Flexible metal - leveraging powerful design tools to create compliant medical devices

Written by Matt Shomper | Additive Medical Engineering Director, Tangible Solutions

Published on August 3, 2020

Titanium is the blank canvas on which advanced additive designs can be placed.

Mechanobiology - the emerging field of biomedical engineering that is concerned with how biological mechanisms adapt and respond to external stimuli, notably stresses and strains - is now teaching us how important the idea of compliance (used here in reference to flexibility) is to medical devices. Indeed, the idea of orthopedic device stiffness has long been debated, with the current trend leading to more patient-specific applications tuned to the loading conditions. The control of orthopedic device stiffness has long been relegated to material development, with PEEK (polyether ether ketone) its shining star - first used in spine devices during the turn of the century to great success. Although PEEK is biocompatible, it’s surface lacks certain osseointegrative capabilities, leading to most implants needing a plasma spray coating of titanium or another material. As metal additive technologies continue to become more advanced, titanium is poised to again become the material king.

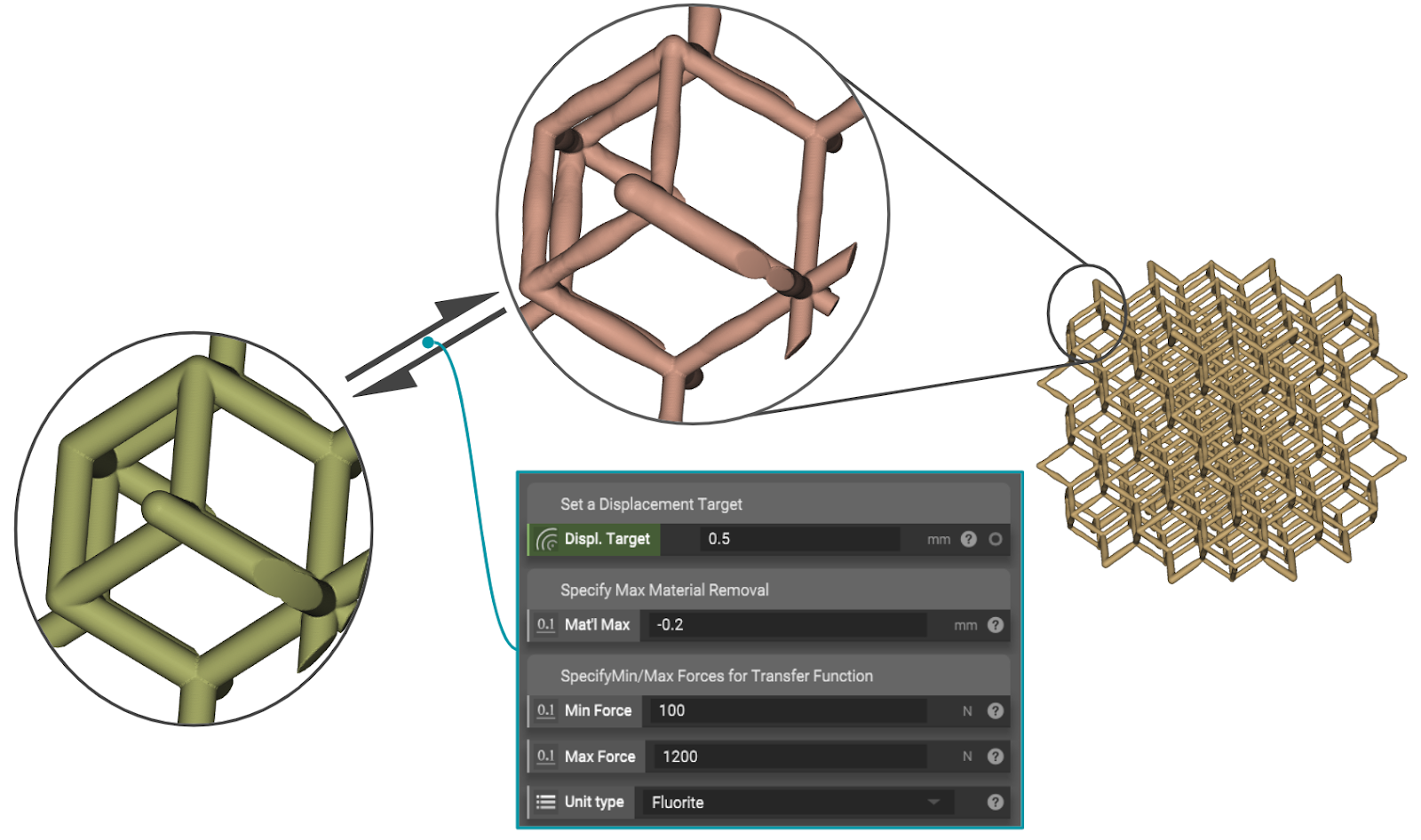

But how can engineers turn the rigid nature of metal into a benefit? The answer lies in a combination of computational modeling and an understanding of material stiffnesses - which we can analyze using Finite Elements Analysis in nTop.

