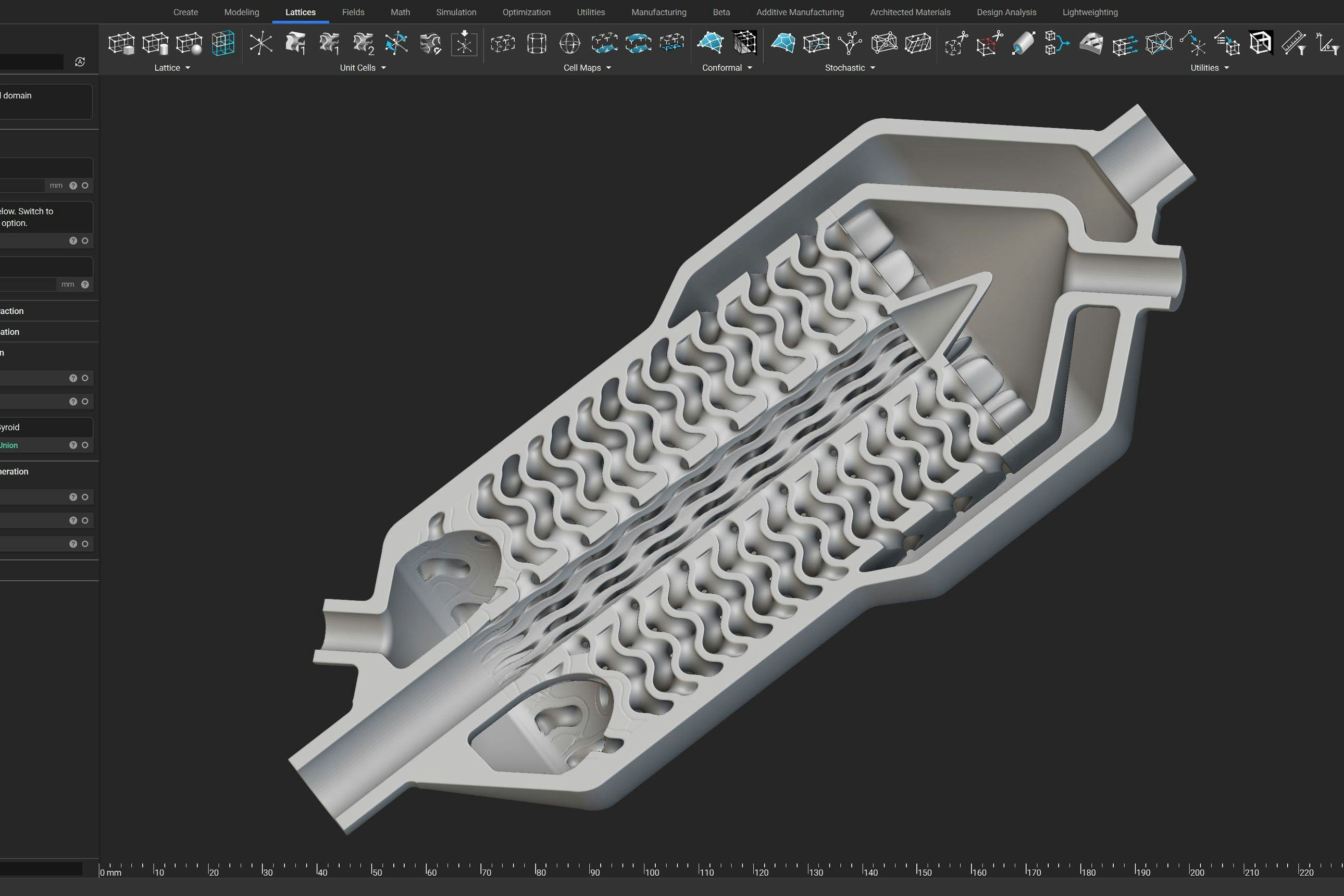

Designing heat exchangers for additive manufacturing

Written by Maiki Vlahinos

Published on August 7, 2020

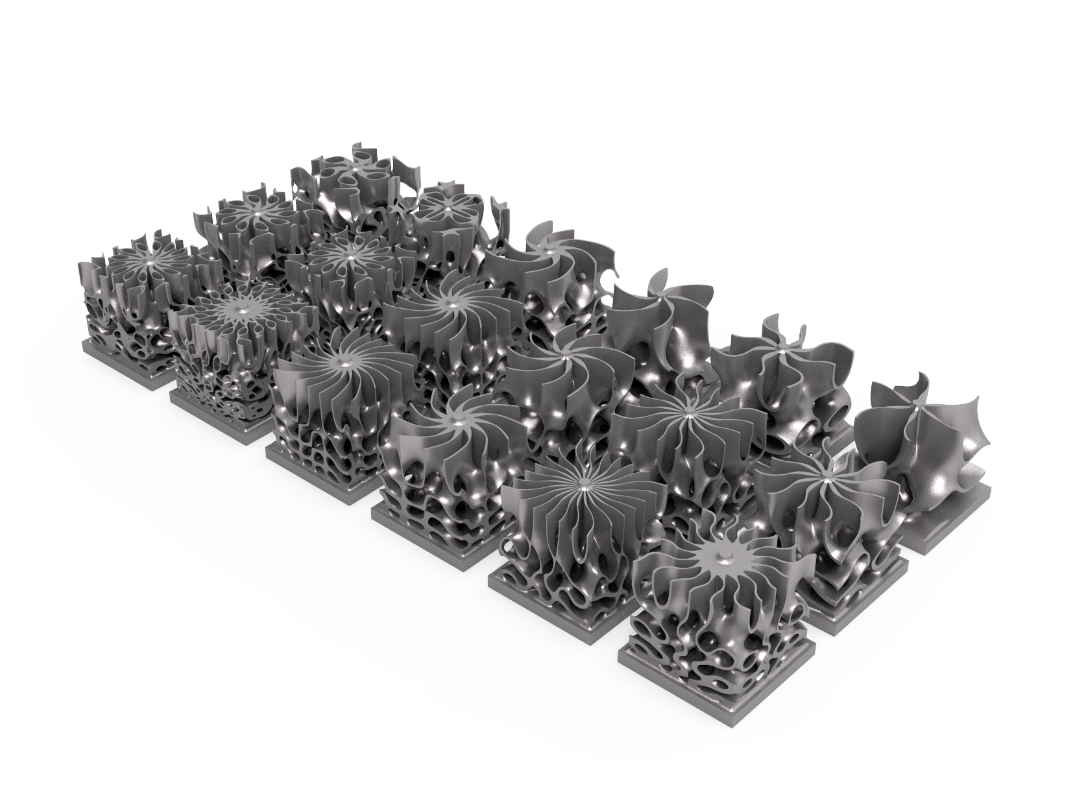

Our Metal DfAM eSeries kicks off week 2 with a focus on Heat Exchangers. A majority of the focus on Triply Periodic Minimal Surfaces (TMPS) and their applicability.

In our day to day lives, we are surrounded by devices used to make our daily routines or spur of the moment decisions more enjoyable, productive, and fulfilling. The devices that enable all of that to happen usually come in the form of electrical or mechanical systems, all of which produce heat. That heat (or temperature) needs to be regulated & directed away from the critical components of those deceives so that they continue to function properly.

There are a multitude of methods used to remove unwanted heat from a system. In our Design for Additive Manufacturing (DfAM) eSeries for Metal Processes we are dedicating a week to heat exchangers. We will briefly go over some of the past and current state of heat exchanger applications with regards to traditional designs & techniques. As well as where some of the industry is at, as a whole, in regards to advanced design methodologies and manufacturing.

The majority of the focus will be on Triply Periodic Minimal Surfaces (TMPS) & their applicability to heat exchangers. Topics covered will be their effectiveness, control of design parameters, printability, validation, characterization of parameters that impact system-level or unit performance, real-time simulation, and the ability to capture design intent at the start of the design process.

Each design covered will show how we built on or worked in parallel with targeting different industries and aspects of the applicability of design, performance, manufacturing & validation of these complex structures.

Maiki Vlahinos

Maiki Vlahinos is a Staff Solutions Engineer at nTop. His primary focus is solving new unique and difficult problems in the Aerospace & Defense Industries. Vlahinos has over a decade of CAE expertise in CAD, FEA, CFD and Optimization. Most recently, his focus has been on innovative design efforts for heat exchangers and fluid domain topologies utilizing CFD Simulation Results before any geometry has been built or generated. Most recently he presented at the 5th Global Webinar on 3D Printing and Additive Manufacturing on Automating Design Exploration for Implicit Geometries.

