Improving the biomechanical profile of additive hip implants with Field Optimization

Written by Chase Allan | Associate Product Manager at nTop

Published on July 5, 2023

Applications

Key Software Capabilities

- Field Optimization

- Lattice structures

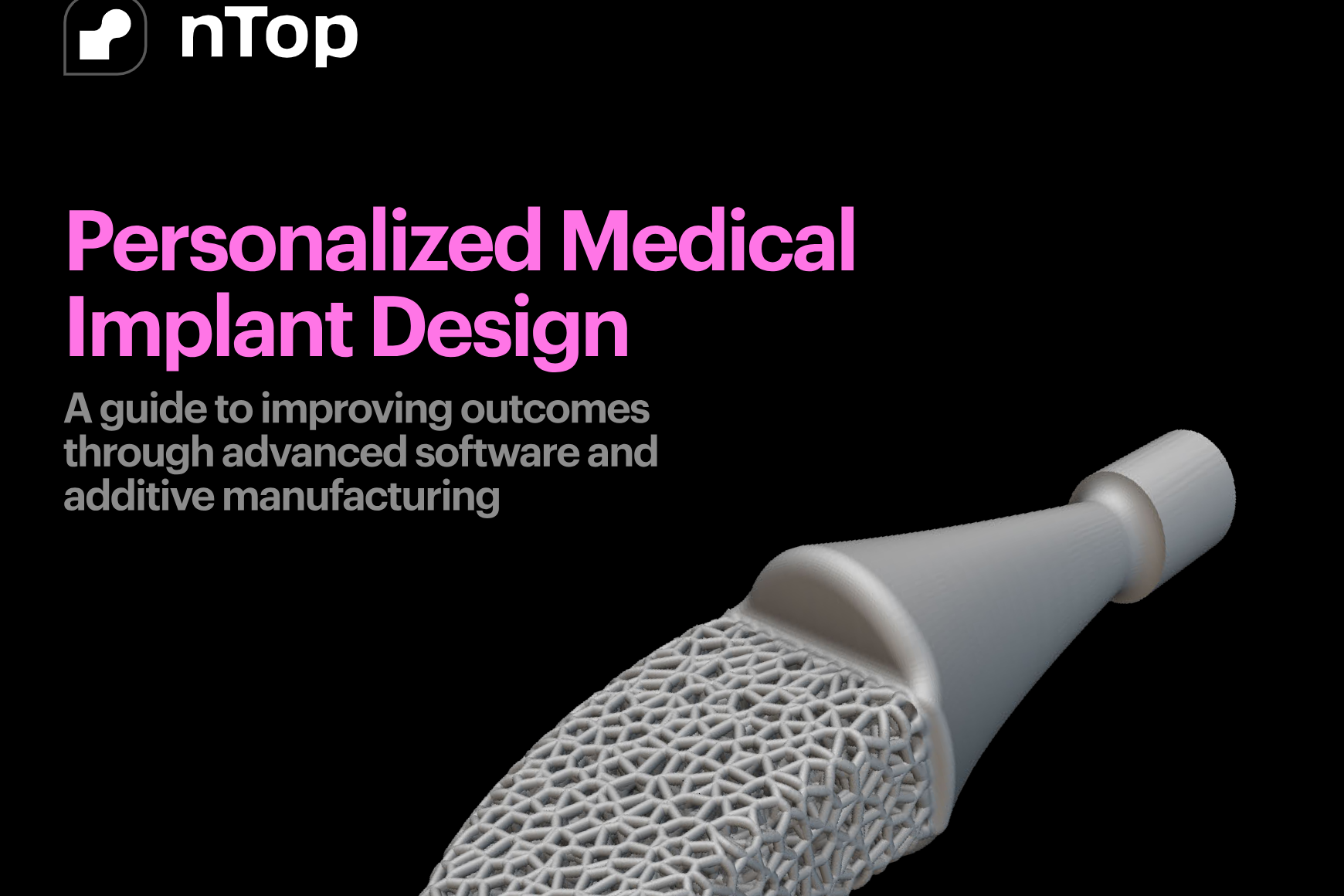

Additive manufactured orthopedic implants are an area of active development that drives growth in the medical implant industry. Yet, managing the competing design requirements to create an ideal biomechanical implant profile is both a challenging optimization problem and an important requirement as it leads to improved outcomes and a better quality of life for the recipient.

For example, AM implants typically have a porous surface lattice structure to achieve the desirable osseointegration properties. At the same time, the implant must have mechanical properties compatible with bone to avoid the effect of stress shielding. Beyond biological requirements, the implant must also be strong enough to withstand the loading conditions during everyday activities and be manufactured to the expected quality standards to receive regulatory clearance.