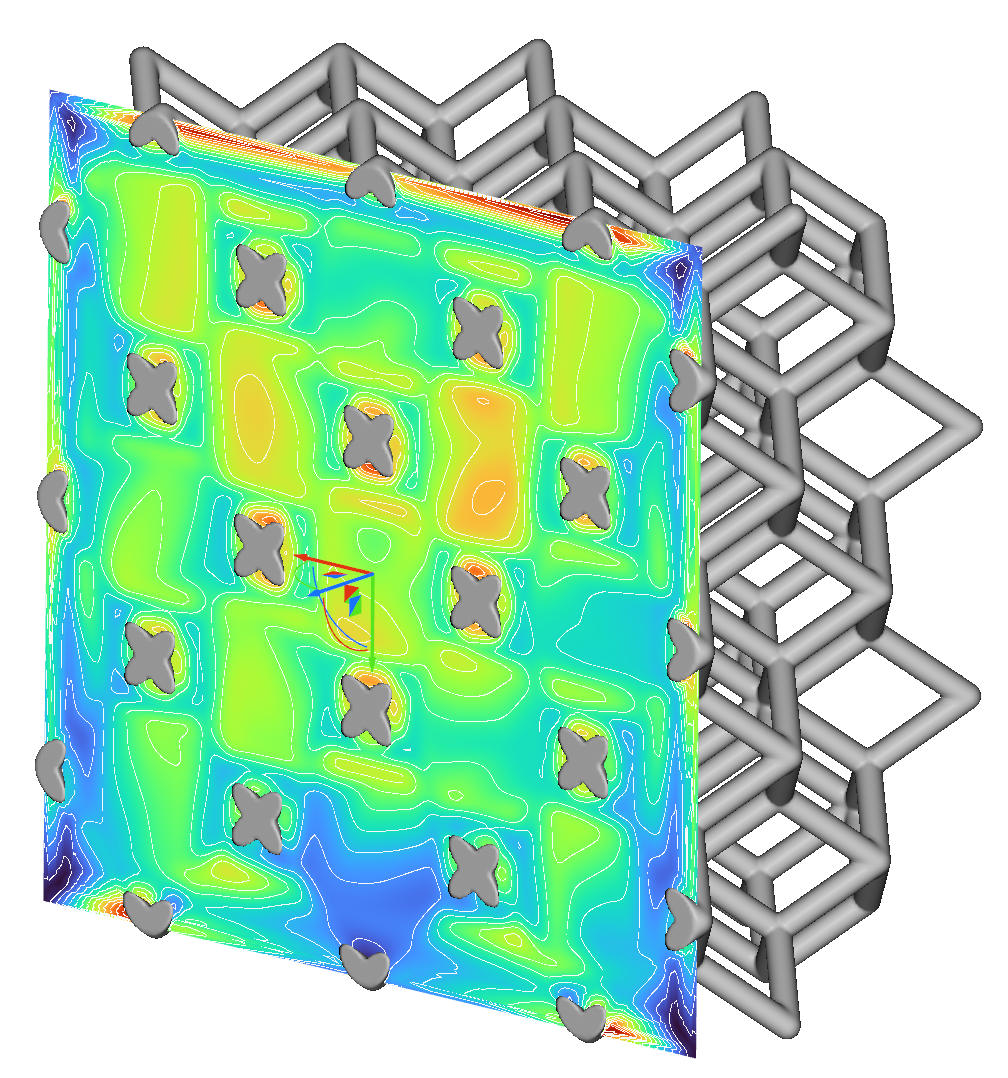

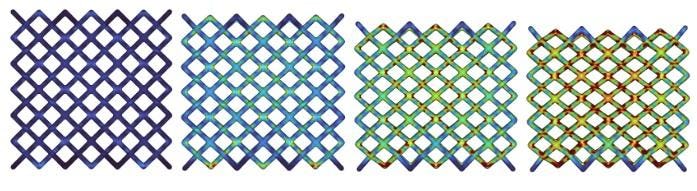