Related content

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

Lightweighting an impeller for additive manufacturing

- ARTICLE

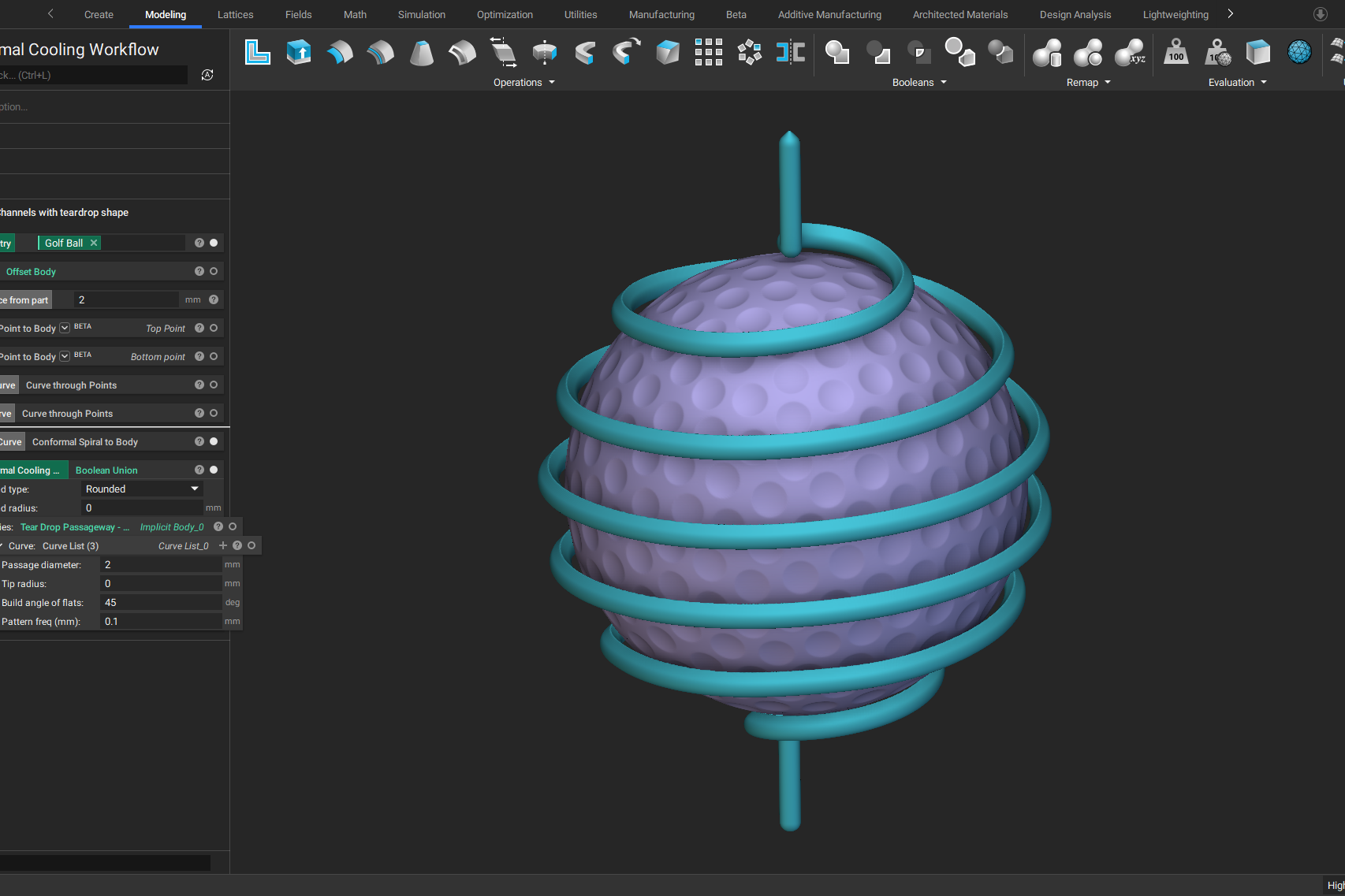

Optimizing thermal management with conformal cooling to extend operational life

- CASE STUDY

Designing a cooler camera housing

- ARTICLE

Advancing structural performance of aerospace heat exchangers