This article describes the steps we followed to design a hip implant concept using the Voronoi optimization module of nTop’s new Field Optimization capability. The result is a process that generates hip implant designs that meet both the desired biological and mechanical functional requirements.

What is Field Optimization?

Field Optimization's Voronoi module generates optimized structures that meet competing objectives and constraints in a closed-loop optimization process.

Field Optimization is a generative design technology that extends nTop’s Field-Driven Design, optimization, and latticing capabilities. It enables nTop users to generate designs with spatially optimized parameters, like a stochastic Voronoi lattice's cell size and beam thickness.

Field Optimization is especially valuable for parts that must meet multiple competing design objectives or constraints and use lattices and other complex features that leverage the benefits of AM technologies.

Compared to manual iterative approaches, Field Optimization helps you save time when the problem or geometry complexity increases. Ultimately, Field Optimization enables you to innovate more confidently and develop fully optimized products that do not leave any performance on the table.

The design challenge

Recent studies reveal that AM orthopedic implants may cause “stress shielding” effects. The consequences of stress shielding can be as serious as loss of bone which may lead to the need for reoperation.

A root cause of stress shielding is the mismatch between the elastic properties of titanium and bone. However, it has been shown that reducing the equivalent elastic properties of a titanium lattice structure to match those of bone can reduce the effects of stress shielding.

Beyond biocompatibility, the implant must also withstand the forces experienced in daily activities. In fact, a recent study showed that the forces experienced by hip implants may exceed the strength of (even traditionally manufactured) cementless implant fixations during certain activities.

These tradeoffs between good biocompatibility and implant strength create a challenging optimization problem and show the need for hip implants with more closely engineered and optimized geometry.