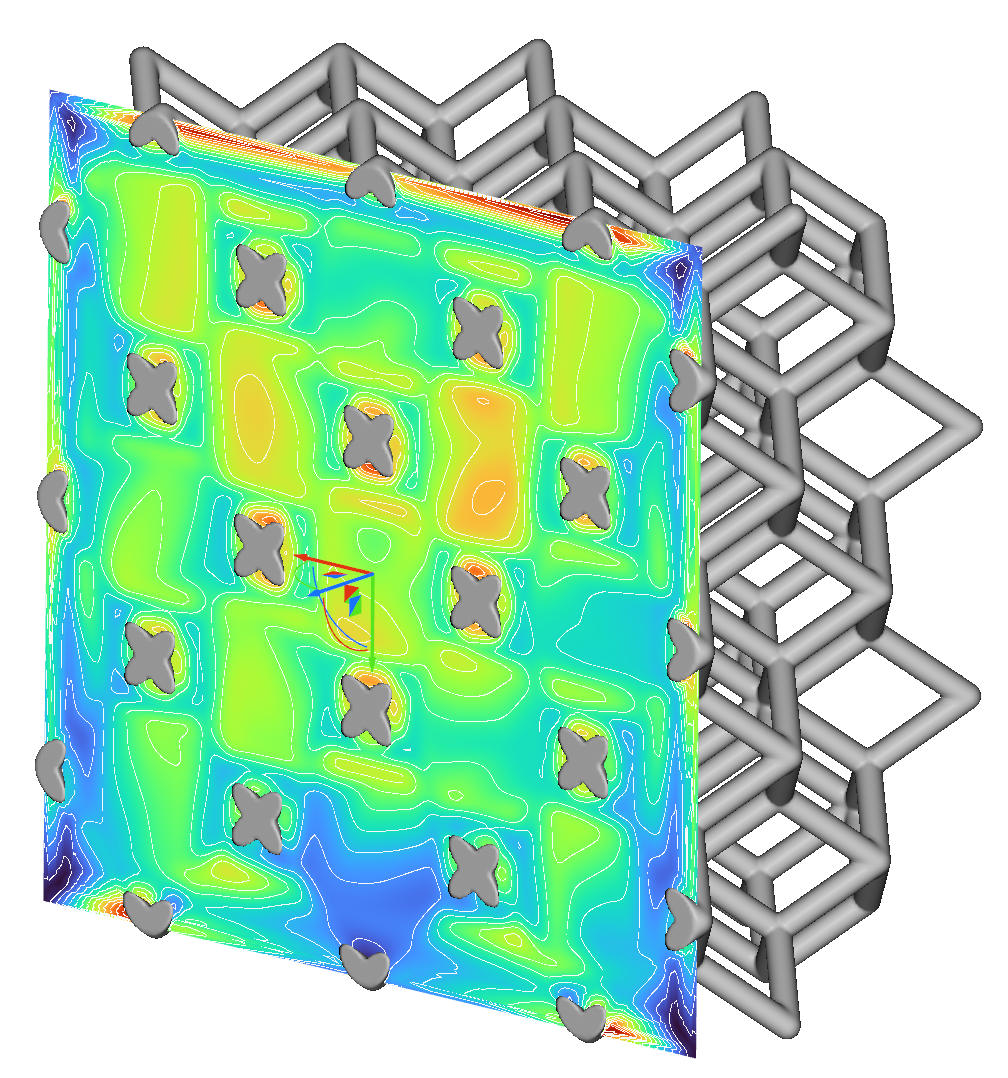

Stress values at different static compression values.

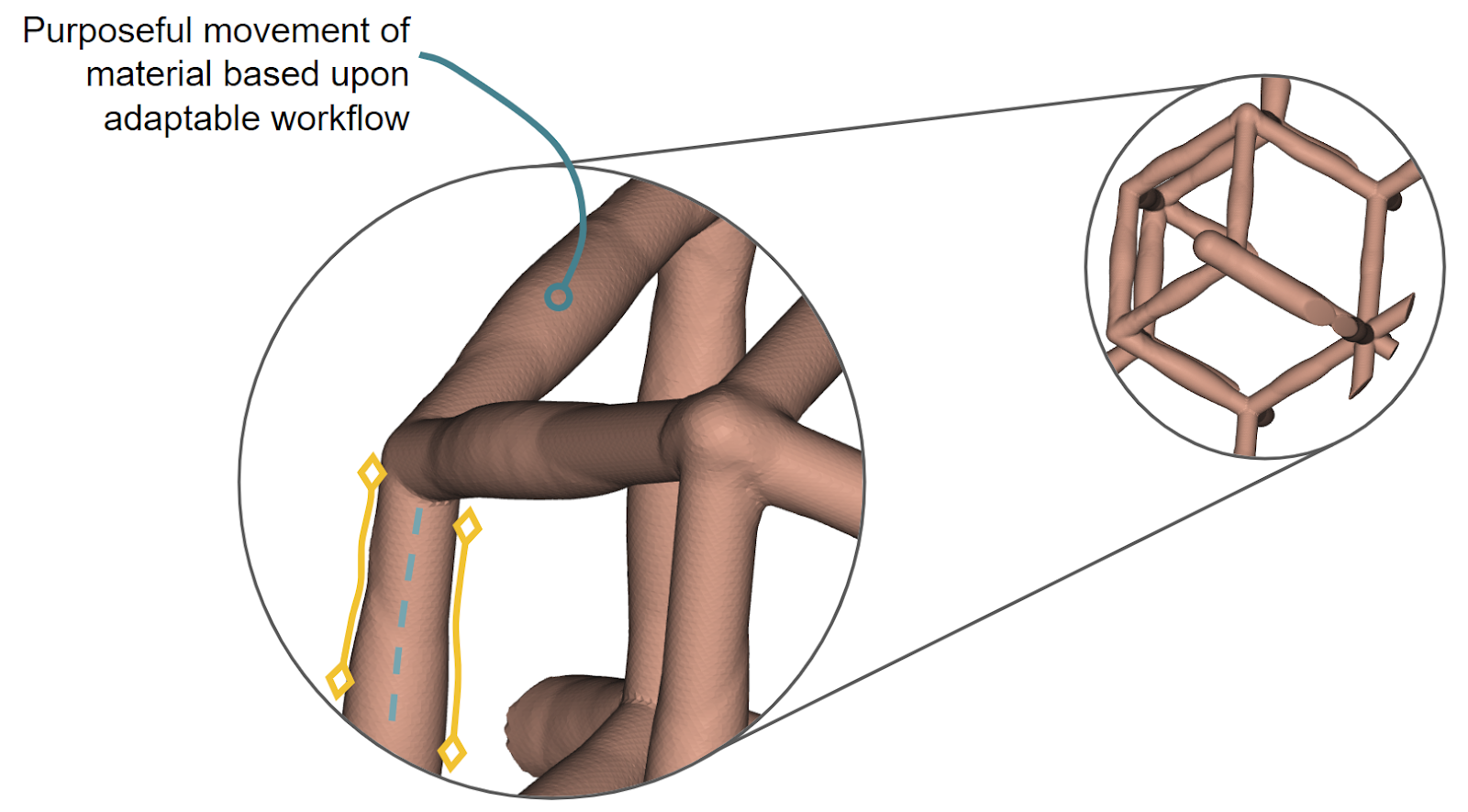

By investigating the stress and displacement parameters at differing compression values, the stress and displacement fields can be combined mathematically into a function.

A heat map of von mises stress values, where colors show the localized stress values of the field.

This function allows us to computationally “tune” the stiffness of a structure exactly, utilizing what I like to call “the movement of material!”