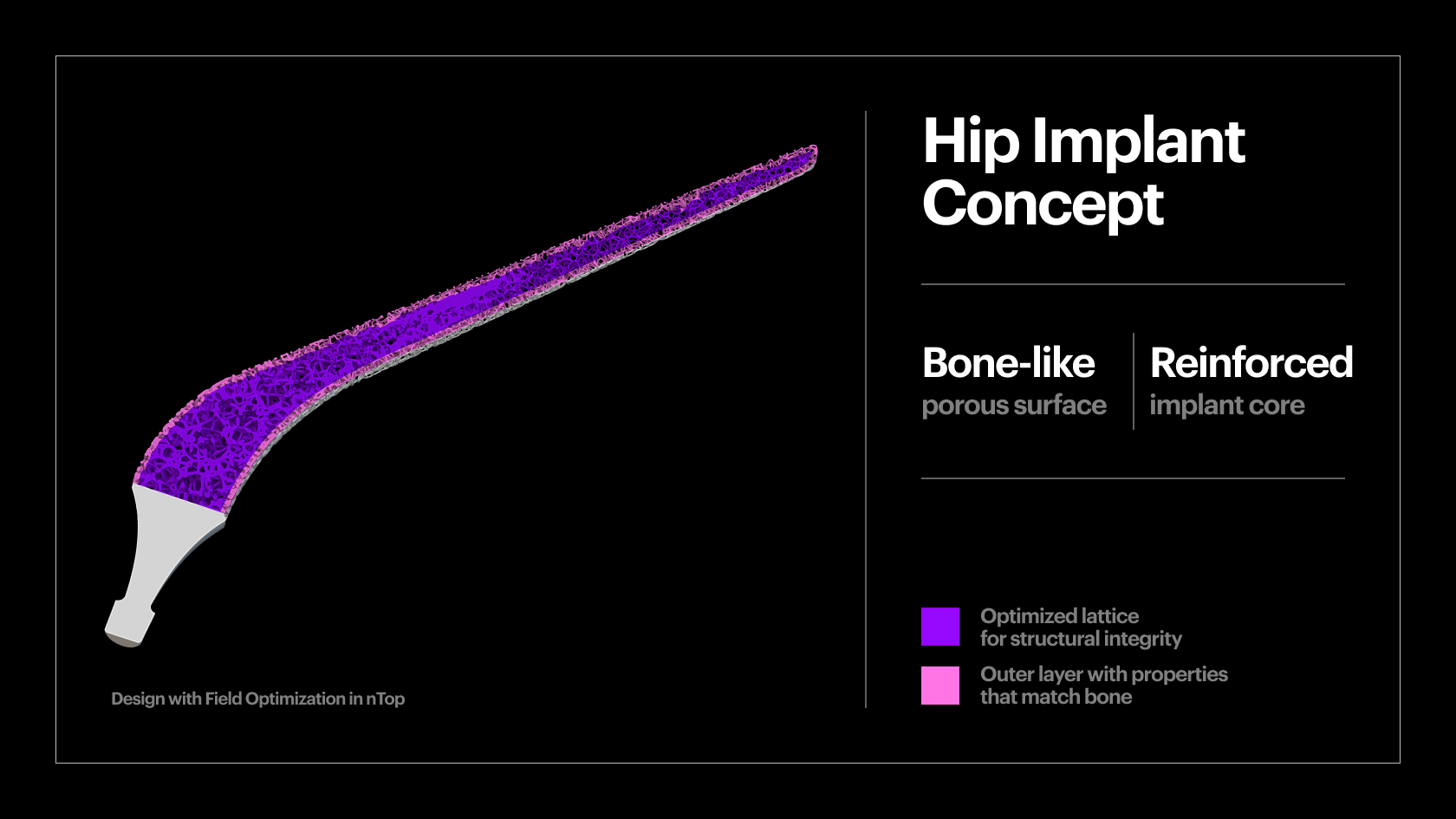

To demonstrate a potential path to addressing these challenges, the objective of this design study was to create a hip implant concept with:

- Surface properties that promote osseointegration

- An outer layer with mechanical properties matching those of bone

- A core optimized to withstand the loading condition

- Geometry that is manufacturable with metal AM processes

Our goal was to demonstrate how nTop can be used to tackle common biomedical engineering problems. We based this proof-of-concept on realistic requirements; however, it should not be interpreted as a proven, end-to-end solution for orthopedic implant design.

Designing with Field Optimization

The cell size (left), relative density (middle), and generated lattice (right).

To tackle this problem, we applied the following steps:

First, using nTop’s lattice homogenization utilities, we analyzed a suitable range of Voronoi lattice structures with different combinations of cell size and beam thickness. The goal was to identify a combination of parameters that results in lattice structures with equivalent Young’s modulus similar to bone when printed in Ti64.

Then, we set up the optimization problem:

- Design space: The shape of the implant was imported as a CAD file with a separate body representing the outer layer. We set the whole implant as the optimization design space, and we applied a passive region constraint to the outer layer, forcing the Field Optimization process to keep the cell size and beam thickness constant and equal to the values we identified in the first step.

- Forces and constraints: We defined multiple loading conditions based on the worst-case scenario forces reported in the findings of a recent in vivo study. We also defined the upper and lower bounds for the Voronoi cell size and beam thickness according to the constraints of our manufacturing process.

- Optimization objectives: Finally, we set the optimization objective to maximize the overall stiffness of the structure while constraining its weight.

Following this process, we created an outer layer with targeted biological properties that can help reduce the effect of stress shielding by helping propagate forces more uniformly. At the same time, we optimized the lattice cell size and beam thickness of the implant’s core for strength, stiffness, and durability.

After the design was complete, two samples were manufactured in Ti64 on an EOS M290 AM system. To send the part to print, we used nTop’s Implicit Interop capability to export the design directly as an nTop Implicit File to EOSPRINT for slicing without meshing. Bypassing the meshing step allowed us to preserve geometric accuracy and avoid heavy meshing computations.

Field Optimization for medical implants

The hip implant concept was manufactured in Ti64 on an EOS M290 machine.

The result of this single-step optimization process was a porous metal hip implant with:

- A bone-like porous surface that promotes osseointegration and accounts for stress shielding effects

- A reinforced core along critical load paths to ensure the implant meets functional requirements

The results demonstrate how Field Optimization can enable medical device engineers to develop the next generation of orthopedic implants. In fact, generating such a stochastic lattice with variable cell size and thickness optimized for these requirements would be impossible with any other tools today.

Before Field Optimization, nTop already offered our users industry-leading tools to create lattice structures that promote osseointegration and mimic the properties of bone. With Field Optimization, biomedical engineers can now use a closed-loop design optimization process that enables them to incorporate multiple objectives and constraints, leading to better-performing parts and significant product development time savings.

Field Optimization in engineering design

In addition to improving the biomechanical profile of implants, optimizing the mechanical properties of lattices can be used across various applications, including lightweight satellite components and consumer products.

Moreover, Field Optimization’s open infrastructure enables users to create custom optimization workflows and encode their know-how into reusable processes. For example, you can expand the functionality of Field Optimization by integrating custom unit cells or using custom test data to define your material properties.

In other words:

As the capabilities of nTop expand, so will the capabilities of Field Optimization. For instance, we are already working on encoding manufacturing constraints for processes like casting, machining, and molding into our optimization technology.