Matt Shomper

Additive Medical Engineering Director, Tangible Solutions

Matt is an innovative engineering leader with a strong interest in next-gen and upcoming technologies and is keeping on the forefront of additive and materials advancement in his field. He is currently building and leading a world-class, highly technical engineering department in the additive manufacturing space. With many cleared medical devices released into the field now residing in numerous patients worldwide, Matt has proficient skill in developing solutions quickly and effectively to provide the most cost-effective solution in the shortest amount of time.

Related content

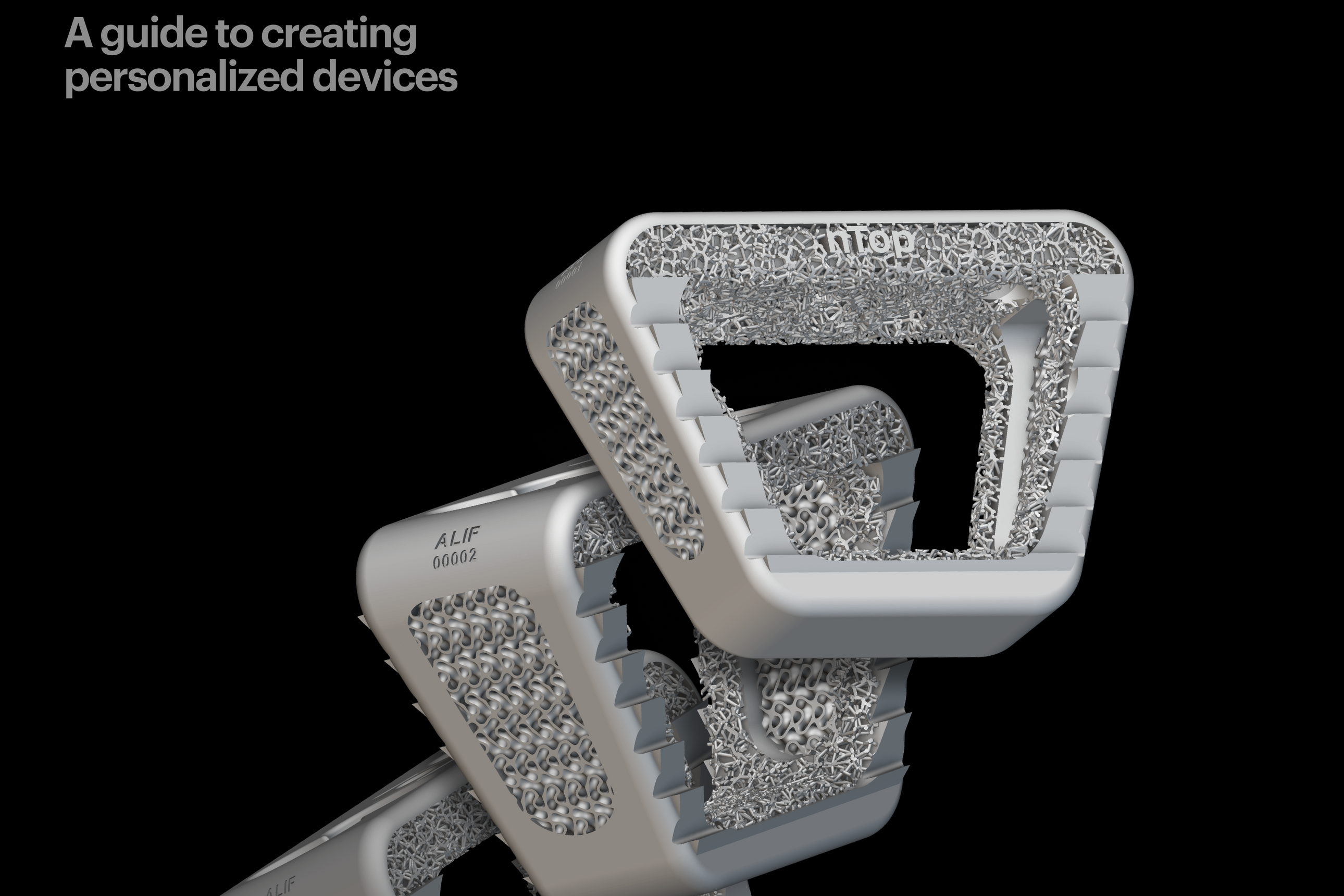

- GUIDE

Download: Advanced design software and additive manufacturing for personalized implants

- GUIDE

Download: Design Automation for Medical Devices

- VIDEO

Design a spooky Halloween candy bowl in nTop

- ARTICLE

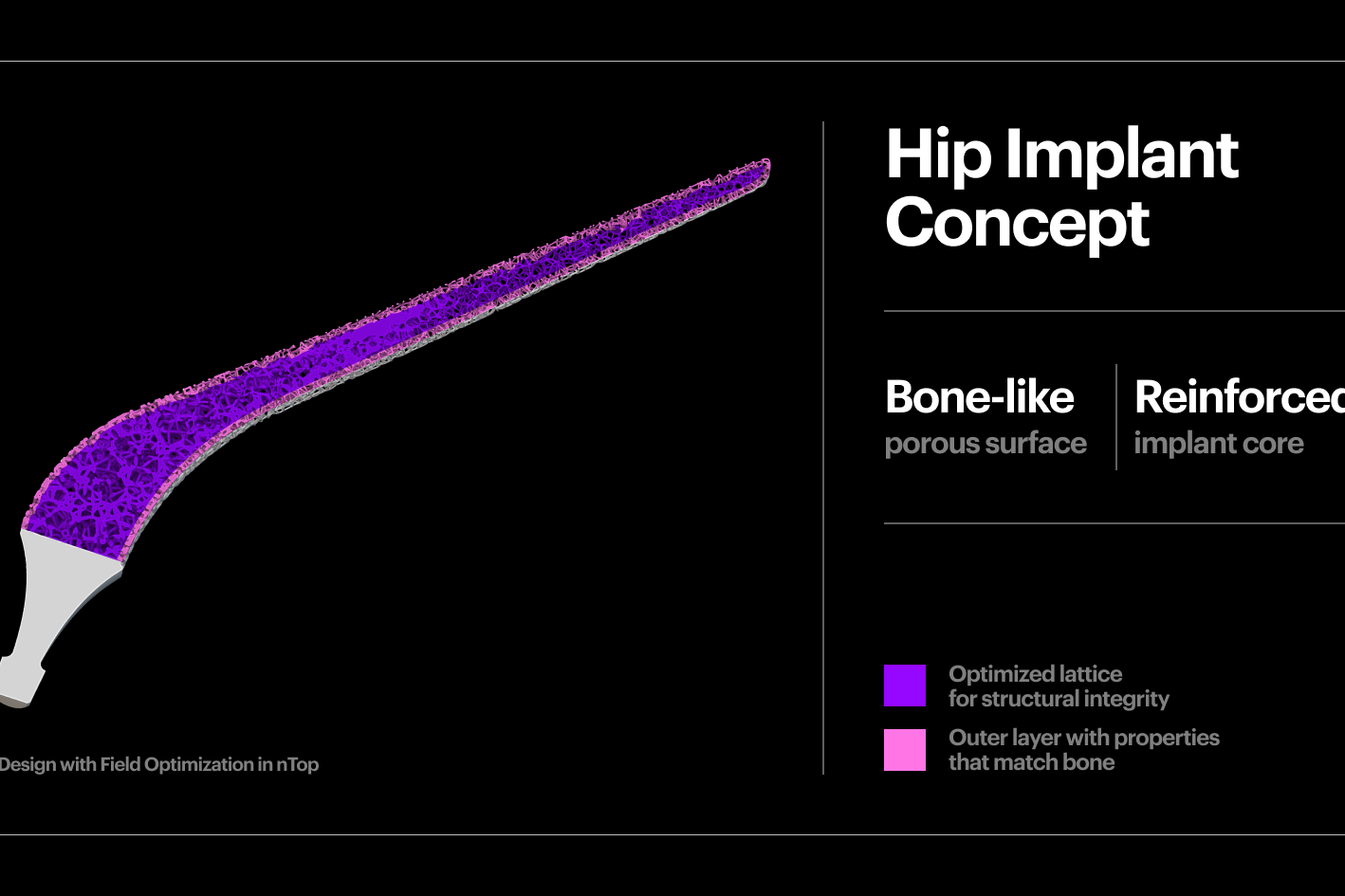

Improving the biomechanical profile of additive hip implants with Field Optimization

- ARTICLE

Design at scale with nTop Automate