Key takeaways

- With Field Optimization, you can encode engineering knowledge and requirements to develop implants with improved biomechanical profiles.

- This hip implant concept has a bone-like porous surface and a core reinforced along critical load paths, meeting competing design objectives.

- Field Optimization’s open architecture makes it a valuable tool for many advanced engineering designs.

Chase Allan

Associate Product Manager at nTop

Related content

- VIDEO

Five ways to lightweight in nTop

- VIDEO

Topology Optimization Design for Cast and Injection-Molded Parts

- VIDEO

Lightweighting an impeller for additive manufacturing

- GUIDE

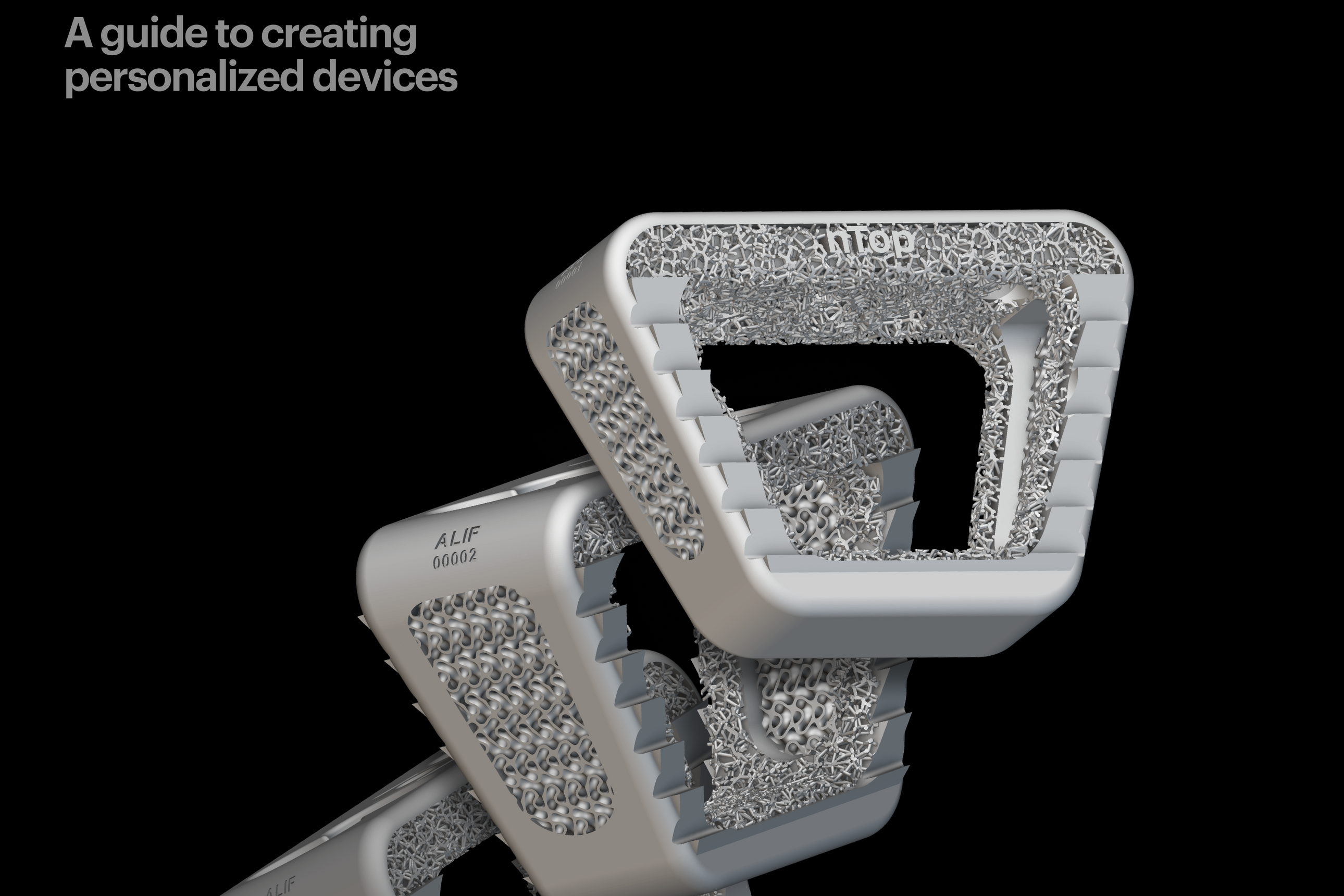

Download: Advanced design software and additive manufacturing for personalized implants

- GUIDE

Download: Design Automation for Medical Devices